Rub-impact damping protection device for high-speed rotating machinery

A high-speed rotation and protection device technology, applied in the field of mechanical parts, can solve the problems that the rotor is not easy to return to the equilibrium position quickly, the friction and vibration reduction effect is limited, and the life of the friction ring is short, so as to achieve simple structure, strong damping effect, and improved The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

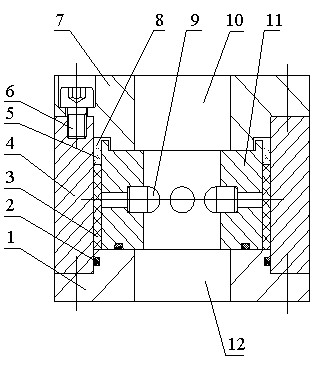

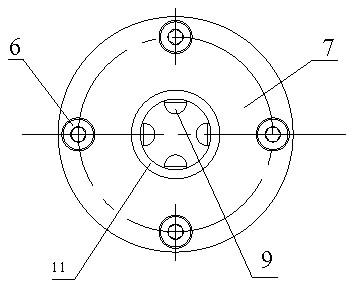

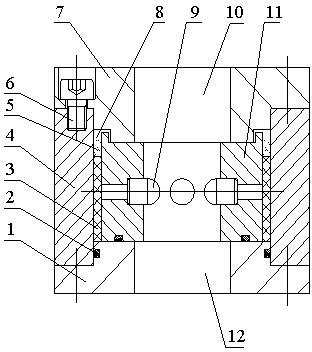

[0012] Such as figure 1 and figure 2 As shown, a rubbing and damping protection device for high-speed rotating machines of the present invention includes an upper cover 7 , a lower cover 1 , a housing 4 , a slider 11 , a rubbing ball 9 and a metal rubber ring 3 . Both the shell 4 and the slider 11 are annular. An upper through hole 10 is provided in the middle of the upper cover 7 , and a lower through hole 12 is provided in the middle of the lower cover 1 . Both the upper through hole 10 and the lower through hole 12 are circular holes. The rubbing ball head 9 is preferably made of bronze, graphite or polytetrafluoroethylene. The casing 4, the slider 11, the upper through hole 10 and the lower through hole 12 are coaxial. The upper end of the shell 4 is fixedly connected with the upper cover 7 , and the lower end of the shell 4 is fixedly connected with the lower cover 1 . There are many ways to fix the connection, for example, using screws 6 to connect. The slider 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com