Pressure balance type ultra-small catalytic reaction efficiency comparison evaluating device

A comparative evaluation device and catalytic reaction technology, which is applied in the direction of using catalysis for chemical analysis, etc., can solve the problems of additional catalysis interference, etc., and achieve the effect of avoiding interference of catalyst performance, good temperature resistance, and reducing material strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

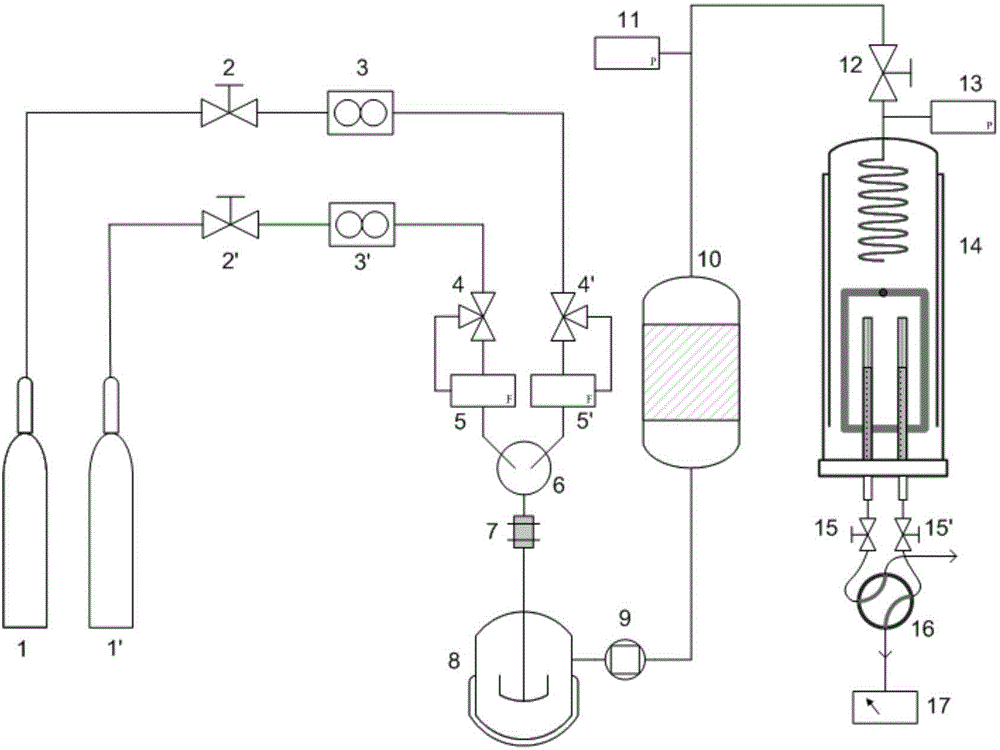

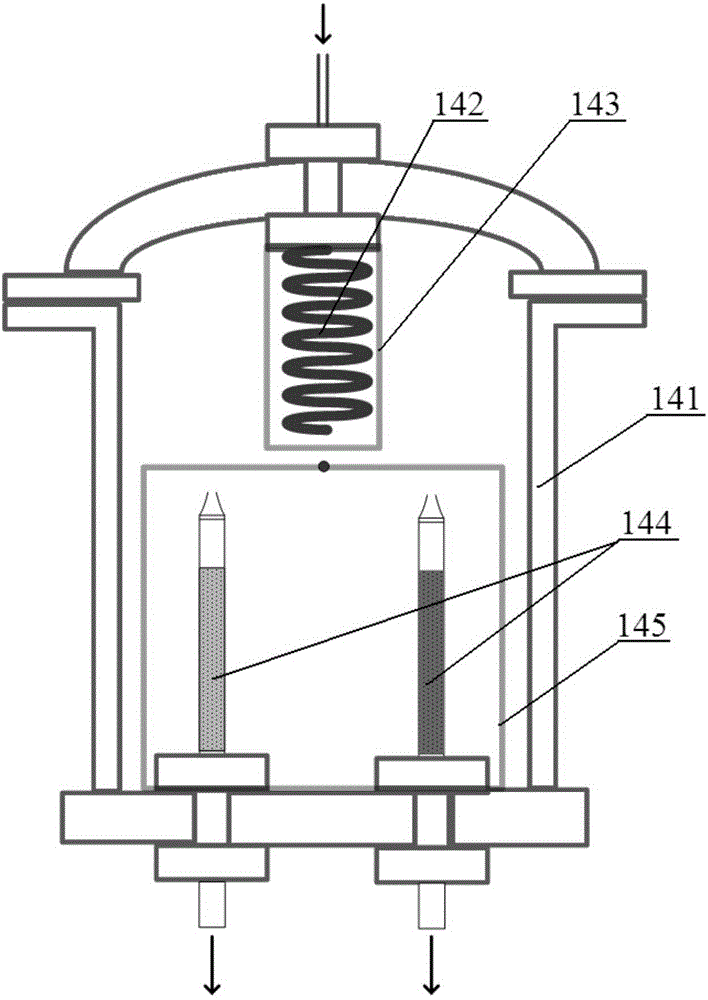

[0025] A pressure-balanced ultra-small catalytic reaction efficiency comparison evaluation device, such as figure 1 As shown, a gas inlet unit, a reaction chamber 14 and a detector 17 are included.

[0026] The air intake unit includes a reaction gas storage tank, a reaction gas premixer 6, a buffer tank 8 and a mixed gas storage tank 10 connected sequentially through stainless steel pipelines. There are two reaction gas storage tanks, namely the reaction gas storage tank 1 and the Reaction gas storage tank 1 ', each reaction gas storage tank is filled with a single reaction gas respectively, and each reaction gas storage tank is connected to the reaction gas premixer 6 through a separate pipeline, and the outlet of the mixed gas storage tank 10 is passed through the pipe The road communicates with the intake coil 142 . A pressure reducing valve 2 or pressure reducing valve 2', a mass flow meter 3 or a mass flow meter 3', a tee Valve 4 or three-way valve 4', flow controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com