Operation structure of automobile seat height adjustor

A height adjuster, car seat technology, applied in the direction of movable seats, etc., can solve the problems of poor operating feel, poor lateral stiffness, and lateral shaking, so as to avoid loosening and abnormal noise, good support strength, and avoid sideways Shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

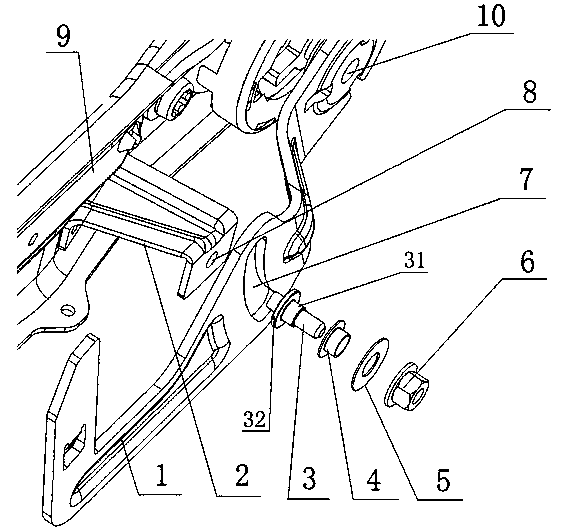

[0019] Example 1: The operating structure of the car seat height adjuster includes an operating handle bracket 1 connected to the central axis 10 of the height adjuster, and an inverted U-shaped lateral side welded on the seat frame 9 to support the operating handle bracket 1. The support plate 2, the limit assembly connected with the lateral support plate 2 and used to limit the rotation stroke and lateral sliding of the operating handle bracket 1; the limit assembly includes a connecting shaft and a nut, and the connecting shaft is in clearance fit with the waist-shaped hole 7, One end of the connecting shaft is riveted on the other side of the lateral support plate 2, and the other end of the connecting shaft is locked on the outside of the operating handle bracket 1 by a nut.

[0020] The assembly process is as follows: first, one side of the lateral support plate 2 is welded on the seat frame 9; secondly, one end of the connecting shaft is riveted to the other side of th...

Embodiment 2

[0022] Example 2: Such as figure 1 The operating structure of the car seat height adjuster shown includes an operating handle bracket 1 connected to the central axis 10 of the height adjuster, and an inverted U-shaped structure welded on the seat frame 9 to support the operating handle bracket 1. The lateral support plate 2, the limit assembly connected with the lateral support plate 2 and used to limit the rotation stroke and lateral sliding of the operating handle bracket 1; the limit assembly includes a limit shaft 3 with two steps in the middle, T Shaped plastic bushing 4, plastic gasket 5 and connecting nut 6, on the other side of the lateral support plate 2, there is a riveting hole 8, and one end of the limit shaft 3 is riveted to the lateral support plate 2 through the riveting hole 8 On this side of the operating handle bracket 1, there is a waist-shaped hole 7 with the same arc center as the rotation center of the operating handle bracket 1, and the T-shaped plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com