Portable paper bag carrying rope installation device and installation method

An installation device and paper bag technology, applied in the field of paper bag processing, can solve the problems of occupying a large production site, low production efficiency, poor quality stability, etc., and achieve the effects of good automation, high production efficiency and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

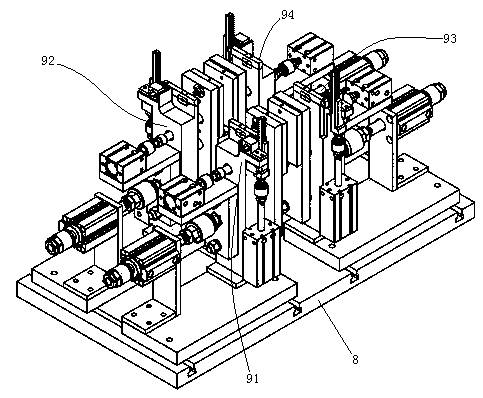

[0034] see figure 1 , a hand rope installation device for a paper bag, including four perforating and threading mechanisms installed on the base 8. Four punching and threading mechanisms are respectively the left front punching and threading mechanism 91, the left rear punching and threading mechanism 92, the right front punching and threading mechanism 93 and the right rear punching and threading mechanism 94. The four punching and piercing mechanisms are distributed in a rectangular shape. The four punching and piercing mechanisms are divided into front and rear pairs. The two punching and threading mechanisms in each pair are oppositely arranged along the left and right directions.

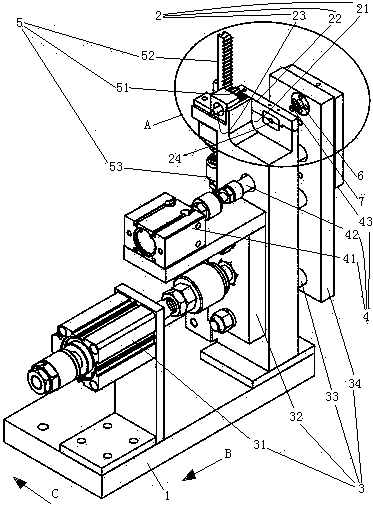

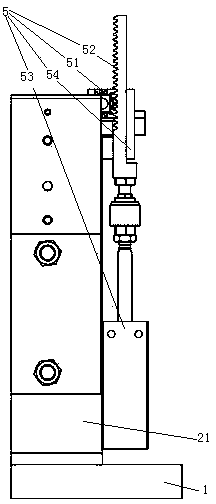

[0035] see figure 2 , The punching and threading mechanism includes a frame 1 and a clip opening mechanism 5 through holes. An anvil 2 and a second actuator 31 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com