Enterprise material management system and method

A management system and material technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of easily exceeding 2 to 3 people, poor flexibility, and poor timeliness, so as to improve the adjustable ability of the stockyard and save time , easy to manage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

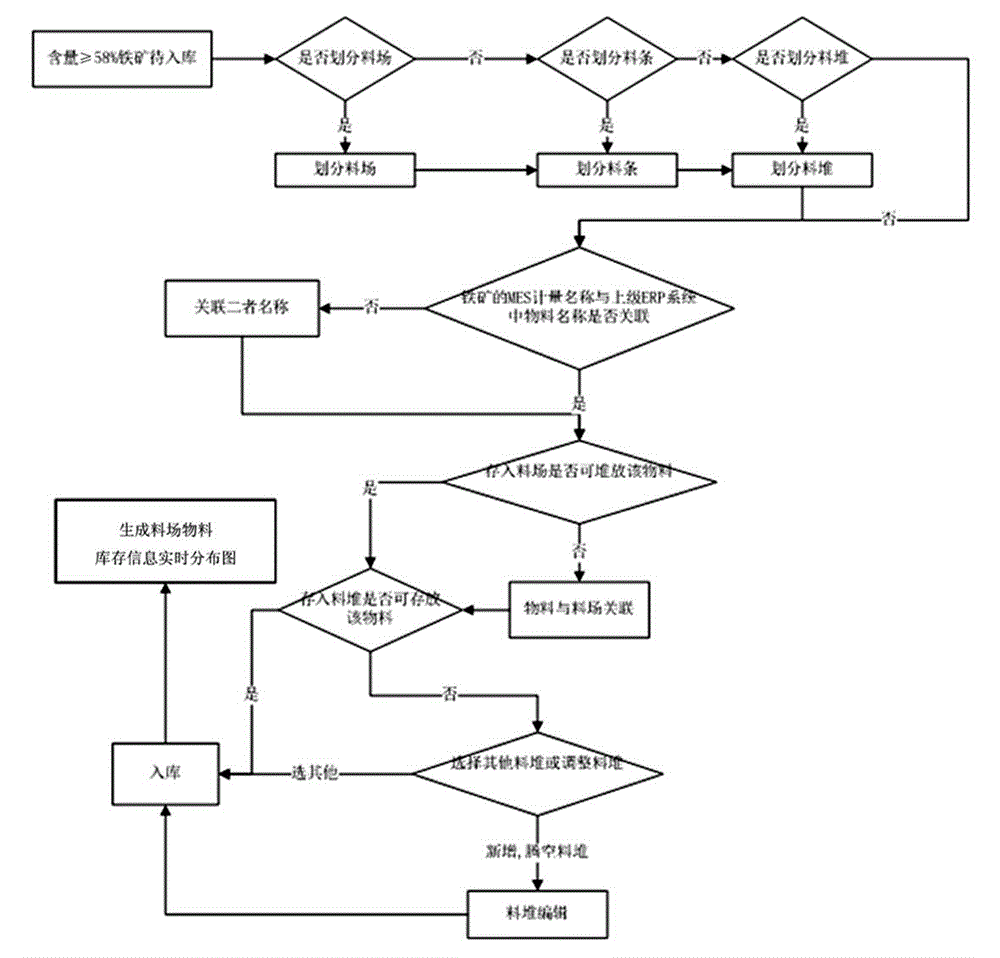

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

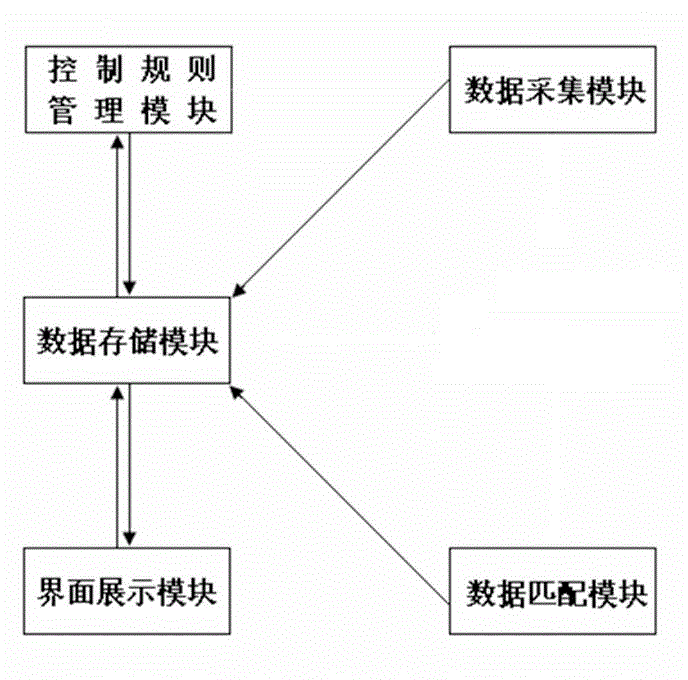

[0025] The enterprise material management system described in the present invention includes a data collection module, a data matching module, a control rule management module, an interface display module, and a data storage module, wherein:

[0026] Data collection module: used to collect and read material storage plans and storage conditions from the material yard site and enterprise management system and store them in the data module;

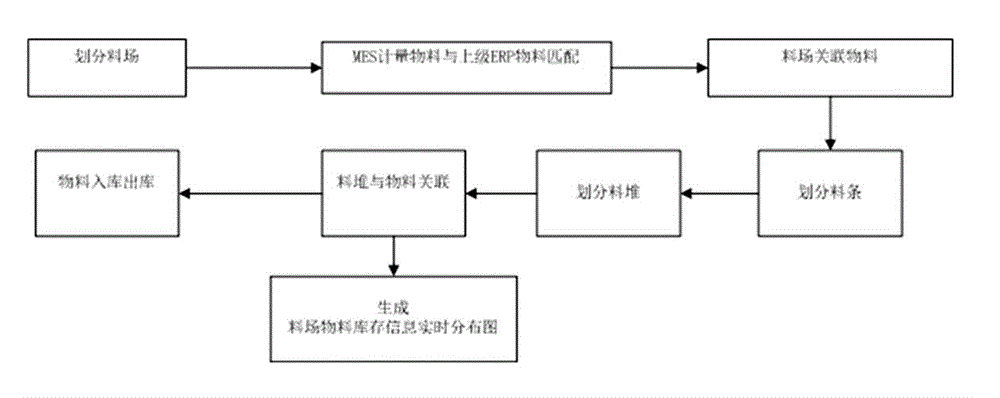

[0027] Data matching module: used to match the metering materials in the MES system with the materials in the upper-level ERP system to obtain matching data and store them in the data storage module;

[0028] Control rule management module: used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com