Crossed back type muck modifier injection port of shield tunneling machine

A soil conditioner and back-mounted technology, which is applied in the field of the slag soil conditioner injection port of the shield machine, can solve the problems of the treatment or replacement of rubber pads, affecting the life of the equipment, and the loss of the check valve at the injection port. The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

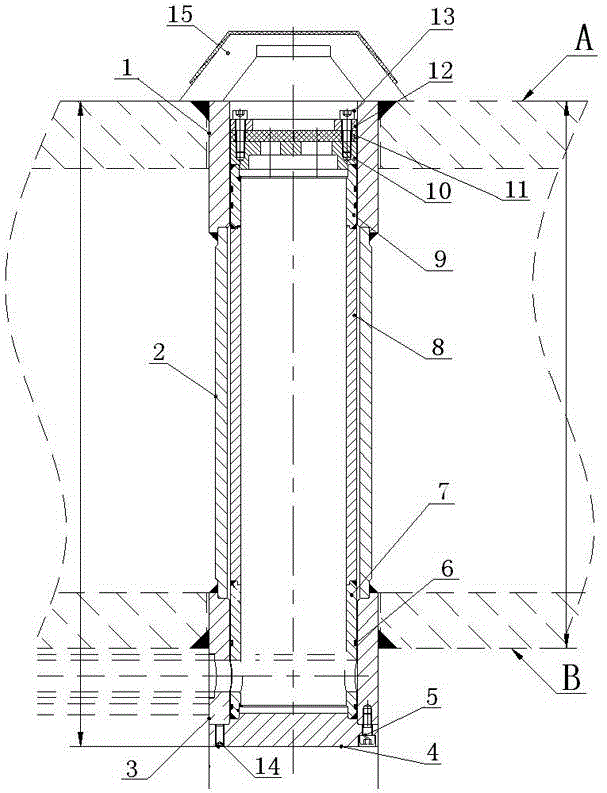

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

[0025] like figure 1 As shown, the cross-shaped back-mounted shield machine muck modifier injection port includes the modifier injection cylinder arranged between the front panel A of the cutter head and the rear panel B of the cutter head, and the nozzle arranged on the front panel A of the cutter head , characterized in that: the improver injection cylinder includes an inner cylinder wall and an outer cylinder wall, and the inner cylinder wall and the outer cylinder wall are fixedly connected by connecting bolts 5 between the inner and outer cylinder walls;

[0026] The inner cylinder wall includes a steel cover plate 4, a fourth seamless steel pipe 7 connected with the steel cover plate 4, a fifth seamless steel pipe 8 connected with the fourth seamless steel pipe 7, and a fifth seamless steel pipe 8 connected with the fifth seamless steel pipe 8. The sixth seamless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com