DC interrupter interrupter

A DC breaking and arc-extinguishing chamber technology, applied in high-voltage/high-current switches, electric switches, high-voltage air circuit breakers, etc., can solve the problems affecting the breaking capacity of arc extinguishing devices, increase the contact area, and increase the pressure gas reaction force and other problems to achieve the effect of reducing burden, improving reliability, and reducing pressure reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

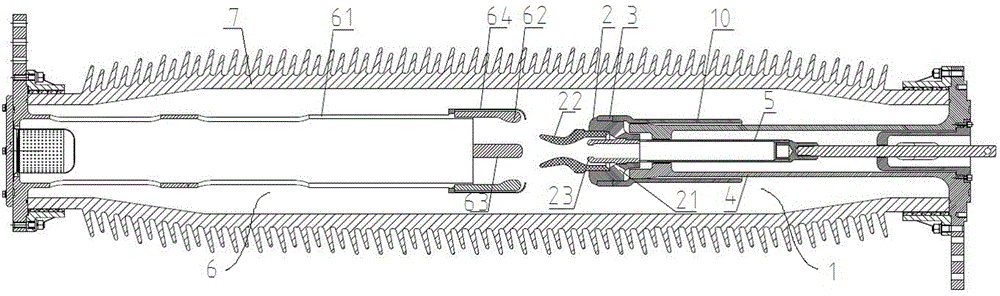

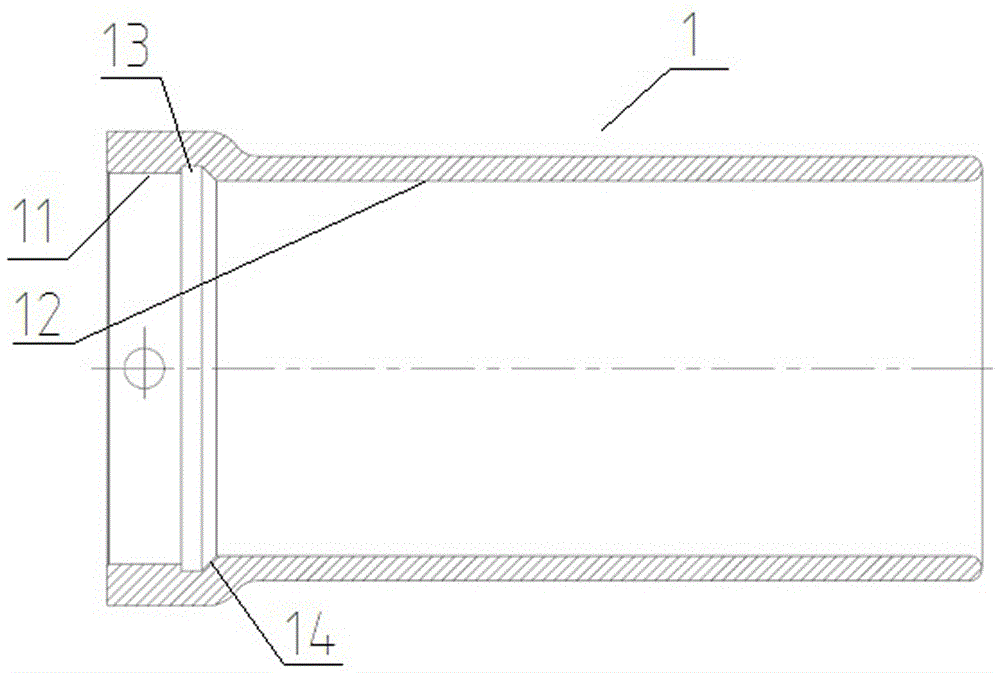

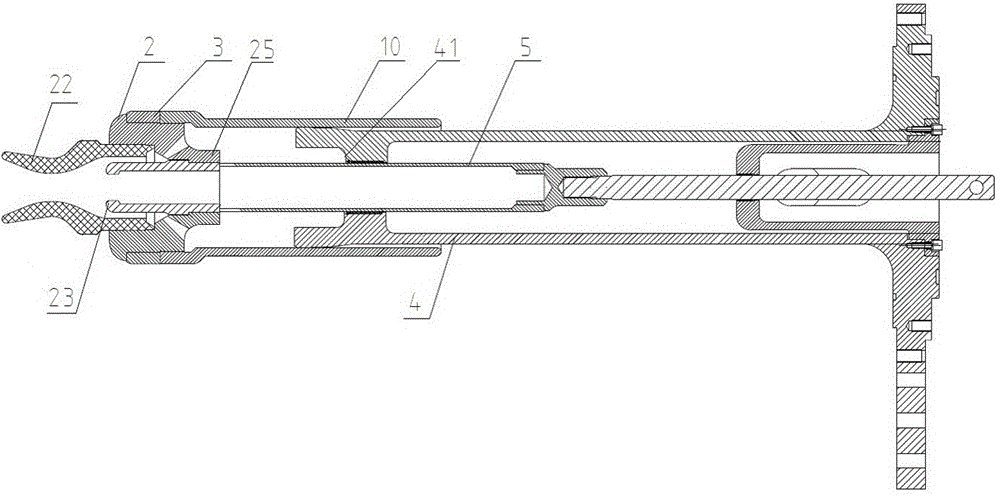

[0016] An embodiment of the arc extinguishing chamber of the DC breaking device of the present invention is Figure 1~Figure 4 As shown, it is used for UHV DC transfer switch to realize arc extinguishing when breaking DC current. The arc extinguishing device includes a porcelain sleeve 7 , a static end assembly 6 and a moving end assembly 1 . The static end assembly 6 includes a static contact seat 61, a static contact finger 62, a static arc contact 63 and a shield cover 64. The moving end assembly 1 includes a moving contact device, a pressure cylinder 10, a moving contact seat 4 and a drive rod 5. The contact device includes a moving contact body 2 and a conductive slip ring 3 sheathed on the outer peripheral surface of the moving contact body 2 . The moving contact body 2 is provided with a gas channel 21 , and is fixed with a nozzle 22 corresponding to the front opening of the gas channel 21 , and is also conductively connected with a moving arc contact 23 . In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com