Vibration-reducing damping part and preparation method thereof

A damper and rubber technology, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve the problems of high cost, environmental pollution, poor flatness of vibration damping and damping parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

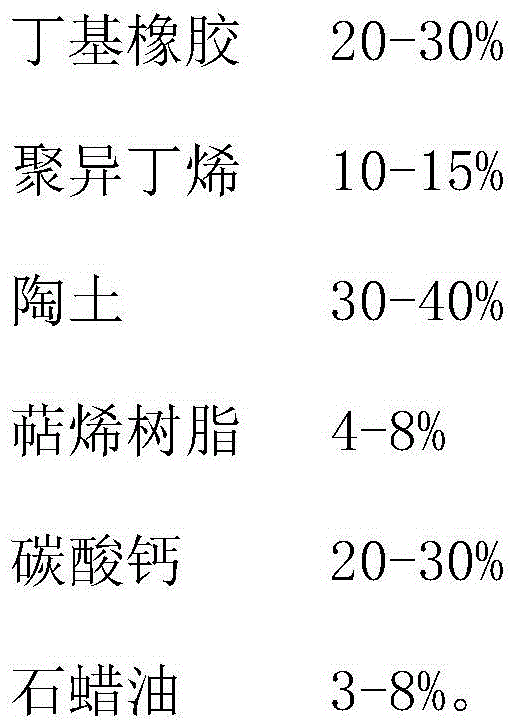

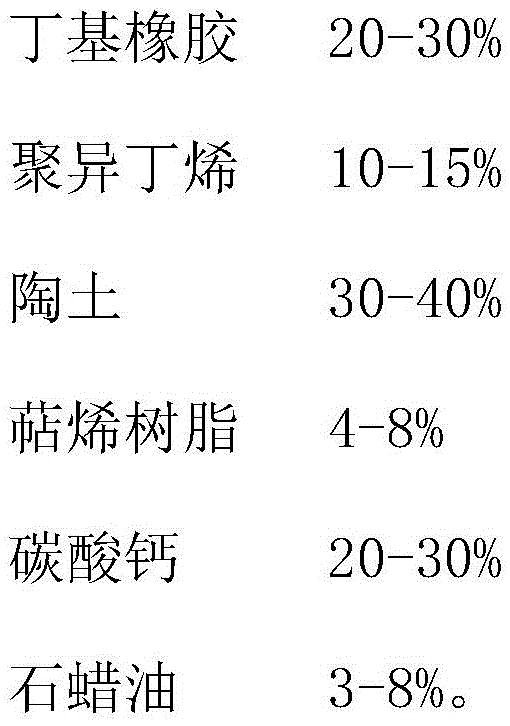

[0020] A vibration damping element, including vibration damping element rubber and aluminum foil, the vibration damping element rubber is laminated on the aluminum foil, wherein the vibration damping element rubber includes the following composition and components in parts by mass: butyl rubber 30 %, polyisobutylene 10%, clay 30%, terpene resin 5%, calcium carbonate 20%, paraffin oil 5%.

[0021] The preparation method of the vibration damping part comprises the following steps: 1) first proportioning the ingredients; 2) sequentially adding butyl rubber, pottery clay, and calcium carbonate to the stirring tank and mixing them uniformly, then adding terpene resin, stirring for 1 minute, and then adding paraffin wax Stir the oil evenly, and finally add polyisobutene and mix evenly, then heat up and knead, the kneading temperature is 150°C, and the kneading time is 15 minutes; 3) Pass the kneaded mixture in step 2) through a 60-mesh filter; 4) It can pass through the filter The g...

Embodiment 2

[0025] A vibration damping element, including vibration damping element rubber and aluminum foil, the vibration damping element rubber is laminated on the aluminum foil, wherein the vibration damping element rubber includes the following composition and components in parts by mass: butyl rubber 20 %, polyisobutylene 15%, clay 35%, terpene resin 4%, calcium carbonate 20%, paraffin oil 6%.

[0026] The preparation method of the vibration damping part comprises the following steps: 1) first proportioning ingredients; 2) sequentially adding butyl rubber, pottery clay, and calcium carbonate to the stirring tank and mixing evenly, then adding terpene resin, stirring for 3 minutes, and then adding paraffin wax Stir the oil evenly, and finally add polyisobutylene and mix evenly, then heat up and knead, the kneading temperature is 160°C, and the kneading time is 8 minutes; 3) Pass the kneaded mixture in step 2) through a 60-mesh filter; 4) It can pass through the filter The granules of...

Embodiment 3

[0028] A vibration damping element, including vibration damping element rubber and aluminum foil, the vibration damping element rubber is laminated on the aluminum foil, wherein the vibration damping element rubber includes the following composition and components in parts by mass: butyl rubber 20 %, polyisobutylene 10%, clay 30%, terpene resin 8%, calcium carbonate 24%, paraffin oil 8%.

[0029] The preparation method of the vibration damping part comprises the following steps: 1) first proportioning ingredients; 2) sequentially adding butyl rubber, pottery clay, and calcium carbonate to the stirring tank and mixing evenly, then adding terpene resin, stirring for 2 minutes, and then adding paraffin wax Stir the oil evenly, and finally add polyisobutylene and mix evenly, then heat up and knead, the kneading temperature is 155°C, and the kneading time is 12 minutes; 3) Pass the kneaded mixture in step 2) through a 60-mesh filter; 4) It can pass through the filter The granules o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com