Mobile sensing type hydrostatic leveling system and method for monitoring vertical displacement deformation

A static leveling and measuring-reading technology, applied in the direction of hydrostatic pressure, can solve the problems of high probability of system failure, long distance of communication control cables, high requirements for lightning protection and grounding, etc., achieve stable accuracy and convenient adjustment of range , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

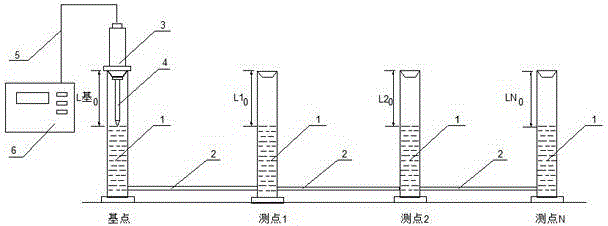

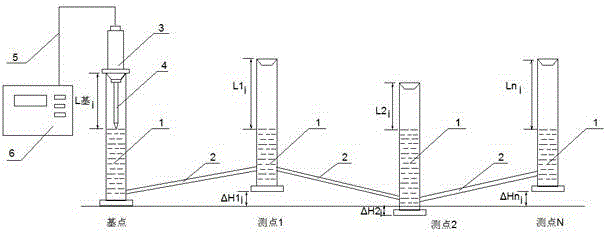

[0028] in accordance with figure 1 and figure 2 Describe the specific implementation of the mobile measuring and reading type static leveling system.

[0029] The static level tube 1 is processed by steel pipe, the bottom of the tube is sealed and has a base structure, the bottom has a connection structure with the connecting pipe 2, and the top has a matching structure with the probe and a protective cover.

[0030] Connecting pipe 2 selects the flexible pipe that anticorrosion performance is better for use.

[0031] The stylus is composed of a stylus, an encoder, a control module, a communication module and a housing. The upper part of the stylus is threaded and connected to a stepping motor. During operation, the stylus is controlled by the control measuring instrument 6 to go down. When the stylus goes down When reaching the water surface, the stylus and the water surface pass through the metal tube and form a closed circuit with the stylus, the stylus stops, the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com