Motor rotor

A technology for electric motors and rotors, which is applied in the field of motor components, can solve the problems of cast copper rotors without fan blades, affect the balance of the correct rotor, and reduce the stall performance, and achieve excellent stall performance, improve efficiency levels, and stall performance. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

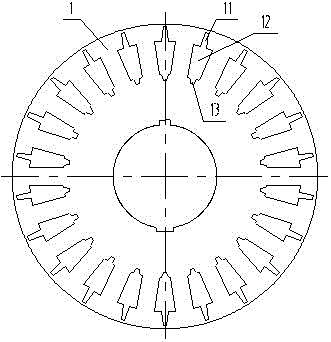

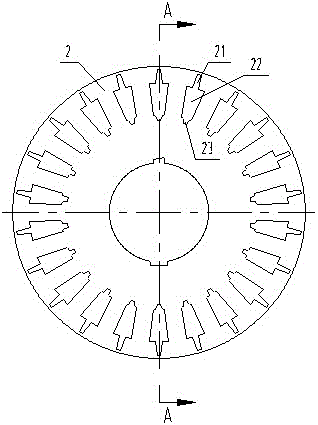

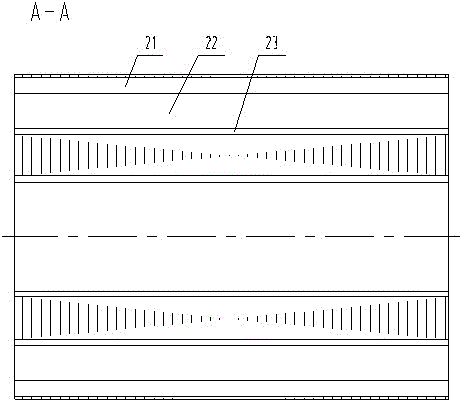

[0026] Such as Figure 1-Figure 11 As shown, the present invention is realized in this way. The rotor core 2 is formed by laminating the rotor punches 1. The outer circumference of the rotor punches 1 is evenly distributed with outer grooves 11, middle grooves 12 and inner grooves 13. The rotor punches 1 are aligned with each other. After being stacked, they are connected into the outer guide bar hole 21, the middle guide bar hole 22 and the inner guide bar hole 23 in the rotor core 2; the middle guide bar hole 22 is inserted with an inverted trapezoidal copper guide bar 3, and the outer guide bar hole 21 is cast with an outer aluminum The guide bar 41, the inner guide bar hole 23 is cast with the inner aluminum guide bar 42, the two ends of the rotor core 2 are cast with the aluminum end ring 43, and the aluminum end ring 43 has an aluminum fan blade 44 and an aluminum balance column 45; the outer aluminum guide bar 41. The inner aluminum guide bar 42, the aluminum end ring 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com