Reboiler

A reboiler and heat exchanger technology, applied in the direction of boiling devices, chemical instruments and methods, etc., can solve the problems of restricting the normal operation of production, difficult maintenance and replacement, and reducing the use effect of reboilers, so as to achieve easy maintenance and replacement, improve The effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

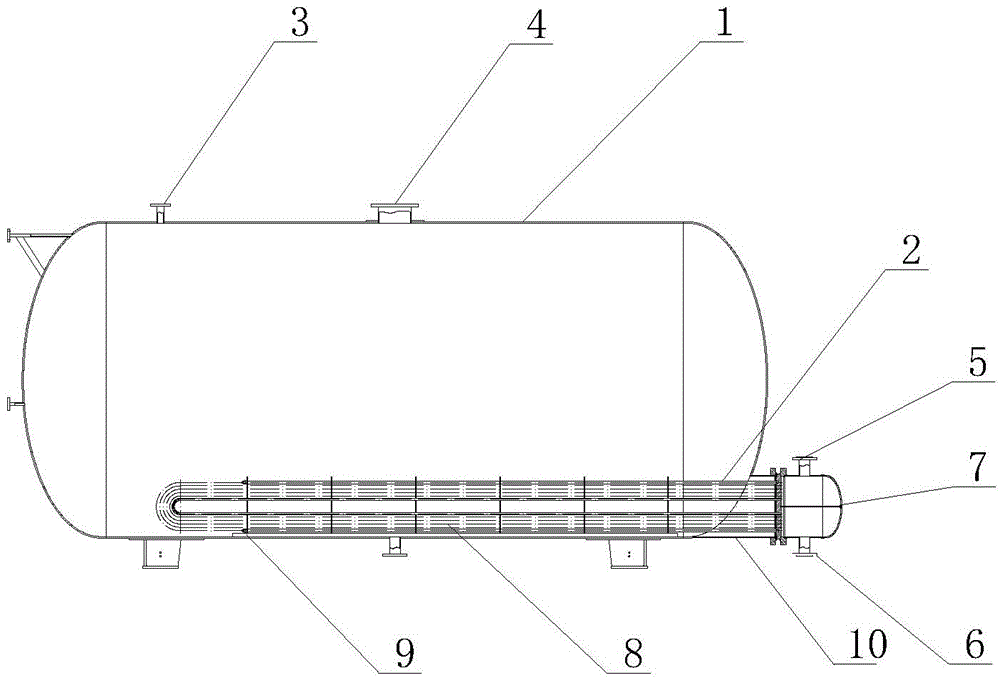

[0010] see figure 1 , a reboiler provided by the present invention comprises a reboiler shell 1 and a heat exchanger 2, and the reboiler shell 1 is provided with a material inlet 3 and a gas phase outlet 4, in order to solve the technical problems described in the background art Problem, the technical solution of this embodiment is that the heat exchanger 2 includes a terminal 7 with heat transfer oil inlet and outlet 5, 6, and a heat exchanger tube 8 connected to the terminal 7. The heat exchanger One end of the tubes 8 is inserted into the reboiler shell 1, and the other end passes through the reboiler shell 1 and is connected to the end 7. The bottom of the heat exchanger tubes 8 is provided with a pad on the reboiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com