Light condensing device used for high-speed camera in microscopic shooting process of nozzle spraying form

A high-speed camera and nozzle spray technology, applied in high-speed photography, condenser, optics, etc., can solve the problems of reduced light quantity, higher light requirements, and impact on clarity, so as to ensure cleanliness, maintain stability, and enhance adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

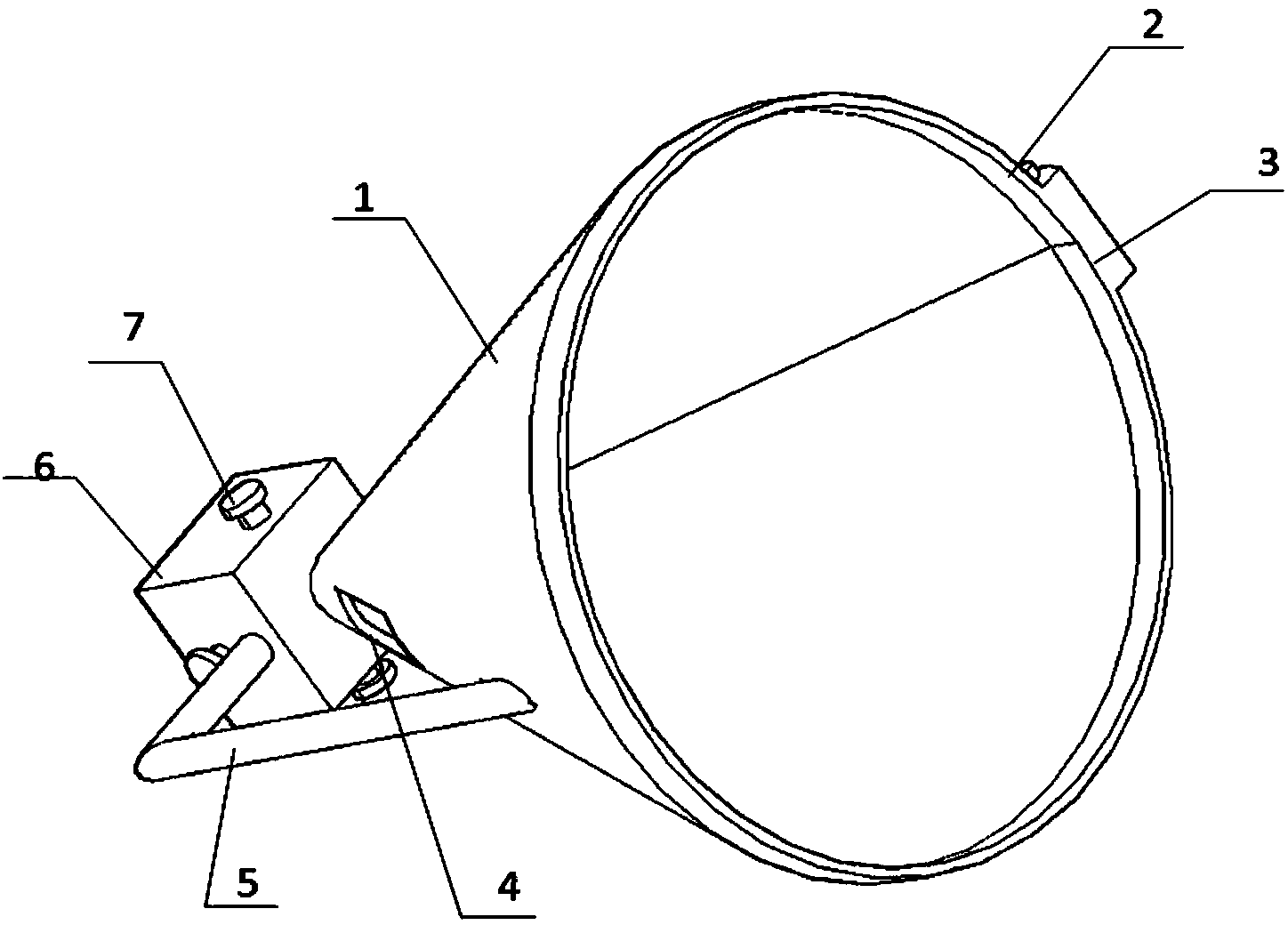

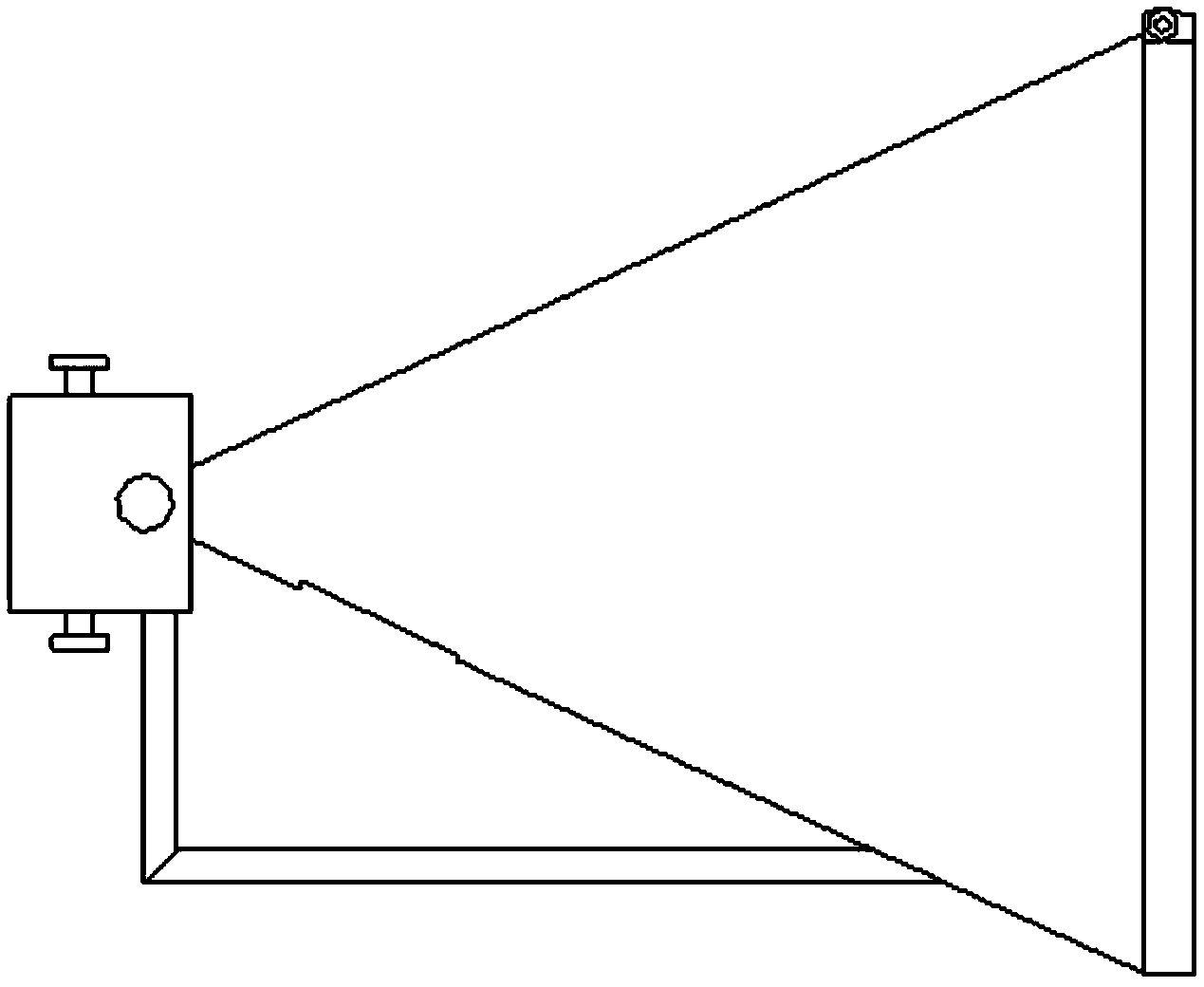

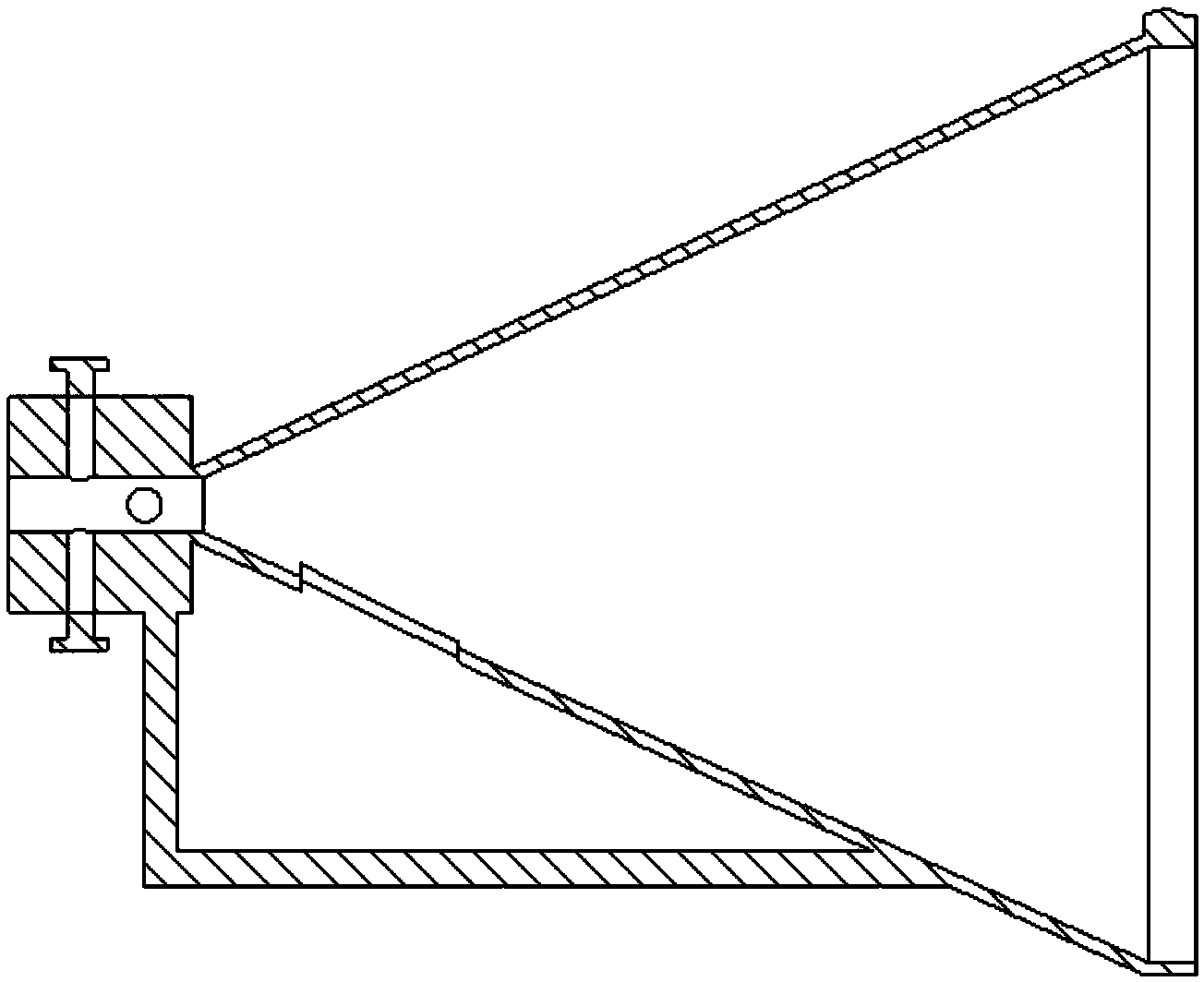

[0026] Concentrating device for high-speed camera microscopic photography of nozzle spray patterns, including:

[0027] The conical surface condenser 1 has a first through hole along the centerline direction of the cone at the top of the cone; the fixture 6 connected to the cone top of the conical condenser has a through hole in the fixture, and the nozzle of the sprayer passes through the through hole 11, The back of the first through hole is located in the conical condenser; the conical condenser is connected to the fixing device through the fixing frame 5;

[0028] The conical condenser is rolled from a piece of flexible fan-shaped reflector; and also includes: an adjustable hoop 3 located on the outer peripheral surface of the cone bottom of the conical condenser, and the tightening and loosening of the hoop is realized by rotating the knob 2. Then adjust the cone angle of the conical condenser.

[0029] The range of the adjustable clamp to adjust the cone angle of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com