Adjustable mattress cover and manufacturing method thereof

A manufacturing method and technology for mattress covers, which are applied to bed sheets, textiles and papermaking, heating/cooling fabrics, etc., can solve problems such as uneven paving, rising costs, and difficulty in setting mattresses, achieving good fit, avoiding The effect of uneven paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

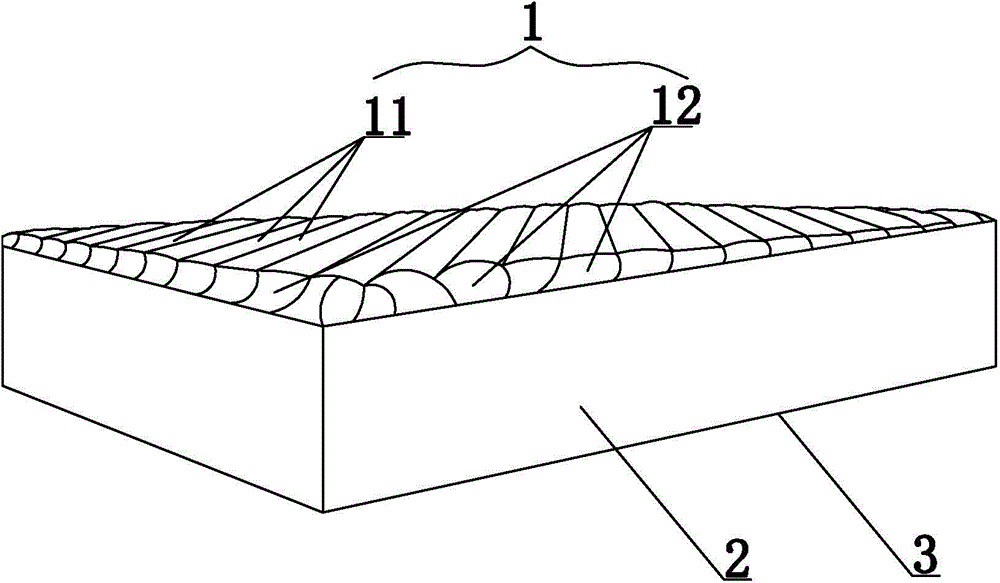

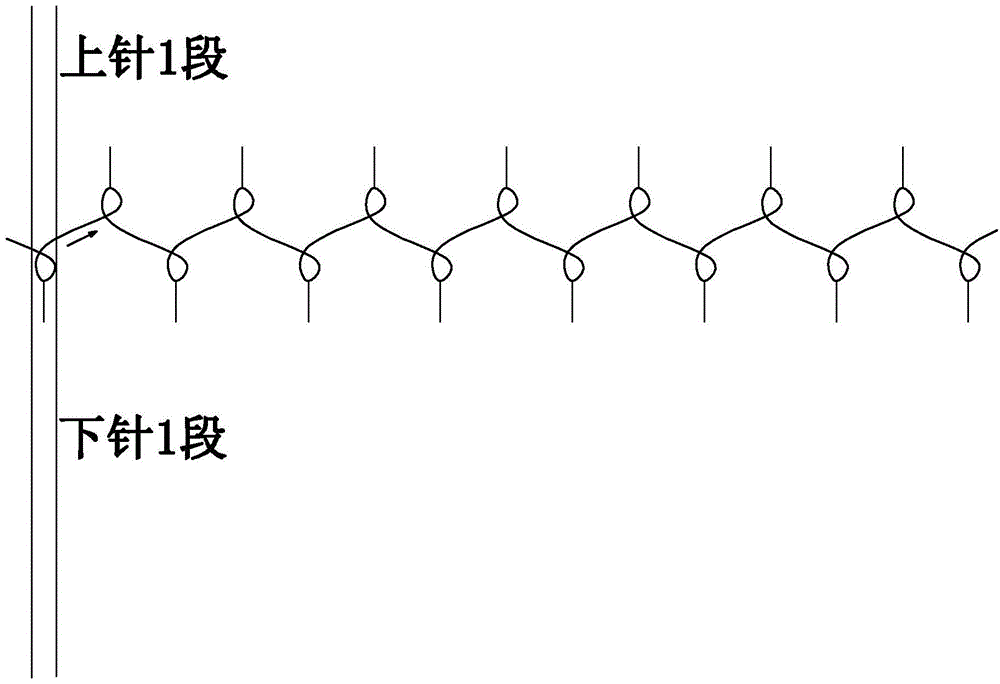

[0021] In this embodiment, a method for manufacturing an adjustable mattress cover uses 75D / 36F DTY polyester yarns as warp yarns and weft yarns, weaves according to weft knitting, uses a circular machine for weft knitting, and weaves The adjustment of the density and circular knitting machine cylinder controls the coil structure and weaving density. In the interval of 50 needles (equivalent to 4cm), use 26.5cm long polyester yarn for weaving. The weaving density: warp yarn 44 needles / inch, The weft yarn is 28 needles / inch. After weaving to form the gray cloth, it is finished after setting. The setting temperature is 180°C. After setting, the width of the door is reduced from 1.9m to 1.5m; figure 1 , including upper cover 1, side cover 2 and lower cover 3, the upper cover 1, side cover 2 and lower cover 3 are integrated structure, and the upper cover 1 and the lower cover 3 are parallel, and the upper cover 1 and the lower cover 3 pass through Vertically arranged side covers 2...

Embodiment 2

[0025] The setting and working principle of this embodiment and embodiment 1 are the same, the difference is that in the manufactured mattress cover, the lower cover 3 has the same structure as the upper cover 1, and is composed of a wave-shaped lower cover body and a bud-shaped lower cover side body, and the upper cover 3 has the same structure as the upper cover 1. The cover body 11 extends from the center to the periphery to form an upper cover body 12, and the upper cover body 12 extends vertically downward to form a side cover 2, and the side cover 2 shrinks from the periphery to form a lower cover body, which extends toward the center to form a Lower overlay. The upper cover 1 and the lower cover 3 have the same structure, and there is no need to distinguish the upper cover 1 and the lower cover 3 during use, and the installation and use are more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com