Cloud service system applicable to packaging and printing machines and control method

A technology of packaging printing and control methods, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems such as inability to complete orders, ignorance of packaging technology, and service personnel who cannot be in place in time, so as to meet the requirements of reducing professional technical ability and realize Effect of cloud storage and printing, shortening service cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

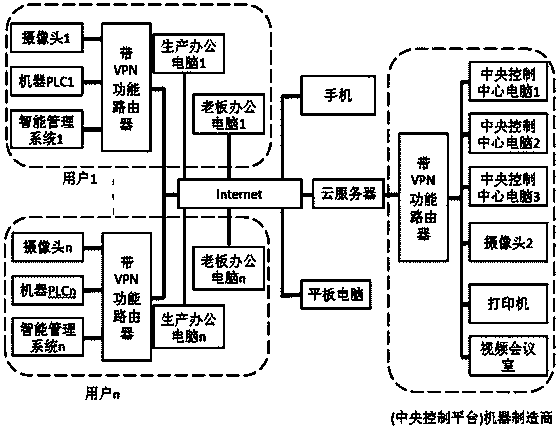

[0032] figure 1 It is a detailed system connection schematic diagram of this embodiment, figure 1 The specific description of the components in the scheme is as follows:

[0033] Camera 1, camera 2, camera n: network cameras, connected to Ethernet so that machine manufacturers can provide services to manufacturers;

[0034] PLC1 and PLCn on the machine (and the packaging and printing machine at the customer or user): represent flexible packaging machinery and equipment;

[0035] On-machine intelligent data management system 1 to on-machine intelligent data management system n: the intelligent system at the user site, including hardware industrial computer and software.

[0036] a An intelligent management platform developed for flexible packaging machinery, which is convenient for exchanging data with cloud service systems;

[0037] b Display all kinds of information provided by the machine manufacturer to the user, such as information on components that need to be maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com