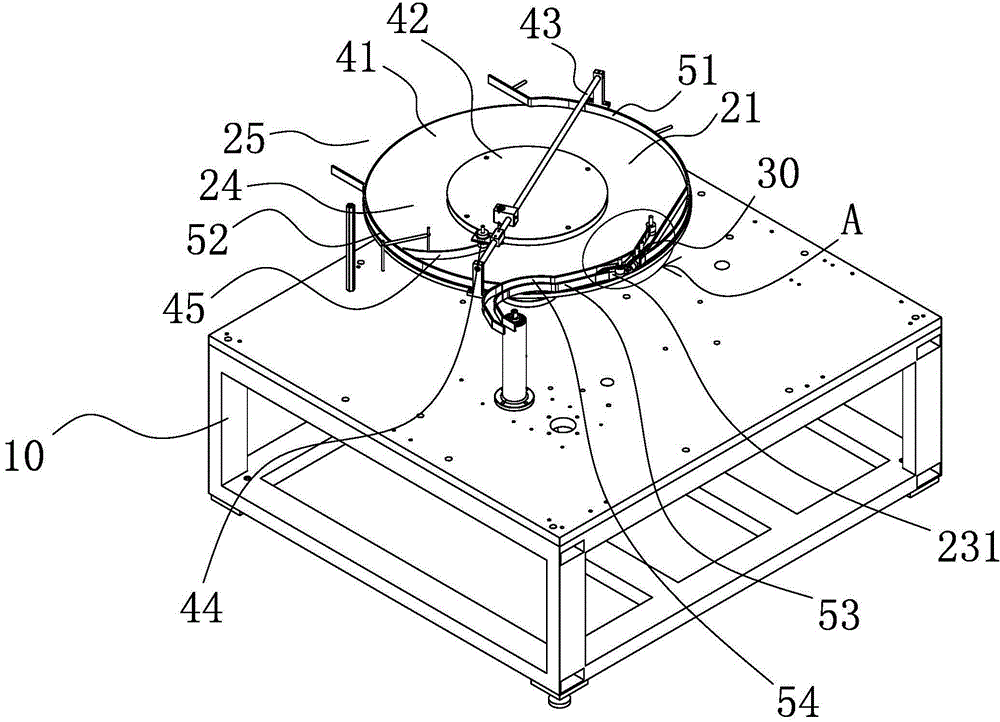

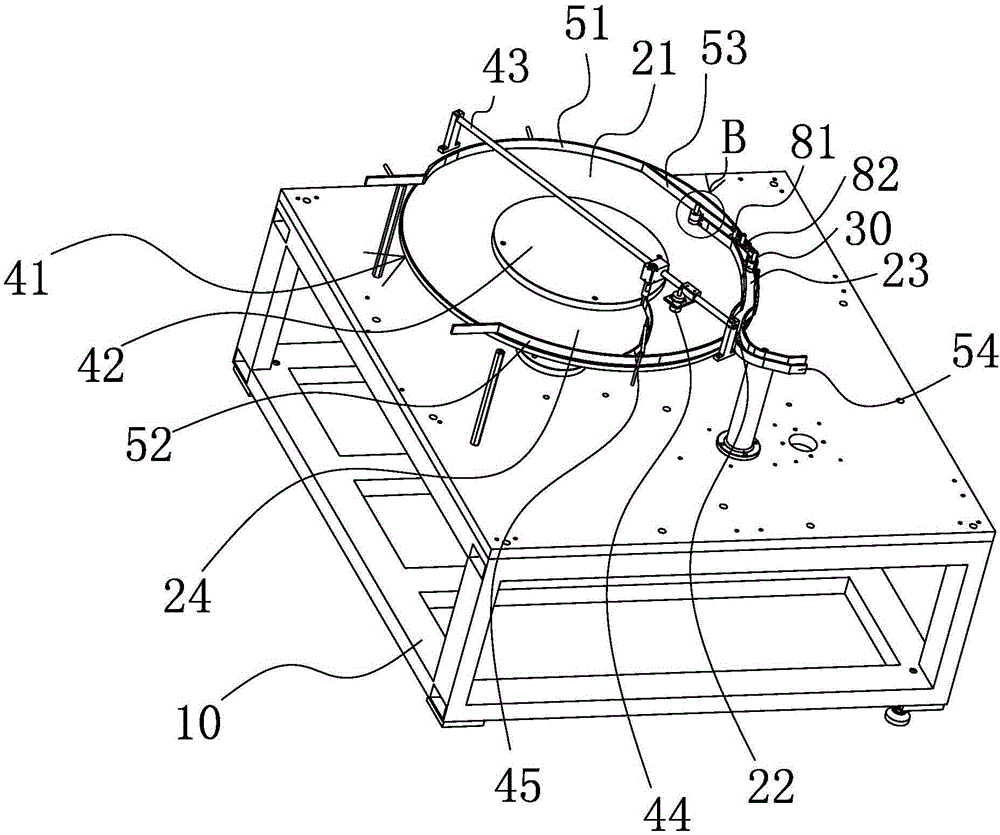

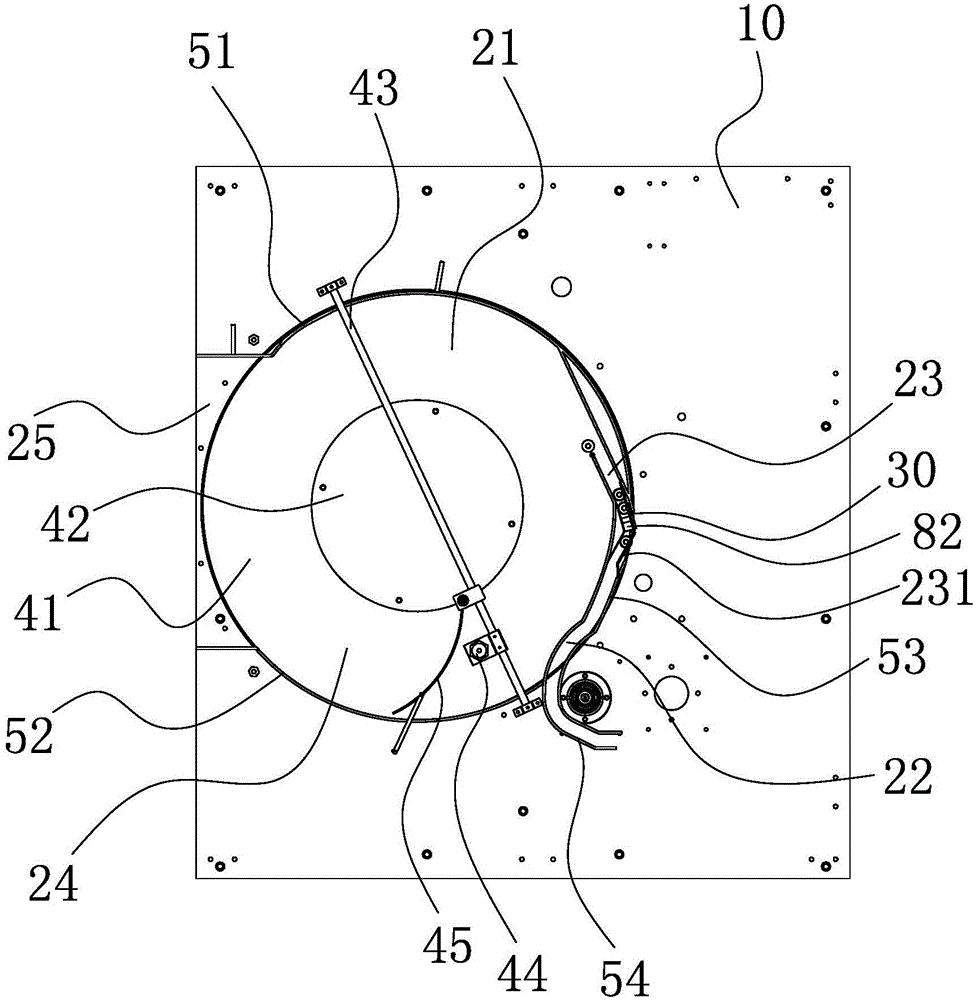

Automatic screening mechanism

A technology of automatic screening and racking, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of complex structure design, low degree of automation, large use area, etc., and achieve reasonable overall structure design, high degree of automation, and working process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0029] The present invention protects an automatic screening mechanism, which is suitable for automatic battery production lines, and is used to screen sideways or inclined battery steel cases 81 and battery cups 82 and remove them from the battery transmission line. In the present invention, the workpiece transported by the incoming material channel 21 can be selected as a separate battery holder 82, or as a battery holder 82 with a battery steel case 81; when the workpiece is selected as the former, the automatic screening mechanism is used for screening And reject the side-lying or inclined battery holder cup 82; when the workpiece selection is the latter, this automatic screening mechanism is used to screen and reject t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com