Worm and gear angle adjusting mechanism of plough share

A worm gear and angle adjustment technology, which is applied to plows, agricultural machinery and implements, and other applications, can solve the problems of inability to position and lock plowshares, adjustment of plowshares, and inability to cultivate slopes, so as to save manpower, maintain moisture, and The effect of a large increase in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

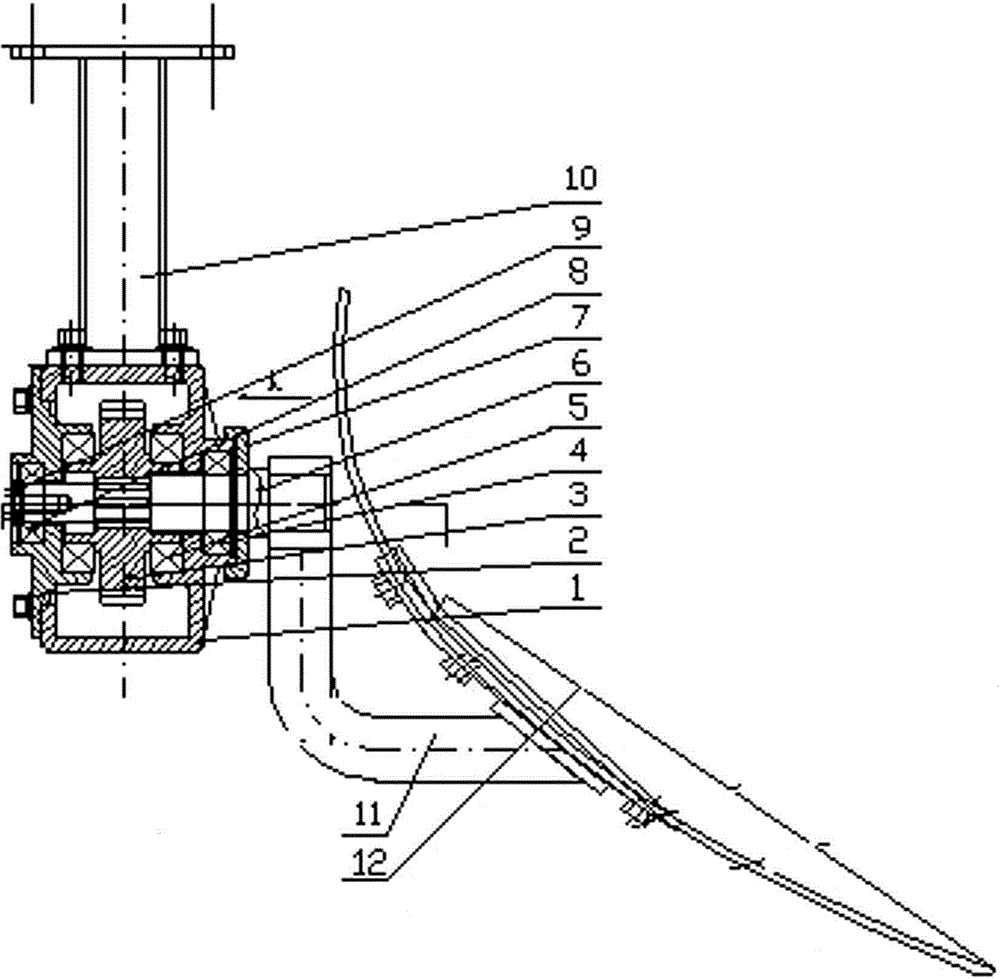

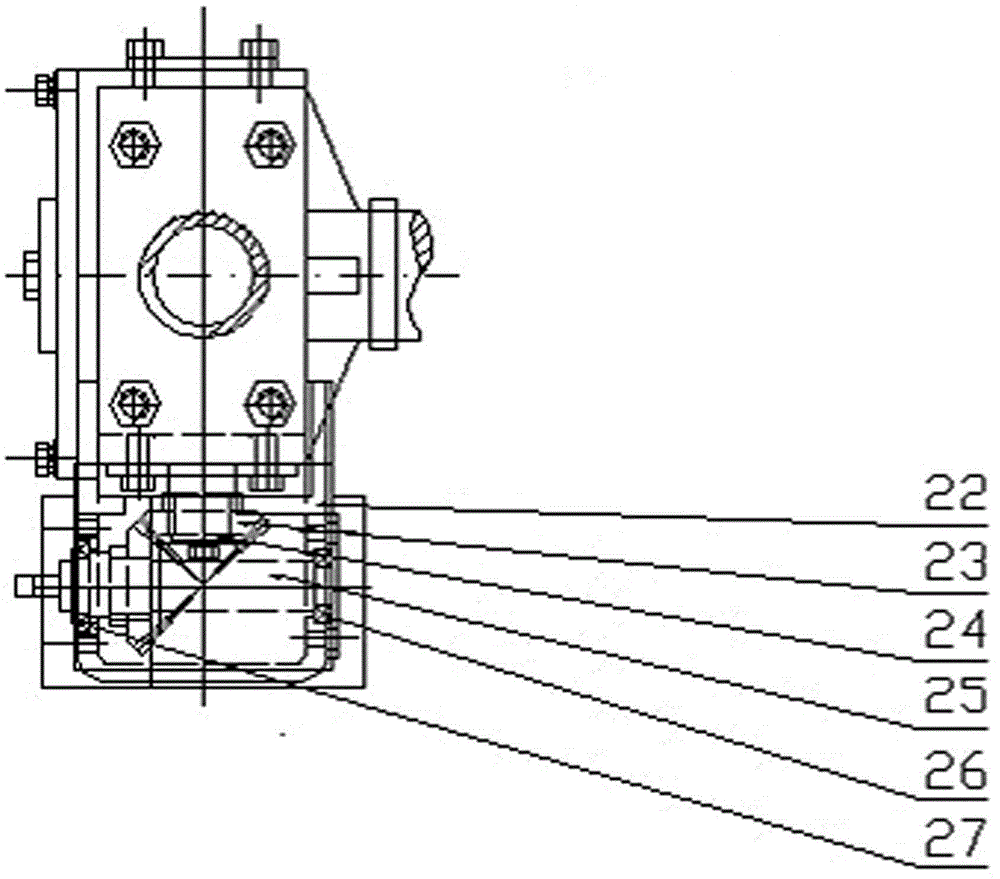

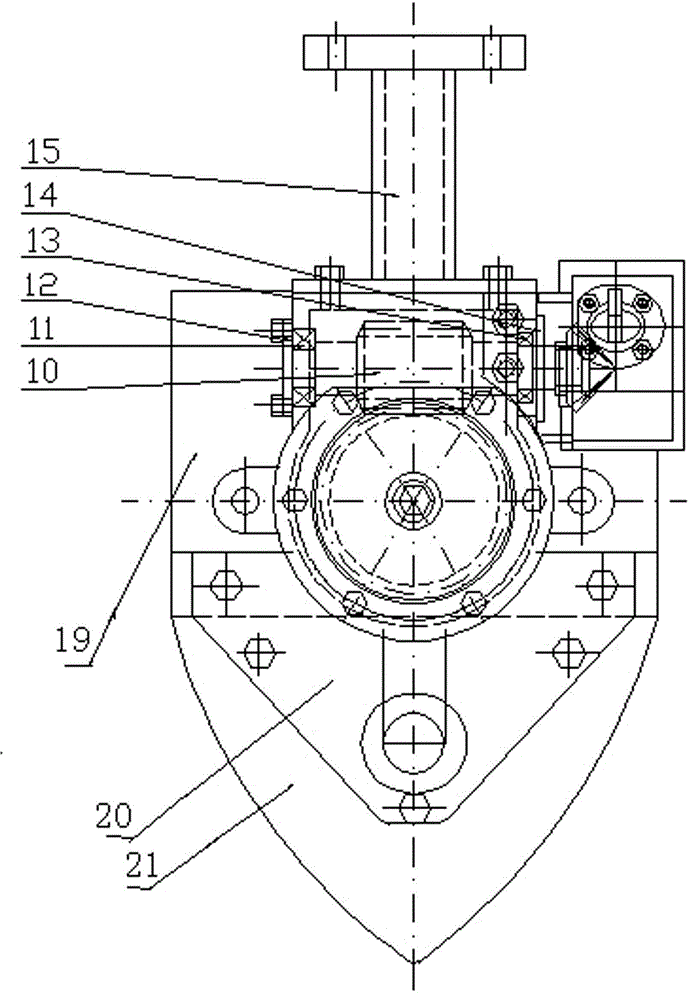

[0013] A plowshare worm gear angle adjustment mechanism, comprising a worm gear housing 1, a turbine shaft 5, a turbine 3 and a plow share 29, a first bearing 7 is installed in the outer end bearing hole on the right side of the worm gear housing 1, and the worm gear housing The second bearing 8 is installed in the outer bearing hole of the large end cover 2 of the body 1, the two ends of the turbine shaft 5 are respectively supported by the first bearing 7 and the second bearing 8, and the inner bearing hole on the right side of the worm gear housing 1 The third bearing 4 is installed, and the fourth bearing 28 is installed in the bearing hole inside the large end cover. The worm gear 3 is supported and positioned by the third bearing 4 and the fourth bearing 28 respectively. The left end of the worm gear shaft 5 is fixed by the shaft The cover 9 is fastened, and the worm gear shaft 5 is welded with a pad 6 near the outer end bearing hole on the right side of the worm gear hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com