Portable paper bag punching and stringing mechanism and carrying rope installation method

A technology for threading ropes and paper bags, applied in the field of paper bag processing, can solve the problems of occupying a large production site, low production efficiency, inconvenient production management, etc., and achieve the effects of good automation, high production efficiency, and convenient production management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

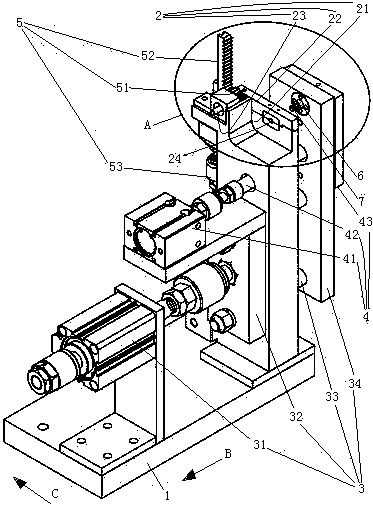

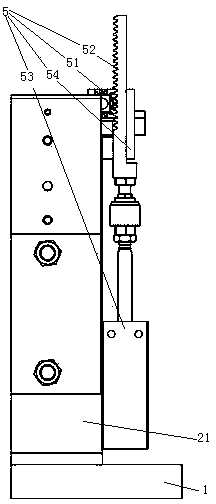

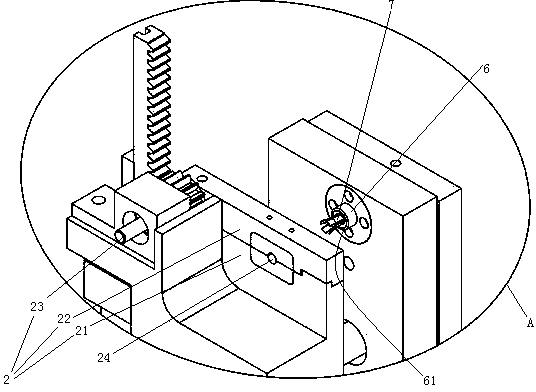

[0032] see figure 1 , a portable paper bag punching and stringing mechanism, including a frame 1 and a clip through hole opening mechanism 5. An anvil 2 and a second actuator 31 are installed on the frame 1 .

[0033] The cutting board 2 includes a fixed half part 21 , a movable half part 22 and a hinge shaft 23 . The movable half part 22 is hinged on the fixed half part 21 through the hinge shaft 23 . The movable half part 22 and the hinge shaft 23 are fixed together. A clip through hole 24 is provided between the fixed half 21 and the movable half 22 .

[0034] The second actuator 31 is a cylinder. A base 32 is connected to the second actuator 31 . The base 32 is fixedly connected with one end of the two second transmission rods 33 . The other end of the second transmission rod 33 is fixedly connected with a second mounting seat 34 . The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com