Hydraulic ball type subsection soft start and overload protection device and its control system

An overload protection, ball-type technology, applied in the direction of grain processing, etc., can solve the problems of insensitive overload response and complex structure, and achieve the effects of sensitive overload response, reduced transmission failure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

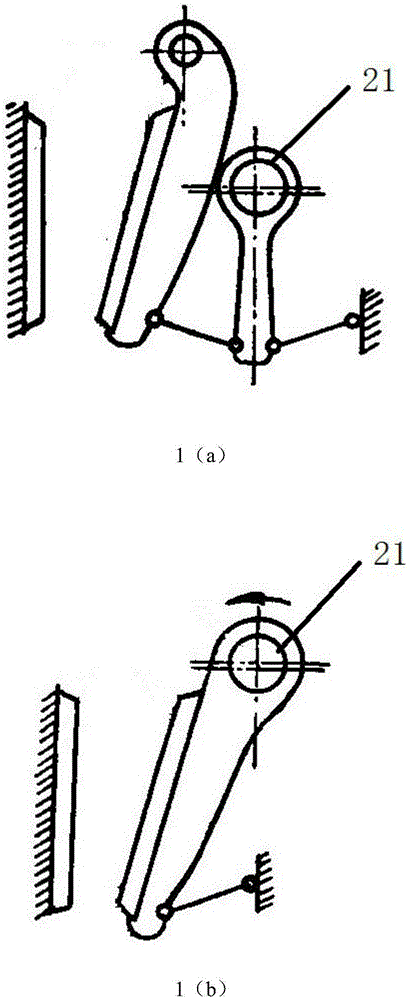

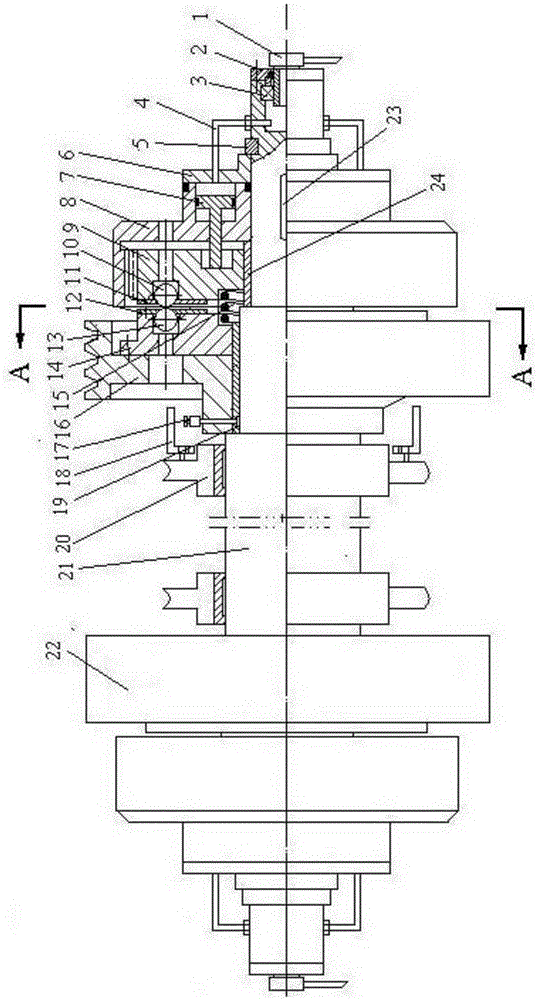

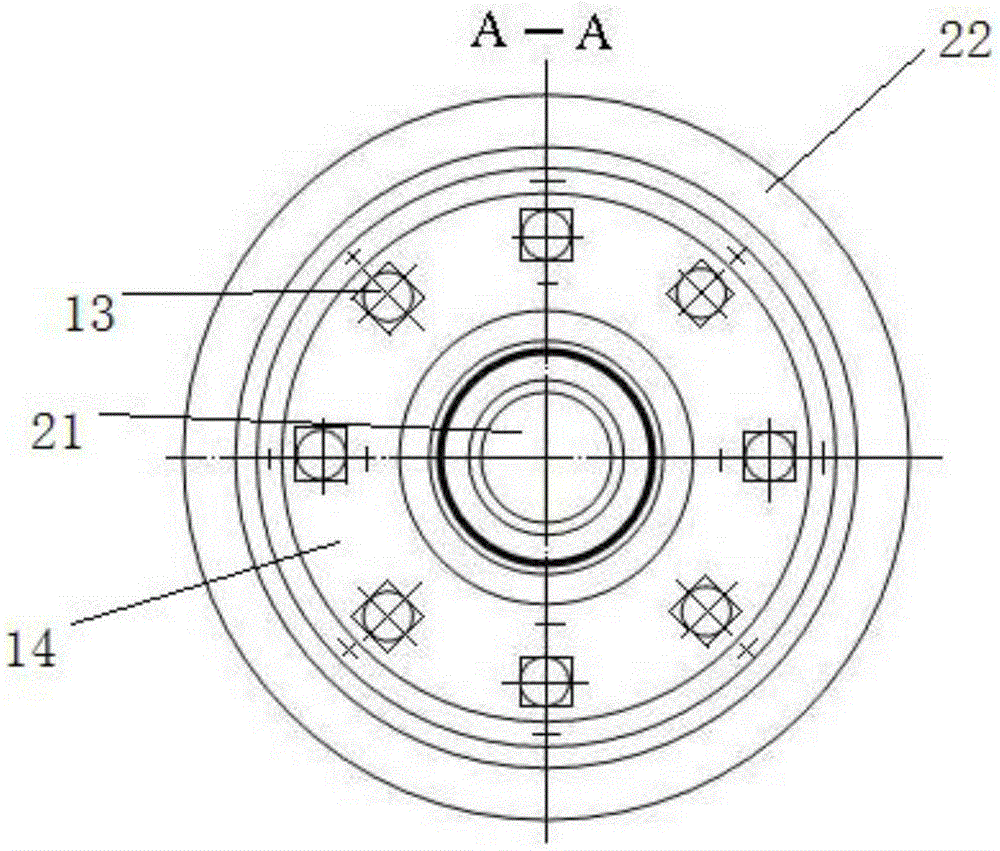

[0027] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] Such as figure 2 and image 3 As shown, a hydraulic ball type segmented soft start and overload protection device of the present invention includes a jaw crusher frame 20, an eccentric shaft 21 mounted on the frame 20, a flywheel 22 and a pulley mounted on the eccentric shaft 21 16. On the eccentric shaft 21, there is a pulley 16 through the first bearing bush 19, and a ball bearing disc driven ball disc 9 through the second bearing bush 24, and the active ball bearing disc 14 is connected to the pulley 16; the active ball bearing disc 14 and the driven ball plate 9 are provided with a separation spring 15, and the end faces of the active ball plate 14 and the driven ball plate 9 are all provided with 8 square socket holes, and the socket holes are respectively loaded with active springs. The force-transmitting steel ball 13 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com