Stamping die rubber cushion intelligent stock layout method and system

A technology for stamping dies and rubber pads, which is applied in the field of intelligent layout methods and systems for rubber pads of stamping dies. It can solve the problems of difficult control of positioning, difficult updating of layout shapes, and difficult position constraints, and achieve the effect of improving design efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

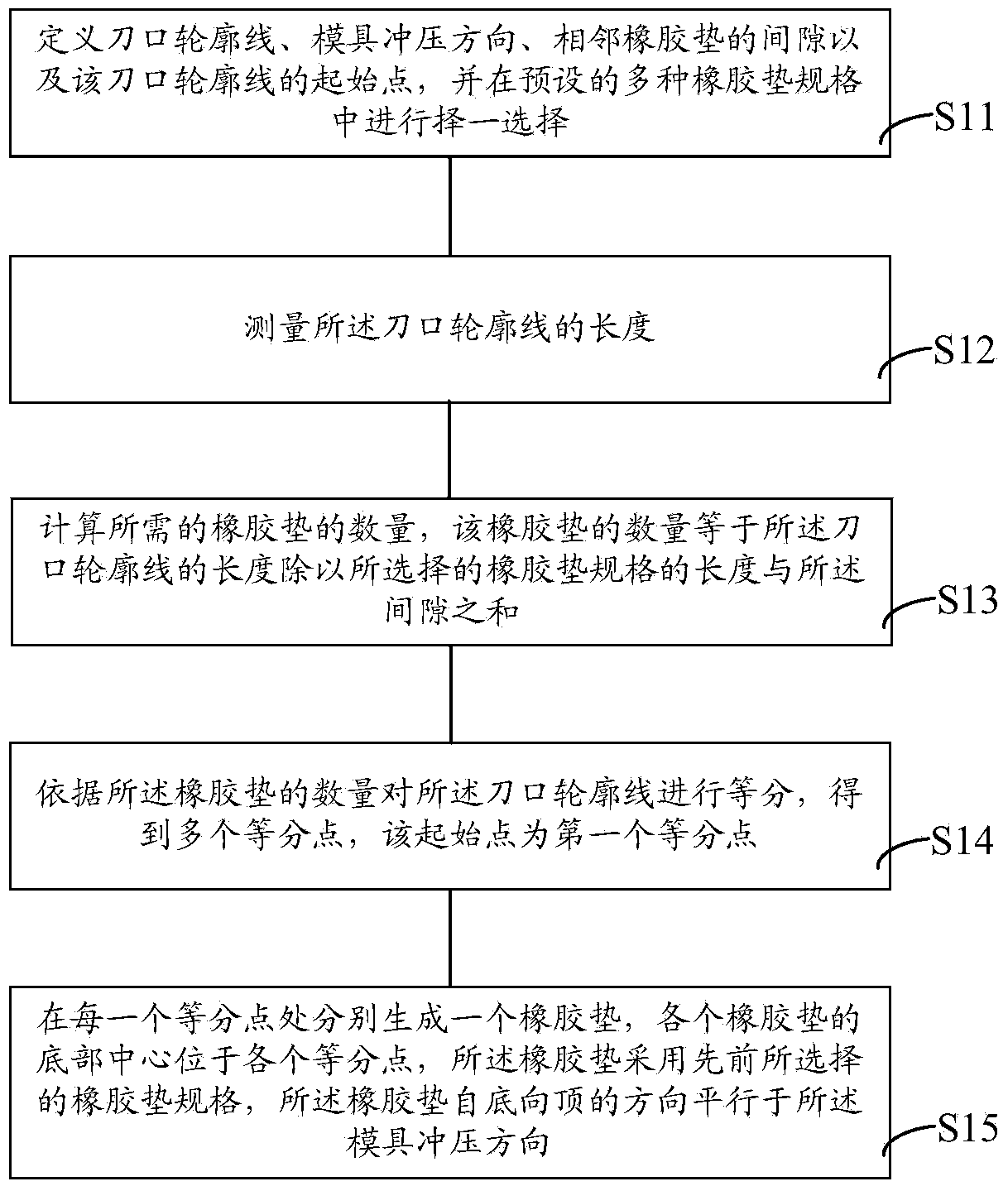

[0049] refer to figure 1 , the stamping die rubber pad intelligent nesting method of the present embodiment includes the following steps:

[0050] Step S11, defining the contour line of the knife edge, the stamping direction of the die, the gap between adjacent rubber pads, and the starting point of the contour line of the knife edge, and choosing one of the preset rubber pad specifications;

[0051] Step S12, measuring the length of the contour line of the knife edge;

[0052] Step S13, calculating the number of rubber pads required, the number of rubber pads is equal to the length of the contour line of the knife edge divided by the length of the selected rubber pad specifications and the sum of the gap;

[0053]Step S14, equally dividing the knife-edge contour lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com