Portable dolly for replacing current transformer, and manufacture method thereof

A current transformer and portable technology, which is applied to electrical components, lifting devices, switch devices, etc., can solve the problems of lowering the working efficiency of replacing current transformers, inconvenient installation and handling, and difficult to fix firmly, so as to achieve the safety of transformers. Reliability, shortened replacement time, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

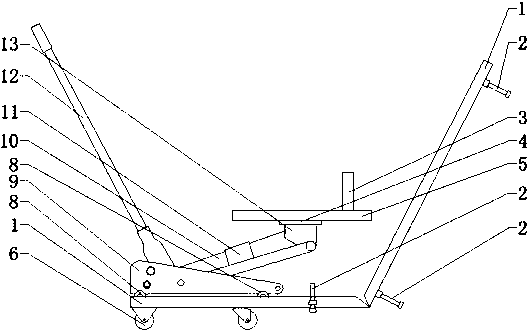

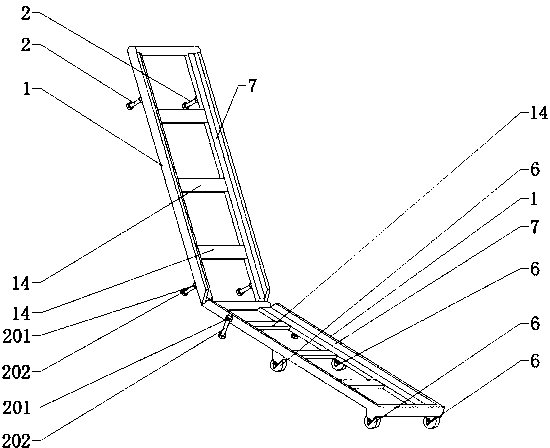

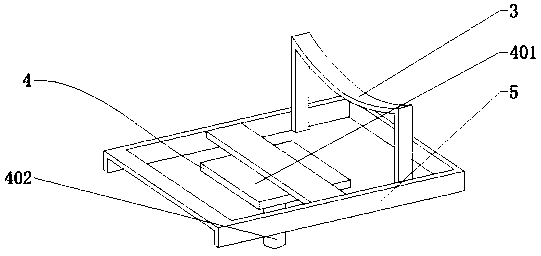

[0048] Embodiment 1: as figure 1 As shown, the portable trolley for replacing a current transformer includes two vehicle frames 1 hinged to each other, and a guide rail 7 is provided on the vehicle frame 1, and a lifting device is slidably connected to the guide rail 7 .

[0049] The vehicle frame 1 includes two No. 4 angle steels, the middle part is connected by three reinforcing ribs 14, and the outer ends are connected by steel pipes. Certainly, vehicle frame 1 also can be other shapes such as concave shape, I-shape.

[0050] See Table 2 for guide rail 7 options:

[0051] Choice of rails

[0052]

[0053] It can be seen from the above table that the technical effect of scheme 2 is the best, and it can bear the weight of the lifting device without deformation; and the current transformer moves flexibly on the guide rail 7 during transportation, and there is no jamming phenomenon during the forward process.

[0054] Such as figure 2 As shown, several supports 2 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com