A machine tool guide rail measuring device

A technology of measuring device and guide rail, applied in the direction of measuring device, instrument, etc., can solve the problems of poor measurement stability and reliability, poor versatility and interchangeability, etc. The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

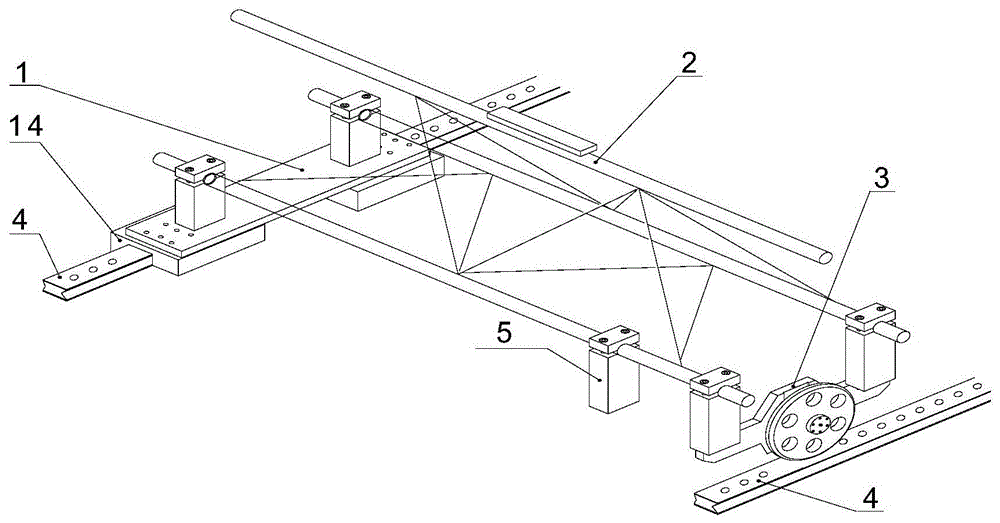

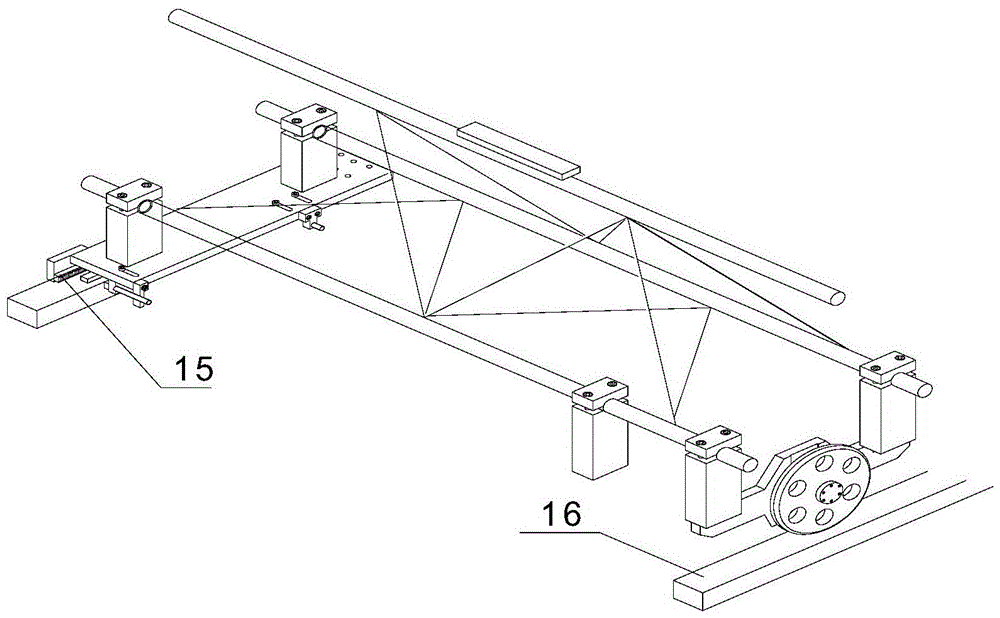

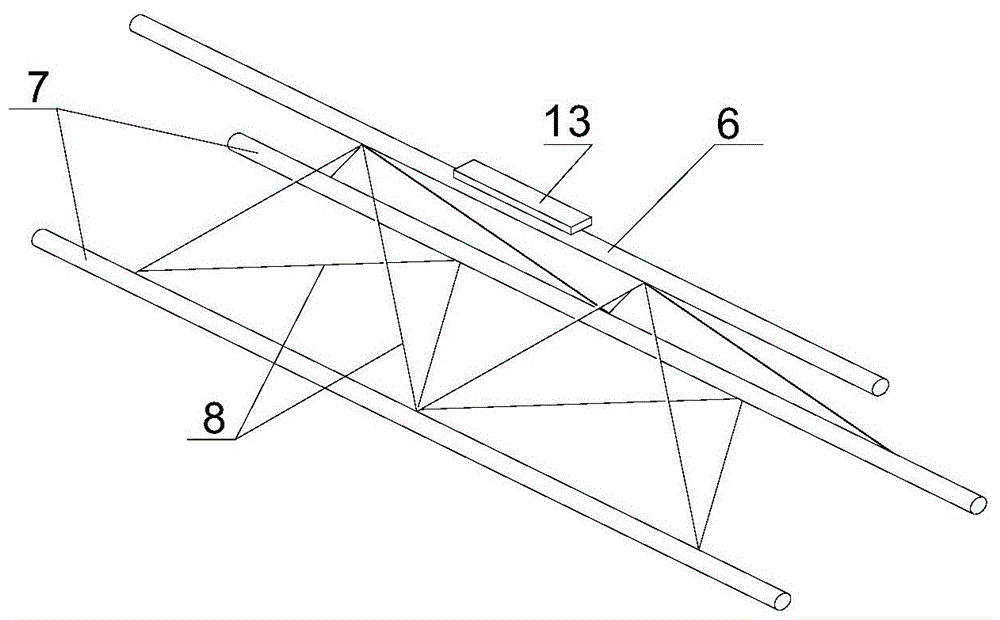

[0014] Referring to accompanying drawing, the machine tool guide rail measuring device of the present application is made up of guide rail support 1, frame beam 2, adjustment support 3, table frame support 5, and described frame beam 2 is by an upper beam 6, two parallel with upper beam A lower crossbeam 7 and connecting rods 8 connecting the upper and lower crossbeams form a truss structure of an equilateral triangle. The upper crossbeam and the two lower crossbeams are respectively three edges of an equilateral triangle. The surface is connected with the measured guide rail, and the upper surface of the guide rail support is respectively fixed to one end of the two lower beams through two equal-height connectors 9. The adjustment support 3 is composed of an adjustment frame 10, a roller 11 and a connecting shaft 12. The height of the adjustment frame 10 can be adjusted, and the adjustment frame 10 is respectively fixed with the other ends of the two lower beams through two eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com