Float-type automatic control flap valve

A buoy type, door body technology, applied in the direction of control valves, functional valve types, valve details, etc., can solve the problems of large overflow water damage, poor door sealing performance, water flow energy loss, etc., to reduce water damage and avoid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

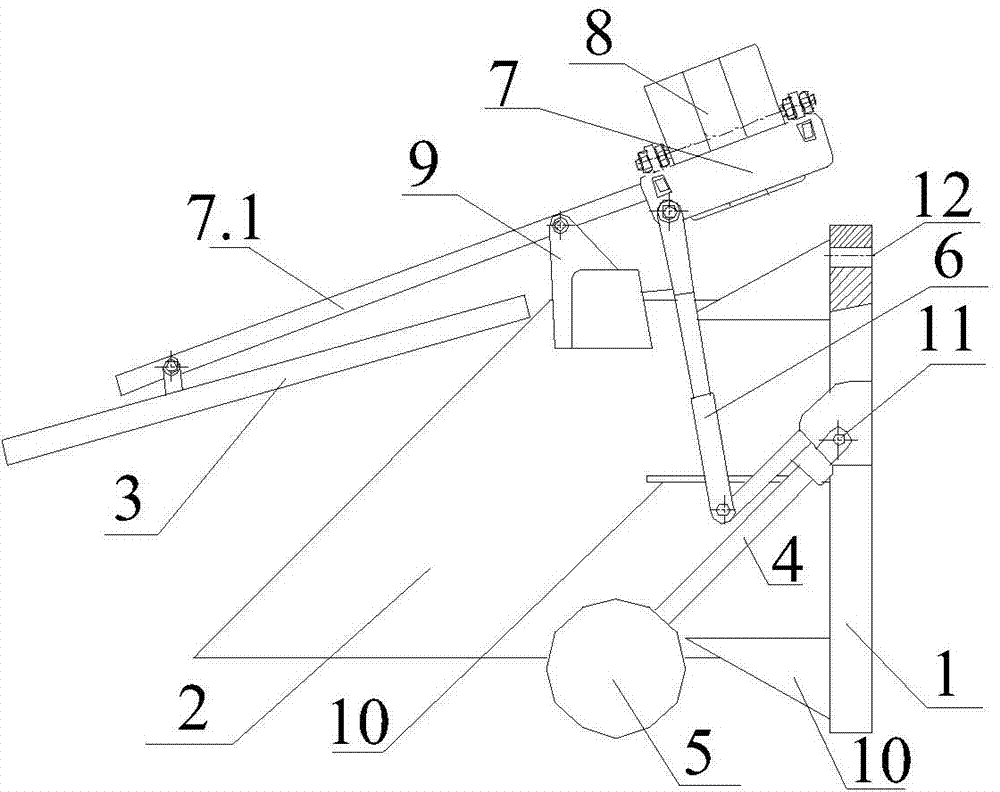

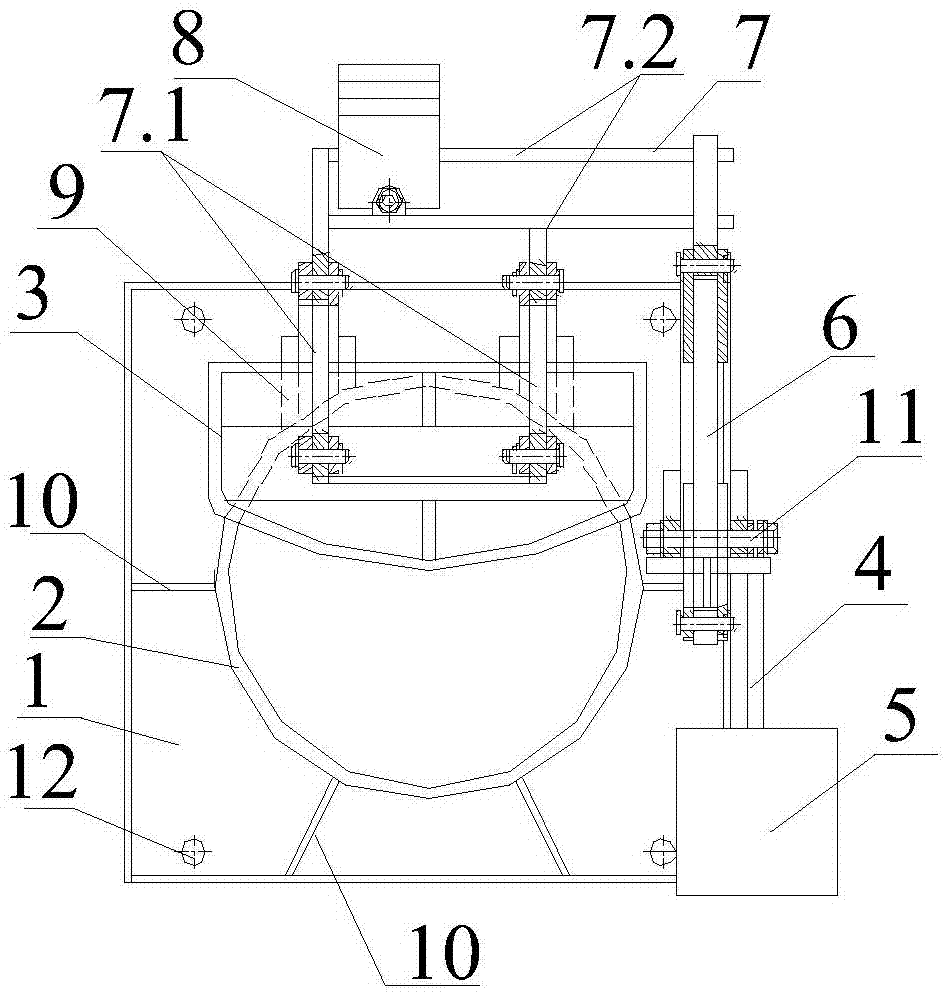

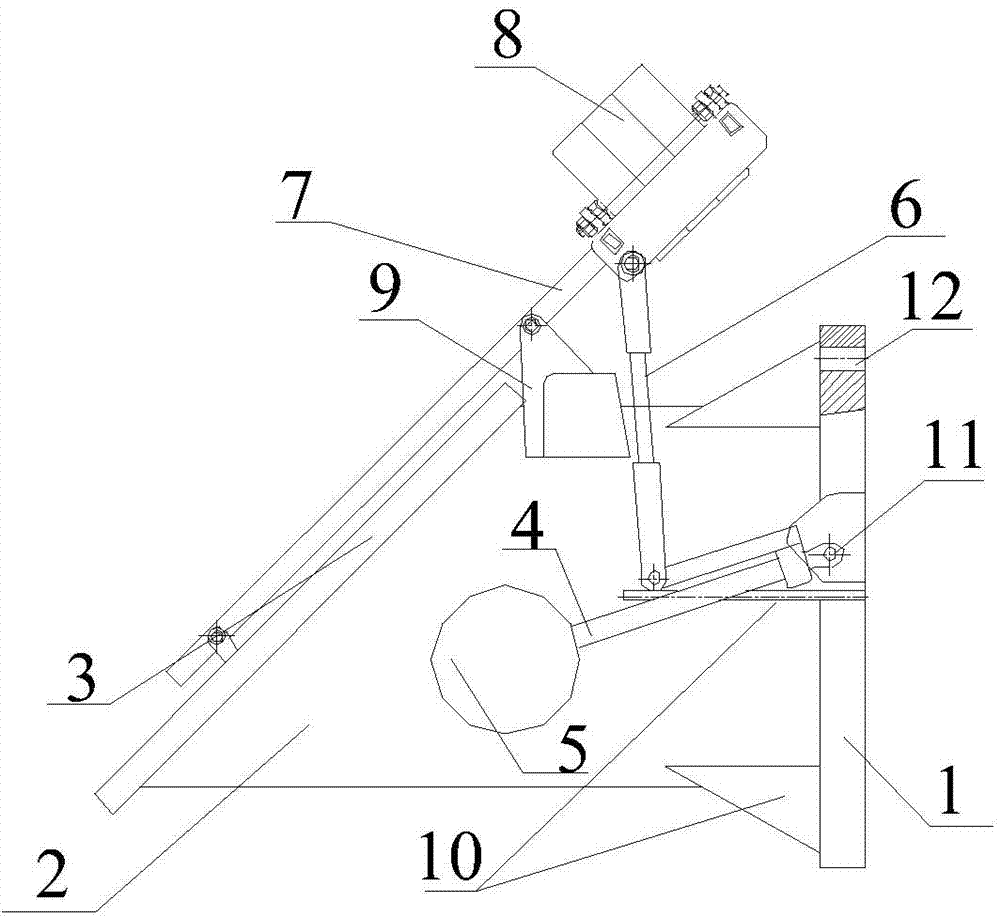

[0015] Such as figure 1 — Figure 4 As shown, the present invention includes a door body 1 with a flow channel, a cylindrical pipe body 2 is fixed on the outer wall of the door body 1, and the longitudinal center section of the pipe body 2 is a trapezoidal structure with a short top end and a long bottom end. The outer end surface of the pipe body 2 forms an inclined flow channel mouth; the outer side of the door body 1 is hinged with one end of the pole 4 through the rotating shaft 11, the other end of the pole 4 is fixed with the cylindrical buoy 5, and the pole 4 is connected with the One end of the hinged door body 1 is fixed to one end of the connecting rod 6, the other end of the connecting rod 6 is hinged to one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com