Spinning spindle capable of fixing bobbins of different internal diameters

A bobbin and spindle technology, which is applied in the field of textile machinery design, can solve the problems of yarn bobbins with different inner diameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

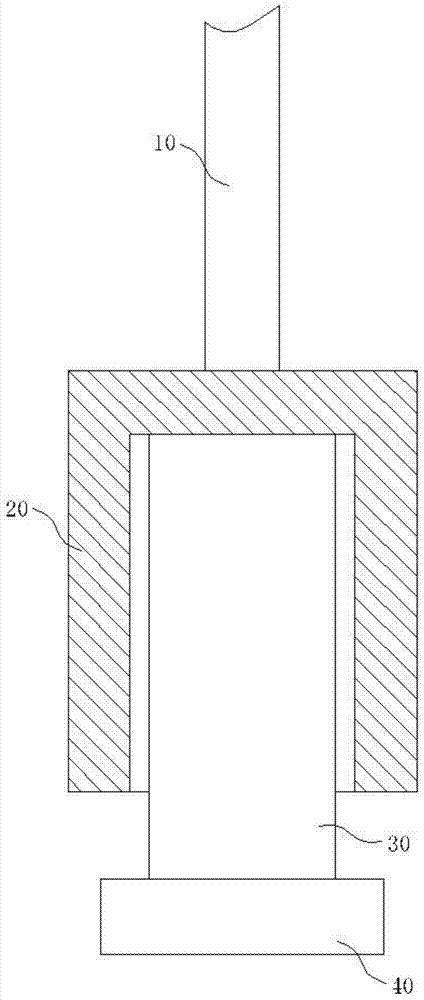

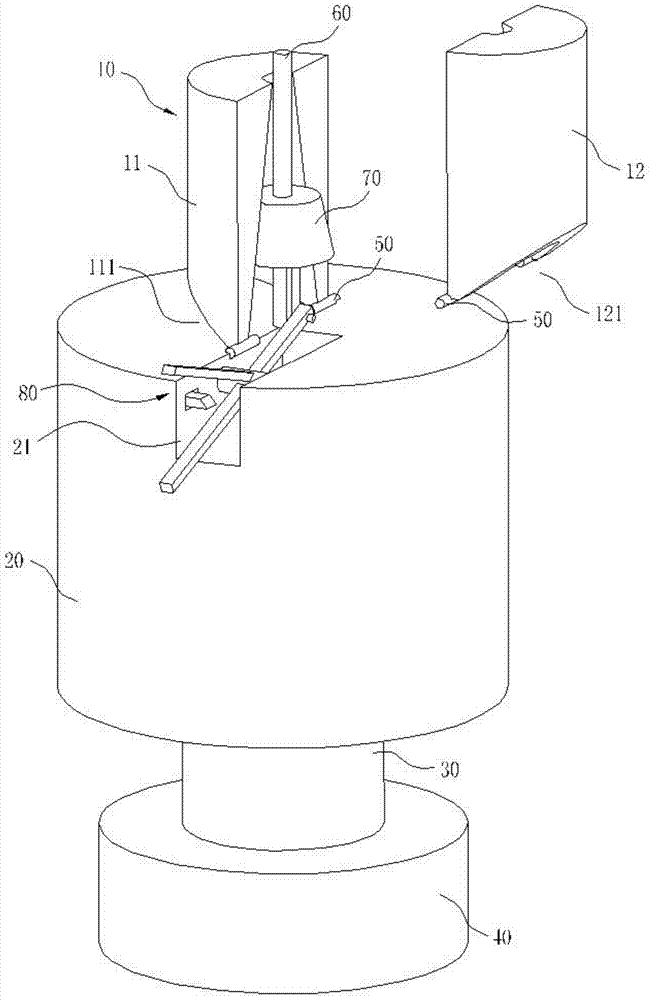

[0026] Such as figure 2 As shown, a textile spindle capable of fixing bobbins with different inner diameters includes a spindle bar 10, a spindle disc 20 fixedly connected to the spindle bar 10, a positioning shaft 30 movably connected to the spindle disc 20, and a spindle fixedly connected to the positioning shaft 30. Seat 40.

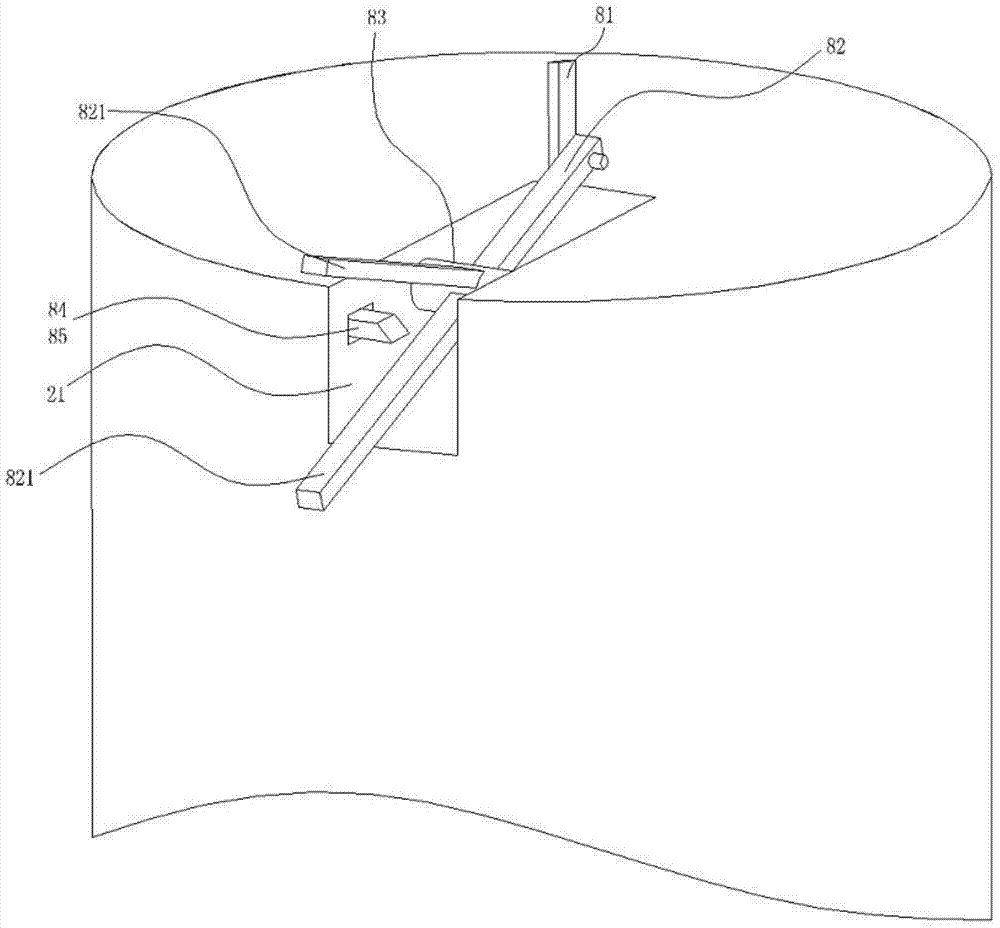

[0027] Such as figure 2 , Figure 4 , Figure 5 As shown, the spindle bar 10 is composed of two tile-shaped parts, the tile-shaped parts 11 and the tile-shaped parts 12 are symmetrical to the center plane of the vertical direction of the spindle bar 10, and the tile-shaped parts 11 and the tile-shaped parts are The lower end of the component 12 is hinged on the top surface of the spindle disc 20 through a coil spring 50, and the lower ends of the shoe-shaped component 11 and the shoe-shaped component 12 are respectively provided with an opening 111 and an opening 121 for the shoe-shaped component 11 and the shoe-shaped component 12 to rotate. . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com