Reagent bottle and its reagent loading device and method

A loading device and reagent bottle technology, applied in the direction of chemical instruments and methods, instruments, laboratory appliances, etc., can solve problems such as inconvenient operation, reagent dripping, and health hazards, and achieve adverse effects, eliminating the need for air intake devices, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

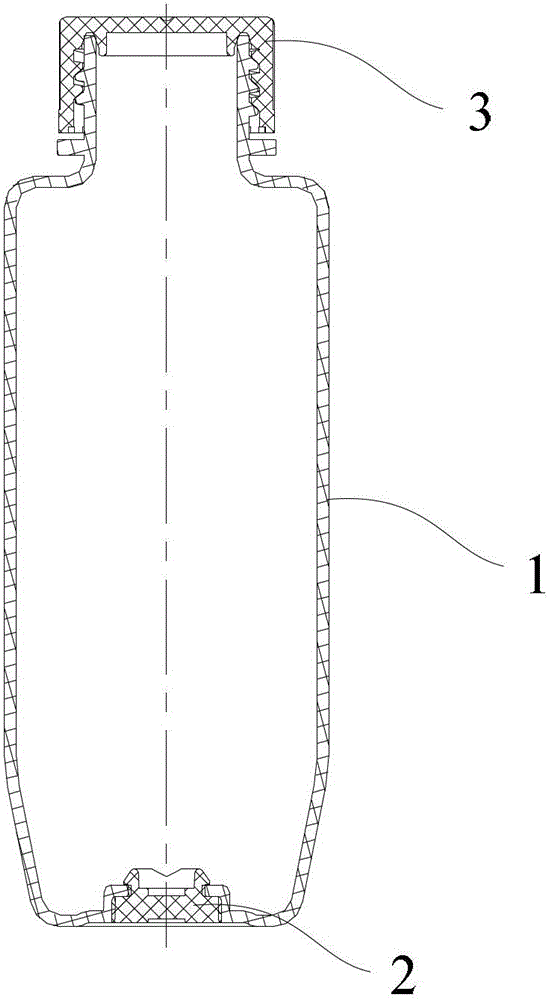

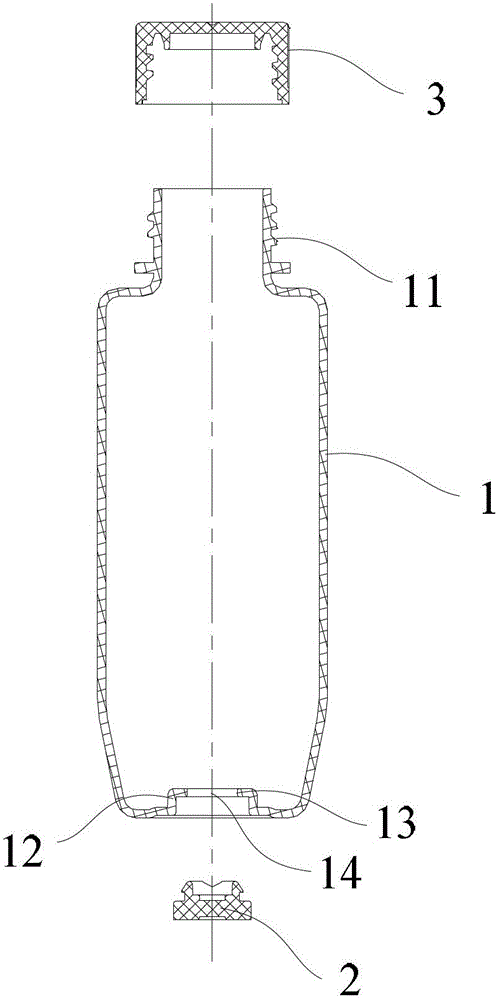

[0031] Such as figure 1 with figure 2 As shown, a reagent bottle provided by the embodiment of the present invention is composed of a bottle cap 3 , a bottle body 1 and a bottle stopper 2 .

[0032] The outer surface of the top bottleneck of the bottle body 1 has an external thread 11, the lower inner surface of the bottle cap 3 has an internal thread, and the bottle cap 3 cooperates with the external thread 11 through the internal thread to cover the top of the bottle body 1. . The bottom of the bottle body 1 has a concave hole 12 which is concave to the inside of the bottle body 1 . The bottom end surface of the concave hole 12 has a flange 13 and a through hole 14 is formed by the flange 13 .

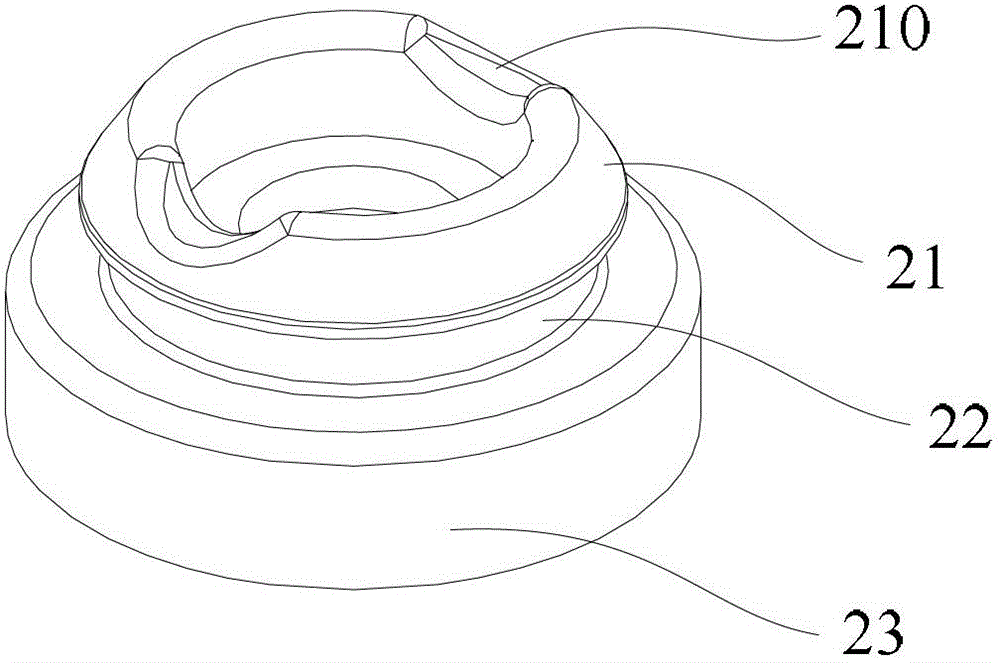

[0033] Such as image 3 As shown, the bottle stopper 2 includes an undercut 21, a neck 22 and a plug body 23, the undercut 21 is located at the top of the neck 22, the plug body 23 is located at the bottom of the neck 22, the undercut 21 and the plug body 23 connect the neck The...

Embodiment 2

[0039] Such as Figure 5 with Image 6 As shown, another reagent bottle provided by the embodiment of the present invention is composed of a bottle cap 3 , a bottle body 1 , a bottle stopper fixing member 4 and a bottle stopper 2 . Wherein, the bottle cap 3 is covered on the top of the bottle body 1; the bottom of the bottle body 1 has a bottle mouth protruding to the outside of the bottle body, and the bottle stopper 2 is plugged in the through hole of the bottle mouth; the bottle stopper 4 It is also a bottle cap, which is placed on the bottleneck at the bottom of the bottle body 1, and simultaneously the bottle stopper 2 is pressed tightly on the through hole of the bottleneck.

[0040] Because the bottle cap is the most commonly used and the easiest part to combine with the bottle body, the embodiment of the present invention uses the bottle cap as the bottle stopper 4. In addition, other common fixing structures such as aluminum seals can also be used, as long as the The ...

Embodiment 3

[0042] A reagent loading device provided by an embodiment of the present invention is as Figure 7 As shown, it consists of a bracket 20 and a puncture needle 30 . The bracket 20 is used to support and guide the reagent bottle 10 .

[0043] Specifically, the bracket 20 is provided with a guide groove 21, and the puncture needle 30 is installed at the bottom of the guide groove 21; the guide groove 21 is used to guide the reagent bottle 10 after it is placed in the loading position, so that the reagent bottle 10 The center of the bottle stopper 2 is automatically aligned with the puncture needle 30 at the bottom of the guide groove 21 .

[0044] Such as Figure 8 As shown, the puncture needle 30 includes a needle point 31, a needle seat 33 and a needle tail thread 35 fixedly connected in sequence, and a through hole 34 is opened in the center of the puncture needle 30, and the through hole 34 forms a long and narrow opening on the oblique side of the needle point 31. 32. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap