Electric cereal hulling device

A peeling device and grain technology, applied in the field of agricultural machinery, can solve the problems of high labor cost, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

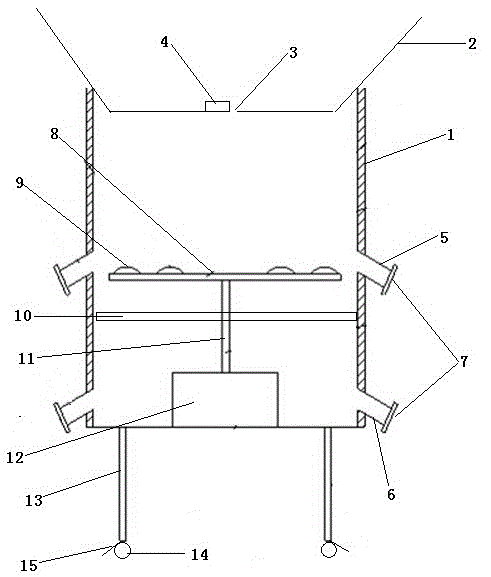

[0015] Example: such as figure 1 As shown, an electric grain peeling device includes a cylindrical barrel made of stainless steel plate 1, a motor 12 is arranged at the bottom of the barrel, and the rotating shaft 11 of the motor 12 is connected to the circular peeling grinding disc 8, and the motor 12 passes through the rotating shaft 11 drives the peeling grinding disc 8 to work, the peeling grinding disc 8 is provided with several grinding disc bumps 9, the top of the cylindrical barrel made of stainless steel plate 1 is provided with a feeding hopper 2, and the bottom of the feeding hopper 2 is provided with a feeding hole 3. The edge of the feed hole 3 is provided with a limit block 4 that can slide along the bottom of the feed hopper 2, and the side wall of the cylindrical barrel made of stainless steel plate 1 is provided with multiple discharges near the peeling grinding disc 8. Port 5, the side wall of the lower part of the cylindrical barrel made of stainless steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com