Chain

A chain and sprocket technology, applied in the chain field, can solve the problems of increasing power loss between the sprocket and the chain 500, reducing the durability of the inner connecting piece plate 501, and reducing the power transmission performance of the chain 500, etc., achieving simple assembly and fewer parts. The effect of reducing and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

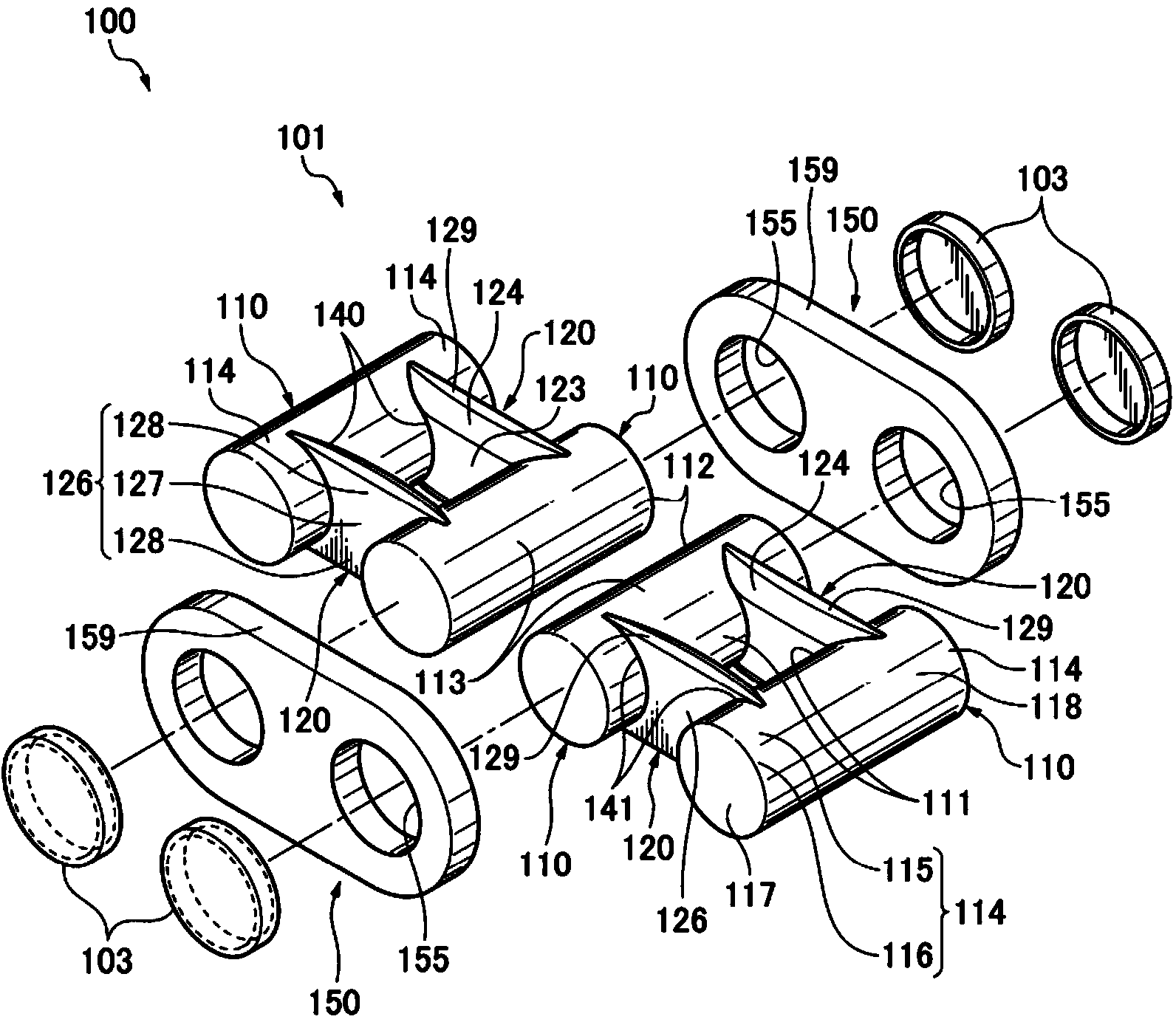

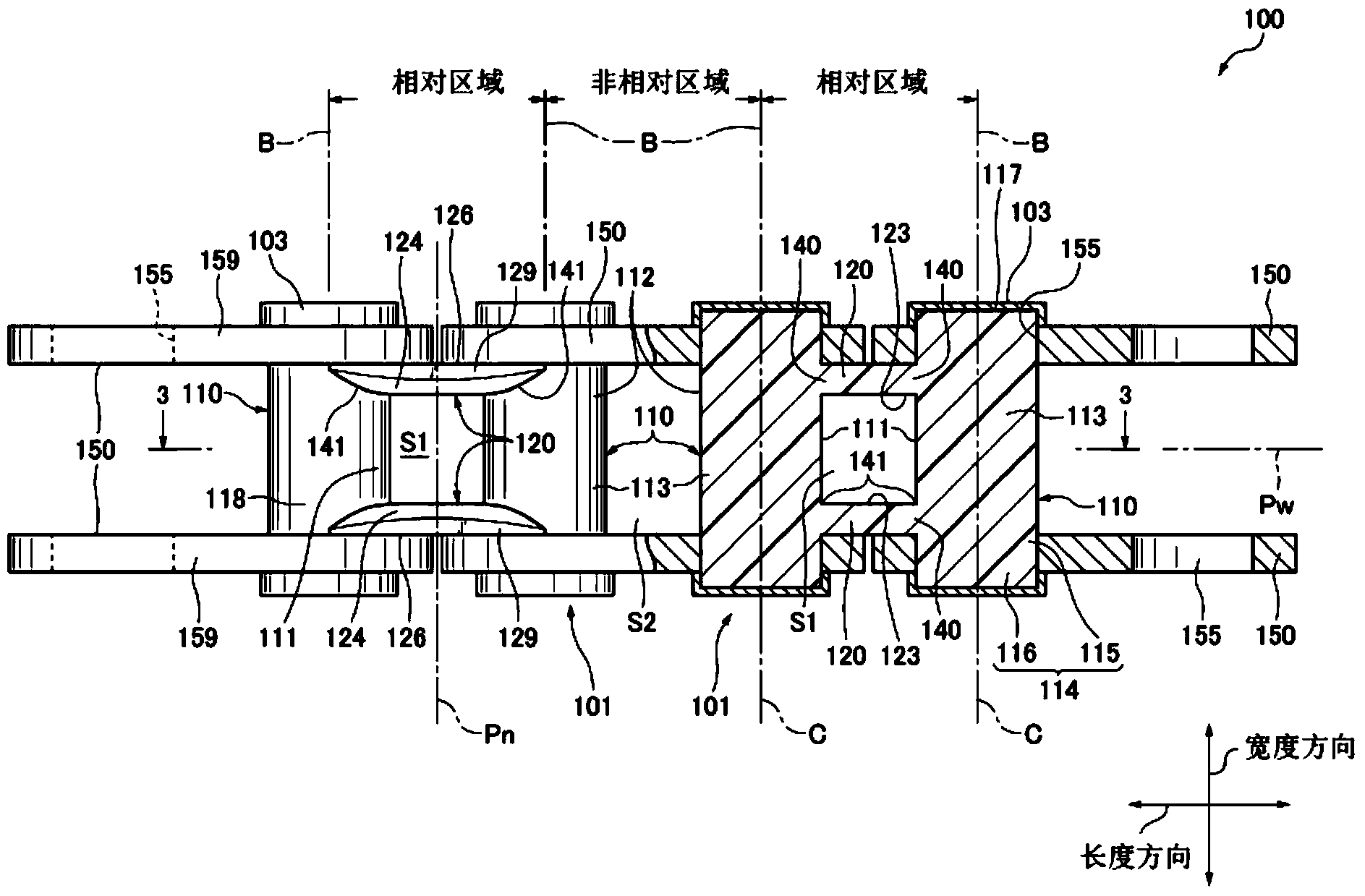

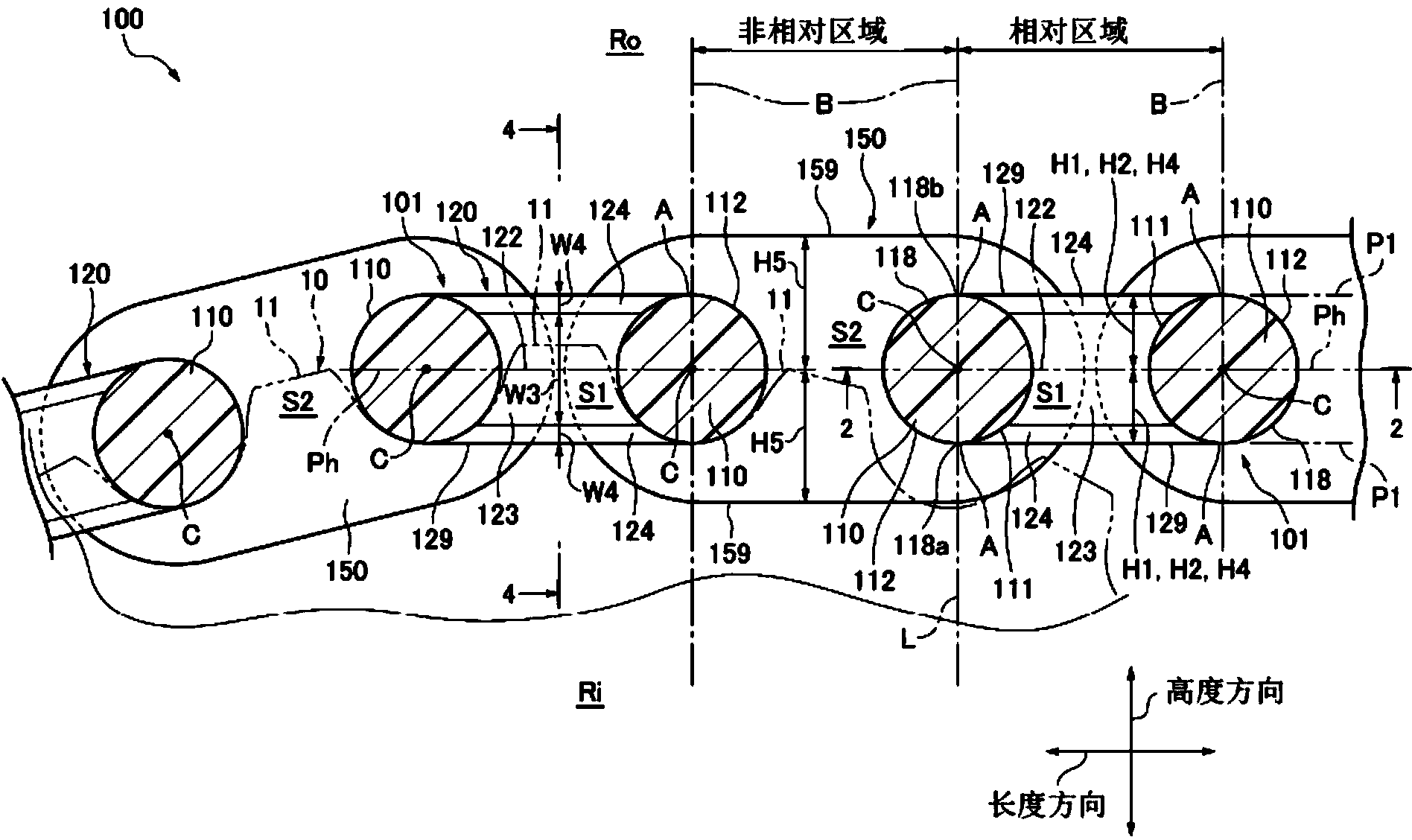

[0044] Below, refer to Figure 1 ~ Figure 4 Examples of the present invention will be described.

[0045] refer to Figure 1 ~ Figure 3 It can be seen that, in the embodiment of the present invention, the chain 100 as a transmission chain is a jointless chain, which is provided with: a plurality of connector units 101 constituting an inner connector; and a plurality of pairs of connectors constituting an outer connector. Plate 150, each connector unit 101 and pair of connector plates 150 of all connector units 101 and all groups of 1 pair of connector plates 150 pass through the connecting pin portion 110 of the connector unit 101 (hereinafter referred to as "pin"). The sections 110") alternate lengthwise and are flexibly connected about the curved centerline C of the pin section 110, thereby forming a jointless chain.

[0046] The chain 100 and the winding of the chain 100 have a plurality of sprockets 10 ( image 3 A sprocket mechanism (a part of one of the sprockets 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com