Sickle

A sickle and handle technology, applied in the direction of the sickle, can solve the problems that the operator's strength cannot be adjusted, cannot adapt to the operator, and the service life of the sickle is short, so as to reduce the cumbersome carrying, reduce the working intensity, and avoid the effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

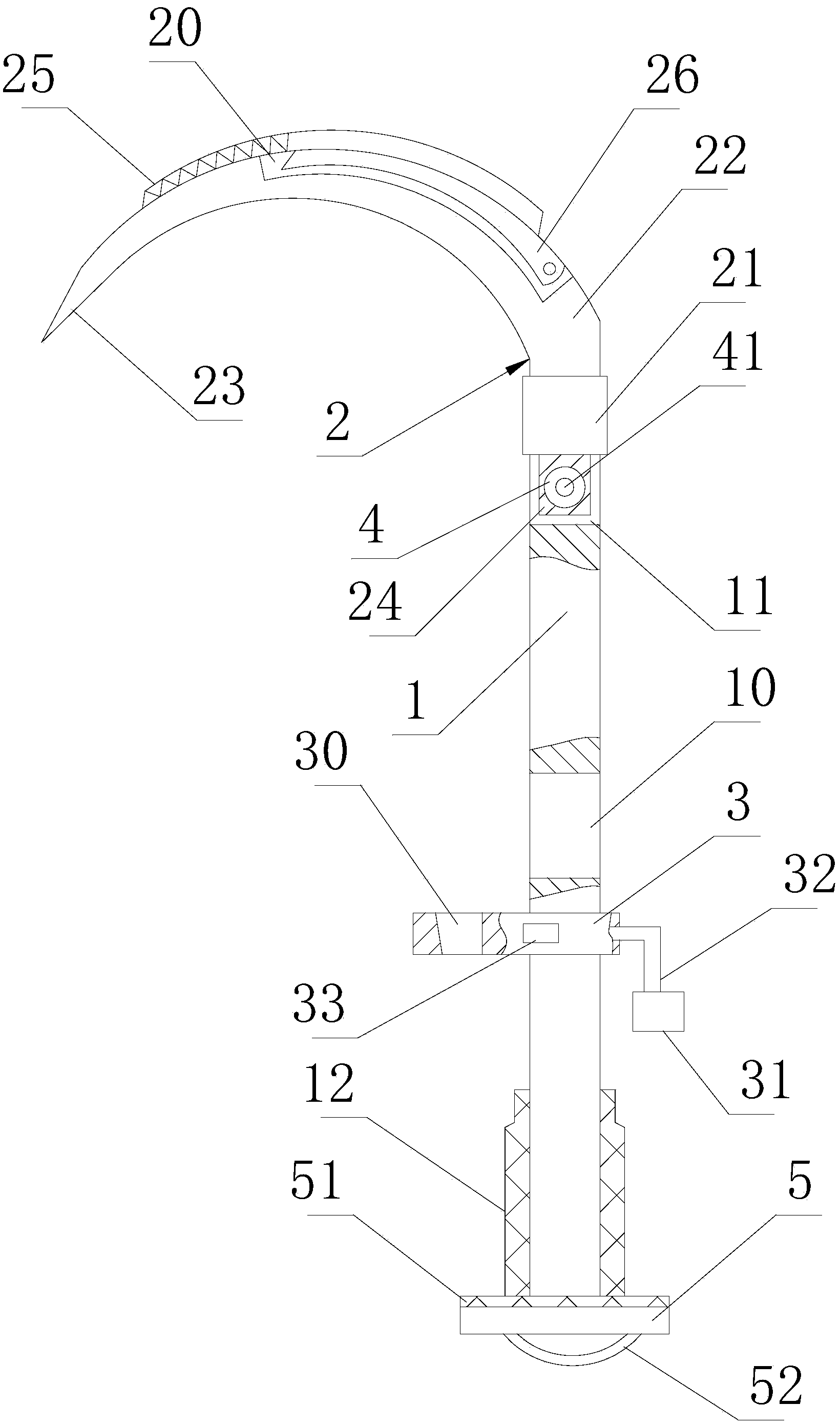

[0010] Such as figure 1 As shown, a sickle includes a handle 1, a knife body 2 that is rotatably connected to the handle 1, a rubber sleeve 12 that is fixedly connected to the handle 1, and the body 2 includes a handle that is rotatably connected to the handle 1. Vertical part 21, circular arc part 22, the bottom end of described vertical part 21 is connected on the handle of a knife 1 through bolt assembly 4 rotation, and the top of described handle of a knife 1 is provided with the mounting groove 11 that vertical part 21 is installed, so The bottom end of the vertical part 21 is provided with a rotating part 24, the front end of the arc part 22 is provided with a pointed corner 23, and the handle 1 is provided with a connecting hole for fixing the cutter body 2 to the handle 1 10. The pointed corner 23 is pierced in the connection hole 10, and a slider 3 for locking the knife body 2 on the knife handle 1 is movably connected to the knife handle 1 below the connection hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com