Soft sealing gate valve

A technology of soft sealing and gate valves, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of reducing the service life of gate valves, increasing the wear of valve plates, and reversing gate valves, so as to achieve simple and convenient disassembly and assembly operations and improve the use of The effect of improving the life and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

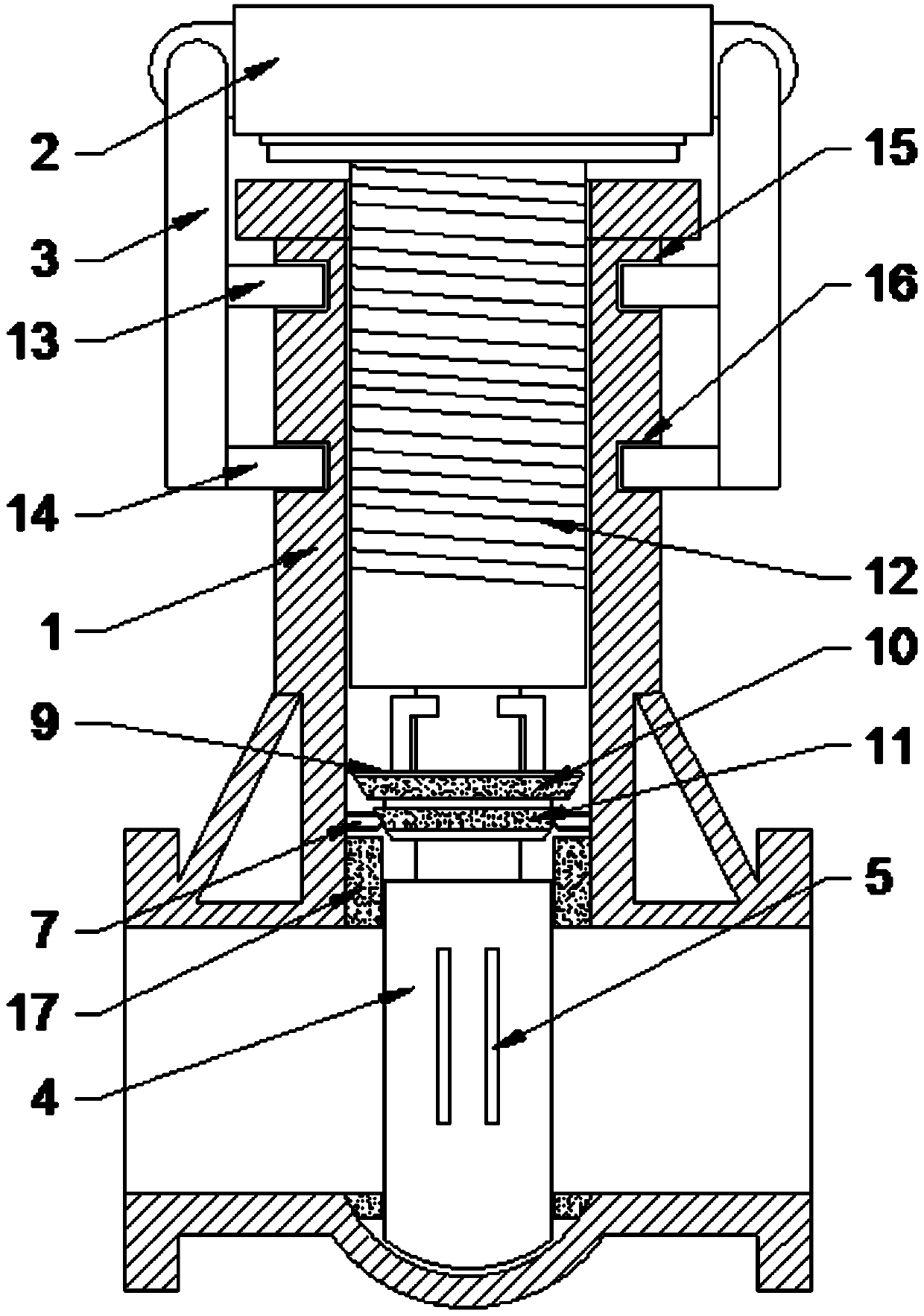

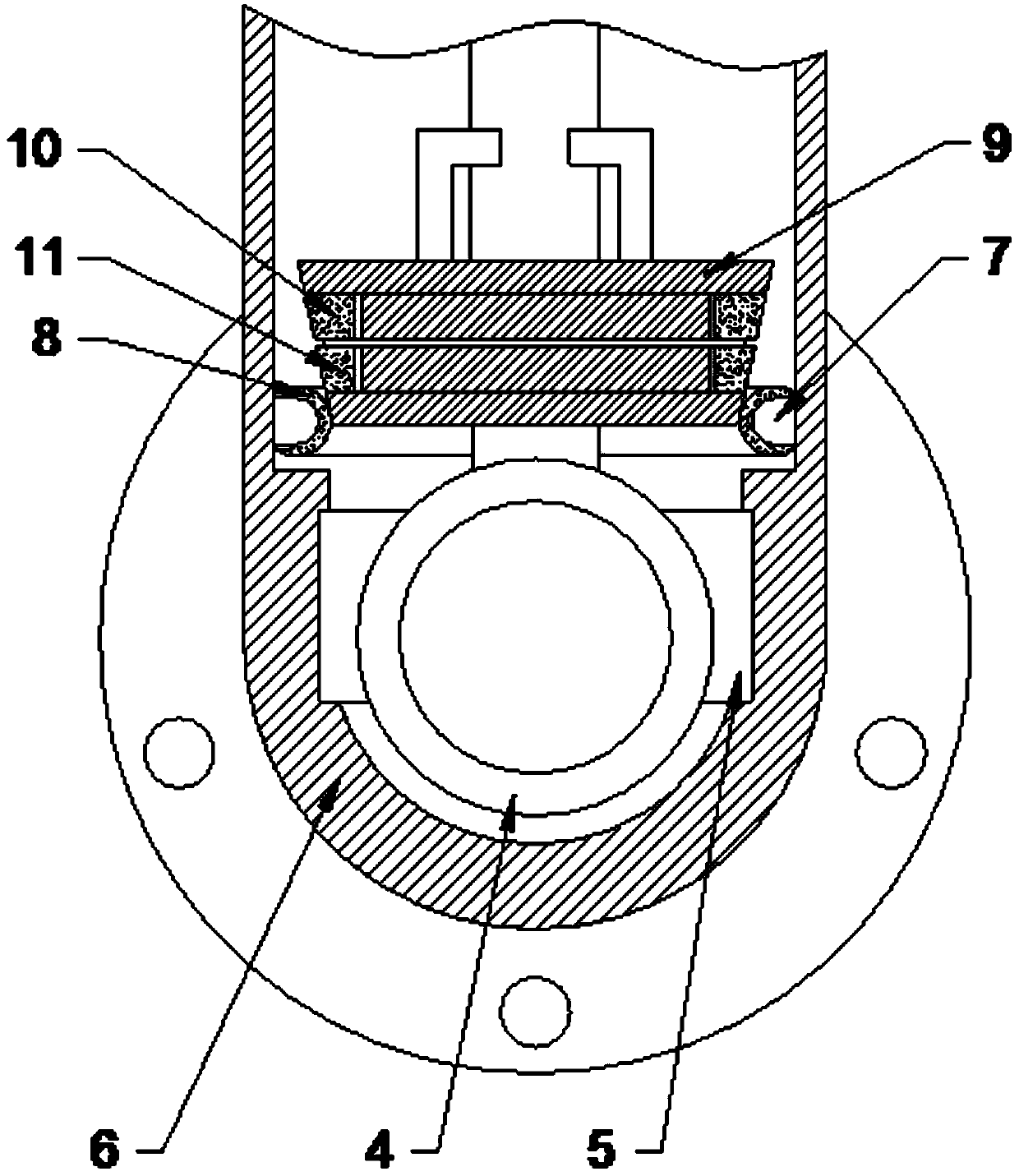

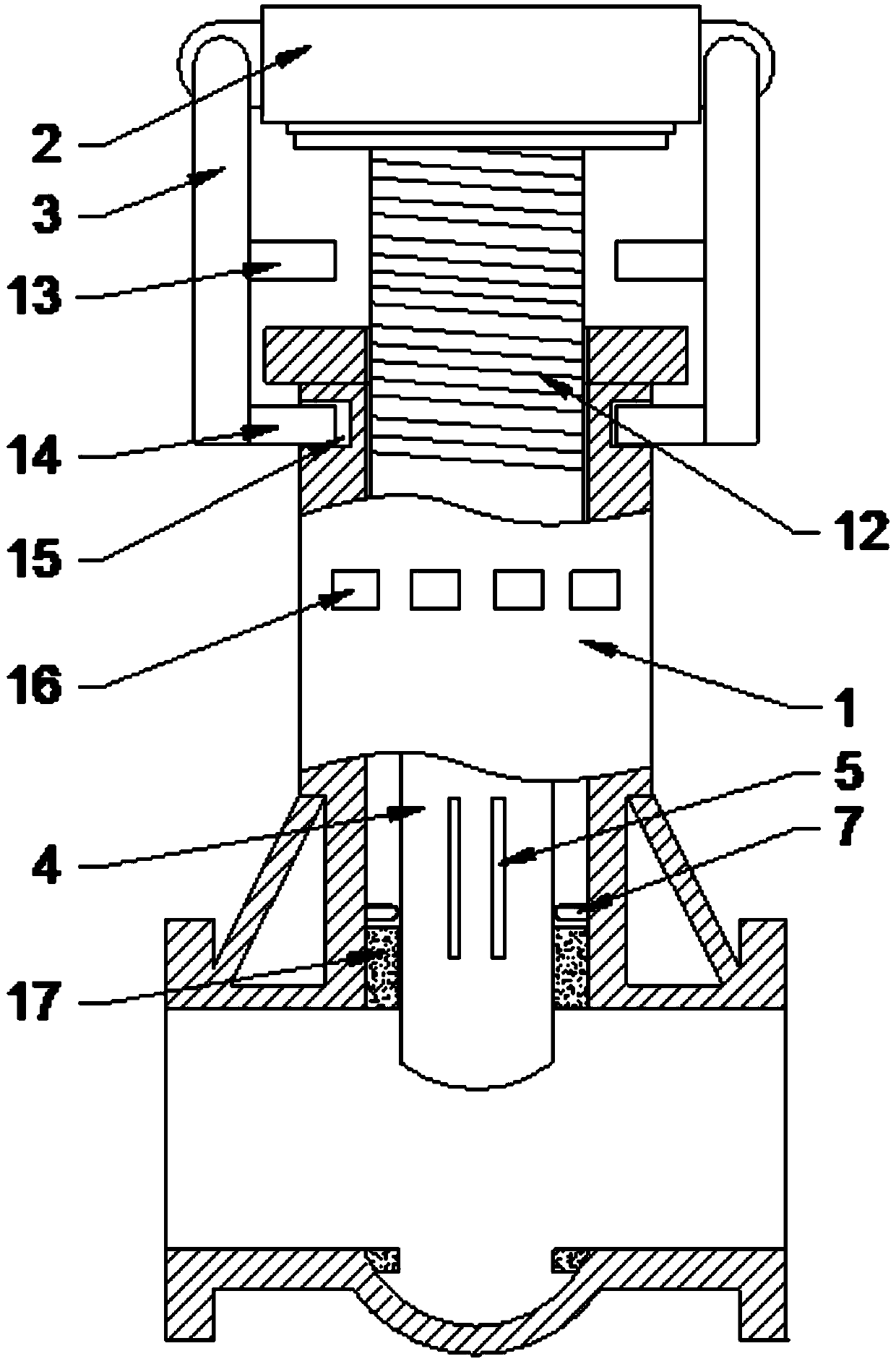

[0027] see Figure 1-3 , a soft-sealed gate valve, including a valve casing 1, the inner cavity of the valve casing 1 is a T-shaped structure, and a valve plate 4 is arranged inside the valve casing 1. In the closed state, the valve plate 4 is located at the intersection of the horizontal end and the vertical end of the valve casing 1. , and the movement direction of the valve plate 4 is the vertical direction of the valve housing 1, the top of the valve plate 4 is connected with a sealing plug 9, and the outer wall of the sealing plug 9 is sequentially embedded with a third rubber pad 11 and a second rubber pad 11 from bottom to top. Pad 10, the inner side of the valve housing 1 is provided with a sealing ring 7, the inner diameter of the sealing ring 7 is equal to the outer diameter of the lower end surface of the sealing plug 9, the outer wall of the sealing ring 7 is provided with a first rubber pad 8, the vertical section of the sealing plug 9 The cross-section is an inve...

Embodiment 2

[0030] see Figure 1-3 , the top of the sealing plug 9 is equipped with a valve stem 12, and the valve stem 12 is connected with the inner side of the valve housing 1 by threading, and has a self-locking function according to the thread, which ensures the stability of the valve stem 12 being screwed up and down, and the valve plate 4 The outer diameter is smaller than the inner diameter of the valve casing 1 at the thread, so that the valve plate 4 can slide out of the valve casing 1 along the vertical end of the valve casing 1, realizing quick disassembly of the soft-sealed gate valve.

[0031] The difference from Example 1 and Example 2 is that

Embodiment 3

[0033] see figure 1 and image 3 , the top of the valve stem 12 is equipped with a rotary cap 2, the side end surface of the rotary cap 2 is connected to the rotary rod 3 through the pin shaft rotation, the pin shaft is between the interference fit and the transition fit, and the rotary rod 3 is connected with the upper insert 13 and the lower insertion rod 14, the outer wall of the valve casing 1 is provided with an upper slot 15 and a lower slot 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com