Electric wire bundling device

A wire and wire hole technology, which is applied in the field of wire tying devices, can solve problems such as leakage, aging of wire rubber, and difficulty in dissipating heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

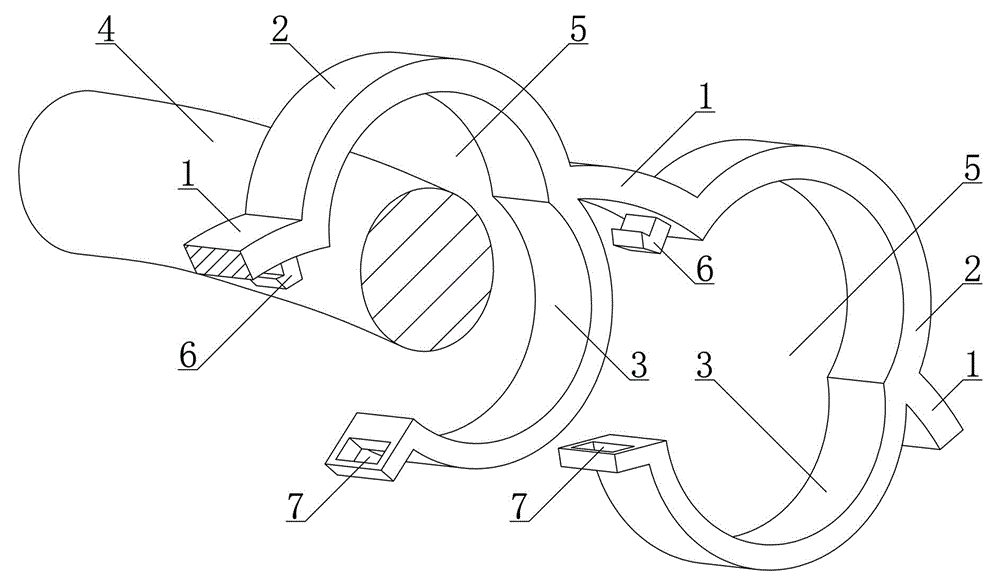

[0018] Such as figure 1 As shown, a wire binding device includes a plurality of single wire binding mechanisms and a spacer 1 connecting two adjacent single wire binding mechanisms, wherein the single wire binding mechanism includes a static binding arm 2 and a dynamic binding arm 3, The dynamic binding arm 3 covers the static binding arm 2 and encloses with the static binding arm 2 to form a wire hole 5 through which a single wire 4 passes. When in use, place the wire 4 at the position of the wire hole 5 between the moving tie arm 3 and the static tie arm 2, cover the moving tie arm 3, and place 4 turns of the wire in the wire hole 5 Among them, and by analogy, other electric wires 4 are also arranged in other electric wire holes 5 in one-to-one corresponding circles respectively, like this, have played the effect of binding a plurality of scattered electric wires together. Due to the existence of the spacer 1, the adjacent single-wire binding mechanisms are separated by a c...

Embodiment 2

[0020] The difference between embodiment 2 and embodiment 1 is: as figure 1 As shown, one end of the static binding arm 2 is elastically connected to one end of the dynamic binding arm 3 , and the other end of the static binding arm 2 is detachably connected to the other end of the dynamic binding arm 3 . Both ends of the spacer bar 1 are respectively elastically connected to two adjacent static binding arms 2 . The dynamic binding arm 3, the static binding arm 2 and the spacer bar 1 are integrally formed plastic structures. Therefore, the elastic connection means that the dynamic binding arm 3 is covered by the elasticity of the plastic to cover the spacer bar 1. The action of the static binding arm 2 and the relative bending of the two adjacent single-wire binding mechanisms.

[0021] The detachable connection is a live buckle connection between the button 6 provided at the other end of the static binding arm 2 and the button hole 7 provided at the other end of the dynamic ...

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 2 is that: one end of the static binding arm is hinged to one end of the dynamic binding arm, and both ends of the spacer are respectively hinged to two adjacent static binding arms. This is the case for moving arms, static arms and spacers made of non-resilient materials, such as rigid plastic or metal.

[0024] In other embodiments, one end of the spacer can be hinged, and the other end can be elastically connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com