Cylinder for rotary type compressor and rotary type compressor

A technology for rotary compressors and cylinders, which is applied in the field of cylinders and rotary compressors for rotary compressors, and can solve problems such as crankshaft inclination and crankshaft eccentric wear, and achieve the effects of reducing eccentric wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described by way of example with reference to the accompanying drawings, in which like parts are denoted by like numerals.

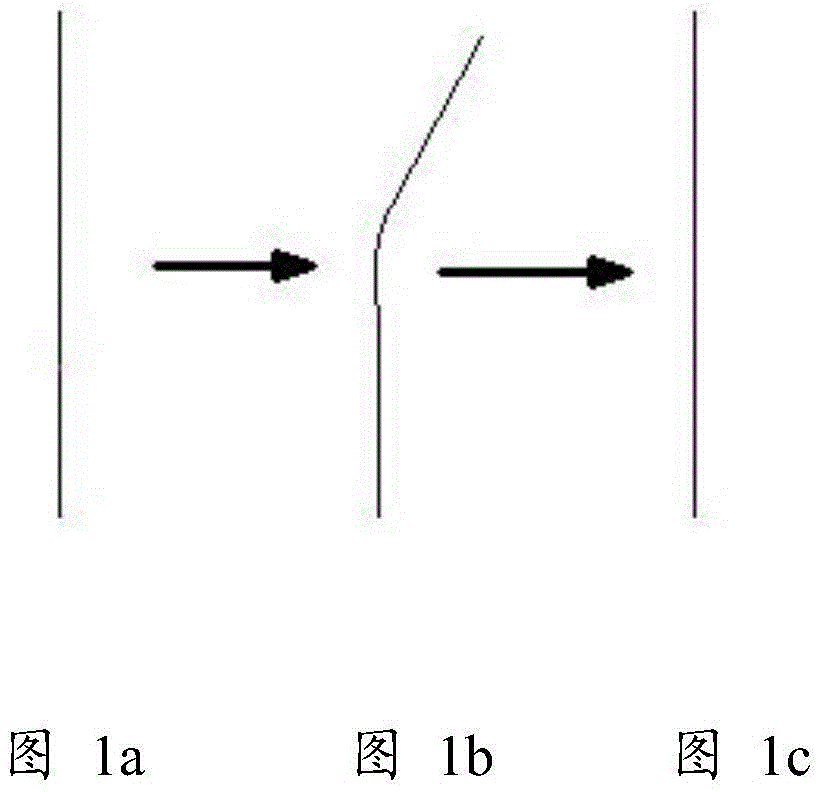

[0014] Figure 1a , 1b , 1c is a schematic diagram of the cylinder of the present invention. The lateral force acts on the vertical plane (equivalent to the inner wall of the cylinder), such as Figure 1a , when the applied force increases, the plane deforms elastically, and the lateral force received is decomposed into the force parallel to the inclined plane and the force perpendicular to the inclined plane, as Figure 1b , to relieve the effect of the lateral force on the plane, and after the force is weakened, the deformed plane returns to a vertical plane, such as Figure 1c .

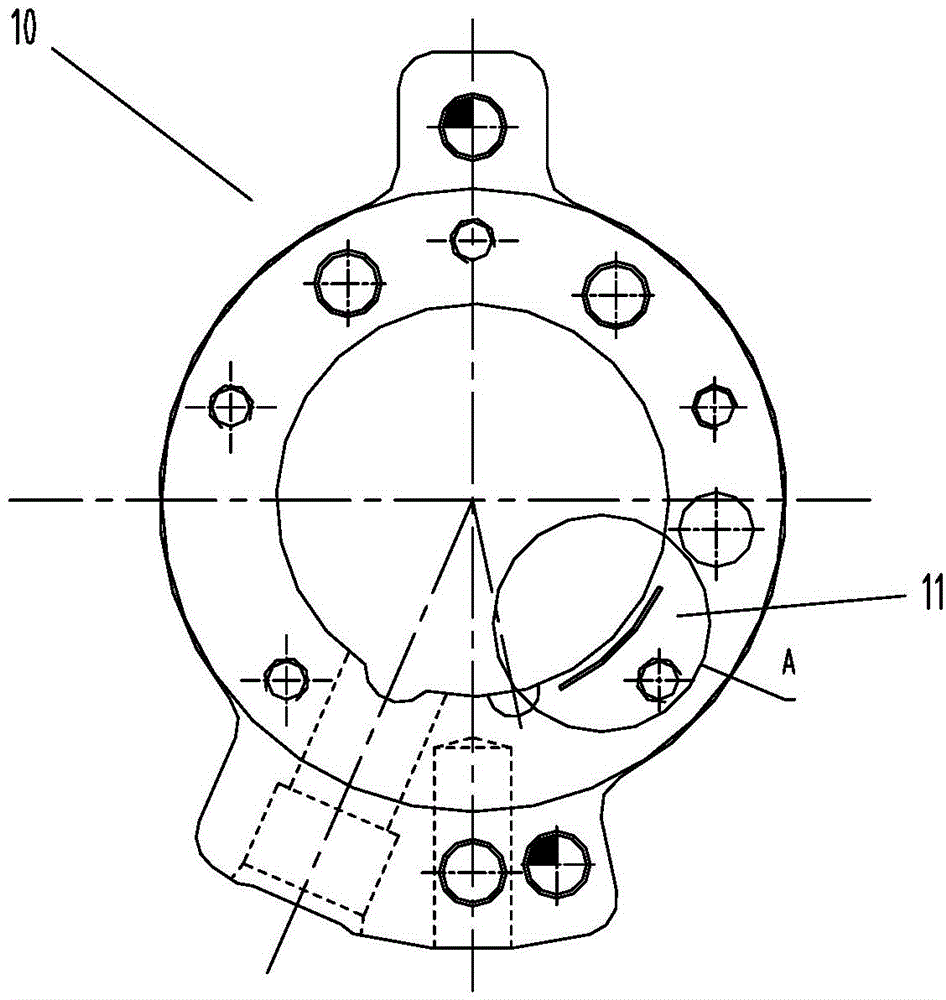

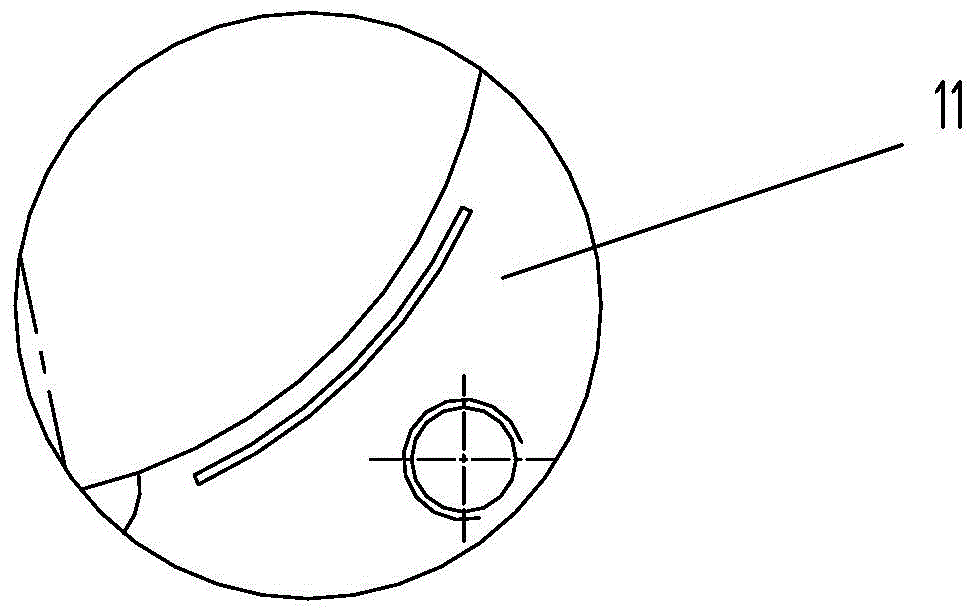

[0015] According to the above principle, figure 2 Shown is the cylinder 10 of the present invention, wherein a flexible hinge mechanism is provided circumferentially on the end face of the cylinder on the side of the high pressure chamber....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com