Full-automatic multifunctional bucket wiping machine

A multi-functional, drum wiping machine technology, applied in the field of steel drum manufacturing and processing, can solve the problems of poor cleaning effect, dust cannot be cleaned and collected, and low efficiency of manual drum wiping, so as to improve adhesion, efficiency, and cleanliness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

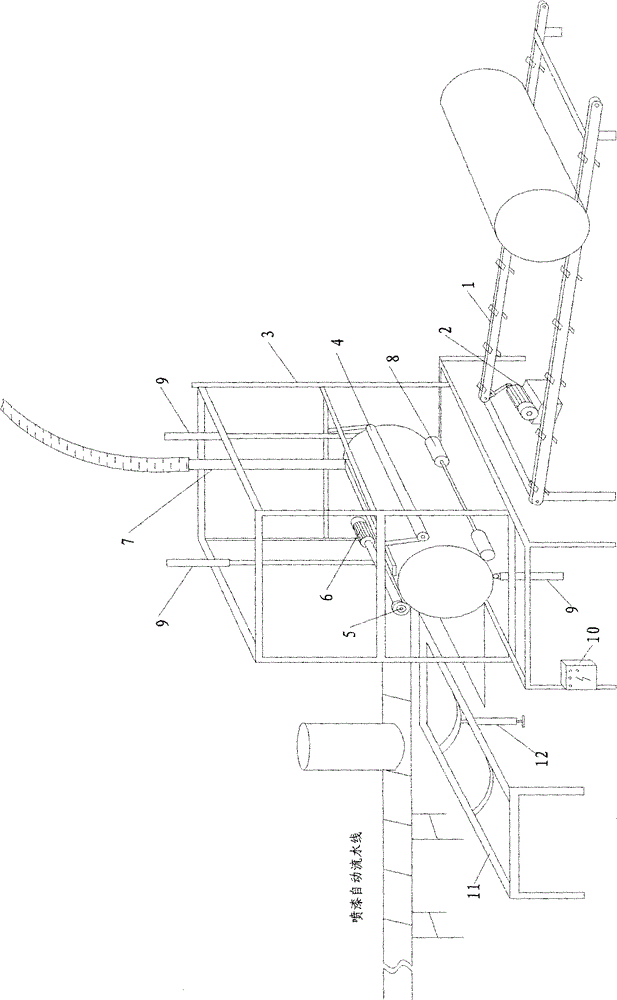

[0014] As shown in the figure: a fully automatic multifunctional wiping machine, which is mainly composed of a steel barrel conveying mechanism, a barrel wiping mechanism and a barrel turning mechanism. The barrel wiping mechanism includes a frame body 3, on which a barrel cleaning roller 4, Polishing roller 5 and polishing roller motor 6, polishing roller 5 is a copper wire polishing roller, a negative pressure dust suction mechanism 7 is arranged between the barrel cleaning roller 4 and polishing roller 5, and the bottom of the frame body 3 is provided with a rotating barrel roller shaft 8, A barrel accommodating space is formed between the barrel cleaning roller 4, the polishing roller 5 and the rotating barrel roller shaft 8, and a number of cylinders 9 are also installed on the frame body 3 to facilitate the movement of the steel barrel; the steel barrel conveying mechanism includes an automatic transmission frame 1 and a The transfer motor 2, the barrel-out end of the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com