Glass fiber and carbon fiber mixed reinforced polyester mineral composite material and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of composite materials, can solve the problems of improving the dynamic and static performance and thermal stability of machine tools, achieve excellent damping and vibration reduction performance, improve mechanical properties, and reduce machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

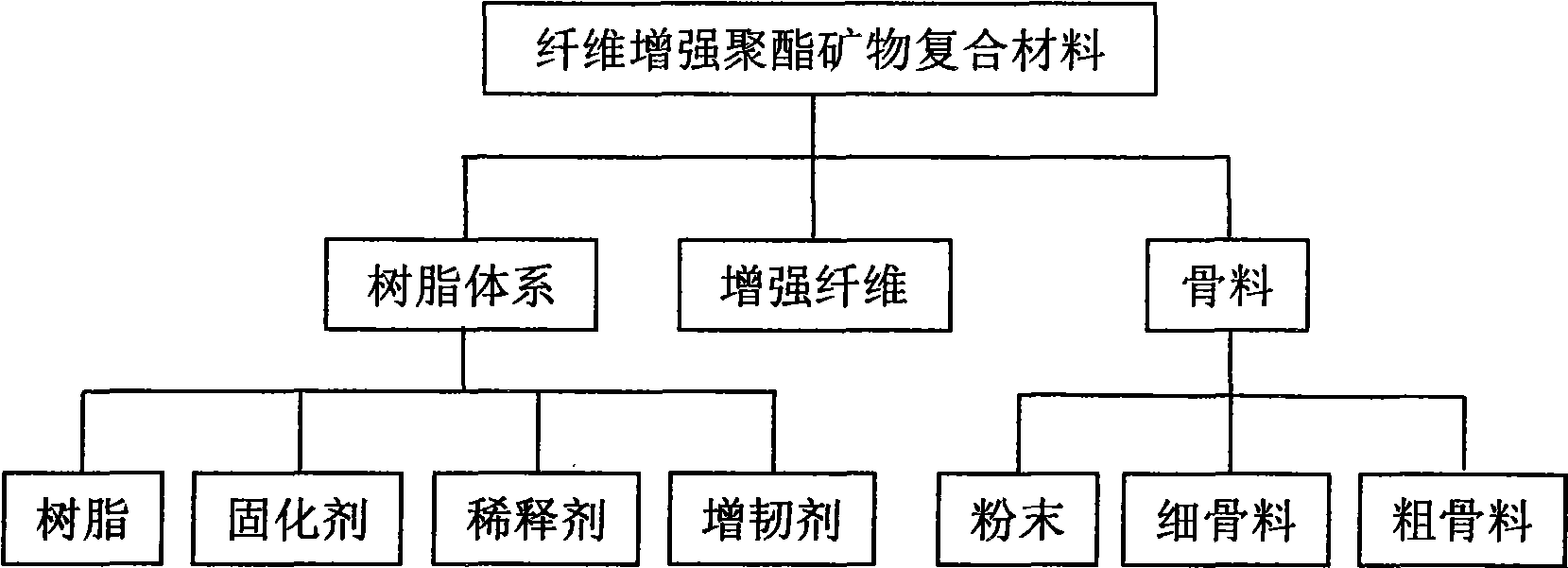

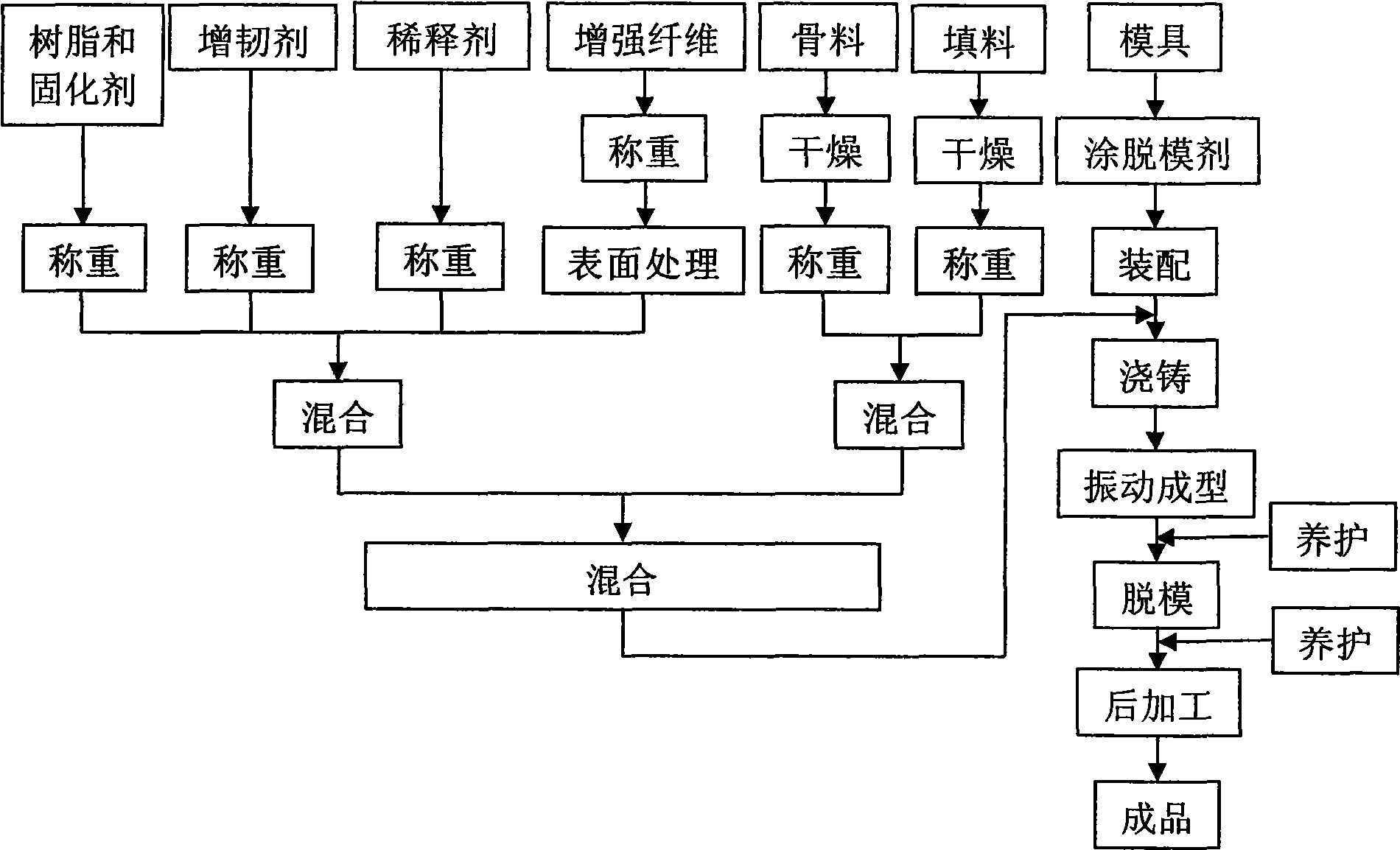

Method used

Image

Examples

Embodiment 1

[0028] Aggregate: 8000g of natural granite particles, of which:

[0029] 0.1mm~0.6mm: 1040g, accounting for 13%

[0030] 0.6mm~2mm: 1360g, accounting for 17%

[0031] 2mm~3.5mm: 1200g, accounting for 15%

[0032] 3.5mm~5mm: 1120g, accounting for 14%

[0033] 5mm~7mm: 1360g, accounting for 17%

[0034] 7mm~10mm: 1920g, accounting for 24%

[0035] Adhesive matrix 975g, wherein:

[0036] Epoxy resin 660g

[0037] Curing agent ethylenediamine 200g

[0038] Thinner acetone 55g

[0039] Toughener dibutyl phthalate 60g

[0040] 25g of reinforcing fibers, including 15g of glass fibers and 10g of carbon fibers.

[0041] The obtained glass fiber and carbon fiber mixed reinforced polyester mineral composite material: the compressive strength is 102.47MPa, and the damping ratio is 0.228.

Embodiment 2

[0043] Aggregate: 50kg of natural granite particles, of which:

[0044] 0.1mm~0.6mm: 7kg, accounting for 14%

[0045] 0.6mm~2mm: 8kg, accounting for 16%

[0046] 2mm~3.5mm: 7.5kg, accounting for 15%

[0047] 3.5mm~5mm: 7kg, accounting for 14%

[0048] 5mm~7mm: 9kg, accounting for 18%

[0049] 7mm~10mm: 11.5kg, accounting for 23%

[0050] Adhesive matrix 7.8kg, of which:

[0051] Epoxy resin 5.5kg

[0052] Curing agent ethylenediamine 1.6kg

[0053] Thinner acetone 0.3kg

[0054] Toughening agent dibutyl phthalate 0.4kg

[0055] 0.2kg of reinforcing fiber, including 0.05kg of glass fiber and 0.15kg of carbon fiber.

[0056] The obtained glass fiber and carbon fiber mixed reinforced polyester mineral composite material: the compressive strength is 117.35MPa, and the damping ratio is 0.197.

Embodiment 3

[0058] Aggregate: 50kg of natural granite particles, of which:

[0059] 0.1mm~0.6mm: 7kg, accounting for 14%

[0060] 0.6mm~2mm: 8kg, accounting for 16%

[0061] 2mm~3.5mm: 7.5kg, accounting for 15%

[0062] 3.5mm~5mm: 7kg, accounting for 14%

[0063] 5mm~7mm: 9kg, accounting for 18%

[0064] 7mm~10mm: 11.5kg, accounting for 23%

[0065] Adhesive matrix 11.6kg, of which:

[0066] Epoxy resin 8kg

[0067] Curing agent ethylenediamine 2.8kg

[0068] Thinner acetone 0.4kg

[0069] Toughening agent dibutyl phthalate 0.4kg

[0070] 0.4kg of reinforcing fiber, including 0.25kg of glass fiber and 0.15kg of carbon fiber.

[0071] The obtained glass fiber and carbon fiber mixed reinforced polyester mineral composite material: the compressive strength is 97.64MPa, and the damping ratio is 0.207.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com