High-pressure fuel supply pump comprising electromagnetic drive-type suction valve

A technology of high-pressure fuel and electromagnetic drive, which is applied in the direction of fuel injection pumps, fuel injection devices, liquid fuel engines, etc., and can solve the problems of unable to reduce the holding current of the electromagnetic drive mechanism, increase the size of the electromagnetic drive mechanism, and generate more sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

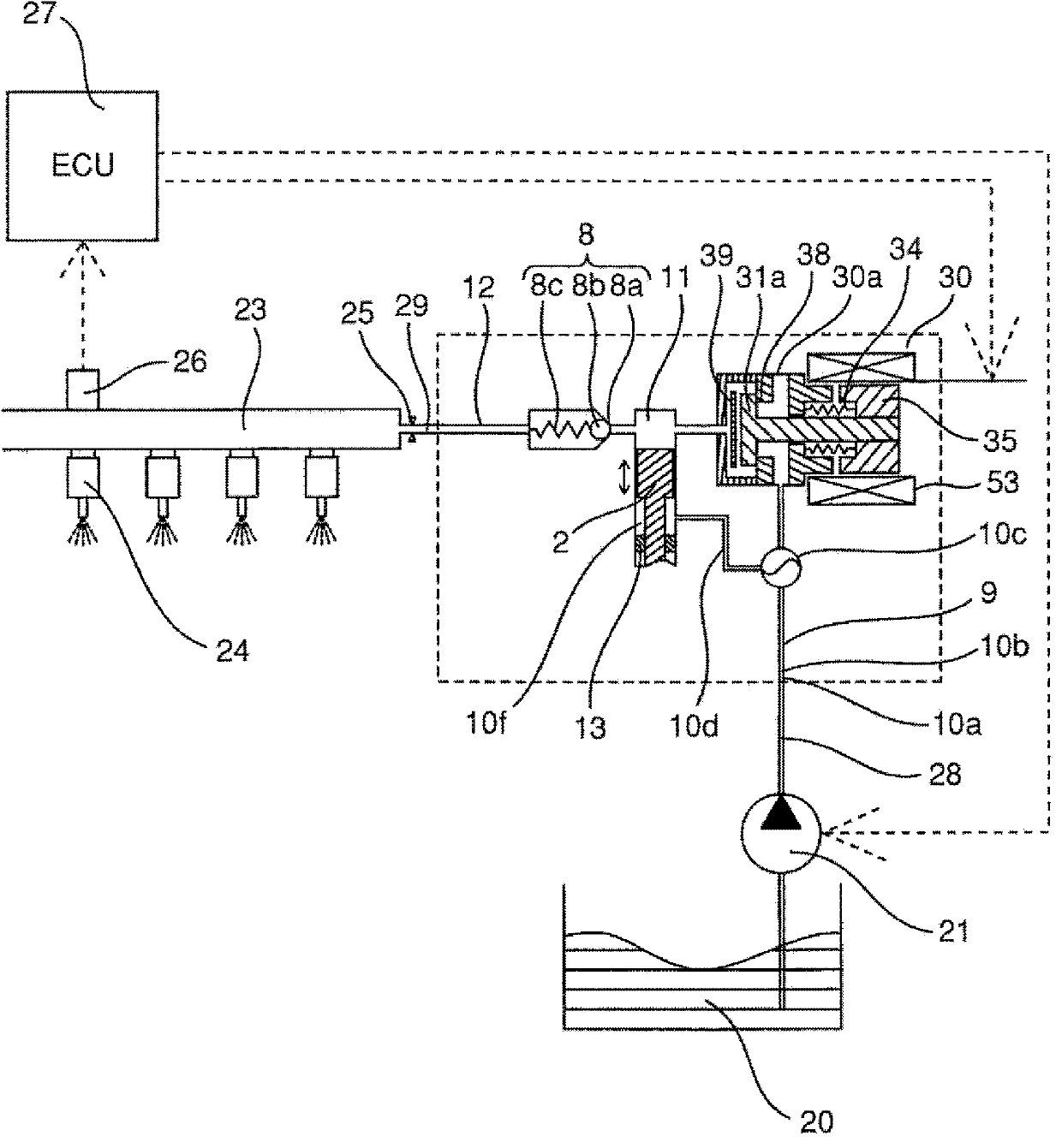

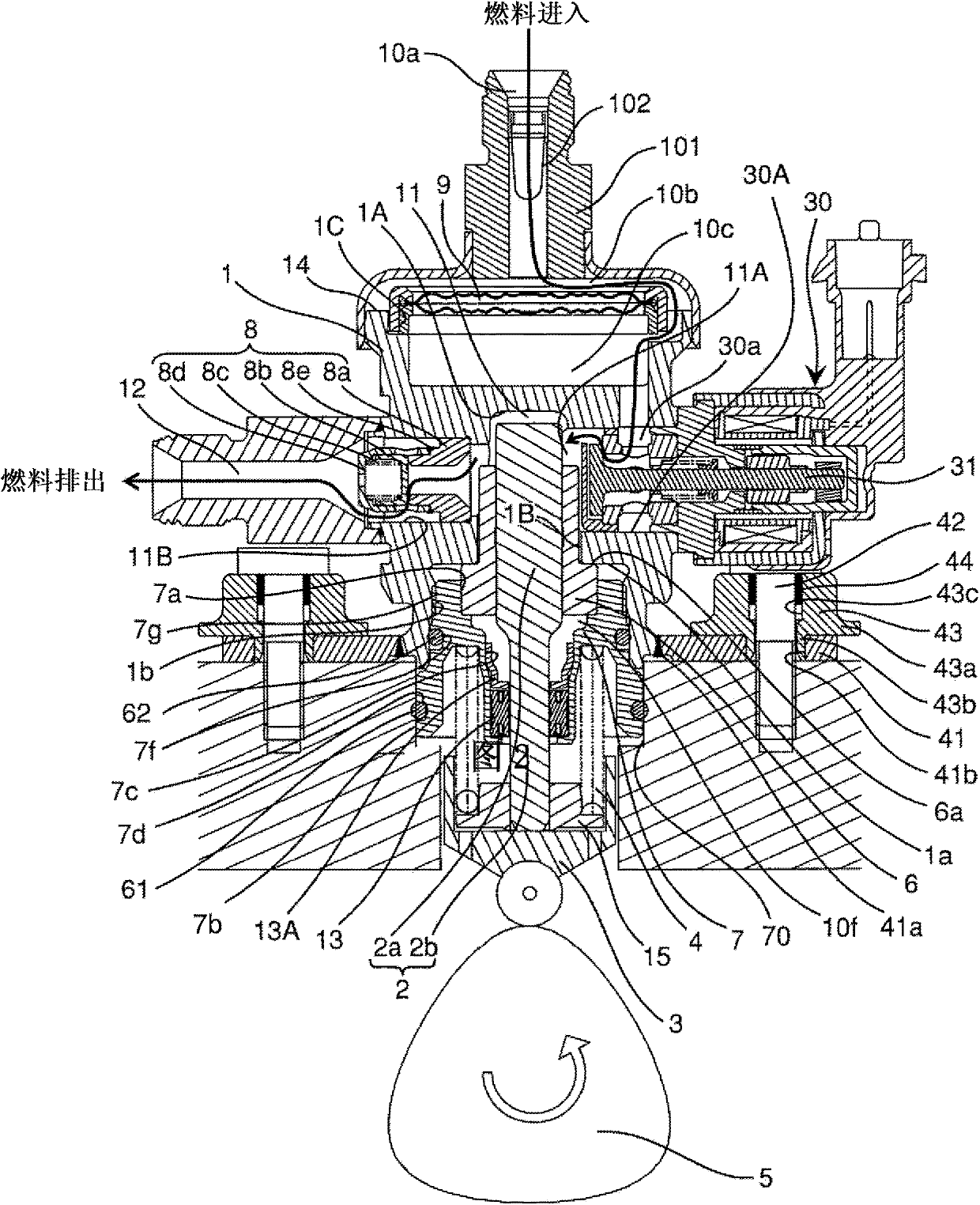

[0025] Below, based on Figure 1 to Figure 8 One embodiment of the high-pressure fuel supply pump including the electromagnetically driven suction valve of the present invention will be described.

[0026] The electromagnetically driven suction valve mechanism of the high-pressure fuel supply pump of this embodiment is configured as follows.

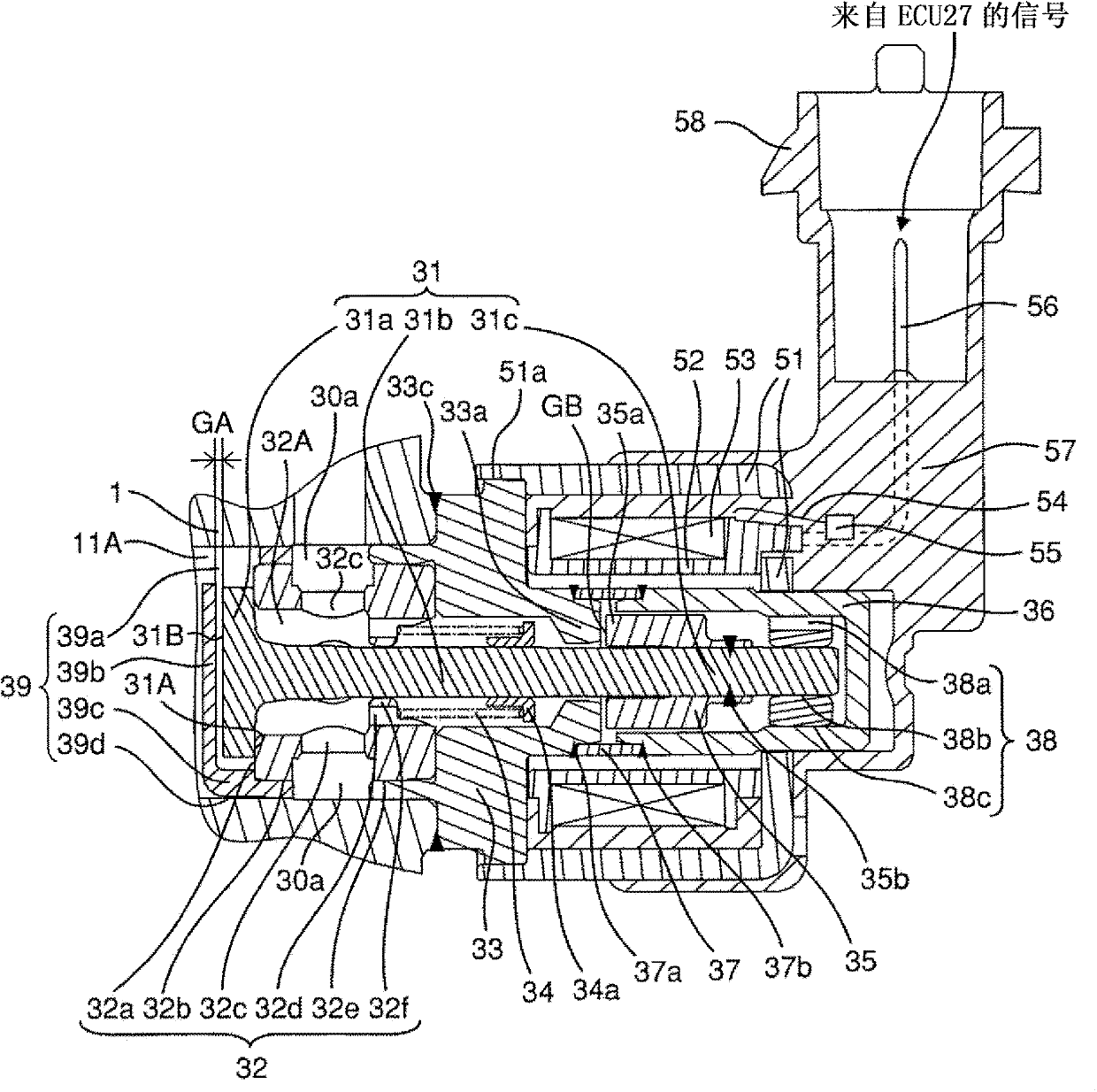

[0027] This electromagnetically driven suction valve mechanism is a so-called normally closed type, in which a valve member 31a and a plunger rod 31b are integrated, and a spring 34 biasing the plunger rod 31b biases the valve member 31a in the valve closing direction.

[0028] This electromagnetically driven suction valve mechanism has a plunger rod 31 b that is operated by an electromagnetic force generated by an electromagnetic coil 53 . The armature 35 fixed to the armature fixing portion 31 c of the plunger rod 31 b approaches the fixed iron core 33 by electromagnetic force, and collides with the end surface of the fixed iron core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com