System and method for shale in-situ volume fracturing tests

A technology of volume fracturing and test system, which is applied in the application of stable tension/pressure to test the strength of materials and the use of sonic emission technology for material analysis, etc. effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

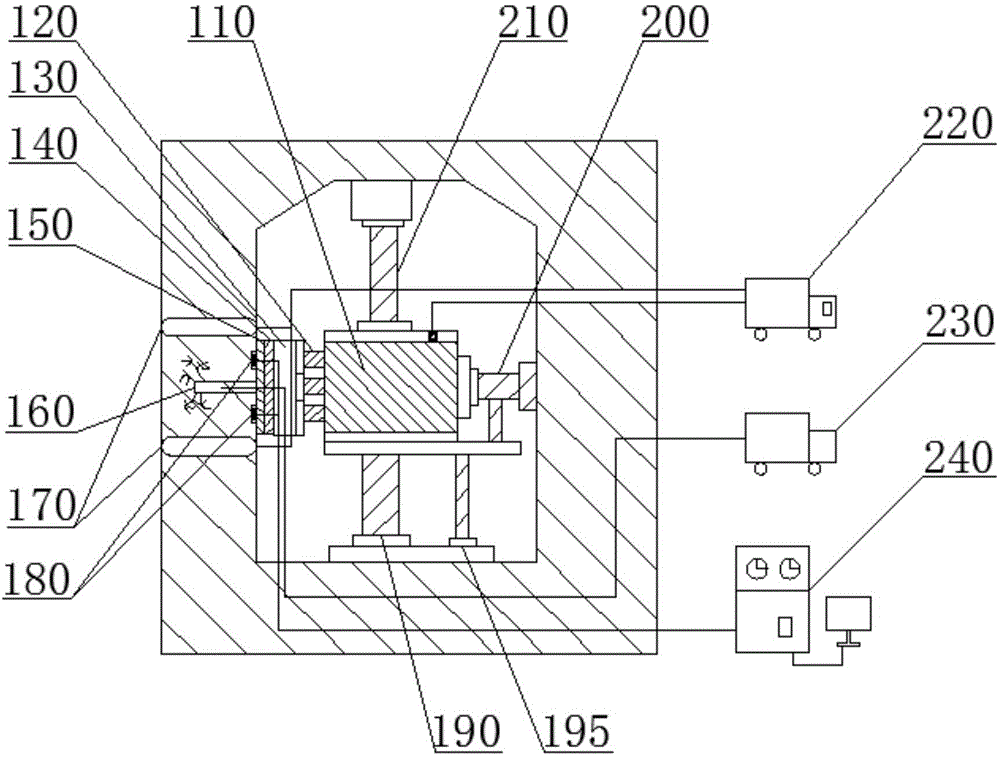

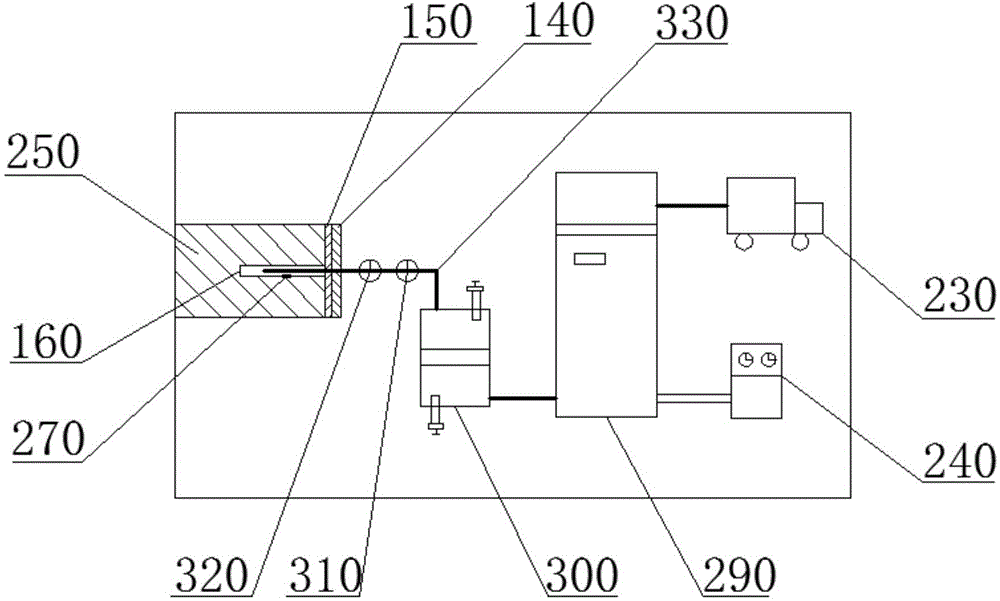

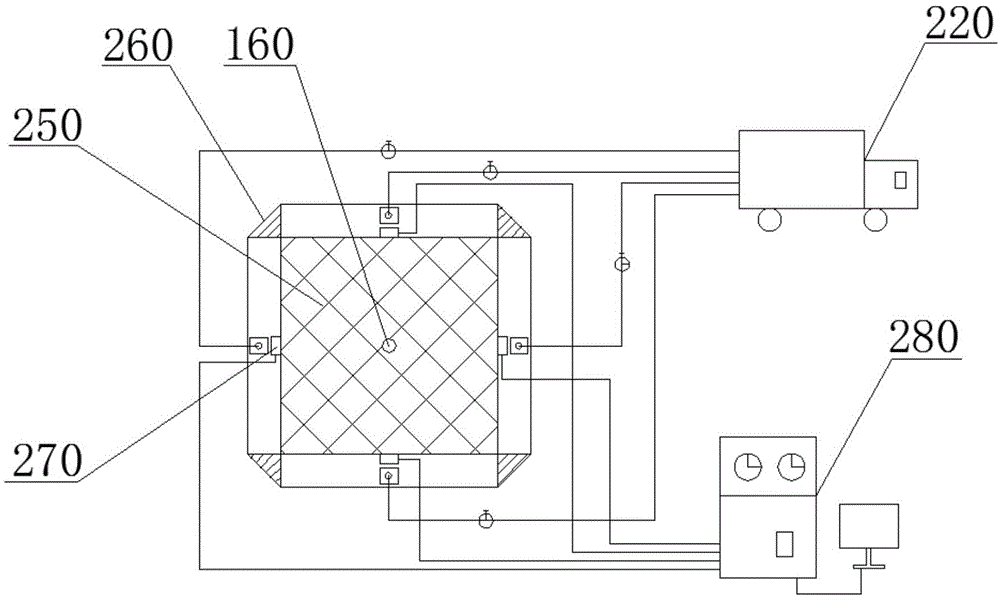

[0033] see Figure 1-4 , the shale in-situ volume fracturing test system includes a cube-shaped shale test piece 250 with a central hole 160, a triaxial loading system for applying pressure to the shale test piece 250, and a triaxial loading system for applying pressure to the shale test piece 250. A volume fracturing system for injecting fracturing fluid and a data monitoring and acquisition system for acquiring sound and load of a shale specimen 250 during fracturing. The triaxial loading system includes 9 hydraulic jacks 120 that press the shale specimen 250 axially and 4 flexible hydraulic bladders 170 that press the shale specimen 250 laterally. Both the hydraulic jacks 120 and the flexible hydraulic bladder 170 are externally connected. There is a hydraulic source 220 . The volume fracturing system includes a liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com