Analysis Method of NC Machine Tool System Component Replacement Time Based on Time Correlation

A technology of numerical control machine tools and replacement time, which is applied in the fields of electrical digital data processing, computer-aided design, special data processing applications, etc., and can solve problems such as calculation deviation of component spare parts inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

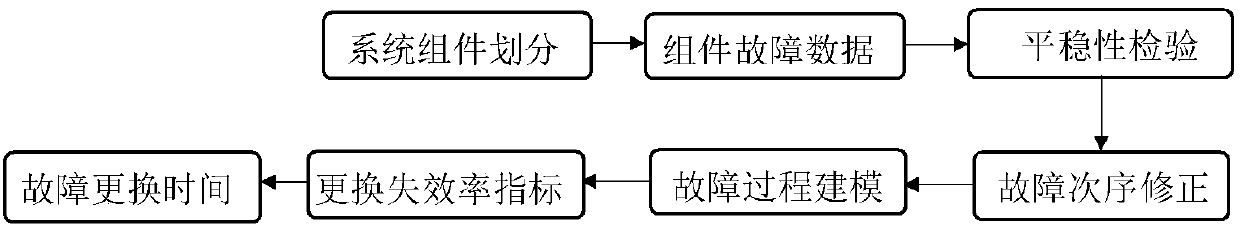

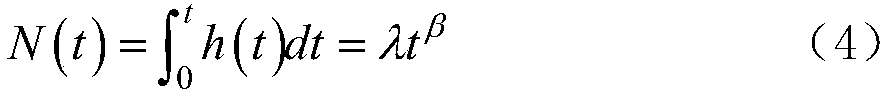

Method used

Image

Examples

Embodiment

[0093] Analysis of replacement time of CNC machine tool system components

[0094] The fault analysis was carried out on 110 fault data of a certain CNC machine tool field collected from 14 sets, and it was found that a total of five components were faulty.

[0095]Table 1 CNC machine tool system component fault information (h)

[0096]

[0097] Due to the lack of fault information of the D and E components, only the replacement time of the A, B, and C components is studied.

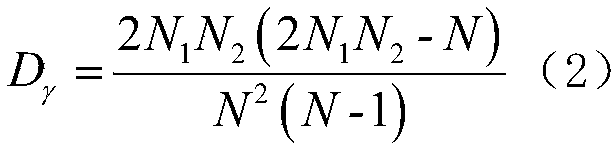

[0098] According to the data in Table 1, the time between failures is calculated, and the three-component stationarity test parameters are shown in Table 2. Take the A component as an example, and calculate the number of runs γ=15, N 1 =10, N 2 = 26, calculated mean E γ = 15.4, D γ =5.55, Z=-0.189, because |Z|<1.96, so the fault data series is considered to be stationary. Similarly, it can be determined that the B and C fault data series are stationary.

[0099] Table 2 Three-component stationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com