An Ultrasonic Atomization Device Based on Capillary Phenomenon

A technology of ultrasonic atomization and capillary phenomenon, which is applied in the field of microgravity and can solve the problem that ultrasonic atomizers cannot be used in weightless or microgravity environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

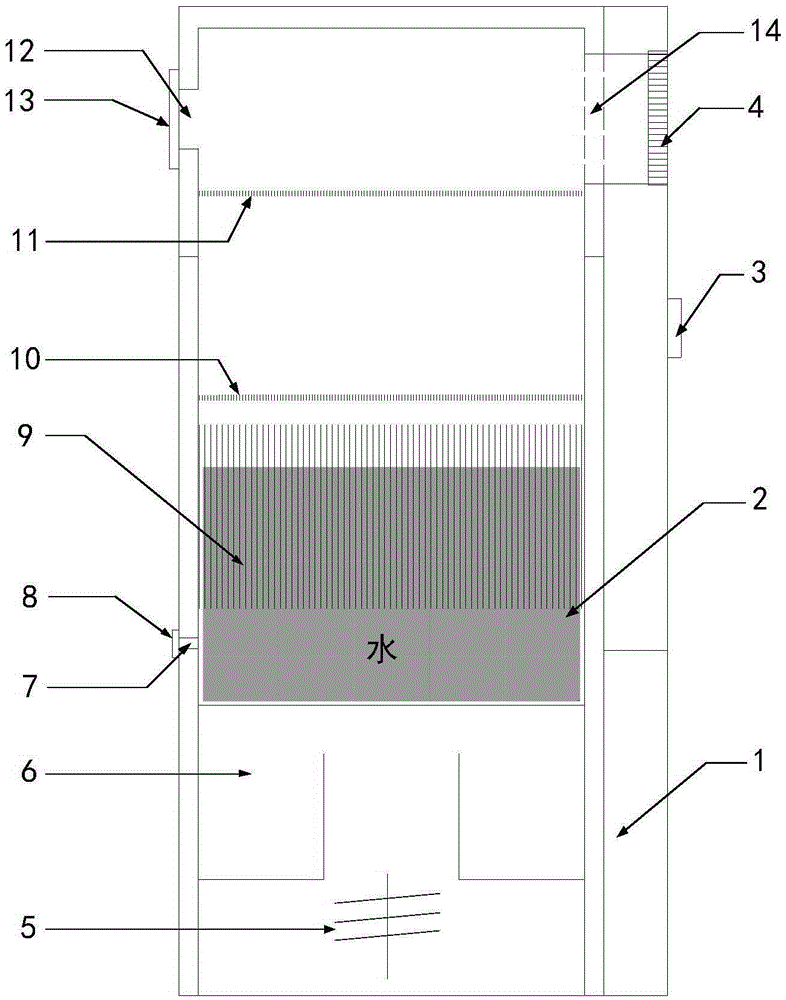

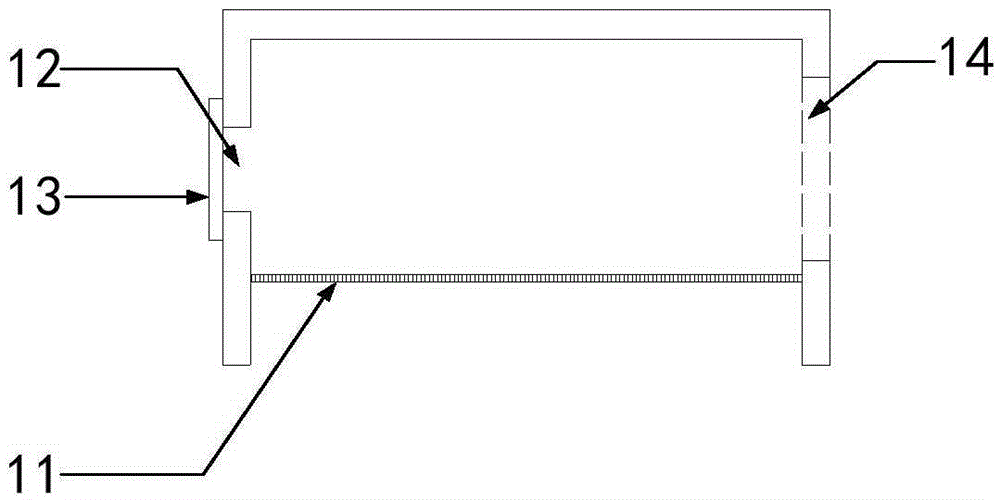

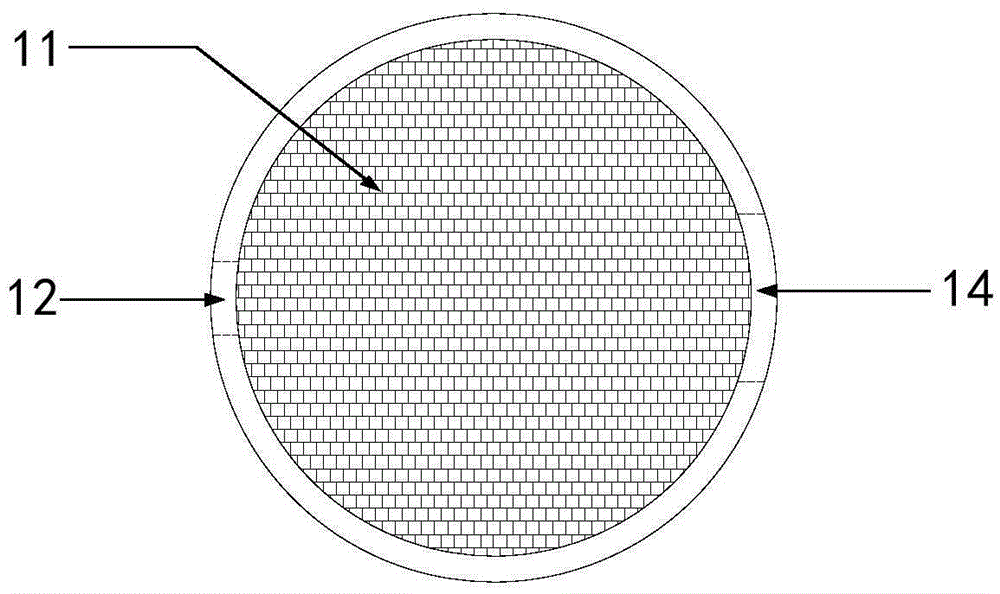

[0022] see Figure 1-3 As shown, the ultrasonic atomization device based on capillary phenomenon of the present invention is composed of an atomizer body and an atomizer cover, including: a power supply 1, a water cup 2, an atomizer switch 3, a diversion fan 4, and a high-frequency vibration source 5 (not less than 1.5MHz), vibration conduction medium 6, water injection hole 7, water injection hole plug 8, capillary hole plug 9, primary microporous screen 10, secondary microporous screen 11, water mist outlet 12, water mist Outlet baffle 13, air inlet 14. The power supply 1 is installed on the bottom of the side wall of the atomizer body, the water cup 2 is set in the cavity of the main body of the atomizer, the atomizer switch 3 is connected to the power supply 1 and installed on the upper part of the power supply 1, the diversion fan 4 and the inlet The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com