Intelligent distributed feeder automation logic test system

A feeder automation and test system technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as different software, few types of test faults, and complex on-site conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

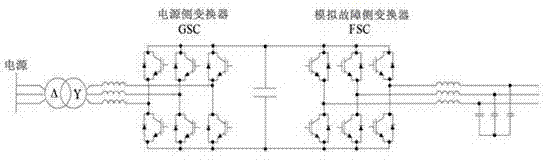

[0037] The invention provides an intelligent distributed feeder automatic logic test system (hereinafter referred to as the test system), which includes a fault simulator, a switch simulator and a communication interface.

[0038] Wherein, the fault simulator is composed of a Back to Back (back to back) voltage type PWM converter structure. The schematic diagram of the topological circuit is as follows: figure 1 shown. Since two three-phase PWM voltage-type converters are used to form the main circuit of the fault simulator through Back to Back connection, the characteristics of the power supply under normal and various fault conditions can be used to test and detect the power supply connected to the power distribution terminal. Troubleshooting capabilities.

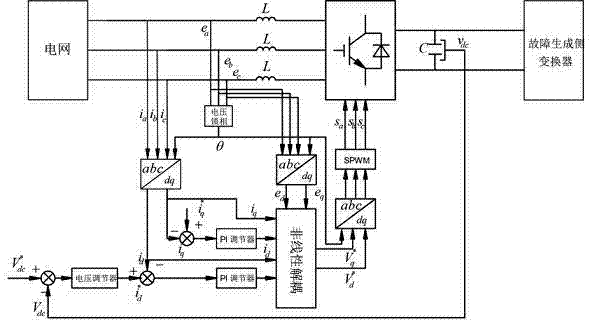

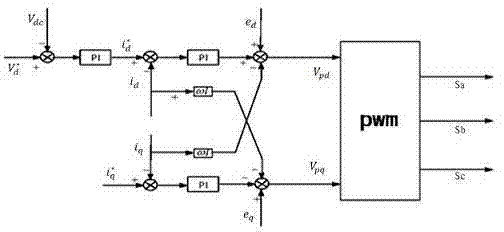

[0039] Taking the power-side converter GSC of the fault simulator as an example, the PWM rectifier can not only make the input current sinusoidal, the power factor is 1 or adjustable, but also can make the energy flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com