A valve buffer feeding device

A valve and material storage technology, which is applied in the field of valve buffer feeding devices, can solve problems such as affecting valve quality, valve damage, and collision, and achieve the effect of ensuring production and inspection quality and avoiding rigid collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

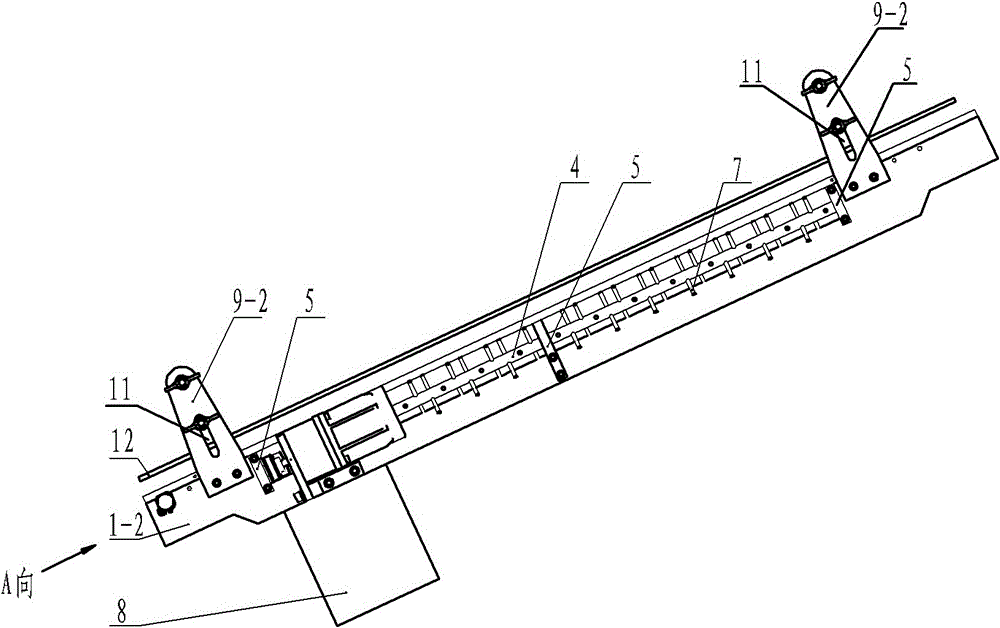

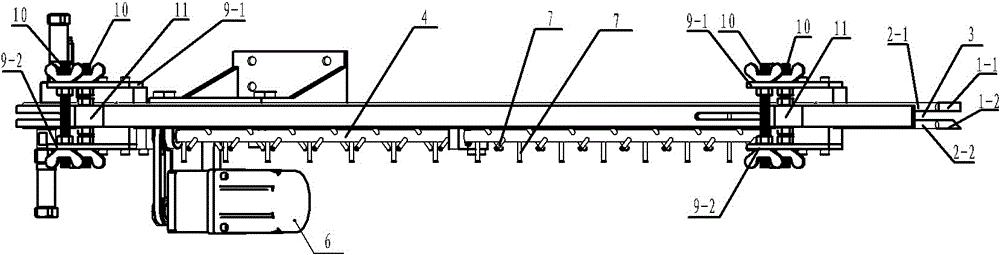

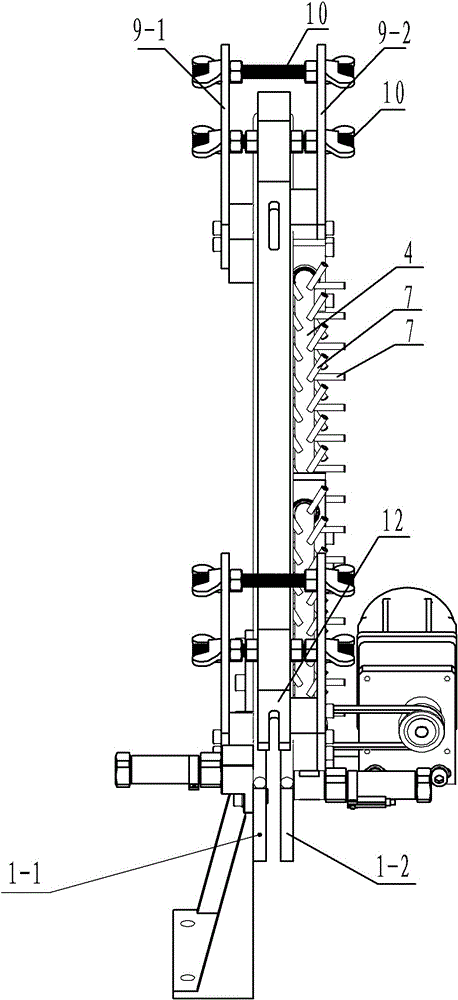

[0012] See figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a buffer feeding device for an intake valve, which includes material receiving plates 1-1 and 1-2 on both sides, and the upper ends of the material receiving plates 1-1 and 1-2 are respectively provided with storage rods 2-1 and 2-2 , forming a material channel 3, a rotating shaft 4 is provided corresponding to the lower ends of the material receiving plates 1-1, 1-2, the rotating shaft 4 is supported by the bearing seat 5, the rotating shaft 4 is connected to the driving motor 6, and a plurality of stops are arranged on the rotating shaft 4 Material strips 7, adjacent blocking strips 7 are arranged crosswise, the rotation of the rotating shaft 4, the adjacent cross-arranged blocking strips form sequential opening and closing, push down the valves one by one, and realize the feeding of the valves one by one, because the valves pass through the blocking strips one by one Pushing it down effectively avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com