A half-shaft oiling anti-rust device

An oil tank and oil coating technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problems of high labor intensity and difficult continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a semi-shaft oiling and anti-rust device, which can automatically complete the operation of semi-shaft oiling and taking out, and reduce the production labor intensity of semi-shaft oiling.

[0023] The semi-shaft oiling and anti-rust device of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

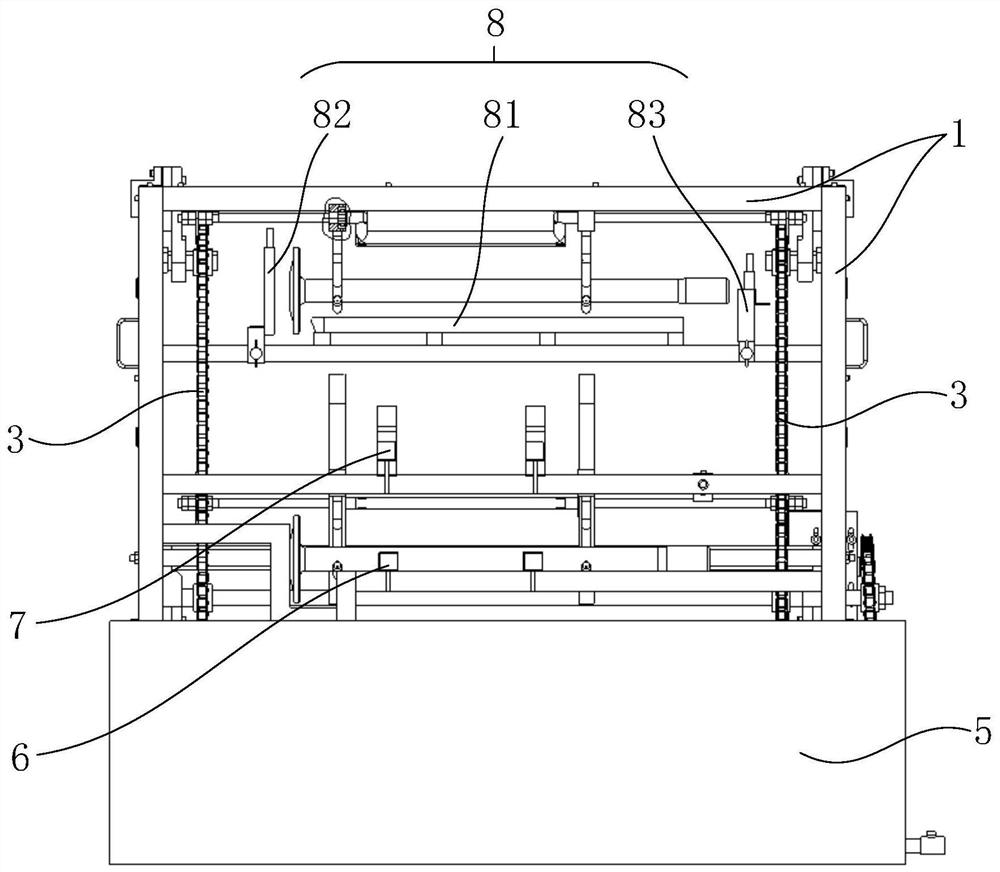

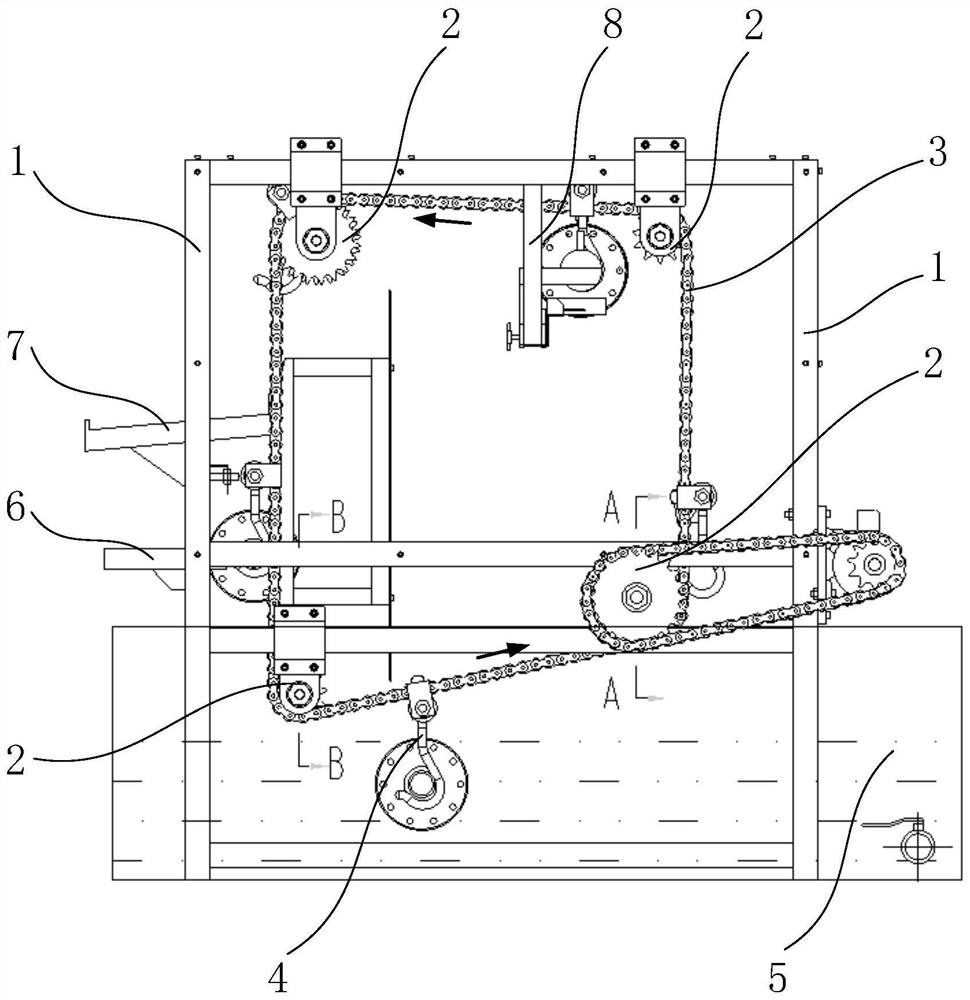

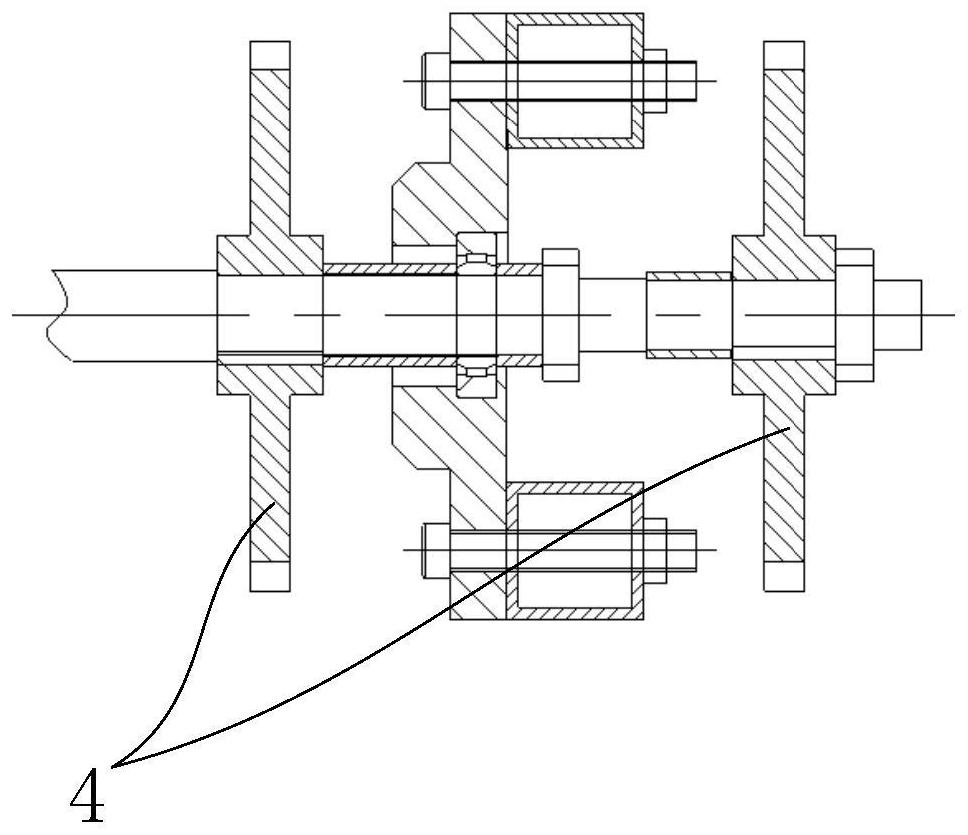

[0024] Such as figure 1 with figure 2 As shown, they are the front view and side view of the semi-axis oiling antirust device provided by the present invention respectively. The device includes a support frame 1, which plays a supporting role and can be made by welding square steel; Two groups of guide sprockets 2 are installed, each group includes at least three guide sprockets 2, and the guide sprockets of the same group are located in the same vertical plane. The guide chain 3 of a closed loop is engaged and installed on every group of guide sprocke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap