A hot-rolled ribbed steel bar data polling wireless transmission system and method thereof

A hot-rolled ribbed steel bar and wireless transmission technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of inability to wire, incomplete data information, and high wiring costs, so as to ensure accuracy and comprehensiveness performance, overcome the harsh environment, and reduce the effect of implementation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

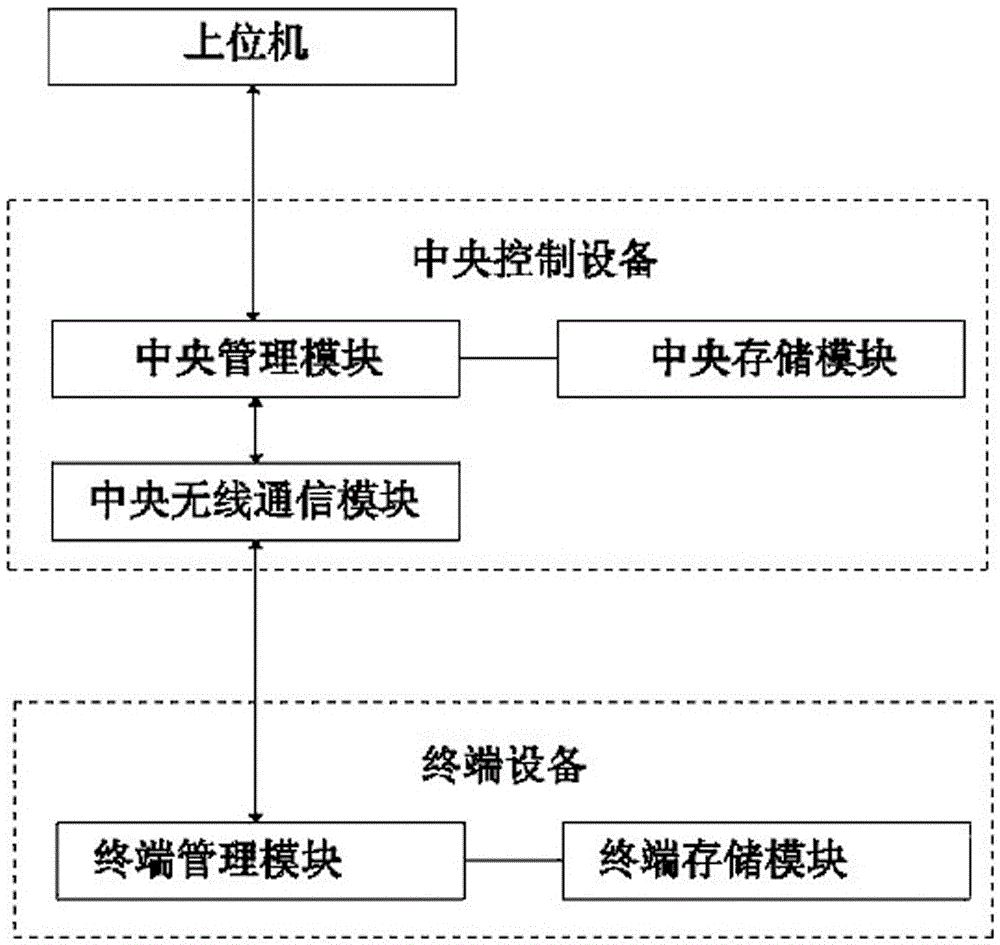

[0024] Such as figure 1 As shown, the present invention provides a hot-rolled ribbed steel bar data polling wireless transmission system, the system includes: a host computer, a central control device and a terminal device, wherein:

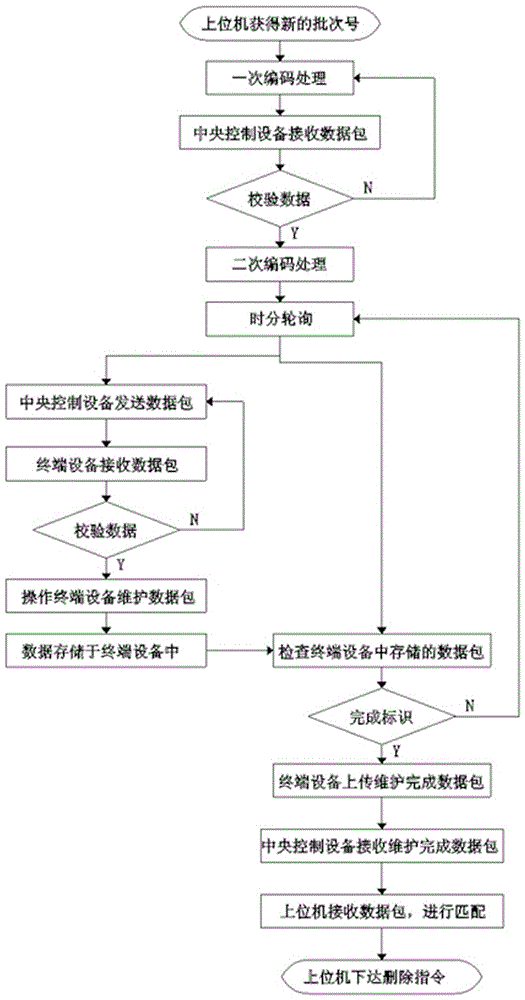

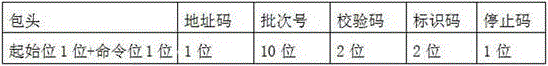

[0025] Host computer: used for the production management system to obtain the production batch numbers of hot-rolled ribbed steel bars that need to be maintained, and perform a coding process on the batch numbers: each batch number is regarded as a data packet, and a data packet is added to each data packet Packet header, an address code, and a check code (used to identify whether the data packet information maintenance work is completed) and a stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com