A self-powered molecular sieve pressing device

A compacting device and molecular sieve technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced gas production and reduced gas purity, and achieve increased service life, simple structure, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

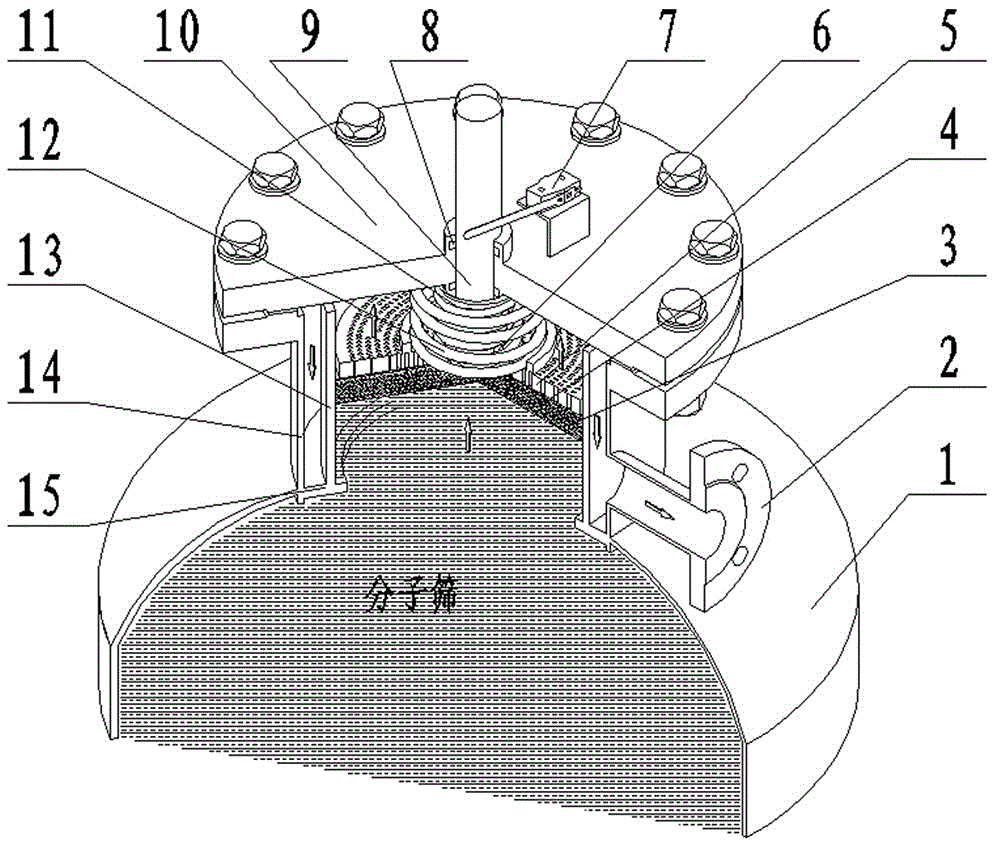

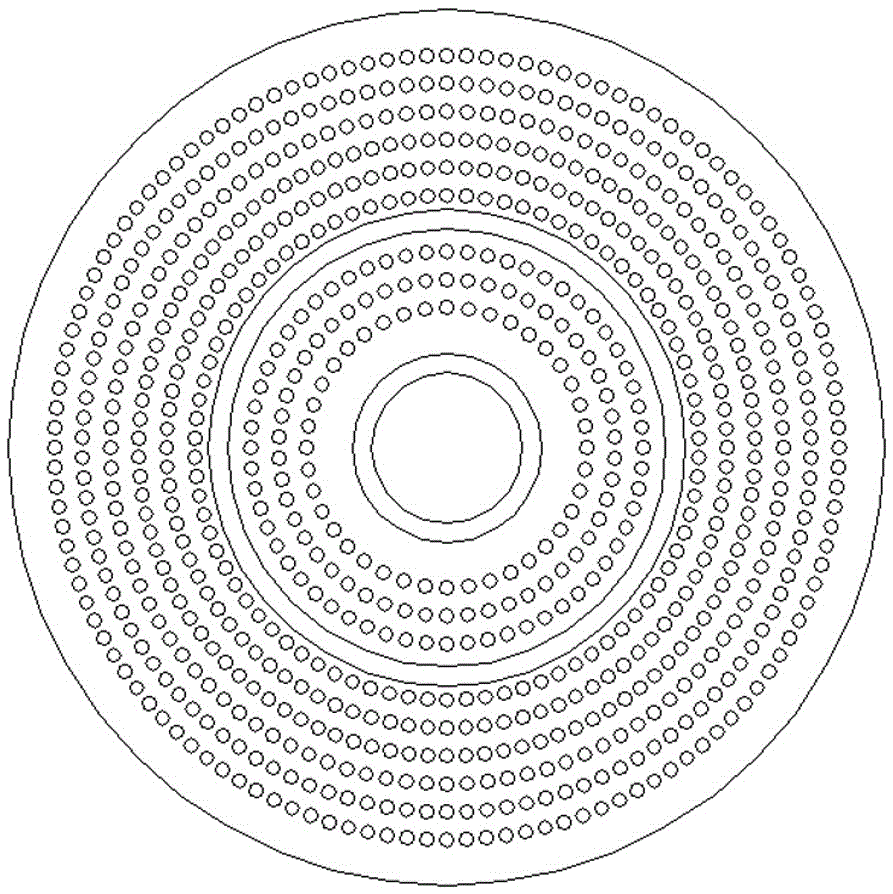

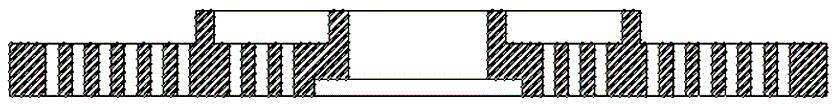

[0019] The present invention will be further described below in conjunction with accompanying drawing: figure 1 As shown, this embodiment includes an adsorption cylinder 1 containing molecular sieves. The top of the adsorption cylinder 1 has a hole and a sleeve protruding from the surface of the adsorption cylinder is arranged coaxially. The sleeve is open at one end and closed at the other end. Cylindrical, the open end of which is connected to the adsorption cylinder 1, a cylinder rod 9 that can move freely in the axial direction runs through the end surface of the closed end of the sleeve body coaxially, and the end surface of the closed end of the cover body is connected to the cylinder rod 9 Seal packing 8 is filled between them, and one end of the cylinder rod 9 extends to the inside of the casing and is coaxially connected with a cylinder piston plate 5 with a through hole, and a compression spring is coaxially sleeved outside the cylinder rod 9, and the compression spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com