Patents

Literature

74results about How to "Improved vibration absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

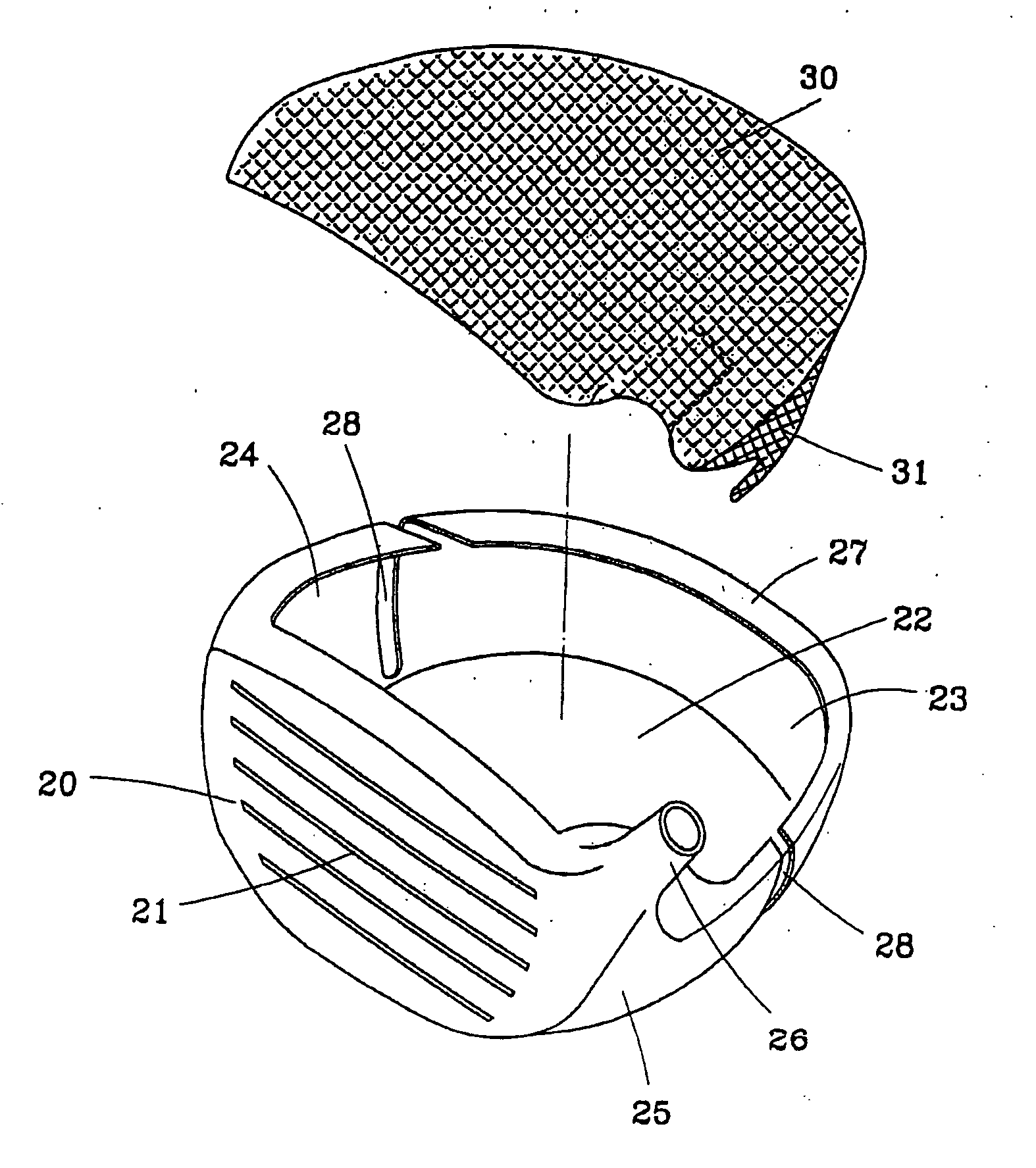

Wood golf club head

A golf club head is mainly consisted of a metallic head housing having and a nonmetallic crown. The metallic head housing, which hollow and is open at a top thereof, has a face, a sole, a rear, a toe and a heel. At the toe and the heel of the head housing is a gap respectively. The crown coupled to the top of the head housing, wherein the crown has two arms coupled to the toe and the heel of the head housing respectively to shield the gaps.

Owner:CHUANG CHENG YU

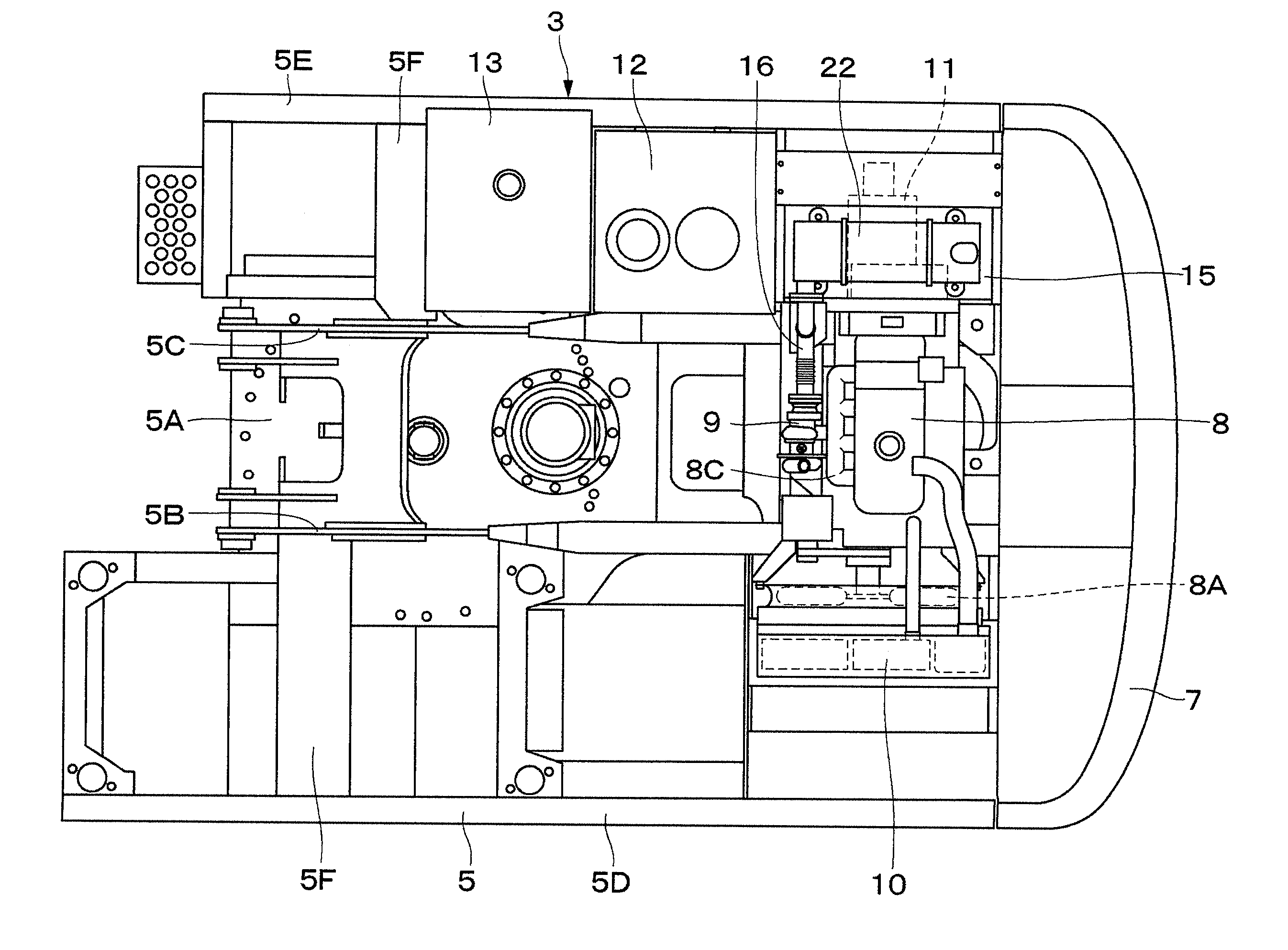

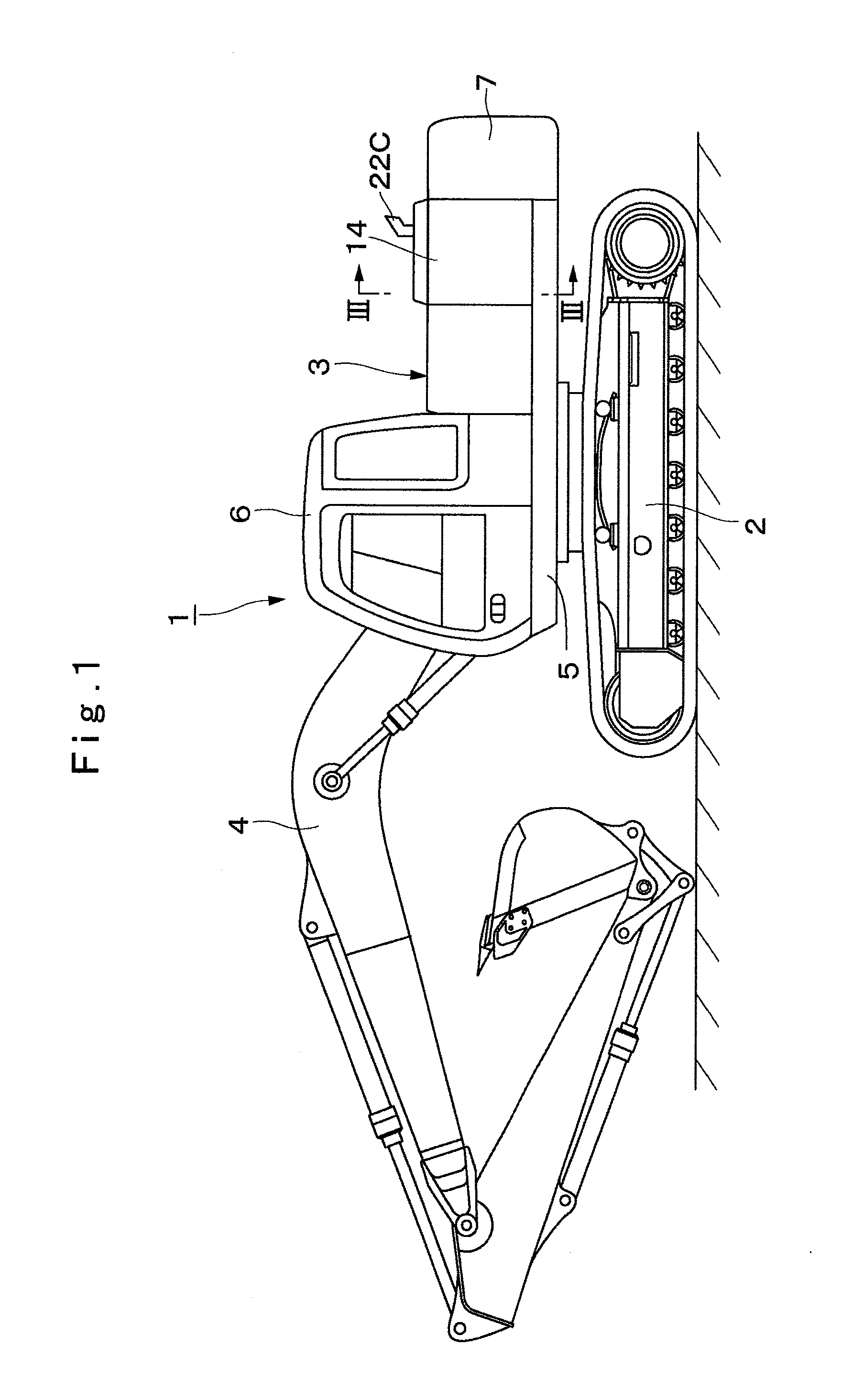

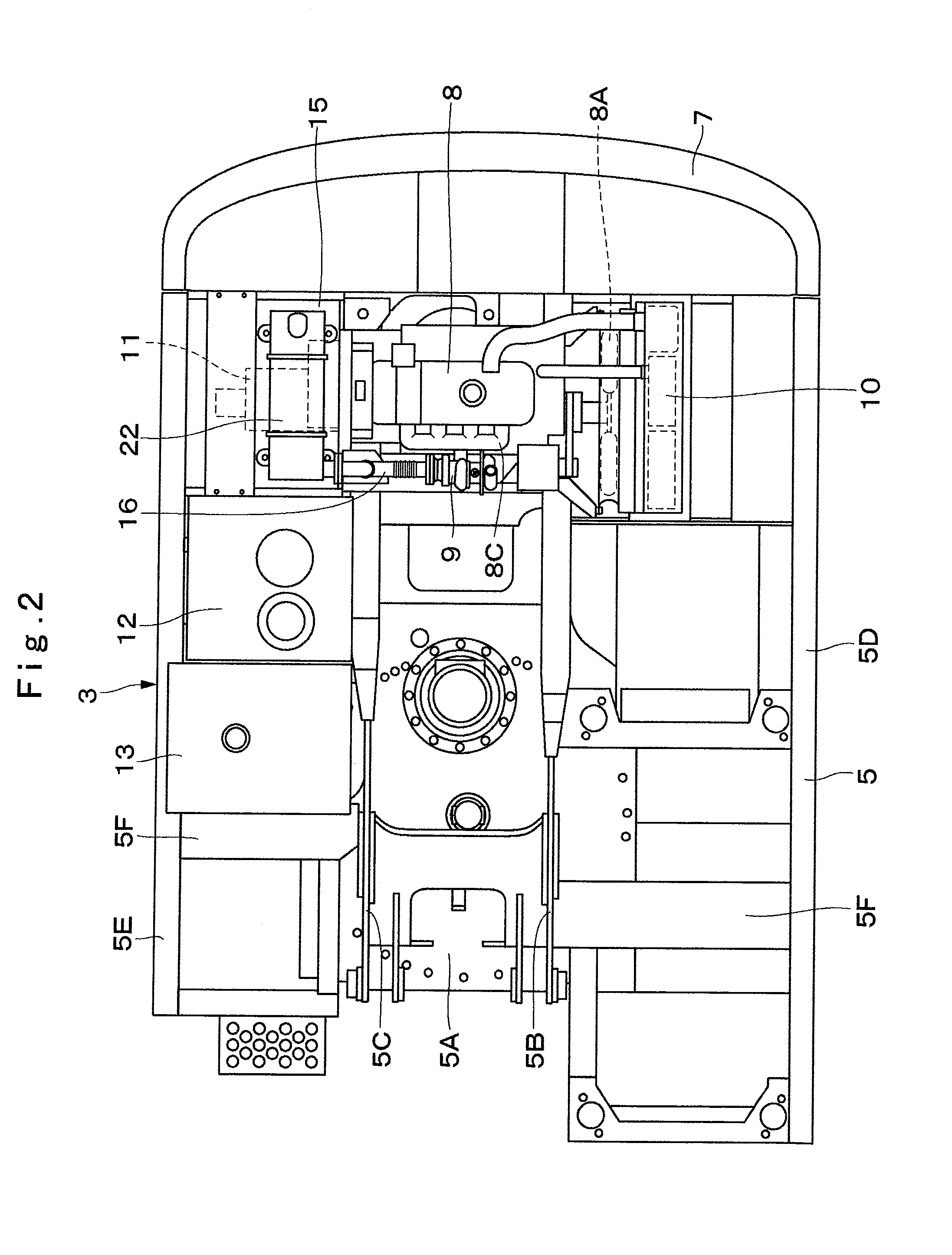

Construction machine

InactiveUS20130319787A1Stable absorptionImprove performanceSilencing apparatusSoil-shifting machines/dredgersEngineeringExhaust pipe

On an upper revolving structure, an engine having an exhaust port is mounted. In the midway portion of the exhaust pipe connecting the exhaust port of the engine and an exhaust gas post-treatment device, a first bellows pipe and a second bellows pipe are arranged through a connecting pipe having an L-shaped bending portion. In this case, the first bellows pipe and the second bellows pipe are arranged so as to have a positional relationship in which axis lines thereof (X1-X1, Z1-Z1) cross each other. That is, the first bellows pipe is arranged in a horizontal direction so that its axis line (X1-X1) extends in the left-right direction of the upper revolving structure. The second bellows pipe is arranged so that its axis line (Z1-Z1) matches the vertical direction of the upper revolving structure.

Owner:HITACHI CONSTR MASCH CO LTD

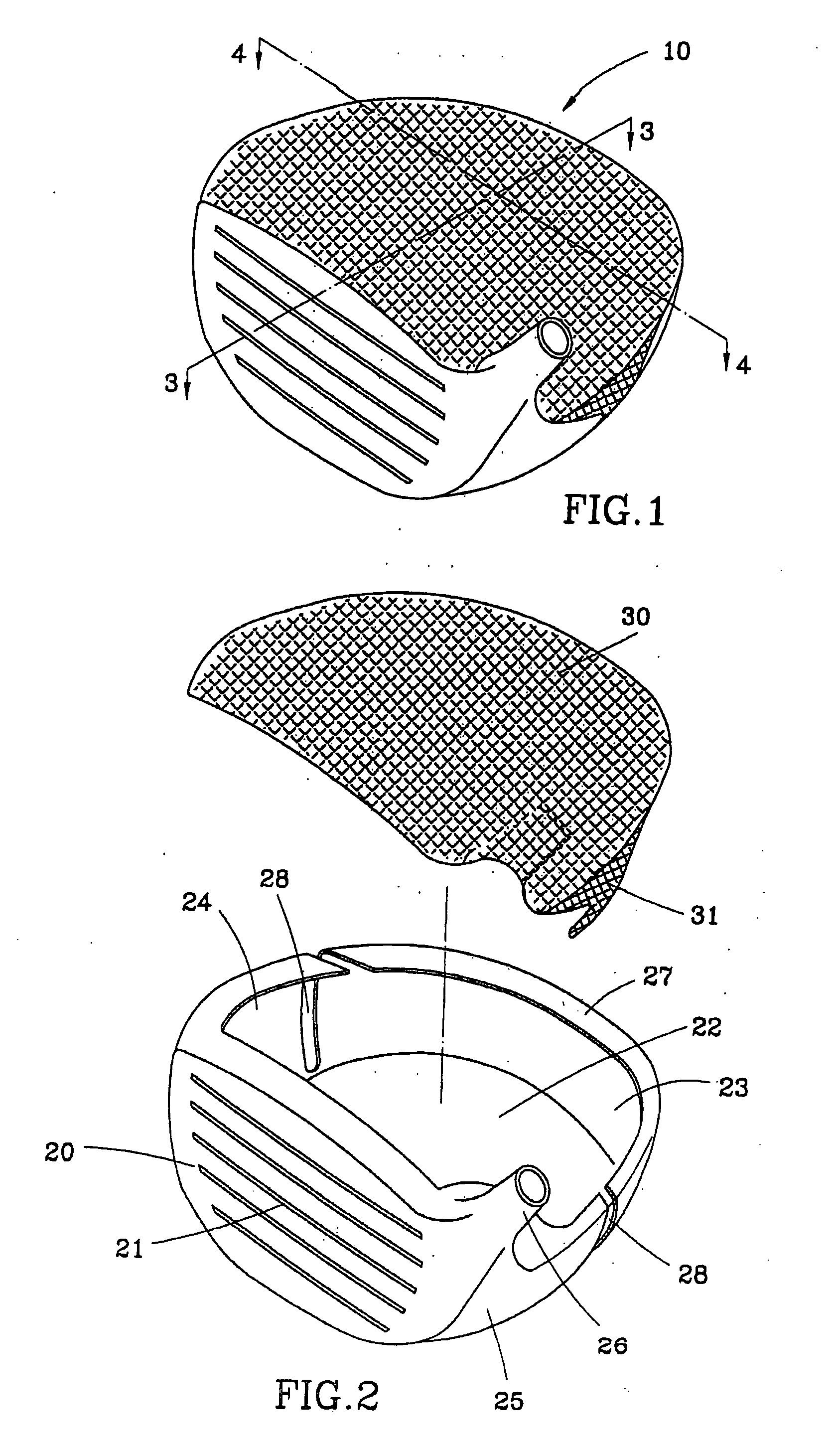

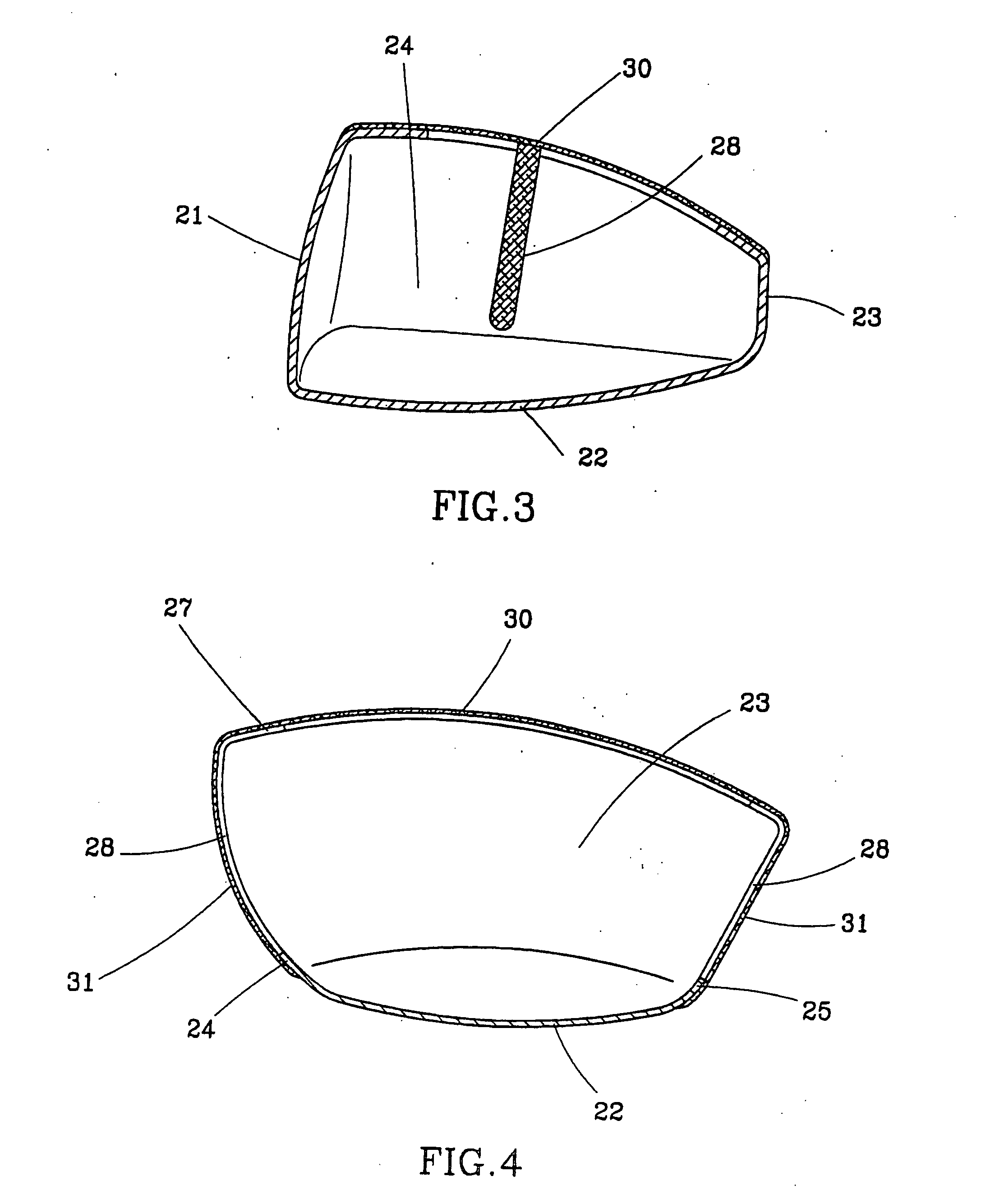

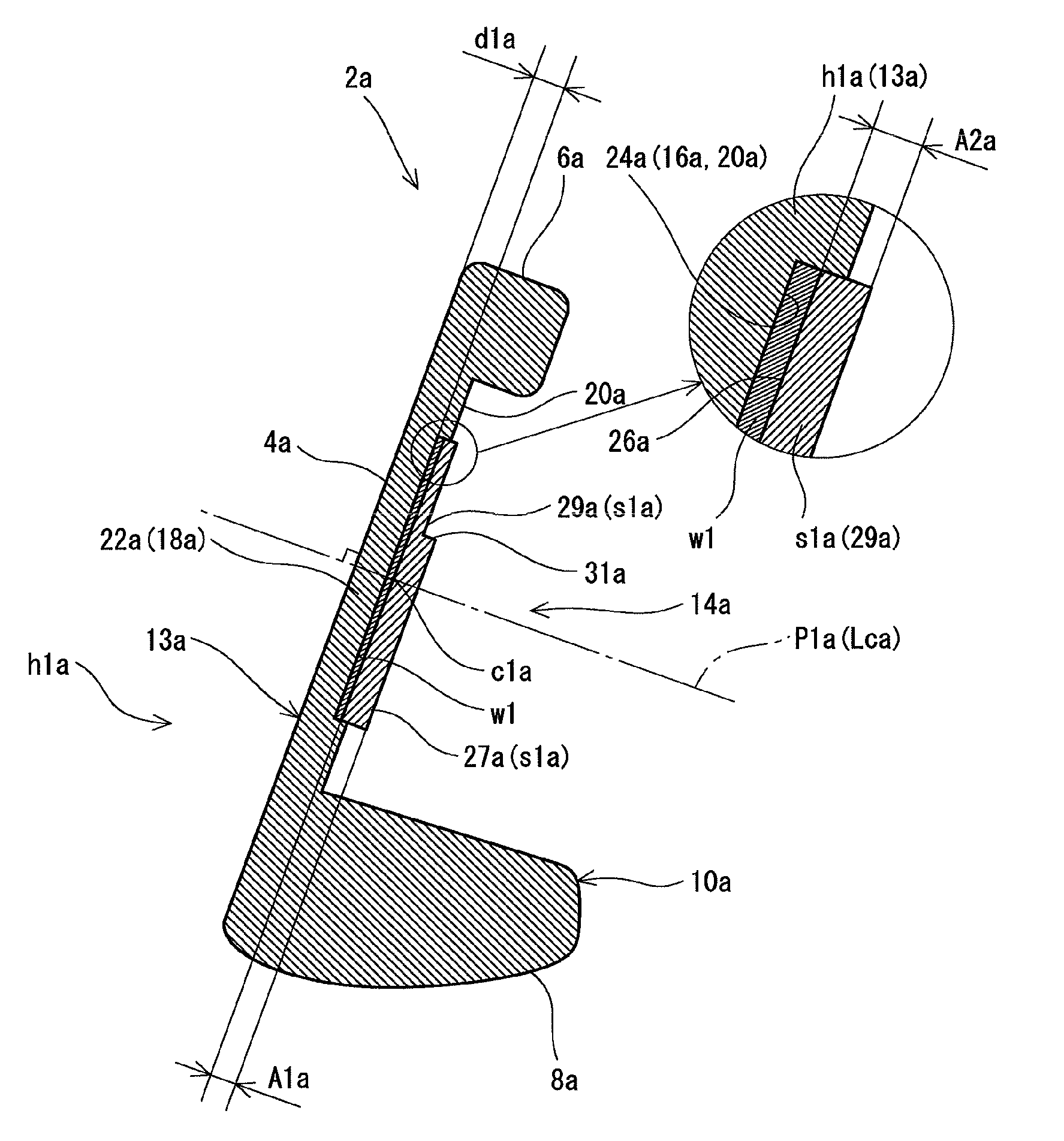

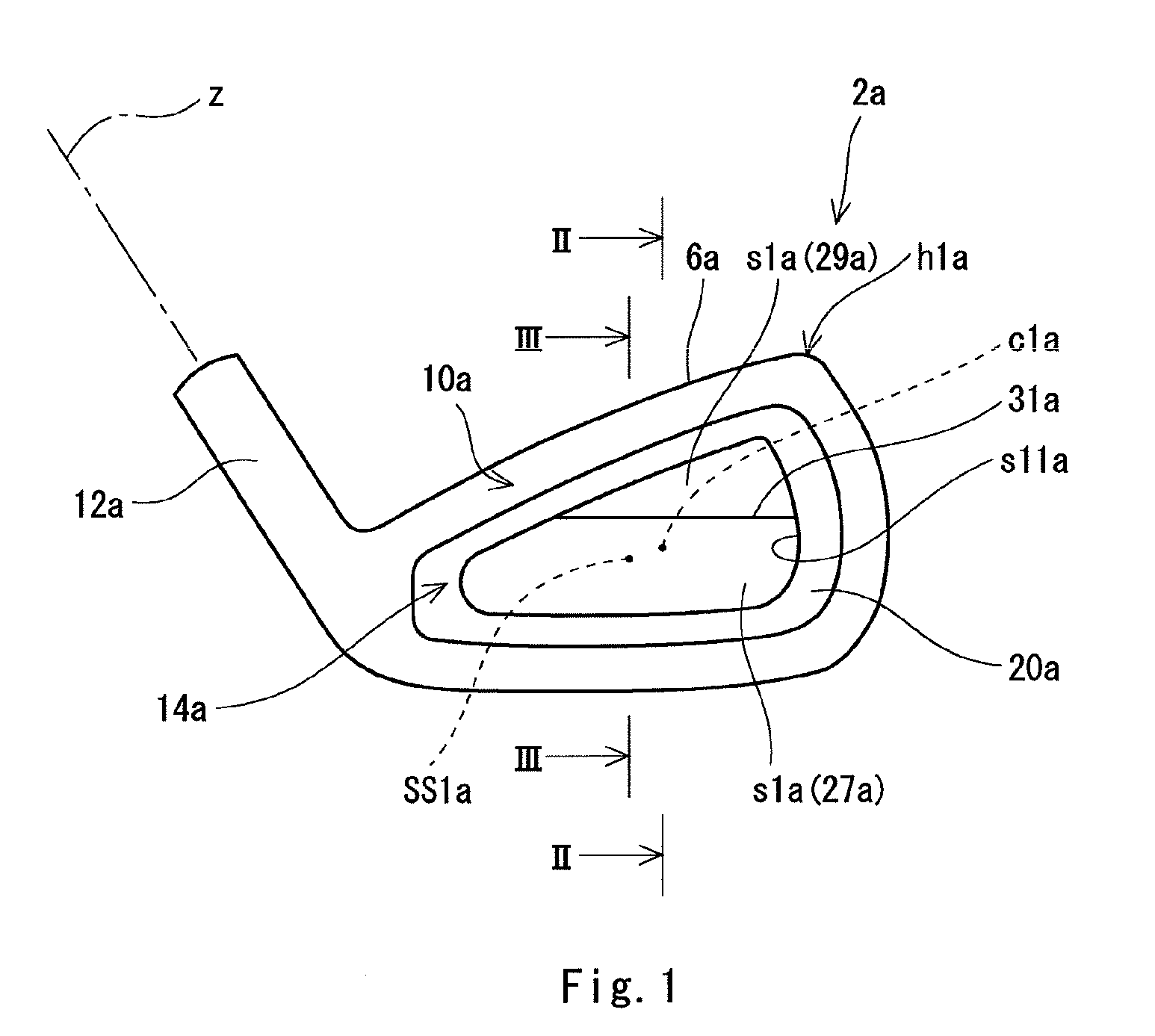

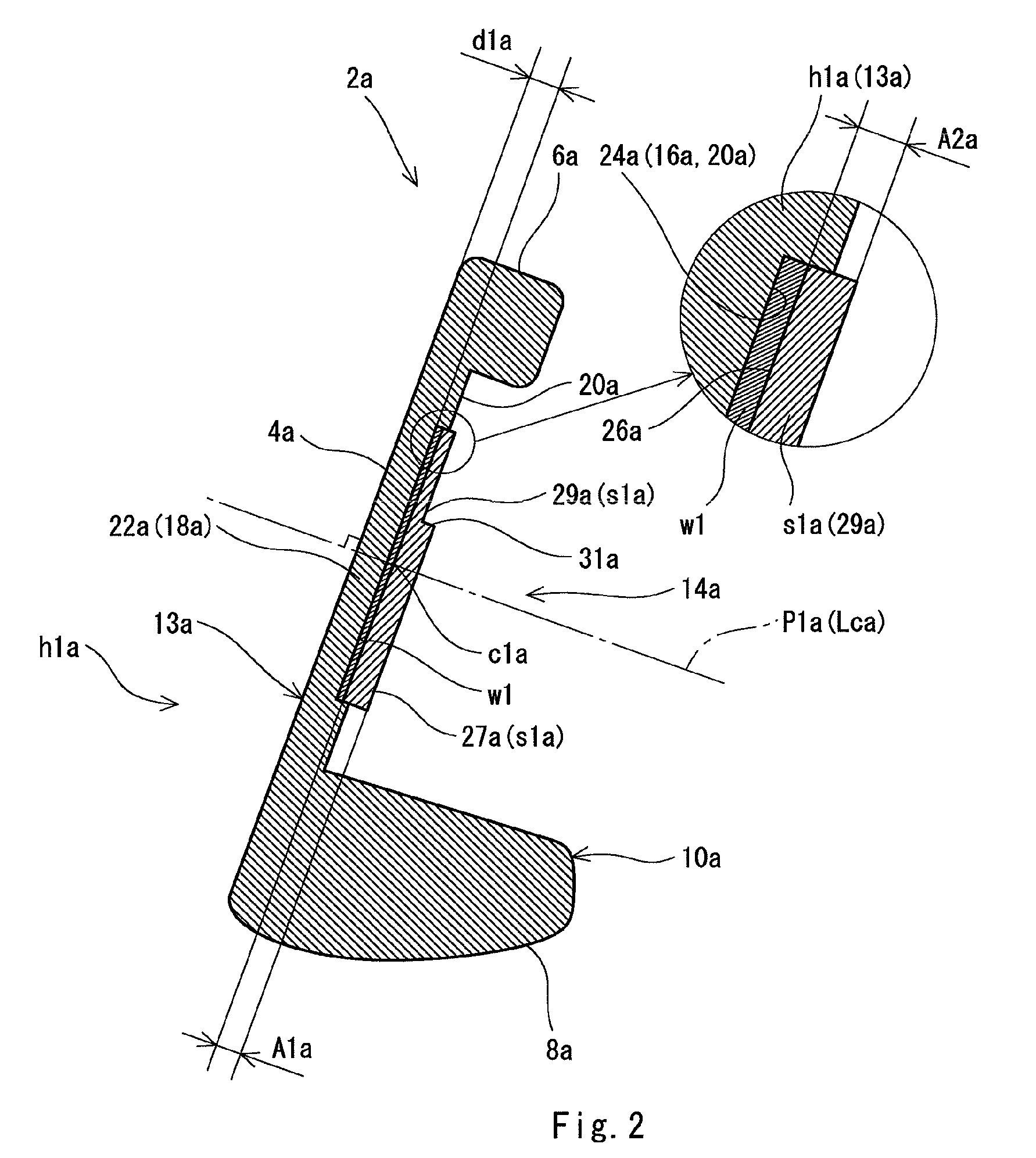

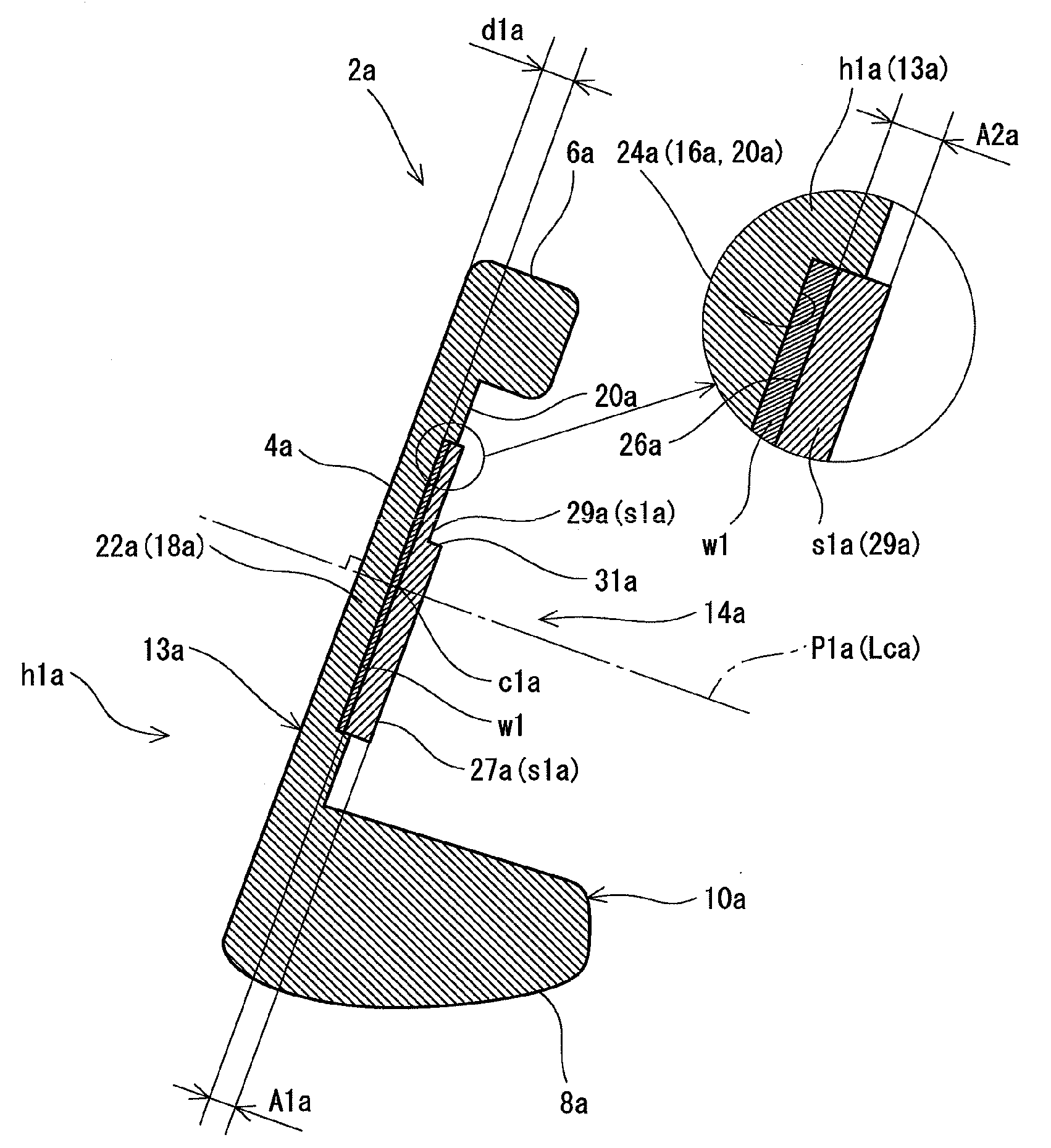

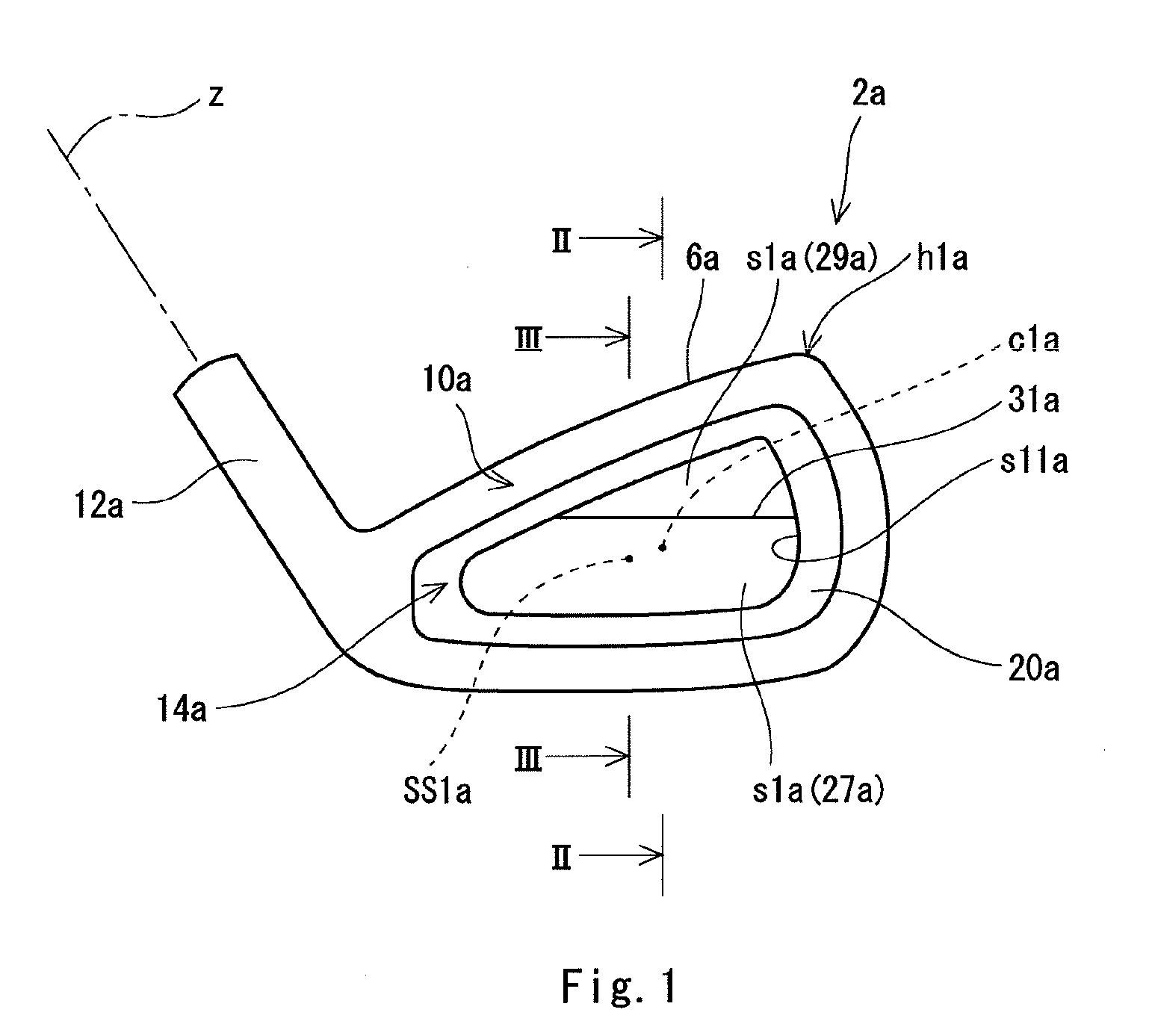

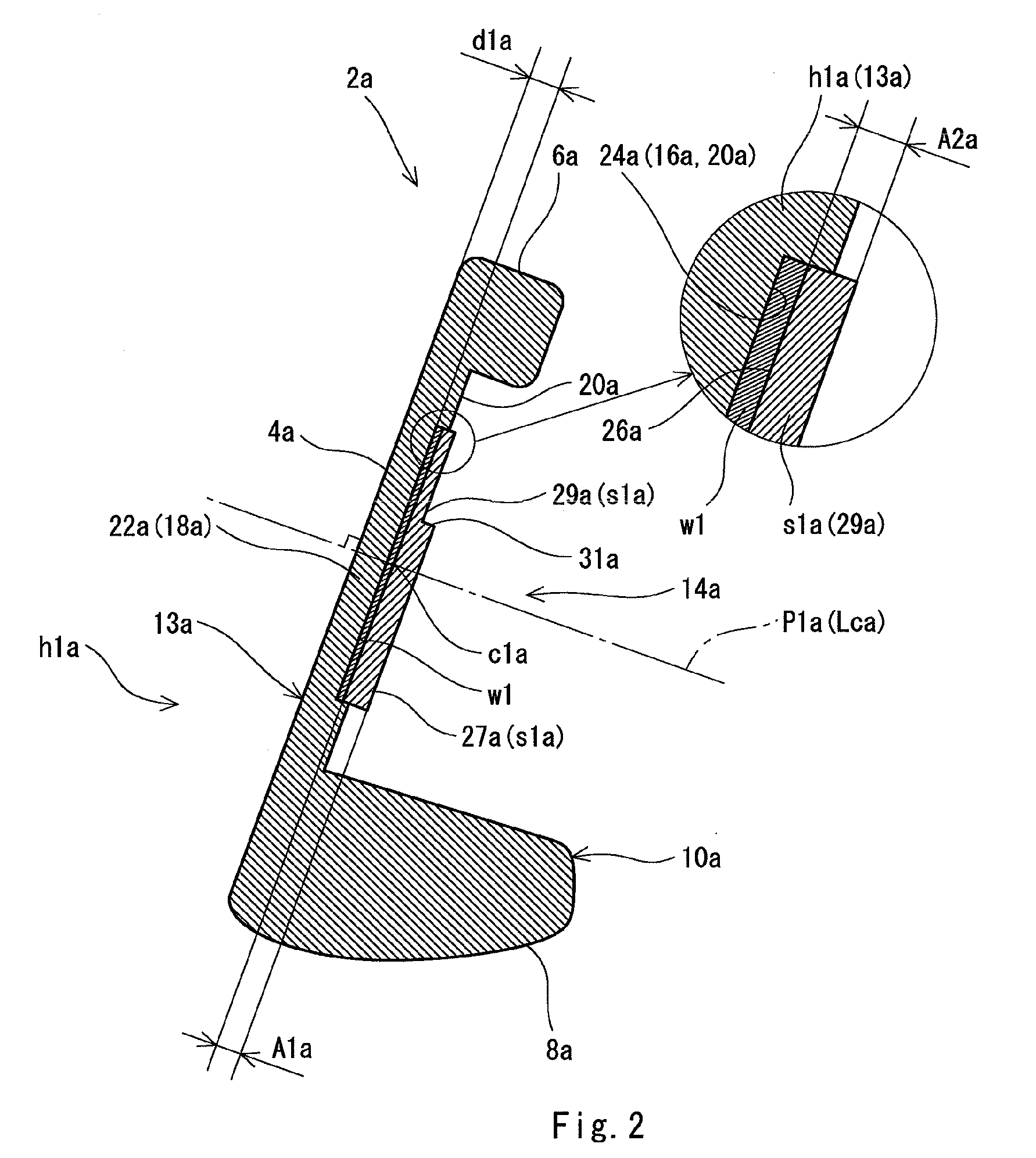

Golf club head

ActiveUS8333667B2Suppress uncomfortable vibrationImproved vibration absorption performanceGolf clubsRacket sportsEngineeringGolf club

A golf club head 2a of a first aspect is provided with a head body h1a, a double-stick tape w1, and an adherend s1a bonded to the head body h1a by the double-stick tape w1. When an average thickness of a lower part of the adherend s1a is defined as f1 and an average thickness of an upper part of the adherend s1a is defined as f2, the thickness f2 is smaller than the thickness f1. A golf club head 2 according to a second aspect is provided with a head body h1, a double-stick tape w1 and an adherend s1 bonded to the head body h1 by the double-stick tape w1. When an average thickness of a heel part of the adherend s1 is defined as t1 and an average thickness of a toe part of the adherend s1 is defined as t2, the thickness t2 is smaller than the thickness t1.

Owner:SUMITOMO RUBBER IND LTD

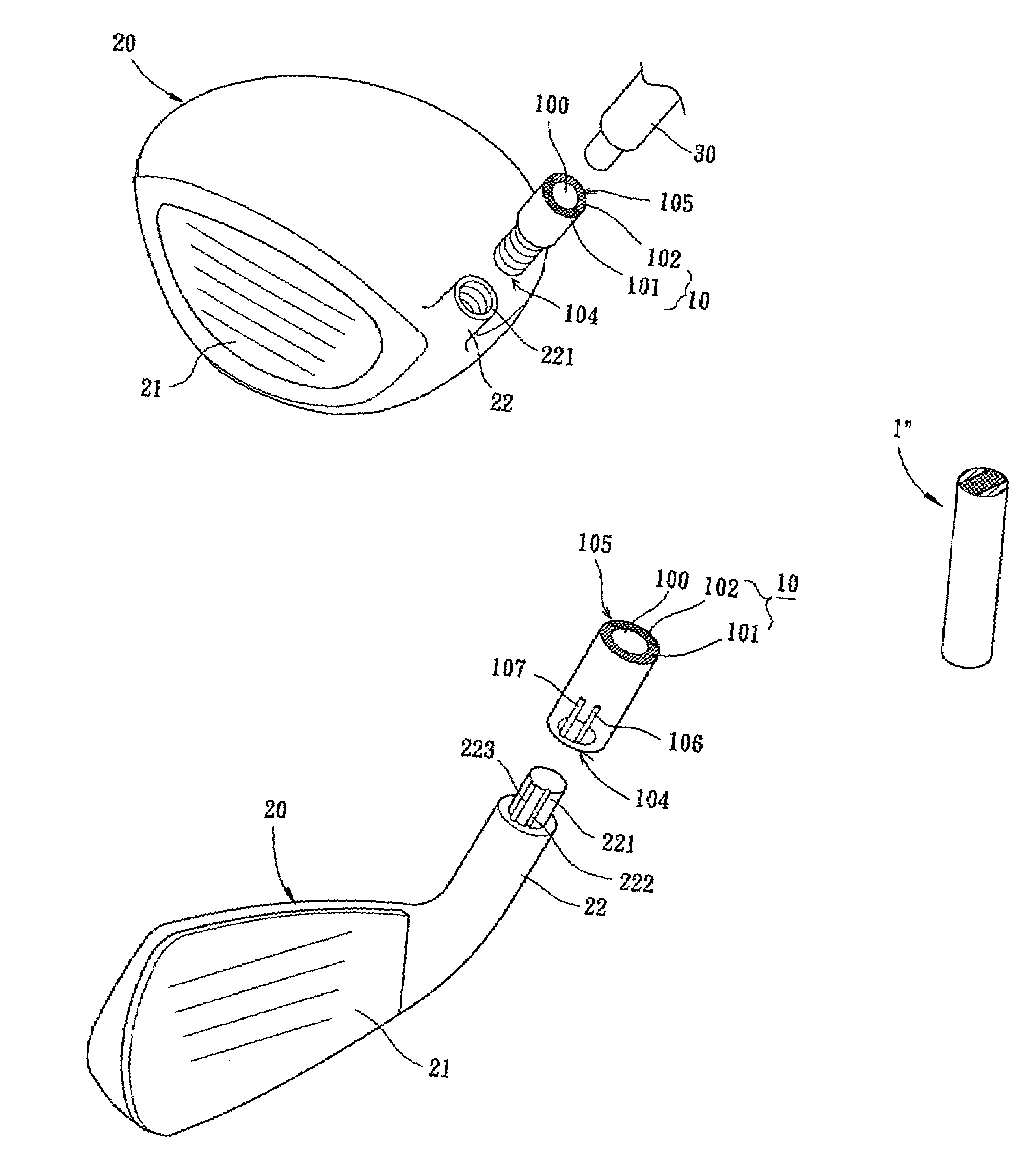

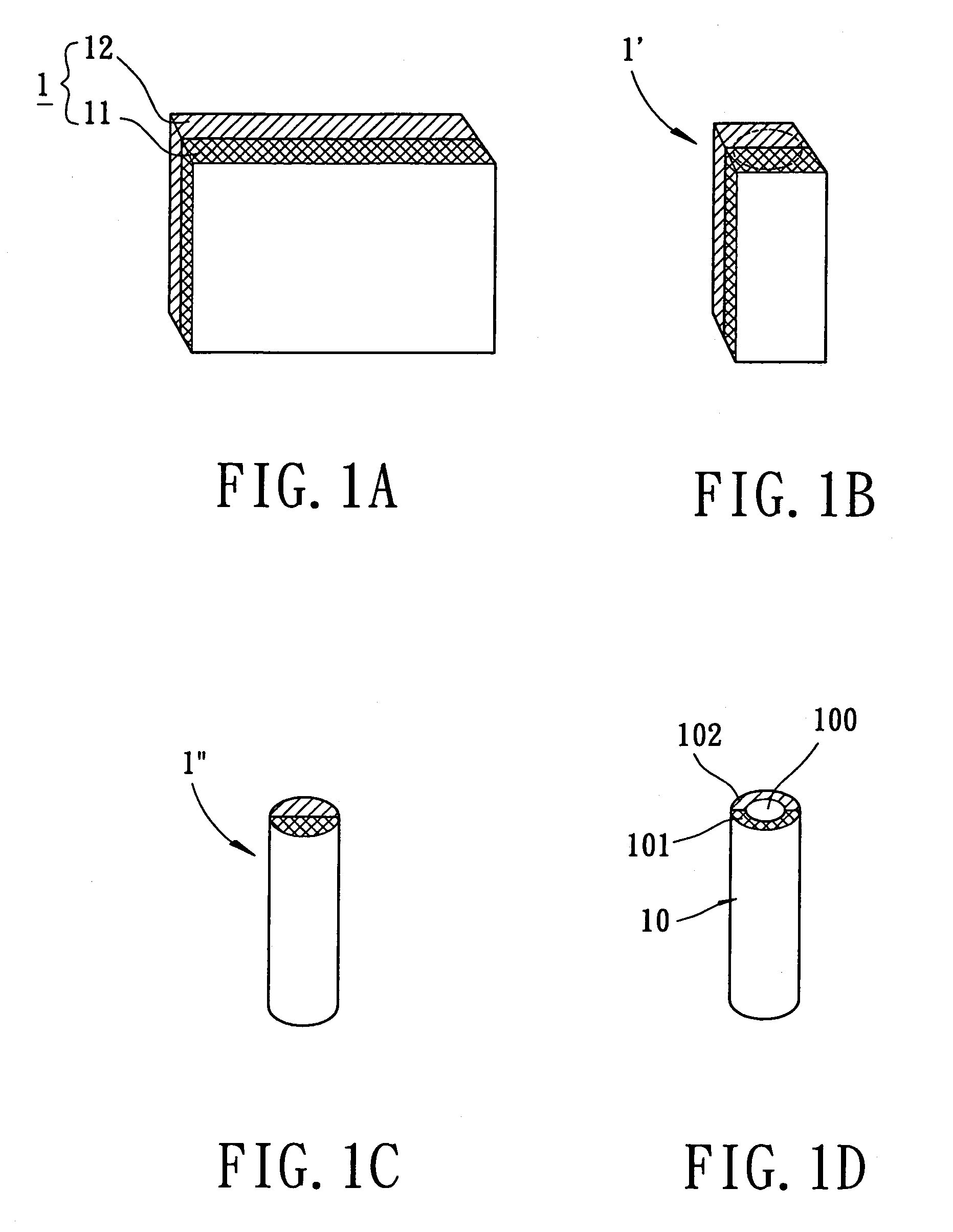

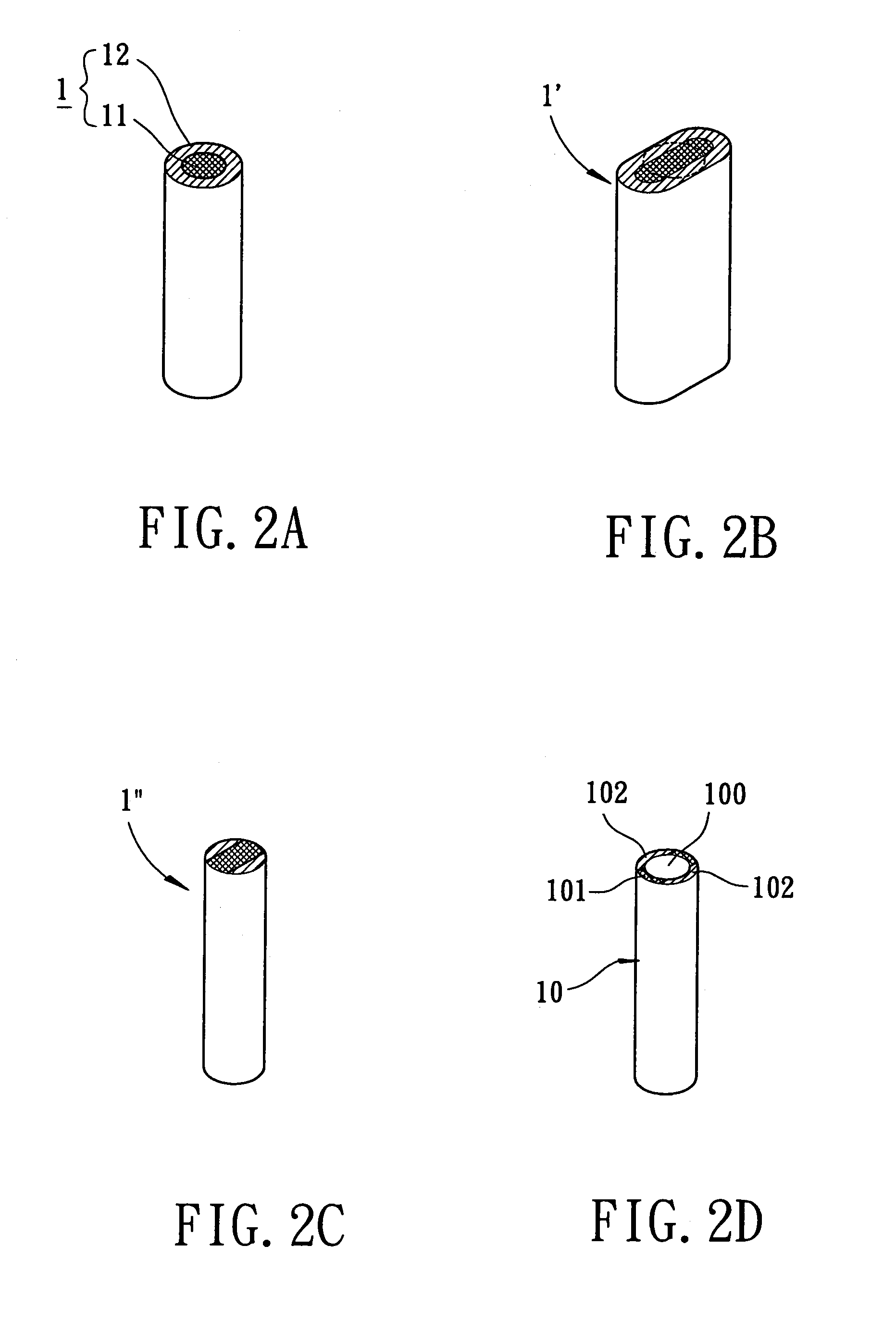

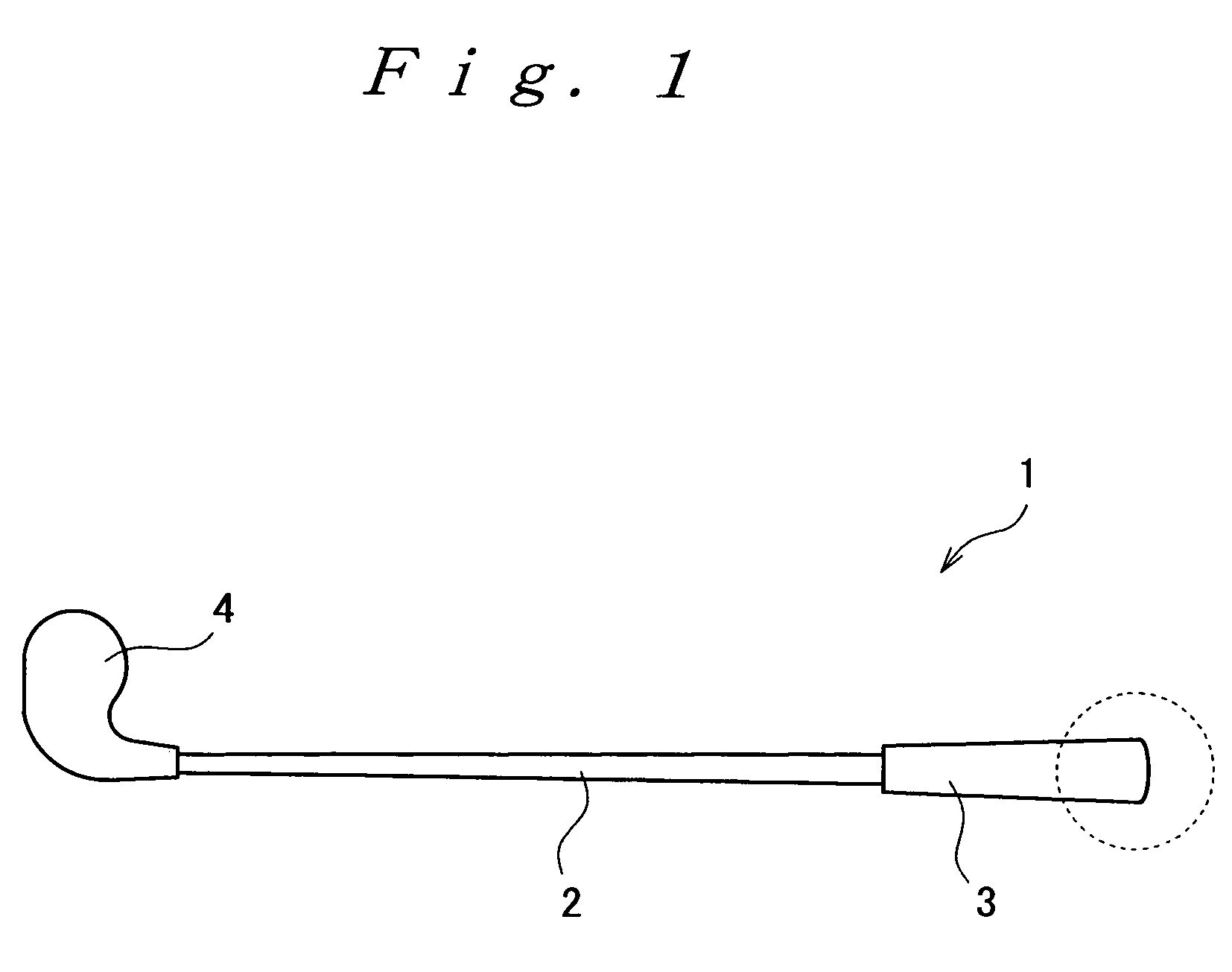

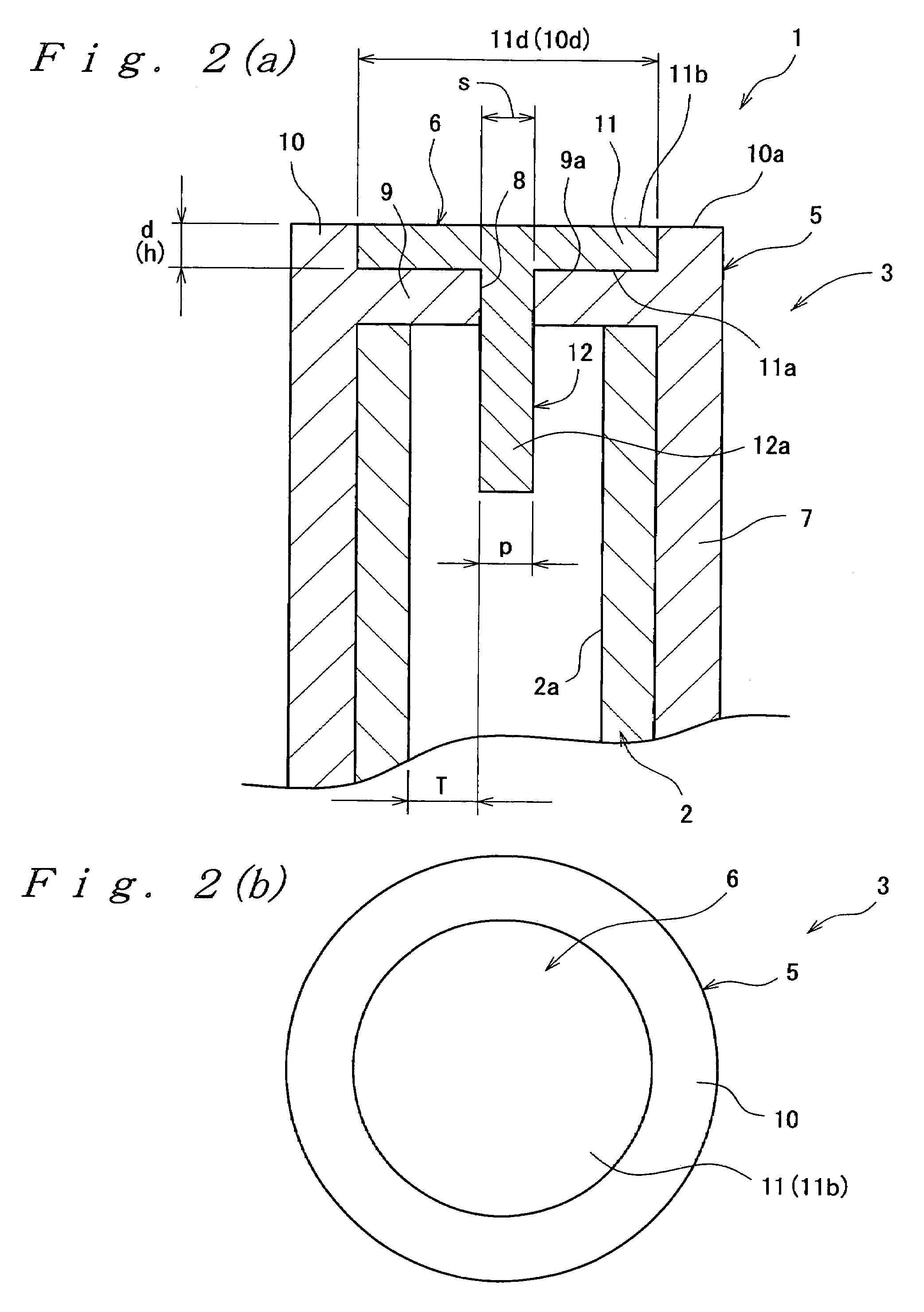

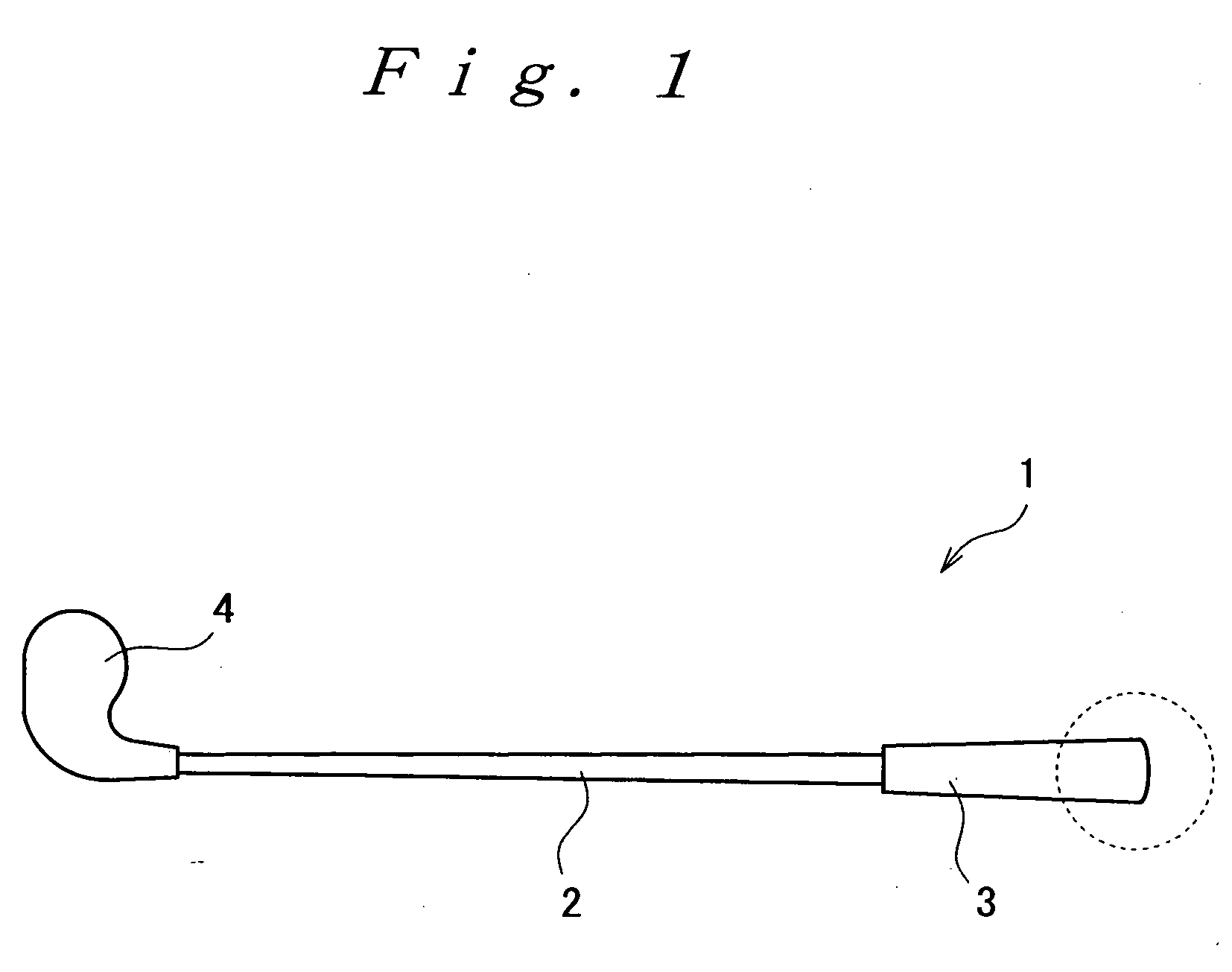

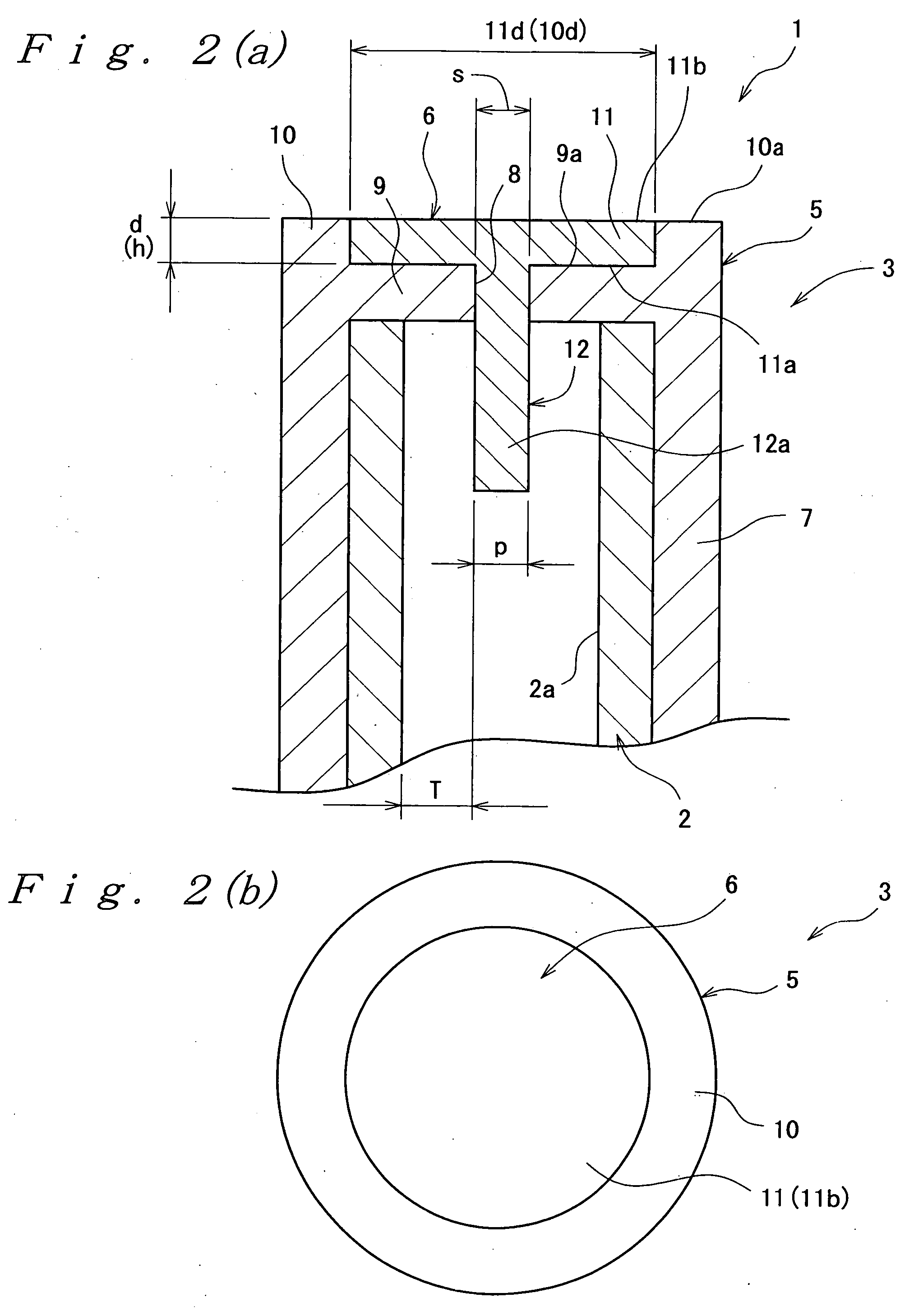

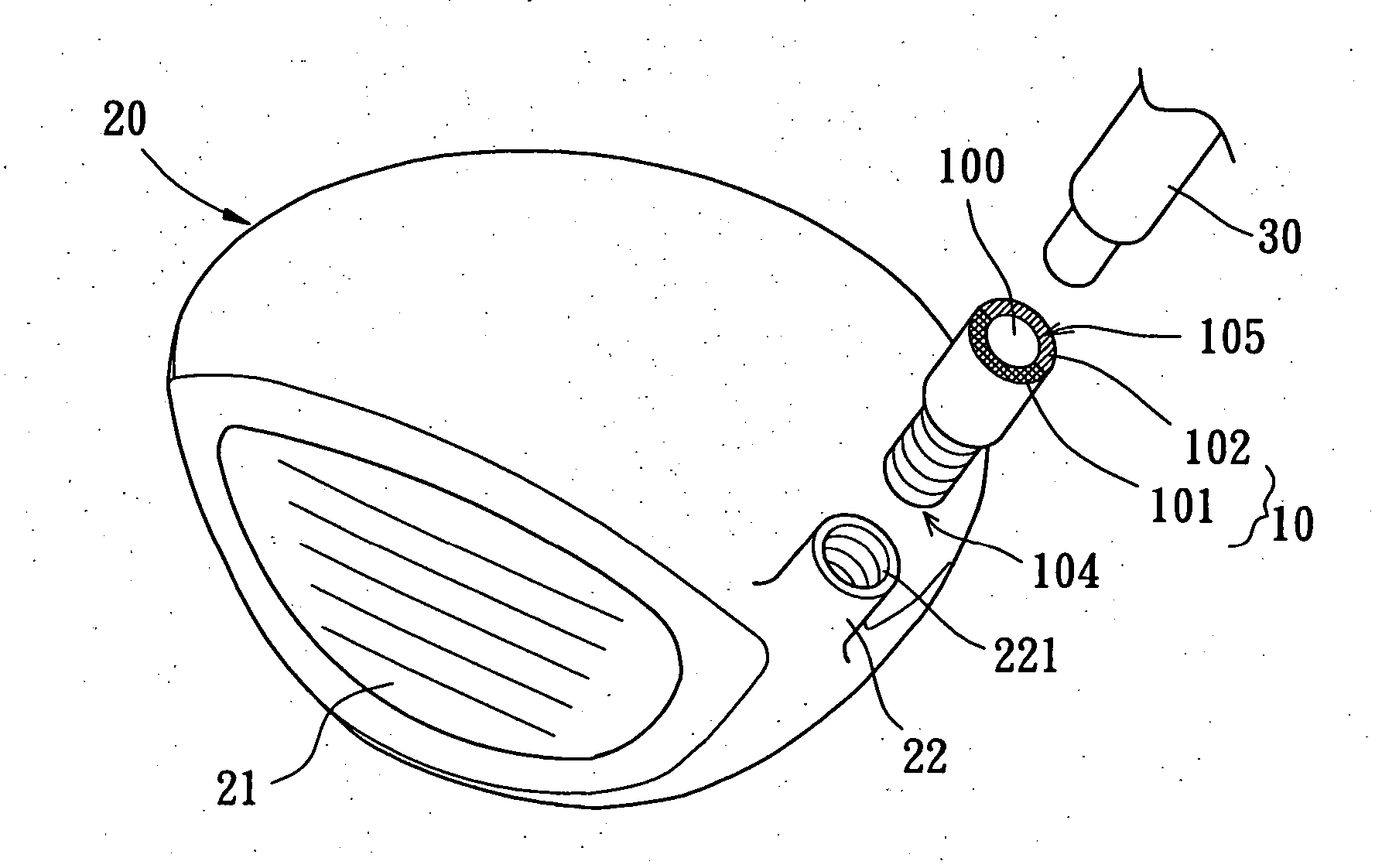

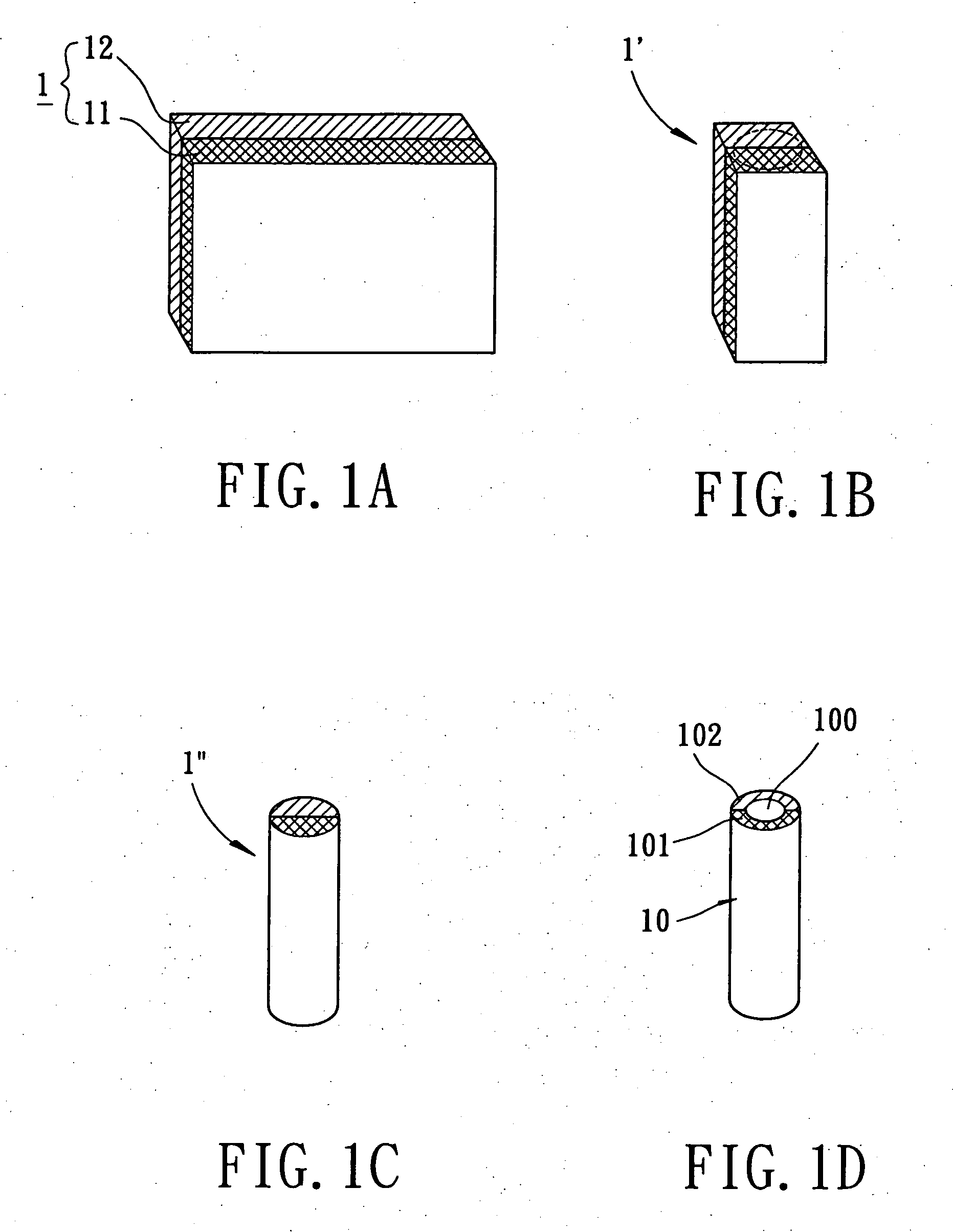

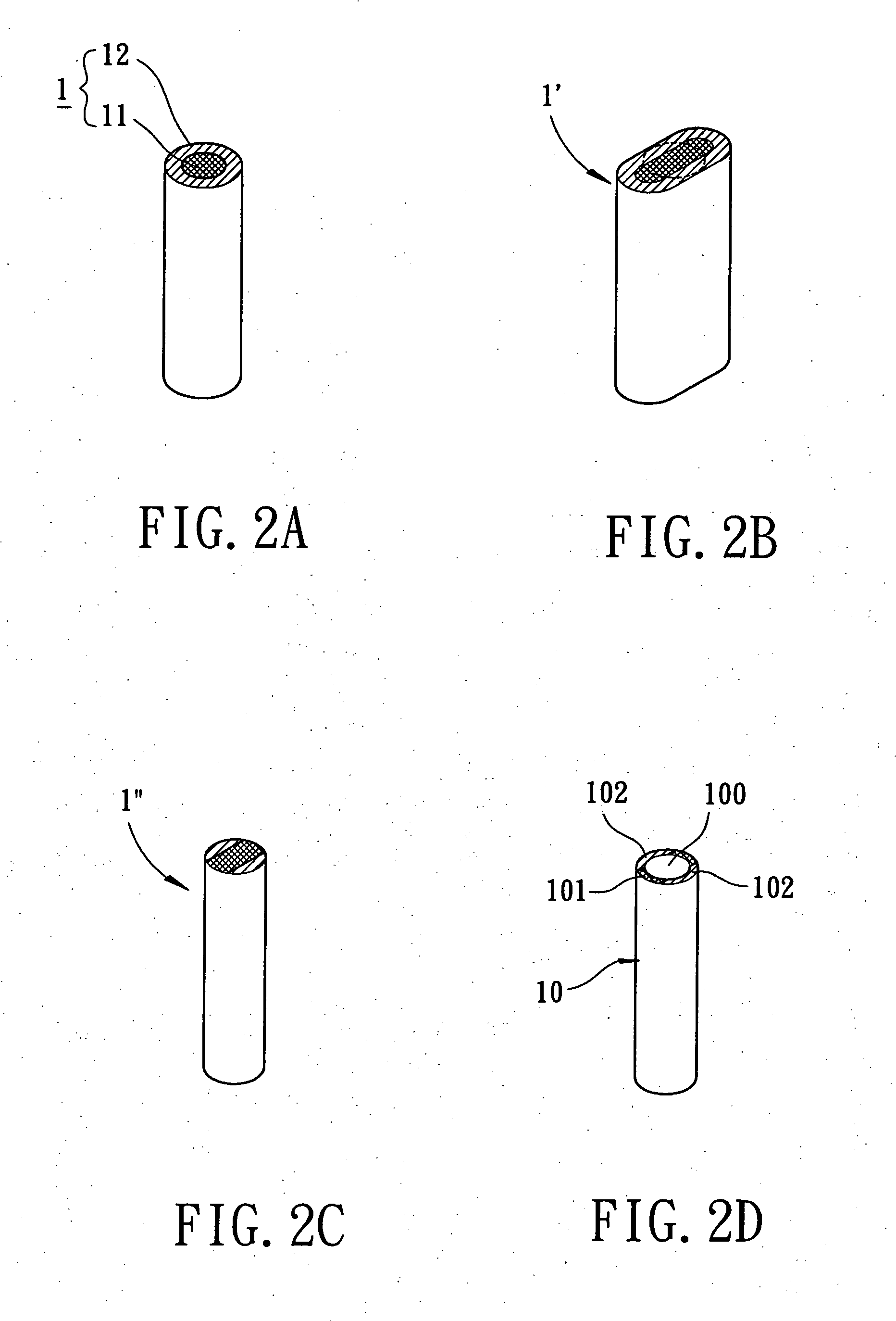

Complex hosel structure for a golf club head having a high degree of vibrational absorbability and elastic deformability

InactiveUS7351159B2Improved vibration absorption performanceImprove structural strengthGolf clubsRacket sportsEngineeringGolf Ball

A golf club head includes a golf club head body and a complex hosel. The golf club head body includes a neck portion located at a heel-side portion, and a connecting portion formed on the neck portion. The complex hosel is constructed from a one-piece tubular member made from a two-layer or multi-layer complex substrate combined along a longitudinal direction such that the complex hosel has at least one first tubular, segmental wall and at least one second tubular, segmental wall that possess two different characteristics of vibrational absorbability and elastic deformability. The complex hosel can provide different vibrational absorbability and elastic deformability characteristics in different radial directions of the neck portion of the golf club head body when assembled.

Owner:FUSHENG IND CO LTD

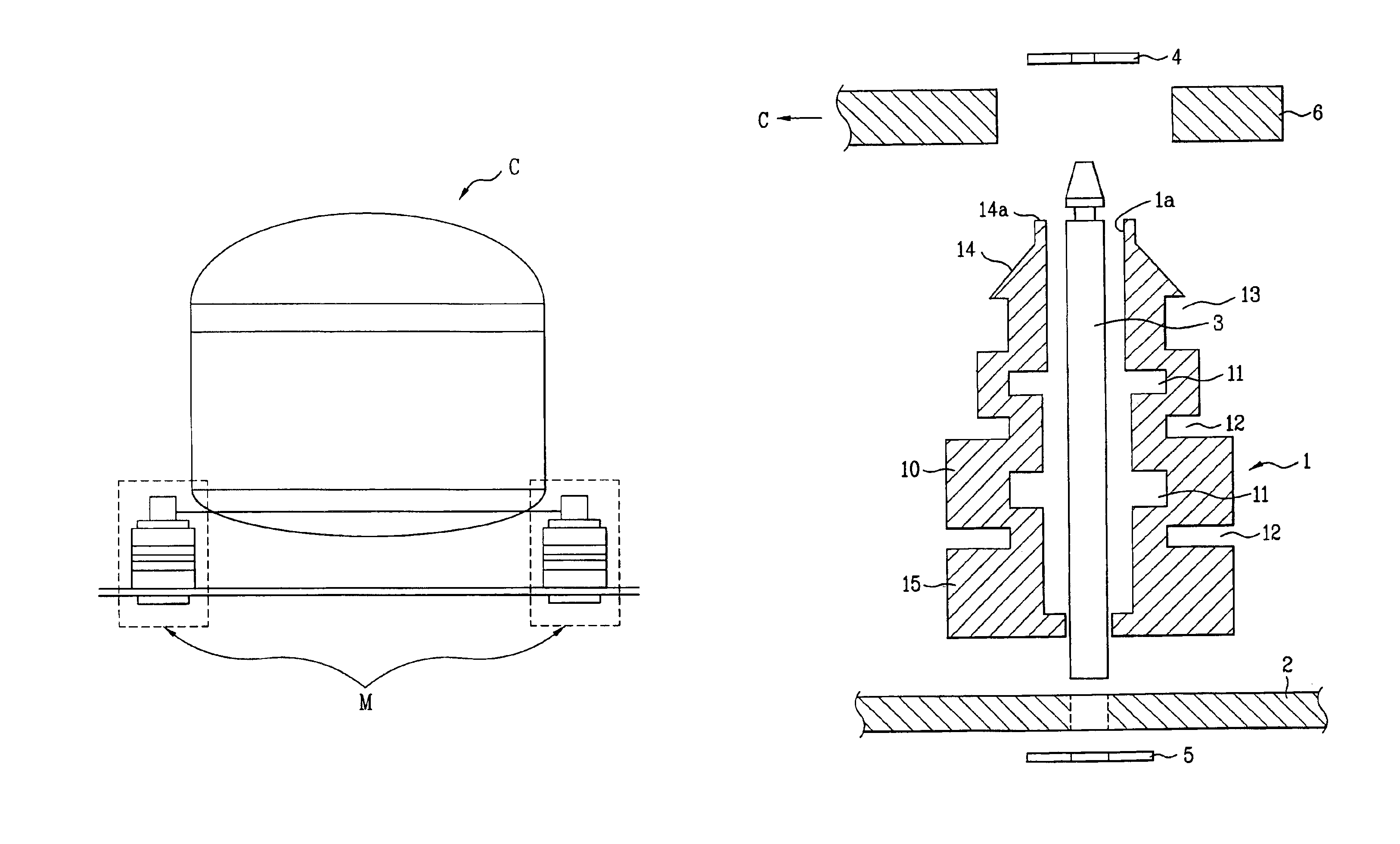

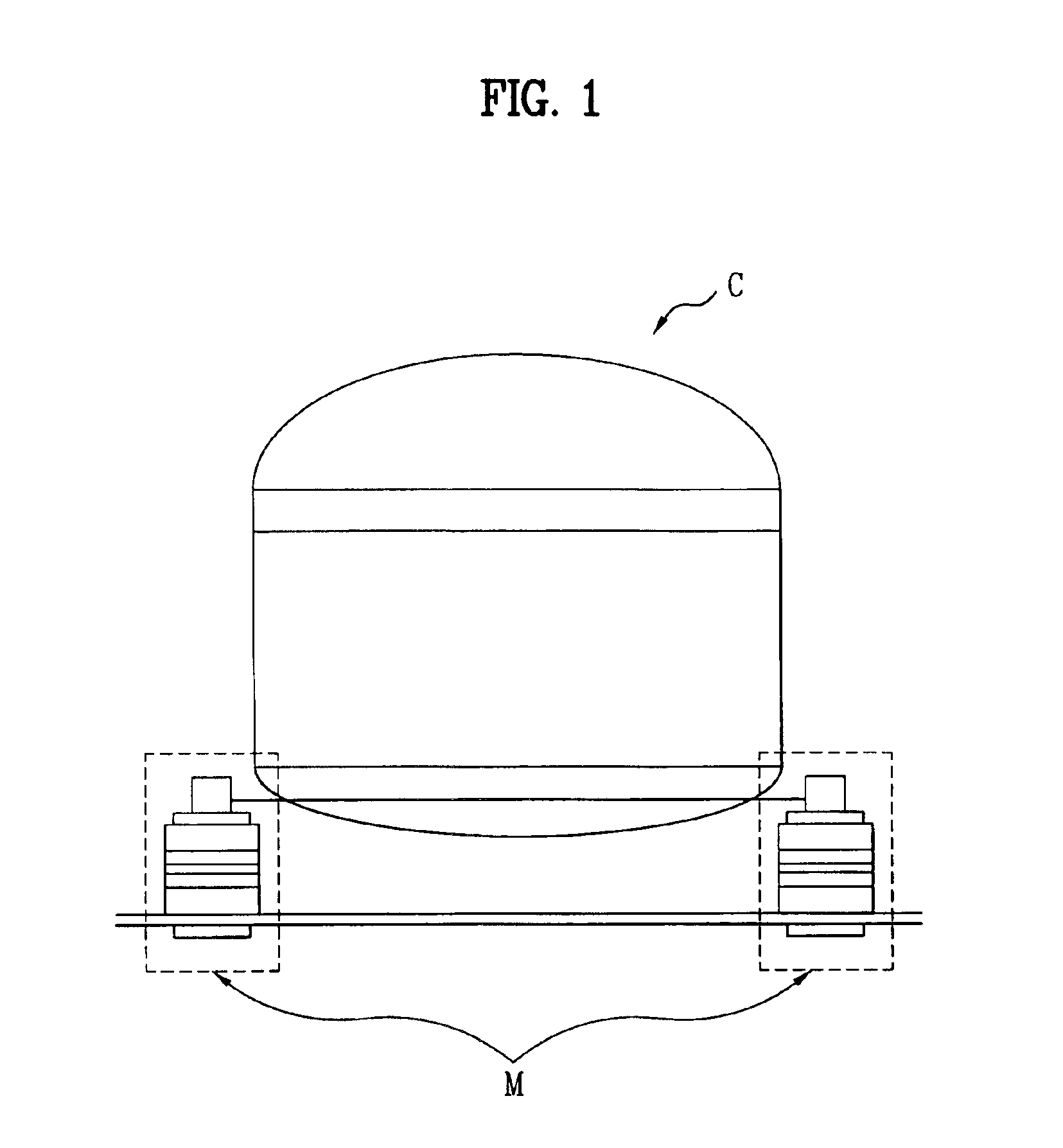

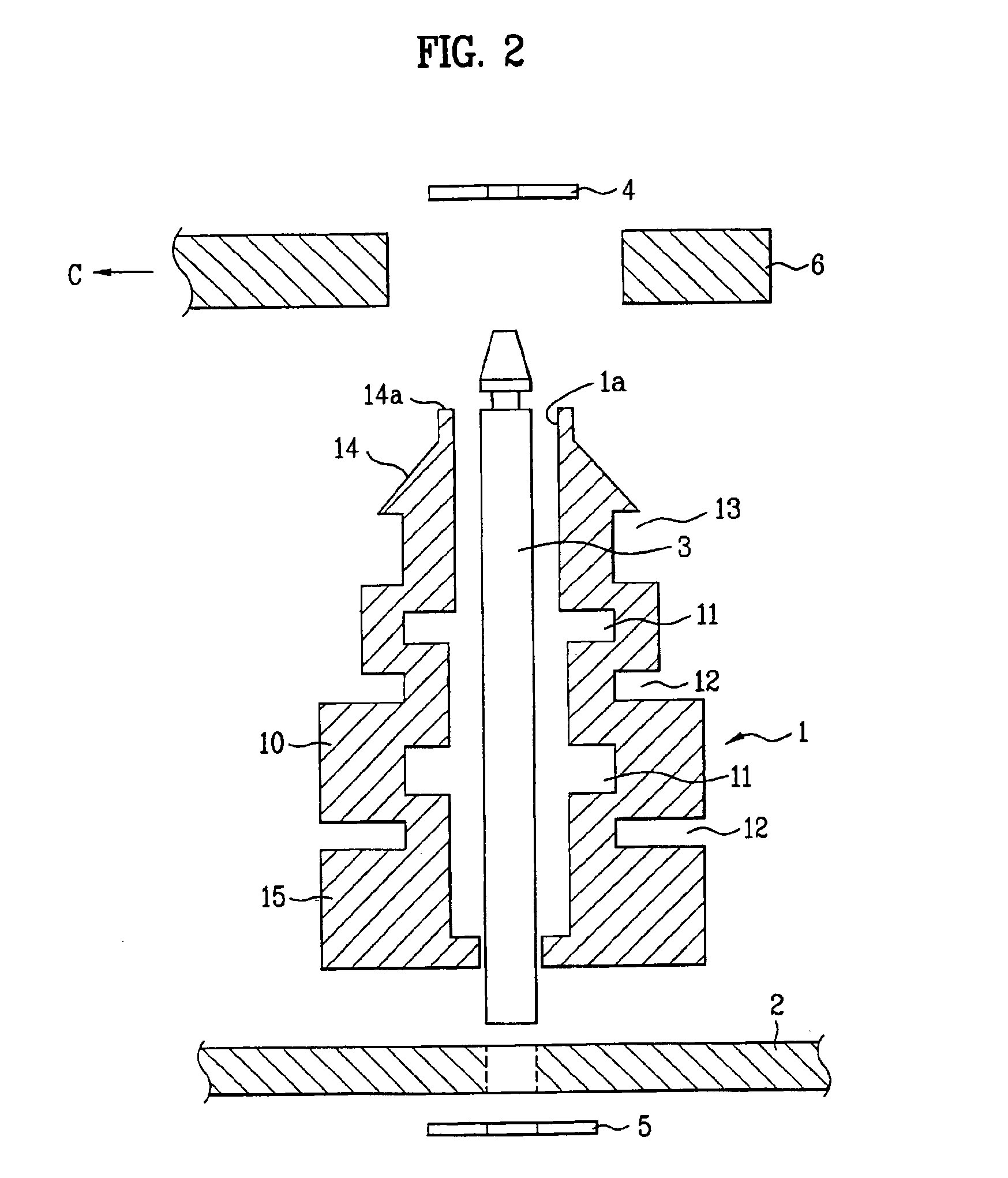

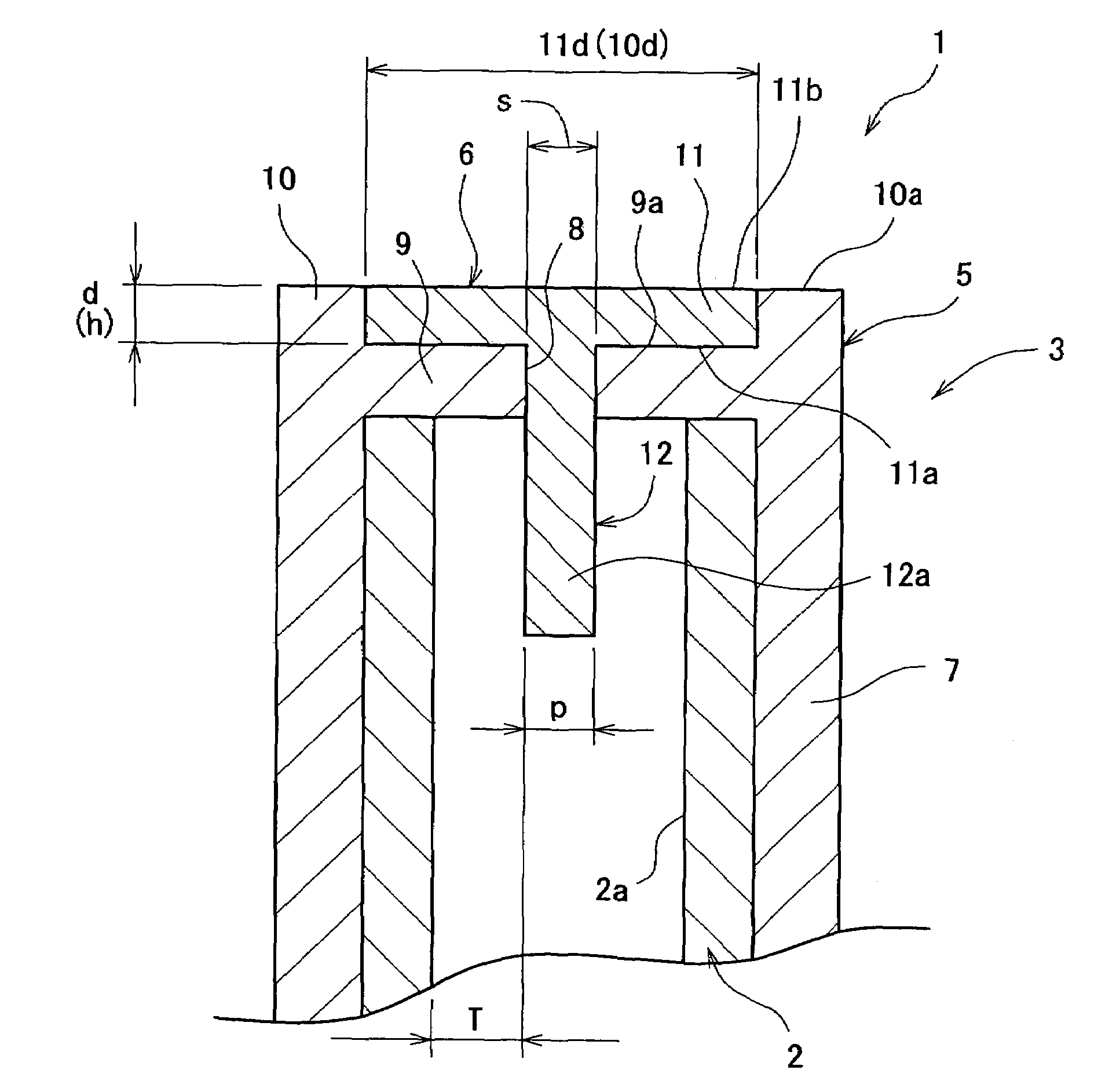

Elastic member and vibration absorption apparatus for a refrigerator compressor

InactiveUS6912865B2Improve absorptionMinimize elastic deformationPortable framesStands/trestlesEngineeringRefrigerated temperature

The present invention relates to an elastic member and apparatus for a refrigerator compressor. A vibration absorption apparatus for a refrigerator compressor according to the present invention is connected to a foot of the compressor for transmitting the vibration generated when the compressor is operated, and includes an elastic member having a hollow passing through the central portion in an axial direction is formed; a base pan installed on a bottom of the refrigerator machinery room, for supporting the elastic member; a stand coupled with the base pan and passing through the hollow of the elastic member; and a stopper installed on the stand, for preventing the elastic member from being escaped from the base pan. The elastic member comprises a body having a plurality grooves enclosing an inner surface and outer surface thereof to have a vertical section in a zigzag; a projection of an upper portion of the body to which the stopper is forcedly attached; and a base being a lower portion of the body.

Owner:LG ELECTRONICS INC

Golf club grip and golf club using the same

A golf club grip includes: a grip body including a grip cylinder portion and a grip end portion disposed at one end of the grip cylinder portion and formed with a through-hole for communicating a grip interior with the outside; and a vibration absorption member formed from a viscoelastic material and formed separately from the grip body. The vibration absorption member is removably attached to the grip body. The vibration absorption member includes: a plane portion and a bar-like portion formed integrally with the plane portion. The bar-like portion extends through the through-hole of the grip end portion as projecting inwardly of the grip cylinder portion.

Owner:SUMITOMO RUBBER IND LTD

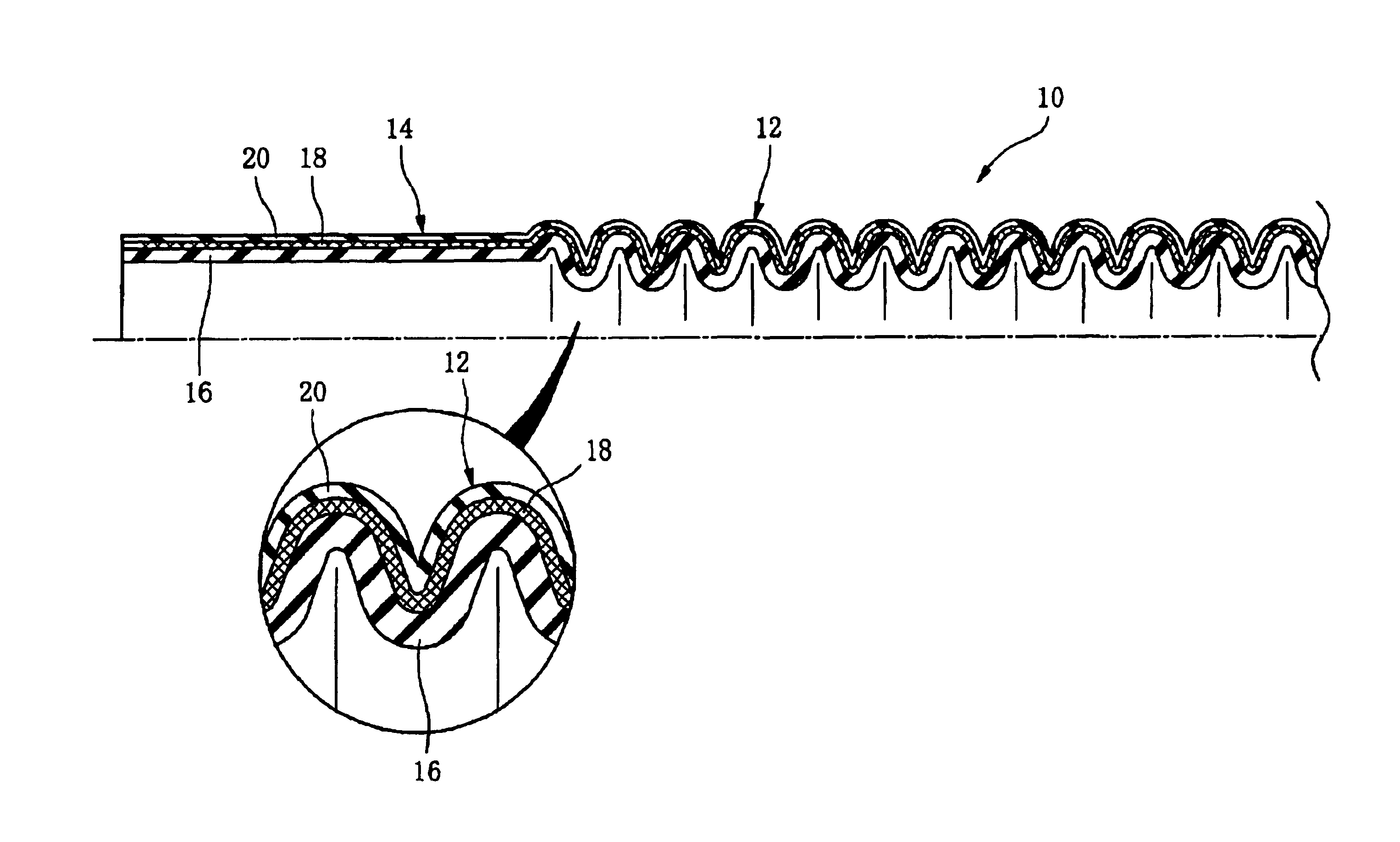

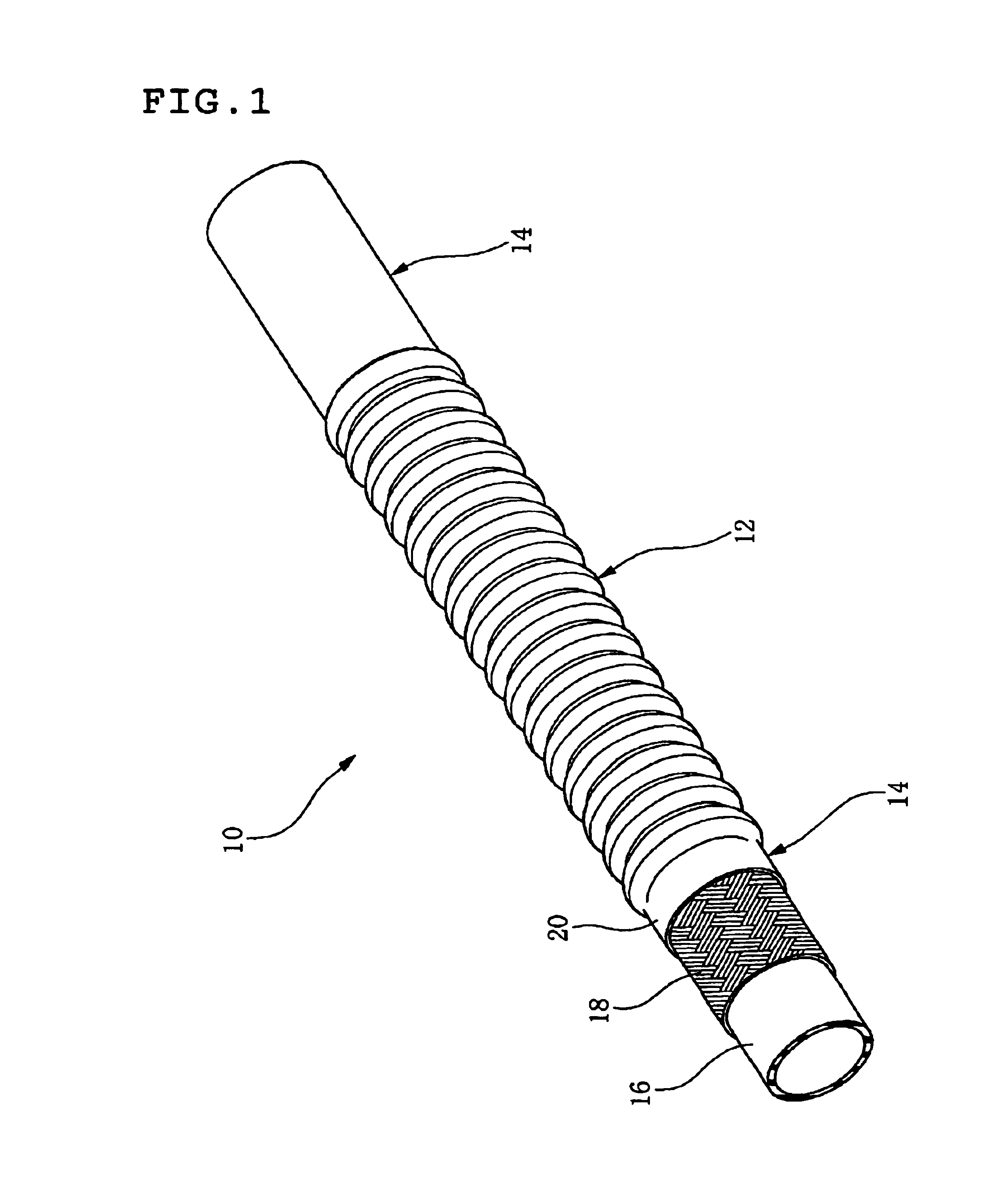

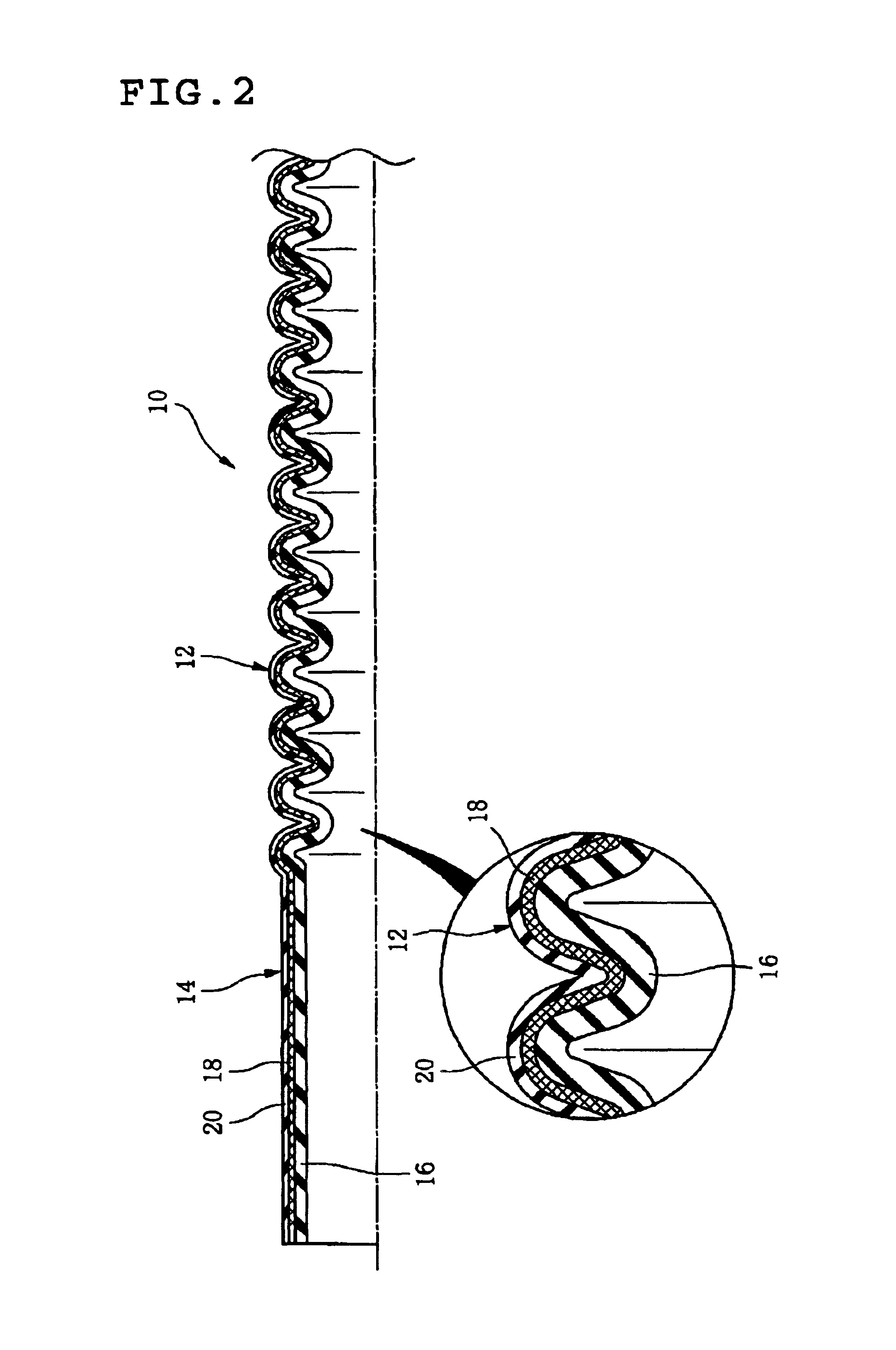

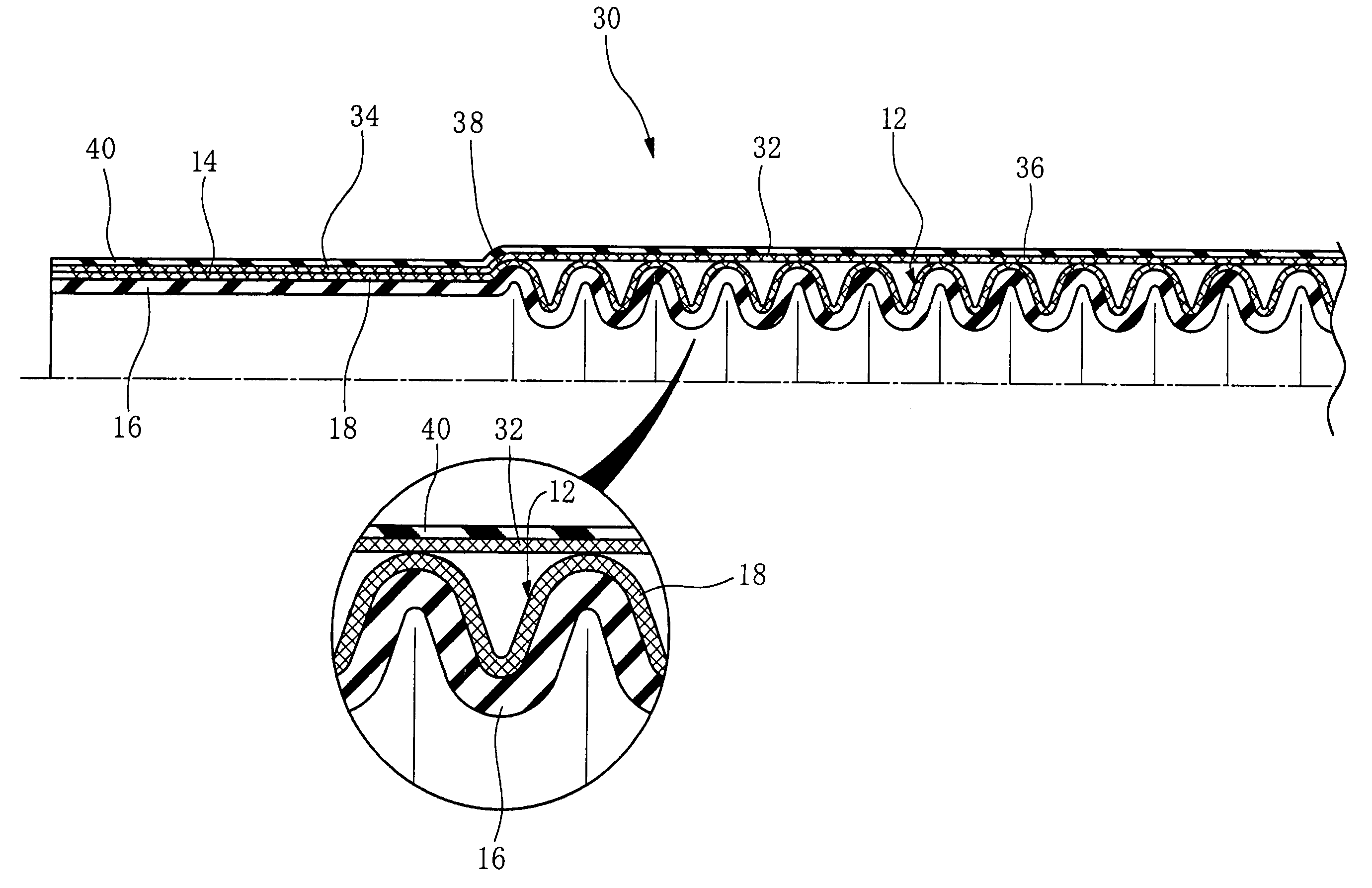

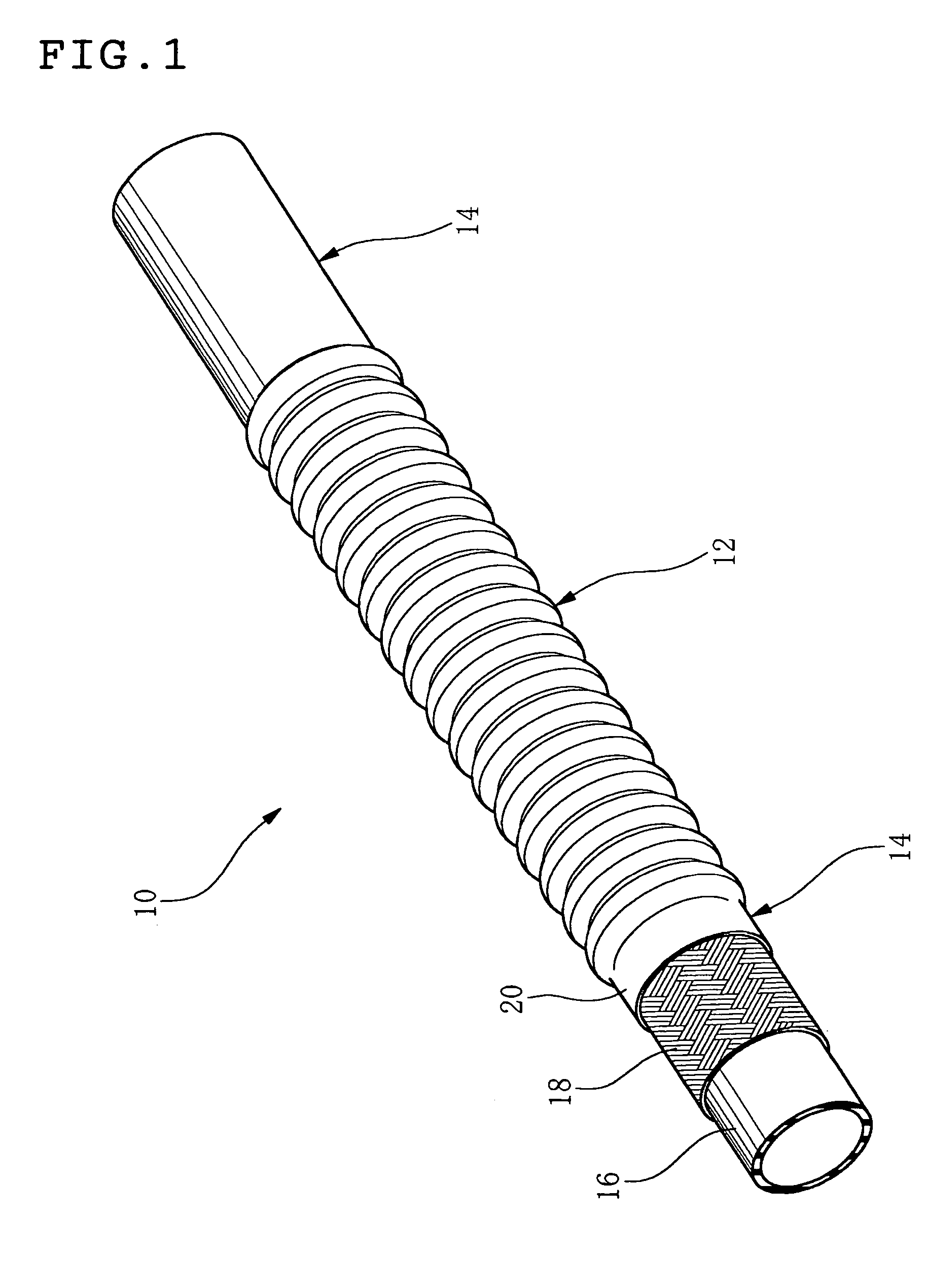

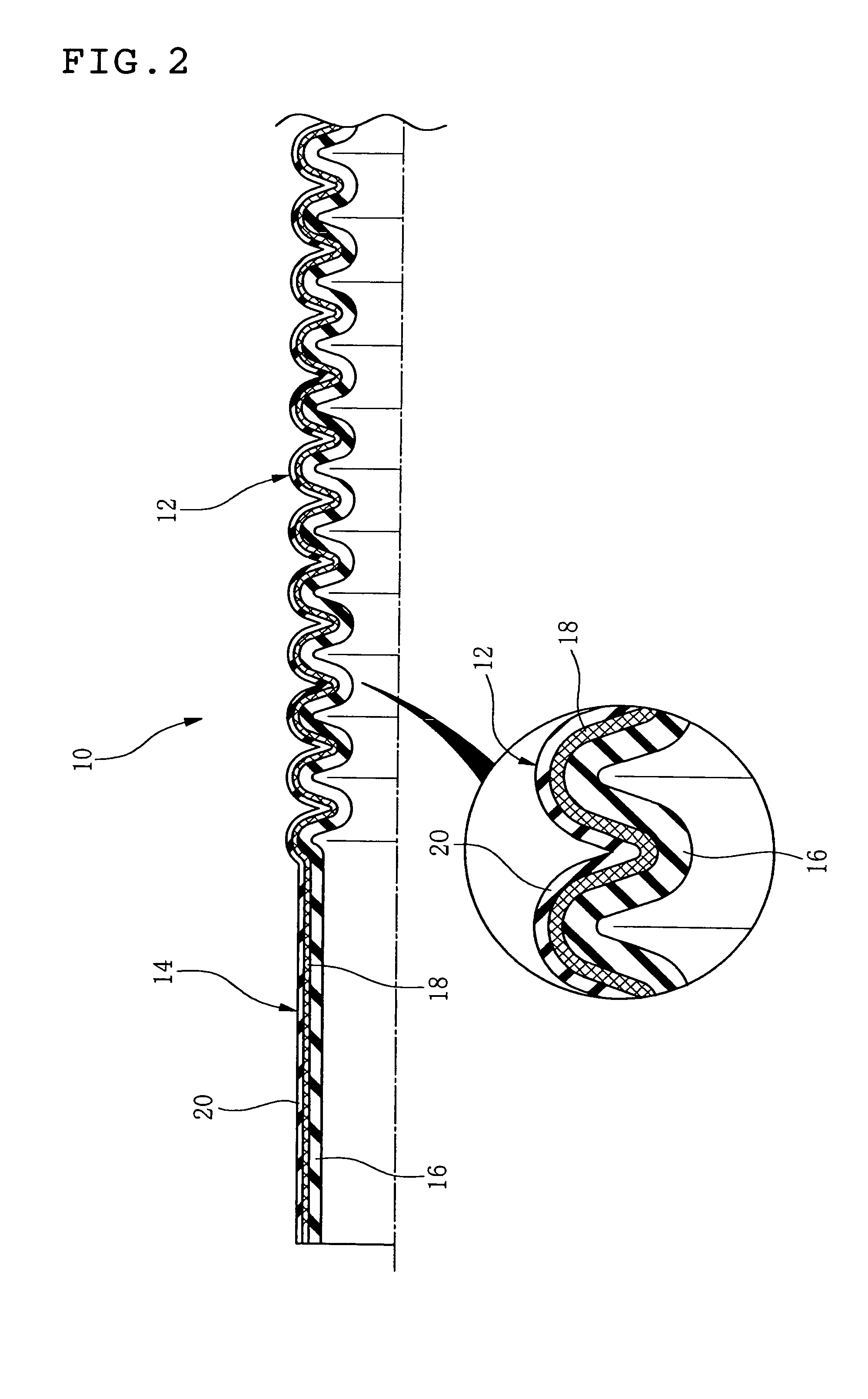

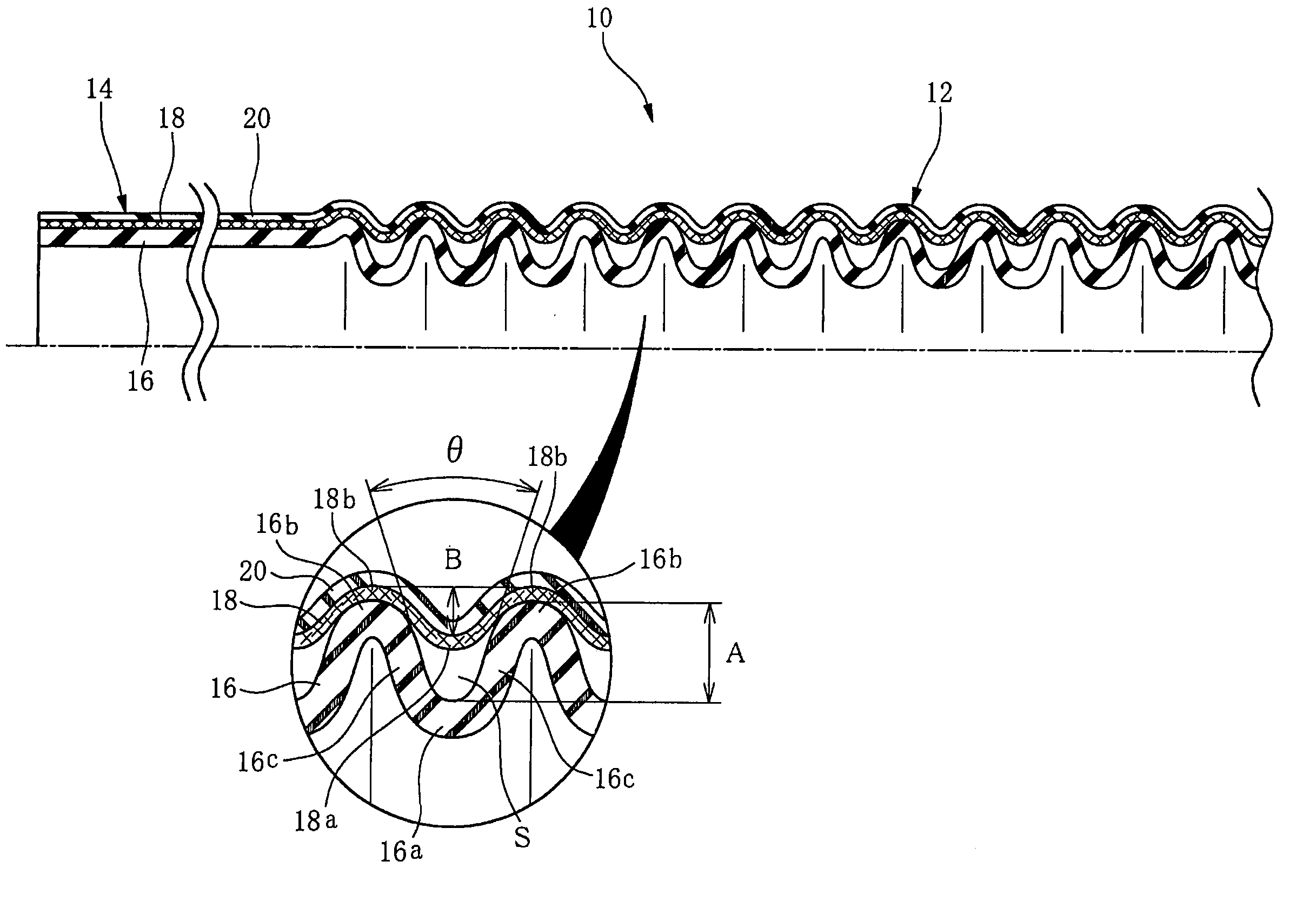

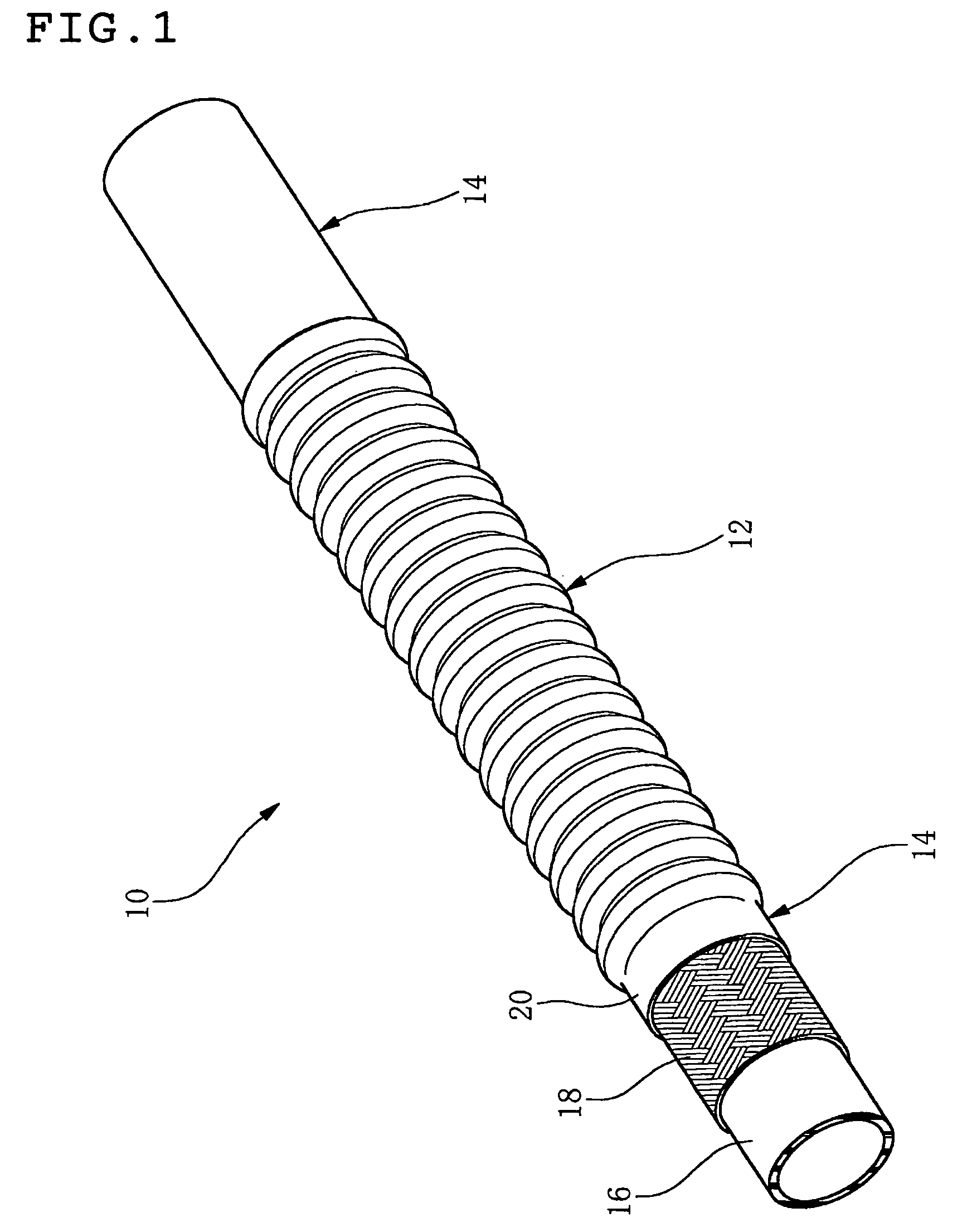

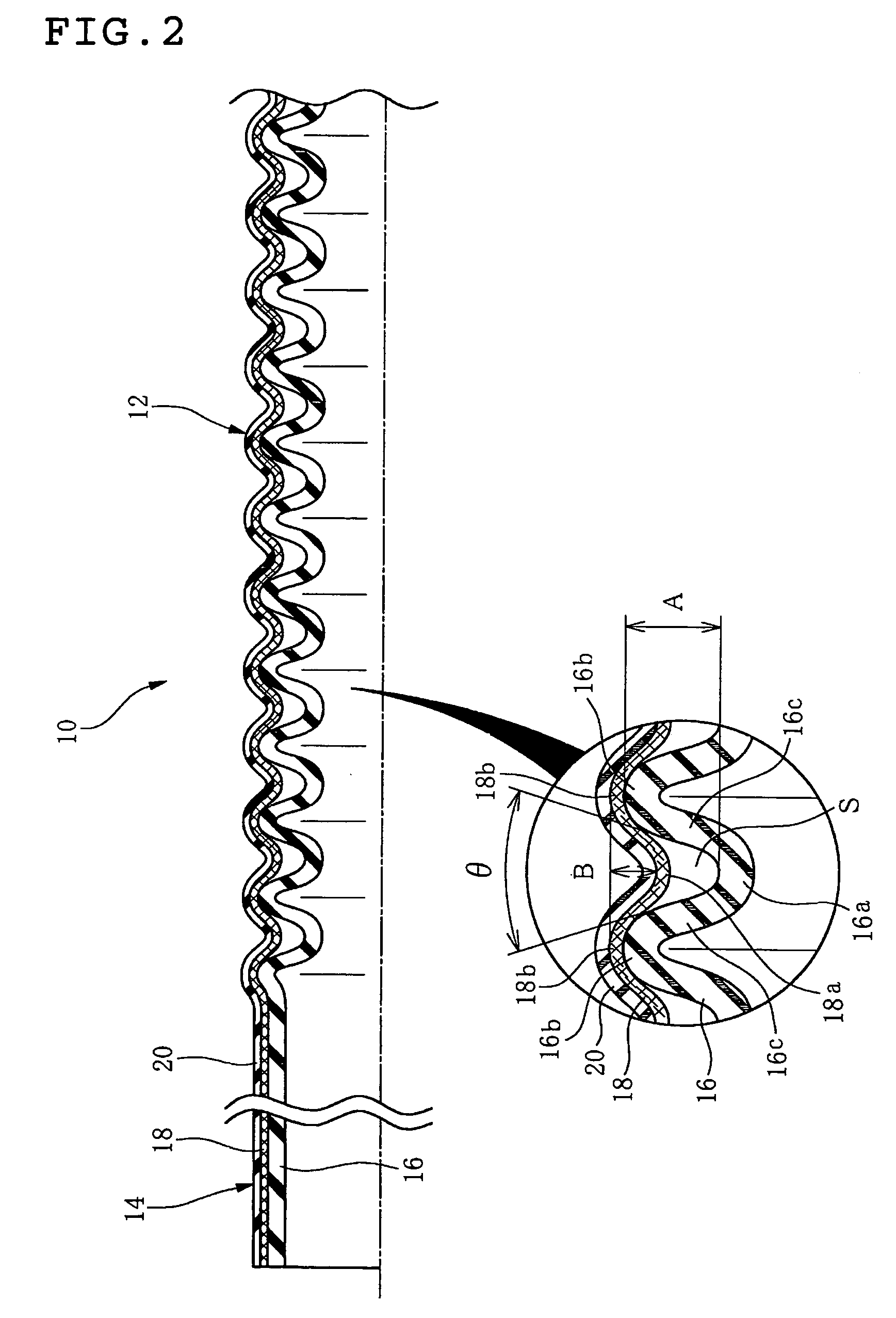

Vibration absorbing hose

InactiveUS6935378B2Large effect to gas permeation resistanceReduce resistanceSpringsLayered productsEngineeringAspect ratio

A vibration absorbing hose including a corrugated portion has multi-layered construction of tubular inner rubber layer, pressure resistant reinforcement layer circumscribing an outer side of the inner rubber layer and outer rubber layer as outermost cover layer. The pressure resistant reinforcement layer is formed, for example, by providing reinforcing yarns, so as to have corrugations along the corrugated portion of the inner rubber layer. The inner rubber layer contains scaly filler in an amount of 50 phr to 200 phr so as to be oriented in a stretching direction of the inner rubber layer. The scaly filler has an aspect ratio of 2 to 90.

Owner:SUMITOMO RIKO CO LTD

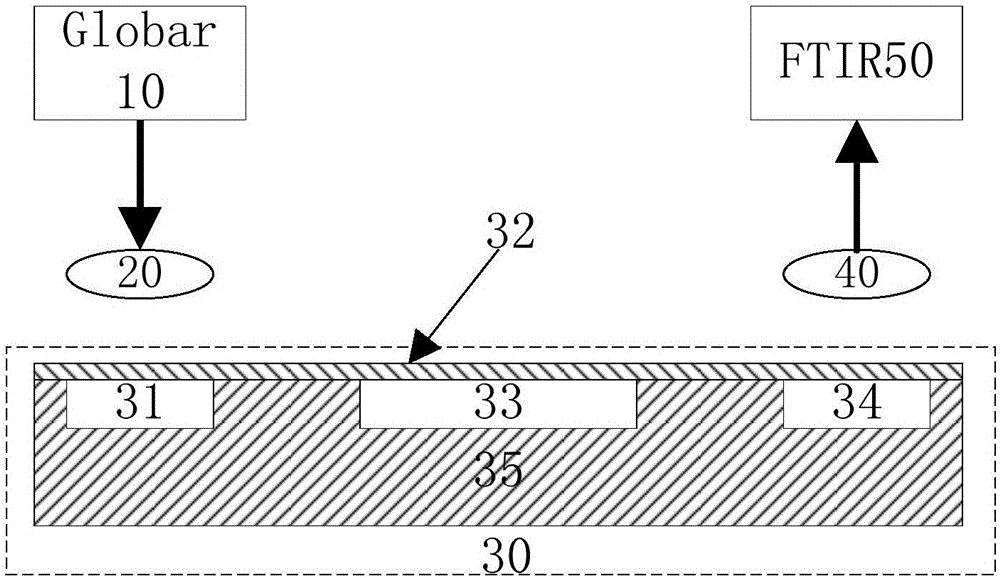

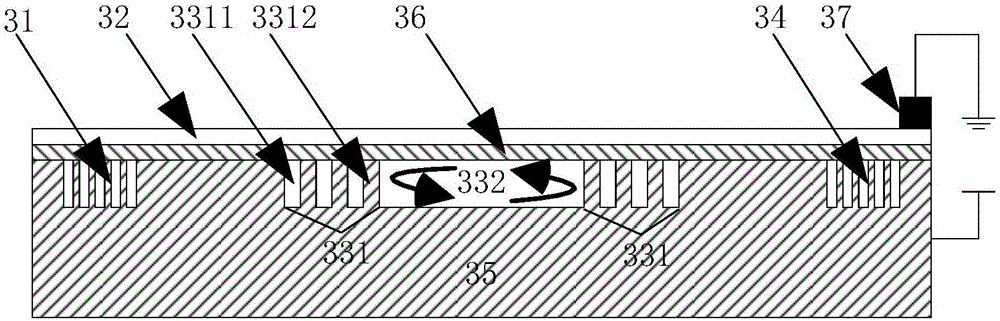

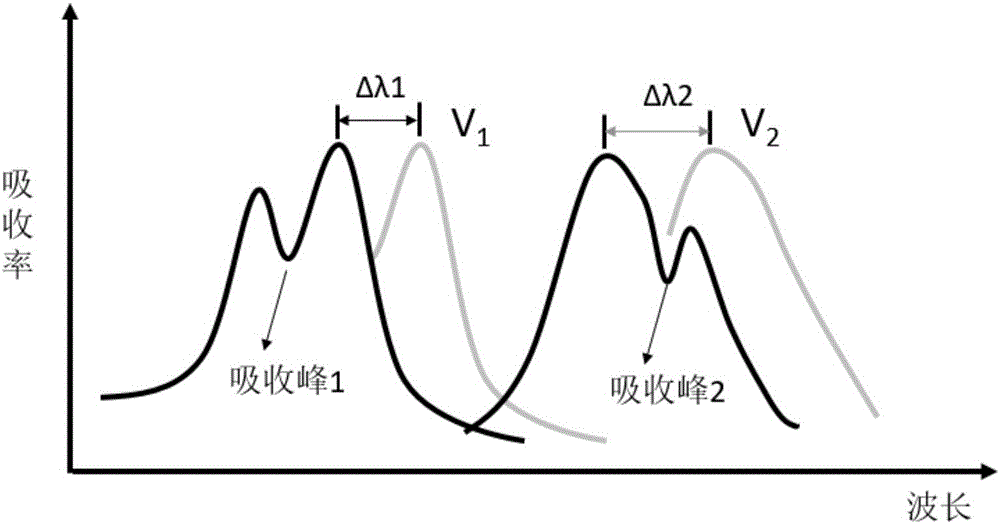

Intermediate infrared graphene plasmon polariton biochemical sensor

ActiveCN106596449AImproved vibration absorption performanceHigh sensitivityPhase-affecting property measurementsColor/spectral properties measurementsInfraredGrating

The invention discloses an intermediate infrared graphene plasmon polariton biochemical sensor. The intermediate infrared graphene plasmon polariton biochemical sensor comprises an intermediate infrared broad band optical source, a first intermediate infrared lens, a graphene plasmon polariton sensing unit and a second intermediate infrared lens; the graphene plasmon polariton sensing unit comprises a doped silicon substrate, a first grating coupling area, a second grating coupling area, a sensing area, and a graphene layer, wherein the graphene layer covers the first grating coupling area, the second grating coupling area and the sensing area; an intermediate infrared light wave emitted by the broad band optical source is focused in the first grating coupling area through the first intermediate infrared lens so as to be coupled with a graphene plasmon polariton, the produced intermediate infrared graphene plasmon polariton reaches the sensing area through the graphene layer, repeatedly reacts with a biological sample in the sensing area, reaches the second grating coupling area through the graphene layer, is scattered to the far field, and is focused to a fourier infrared spectrometer through the second intermediate infrared lens to implement spectral measurement and analysis. The intermediate infrared graphene plasmon polariton repeatedly reacts with the biological sample in the sensing area, and the detection sensitivity of biomolecules is improved.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

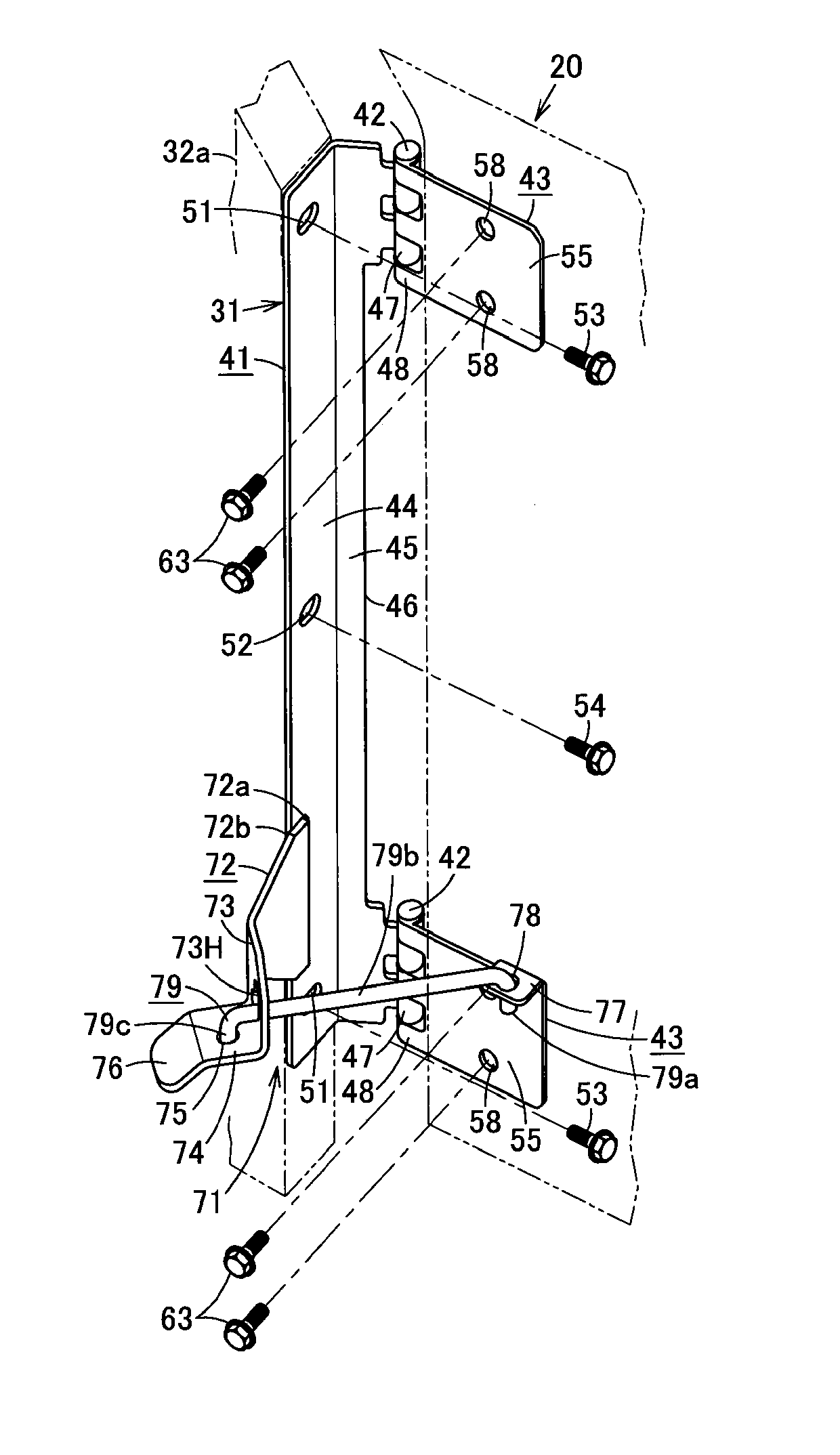

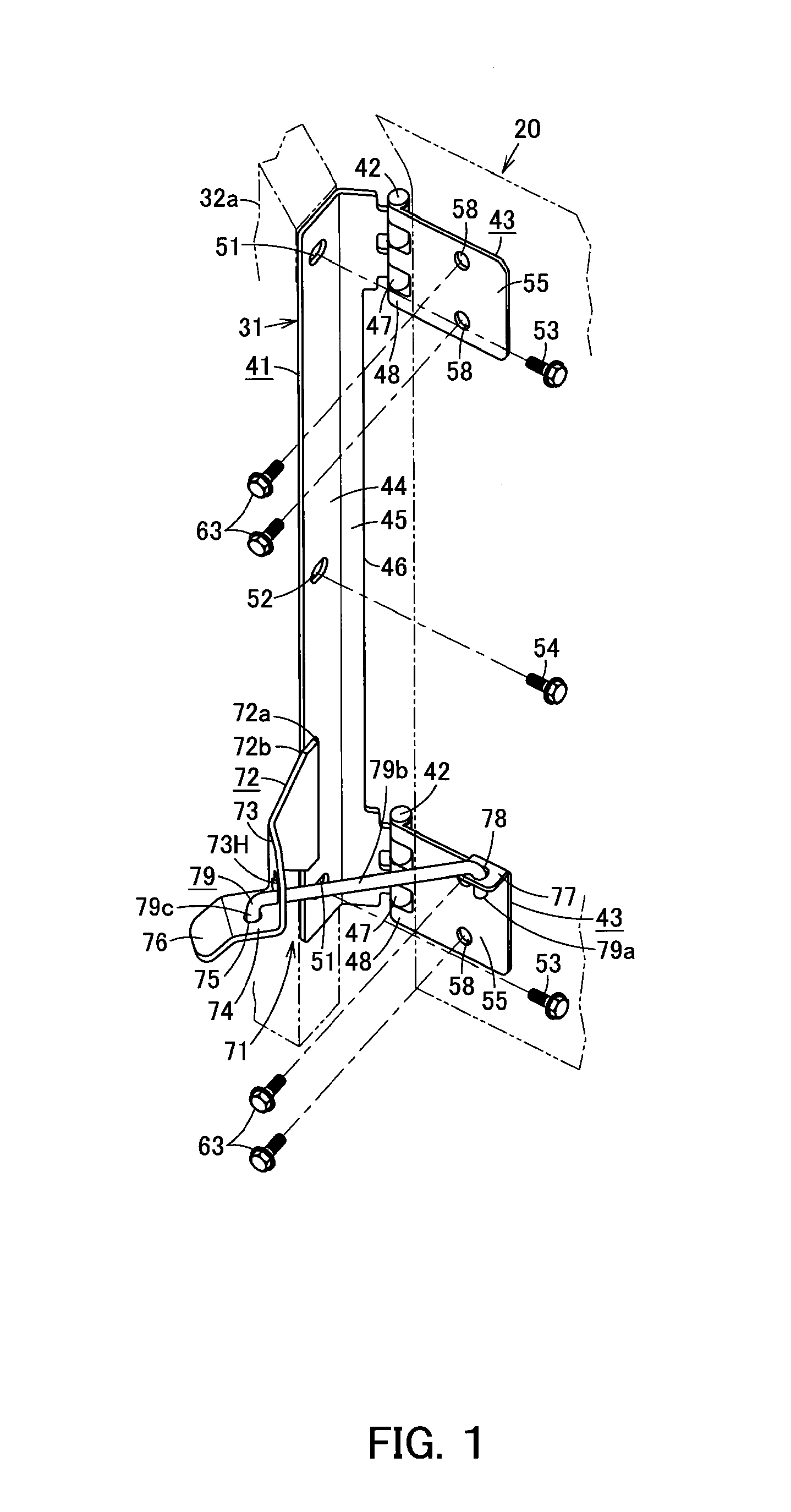

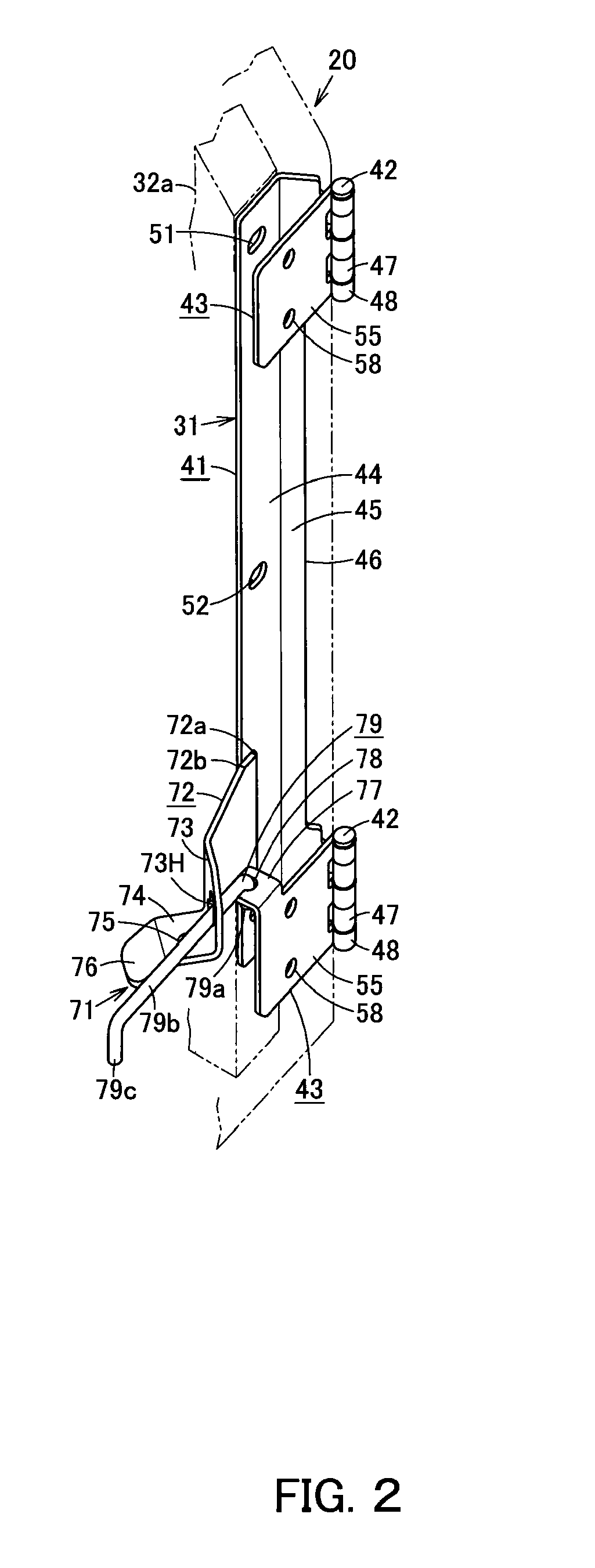

Hinge and door unit

InactiveUS20110126469A1Easily and finely stateImproving mounting workabilityWing accessoriesWing fastenersEngineeringMechanical engineering

Owner:CATEPILLAR SARL

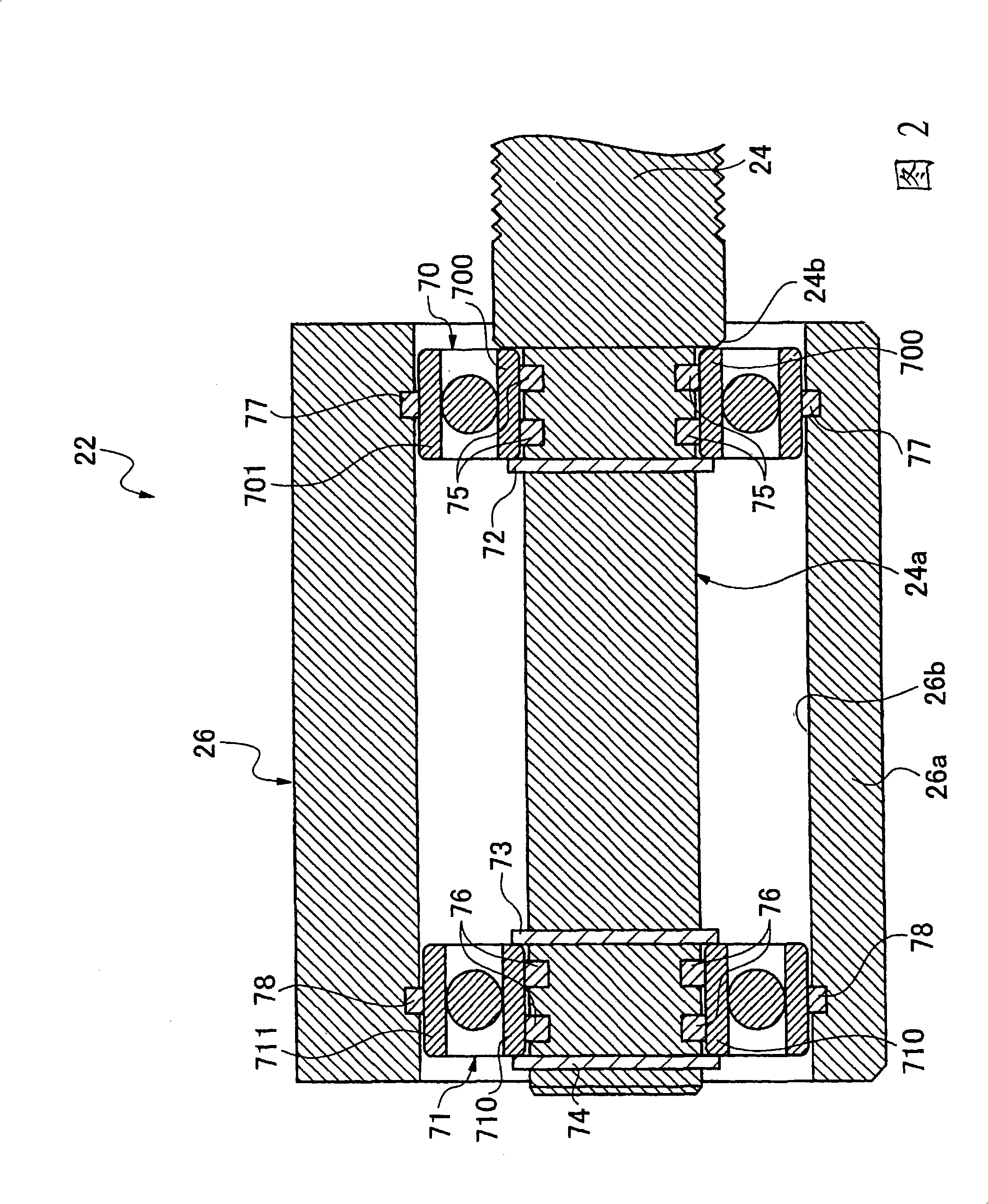

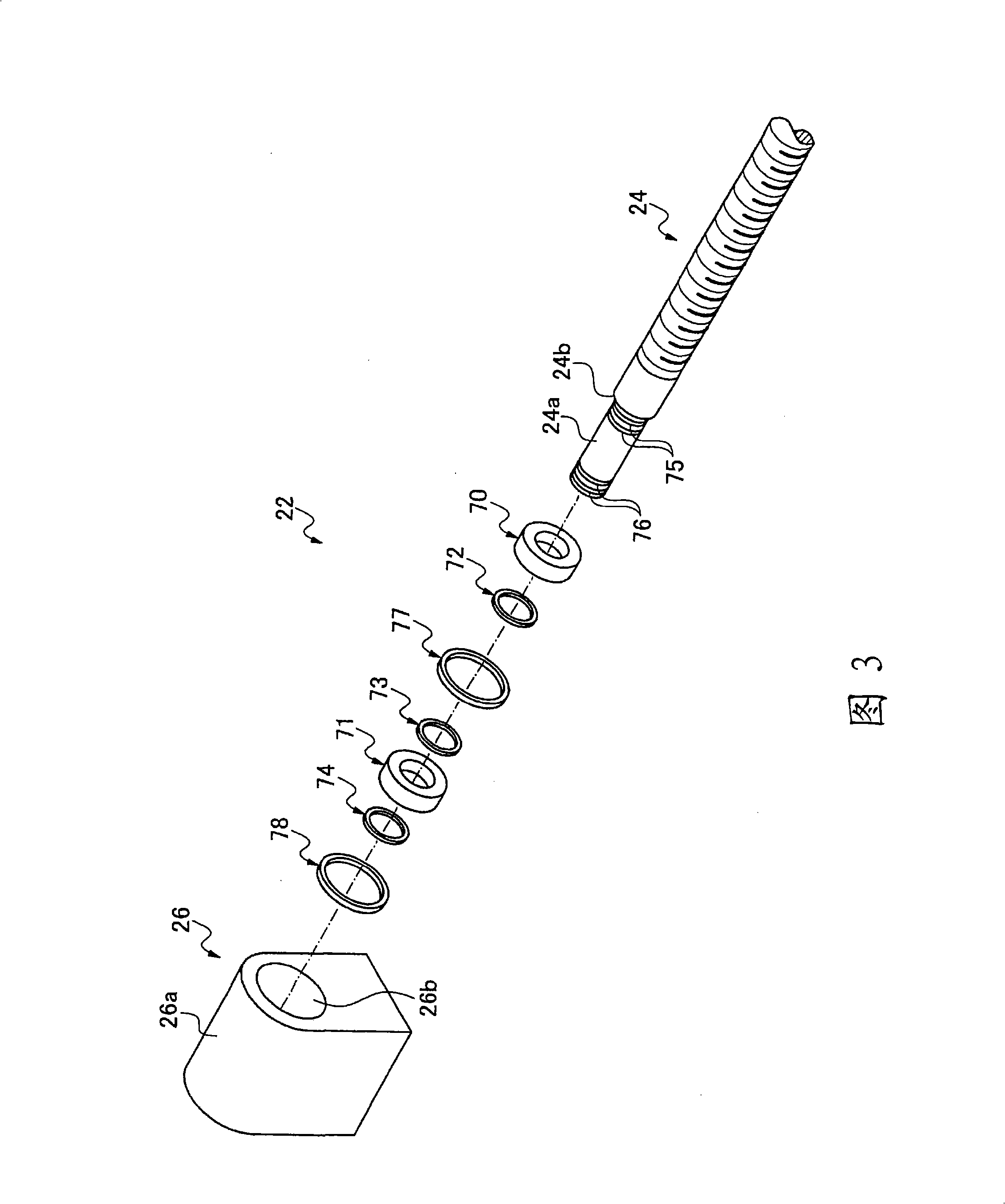

Driving mechanism and cutting apparatus

InactiveCN101256979AReduce vibrationReduce slidingRolling contact bearingsSemiconductor/solid-state device manufacturingBall bearingEngineering

The invention provides a driving mechanism and a cutting device, wherein one end of the feed screw shaft of the driving mechanism is connected with a driving source, while the other end is supported rotatably, moving with a plurality of slide bodies connected with the feed screw screwed on the feed screw shaft, which prevents the vibration of the feed screw shaft in such a driving mechanism with the structure. A driving mechanism having a driving unit in which a drive source is connected to a feed screw shaft and a feed nut is in screw engagement with the feed screw shaft and connected to an active element through a sliding body, wherein the active element is moved by being driven by the driving unit. An inner ring of a bail bearing for supporting the feed screw shaft is fixed to the outer periphery of a free end portion of the feed screw shaft, and an outer ring elastic body which supports an outer ring of the ball bearing slidably in the axial direction of the feed screw shaft and which absorbs vibration of the feed screw shaft is disposed at the inner periphery of a tubular portion for containing the ball, bearing at a terminal support portion.

Owner:DISCO CORP

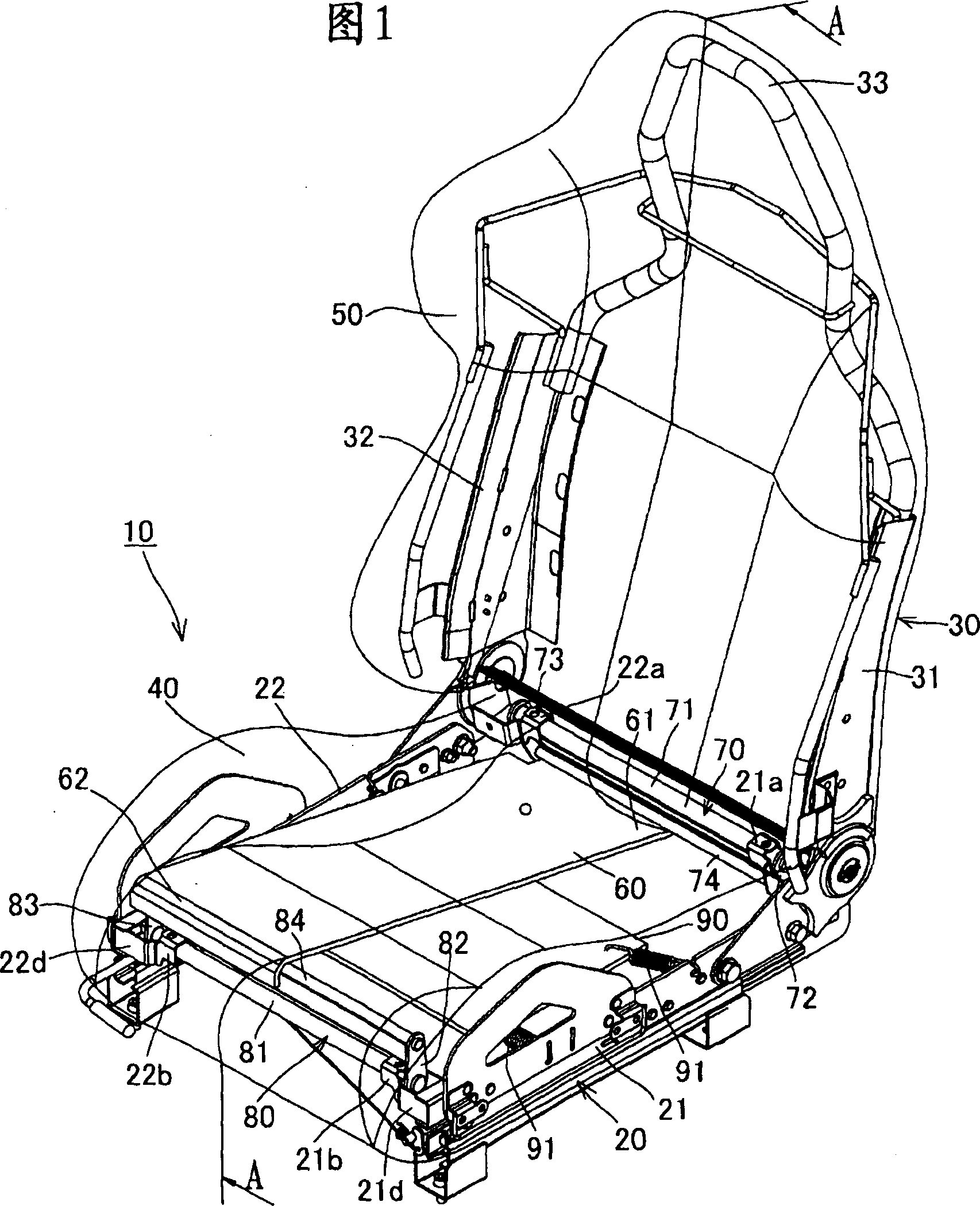

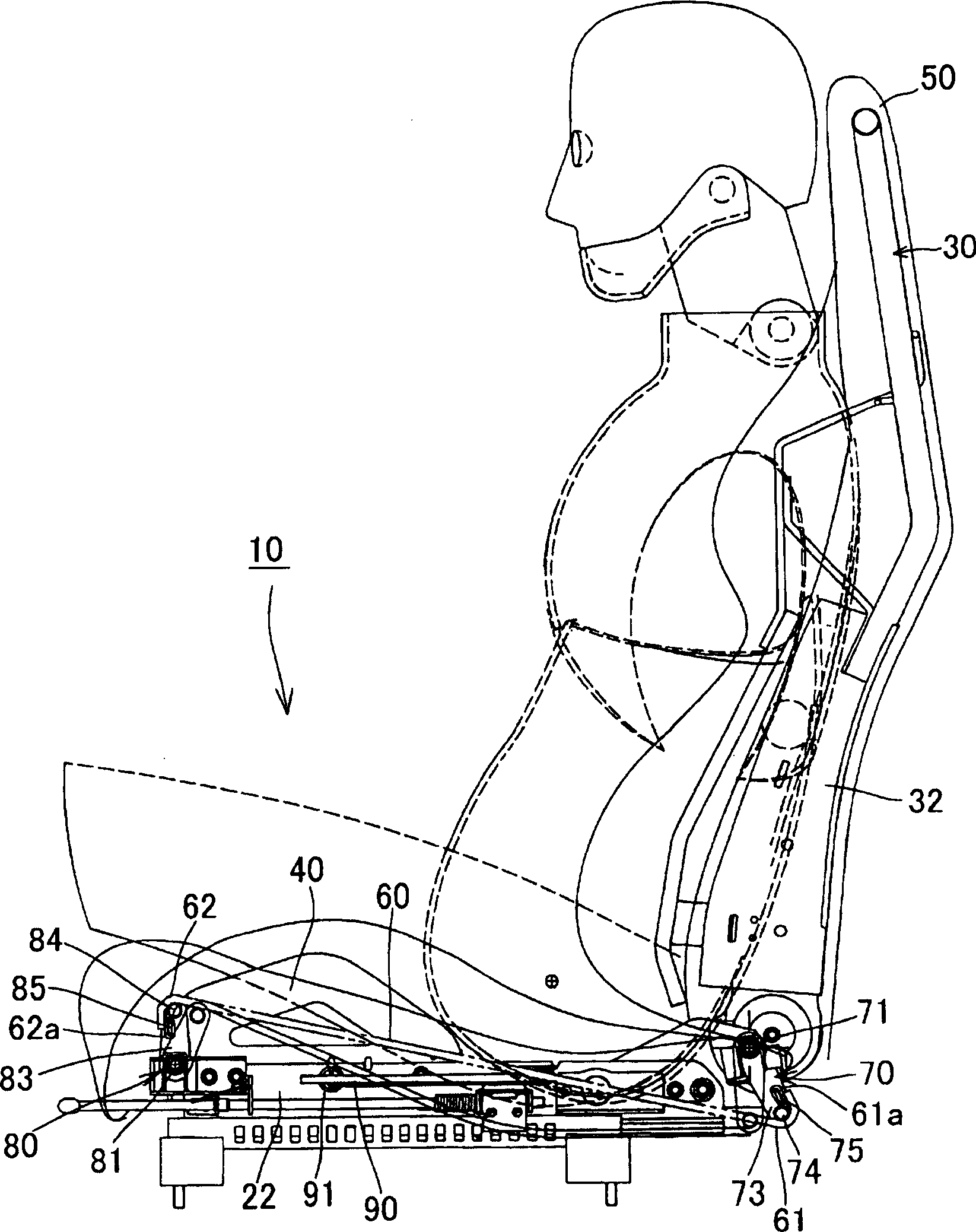

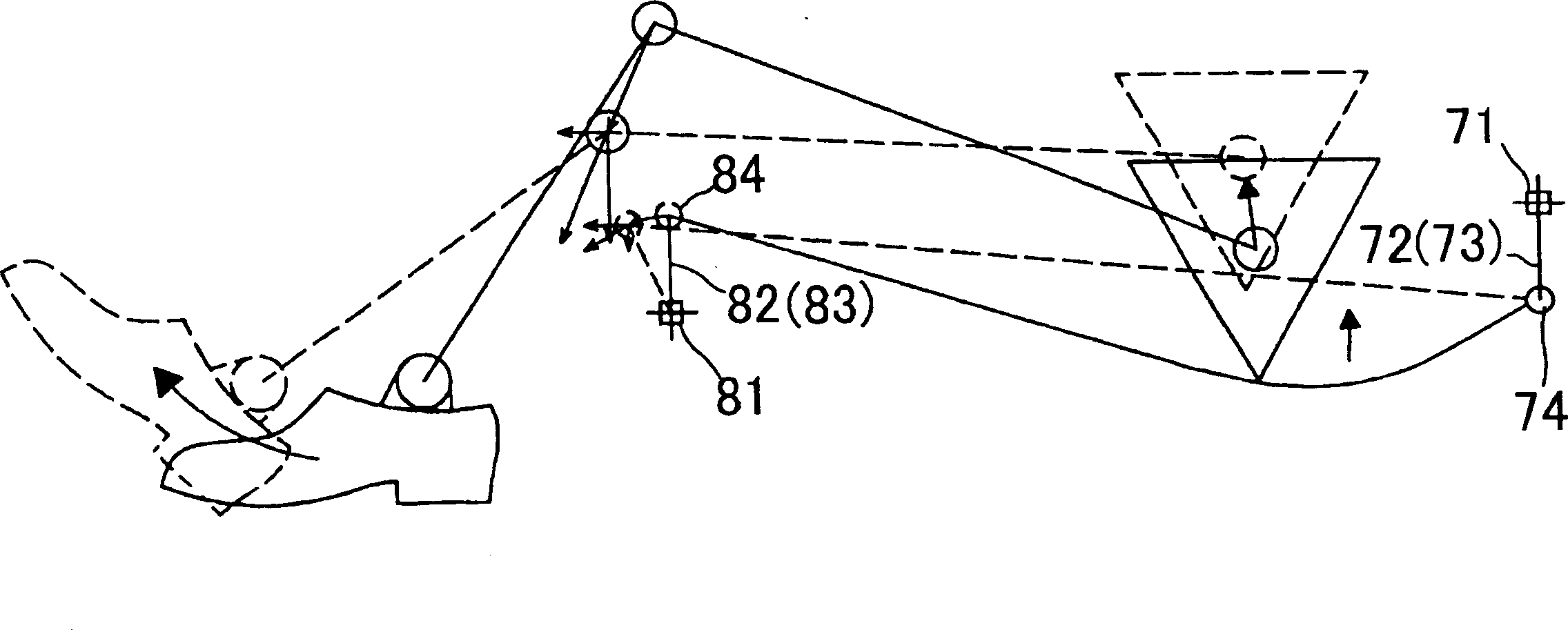

Base net supporting mechanism for seat and seat structure thereof

ActiveCN1880122AImprove the sense of strokeImprove sitting comfortSeat framesStoolsCushionEngineering

In order to improve seating comfort and vibration absorbency, a structure including a first torsion bar unit 70 disposed in the rear of a seat cushion, and a second torsion bar unit 80 disposed in the front of the seat cushion, and a base net 60 stretched between a rear supporting frame 74 of the first torsion bar unit 70 and a front supporting frame 84 of the second torsion bar unit 80, is provided. Owing to the elastic force of a front torsion bar 81 of the second torsion bar unit 80 positioned in the front of the seat, a sense of stroke at the time of seating is enhanced. Owing to the elastic force of a rear torsion bar 71 of the first torsion bar unit 70 positioned in the rear of the seat, similarly to the conventional structure, a load of a seated person can be sufficiently received and a stable seating comfort can be obtained. Since both the first torsion bar unit 70 and the second torsion bar unit 80 work together to vibration inputted during driving, vibration absorbency is more enhanced than ever.

Owner:DELTA TOOLING CO LTD

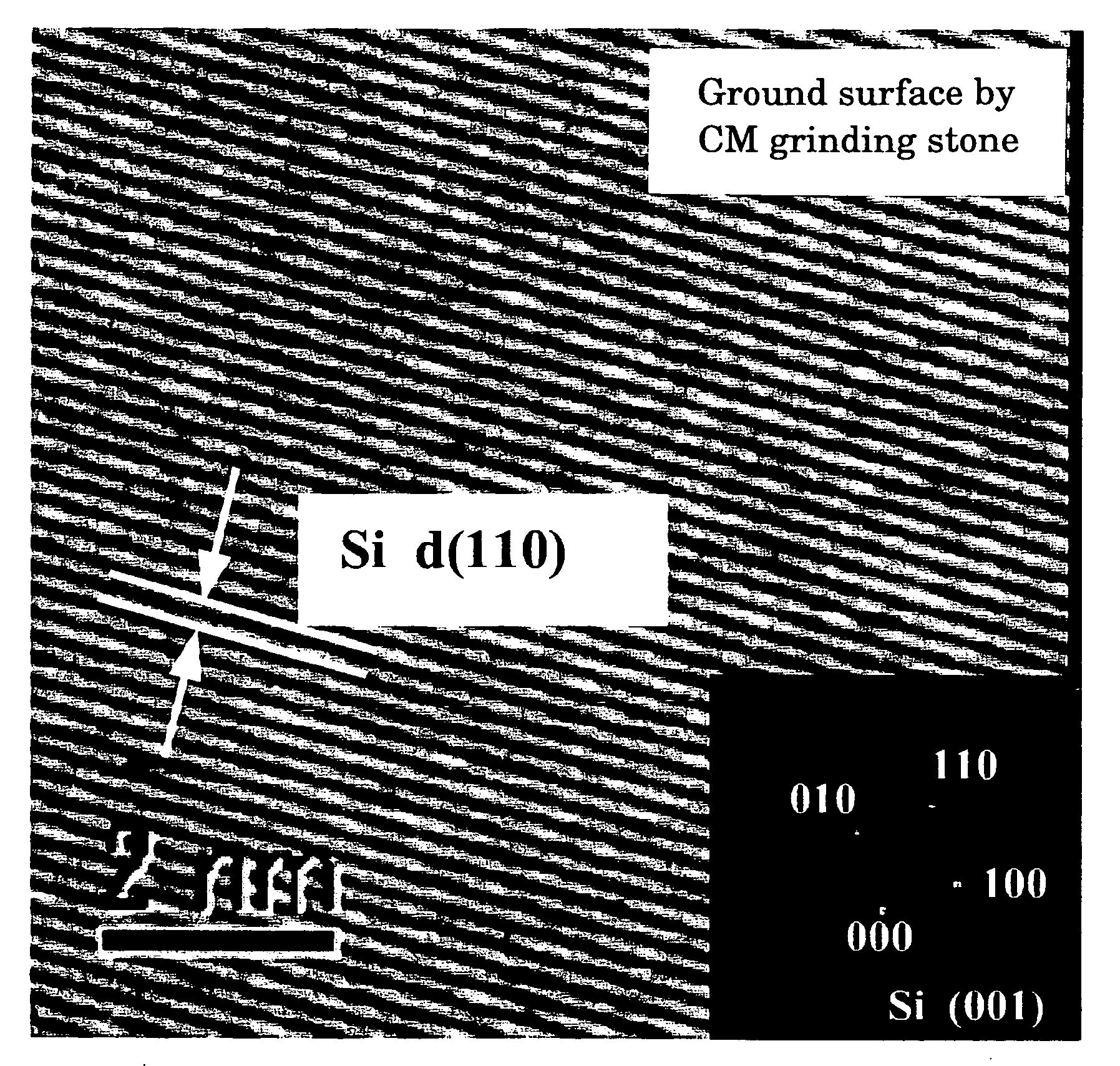

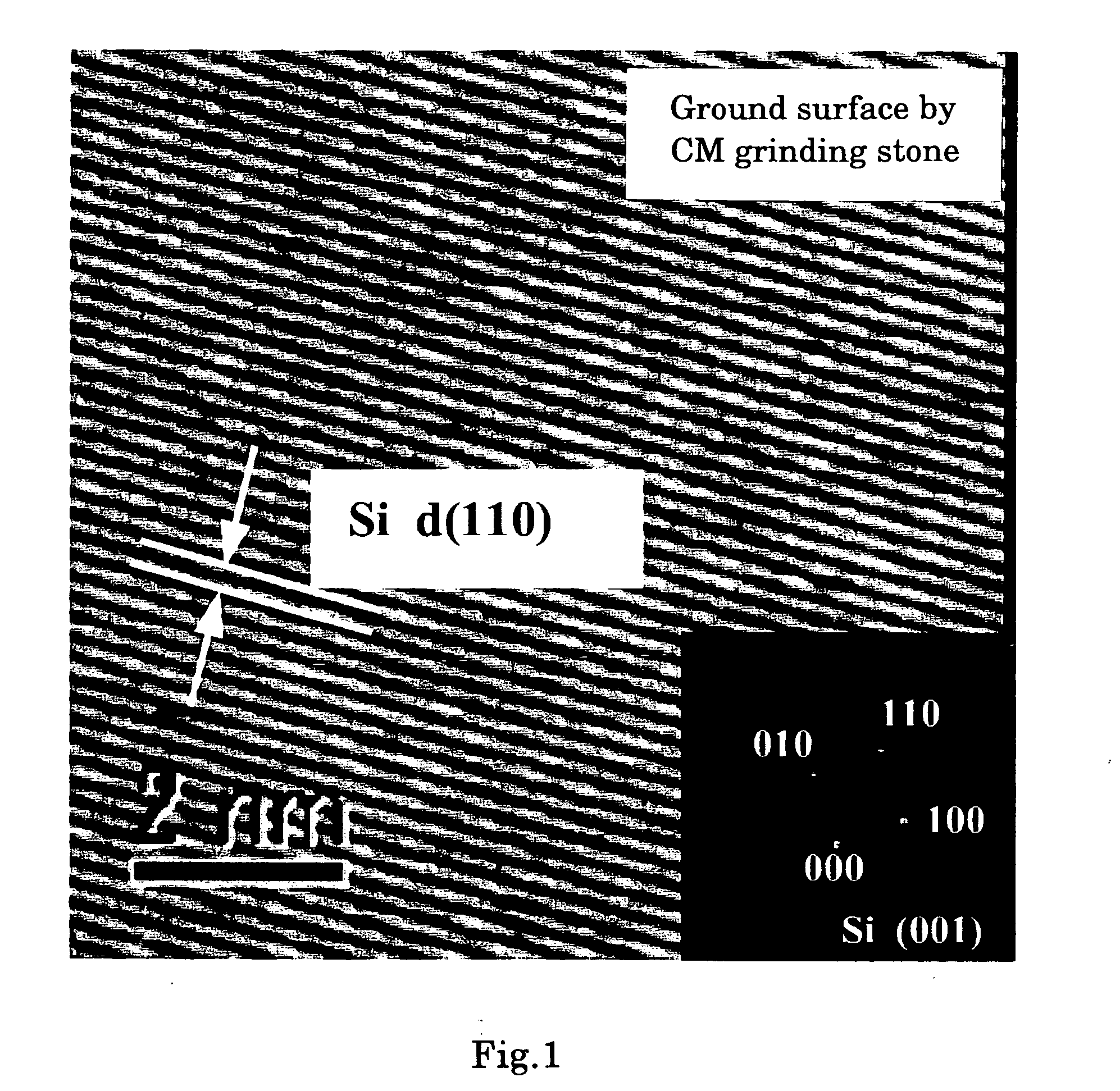

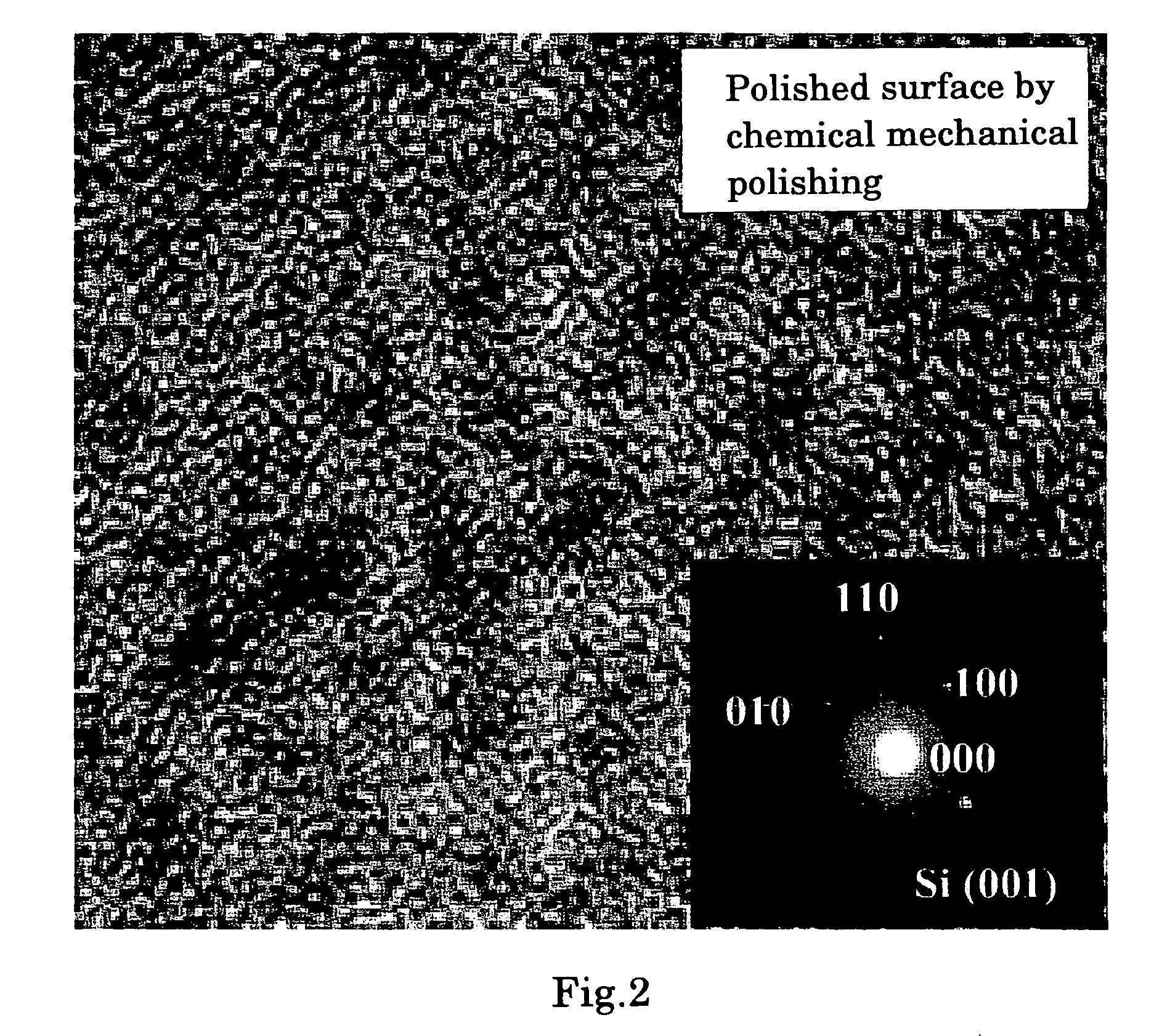

Synthetic grinding stone

ActiveUS20100037530A1Good grinding effectImprove grinding forcePigmenting treatmentOther chemical processesCerium oxideAdamite

Owner:TOKYO DIAMOND KOGU +1

Vibration absorbing hose

Owner:SUMITOMO RIKO CO LTD

Vibration absorbing hose

InactiveUS6983769B2Good flexibilityImproved vibration absorption performanceLayered product treatmentSynthetic resin layered productsYarnEngineering

Owner:SUMITOMO RIKO CO LTD

Golf club grip and golf club using the same

A golf club grip includes: a grip body including a grip cylinder portion and a grip end portion disposed at one end of the grip cylinder portion and formed with a through-hole for communicating a grip interior with the outside; and a vibration absorption member formed from a viscoelastic material and formed separately from the grip body. The vibration absorption member is removably attached to the grip body. The vibration absorption member includes: a plane portion and a bar-like portion formed integrally with the plane portion. The bar-like portion extends through the through-hole of the grip end portion as projecting inwardly of the grip cylinder portion.

Owner:SUMITOMO RUBBER IND LTD

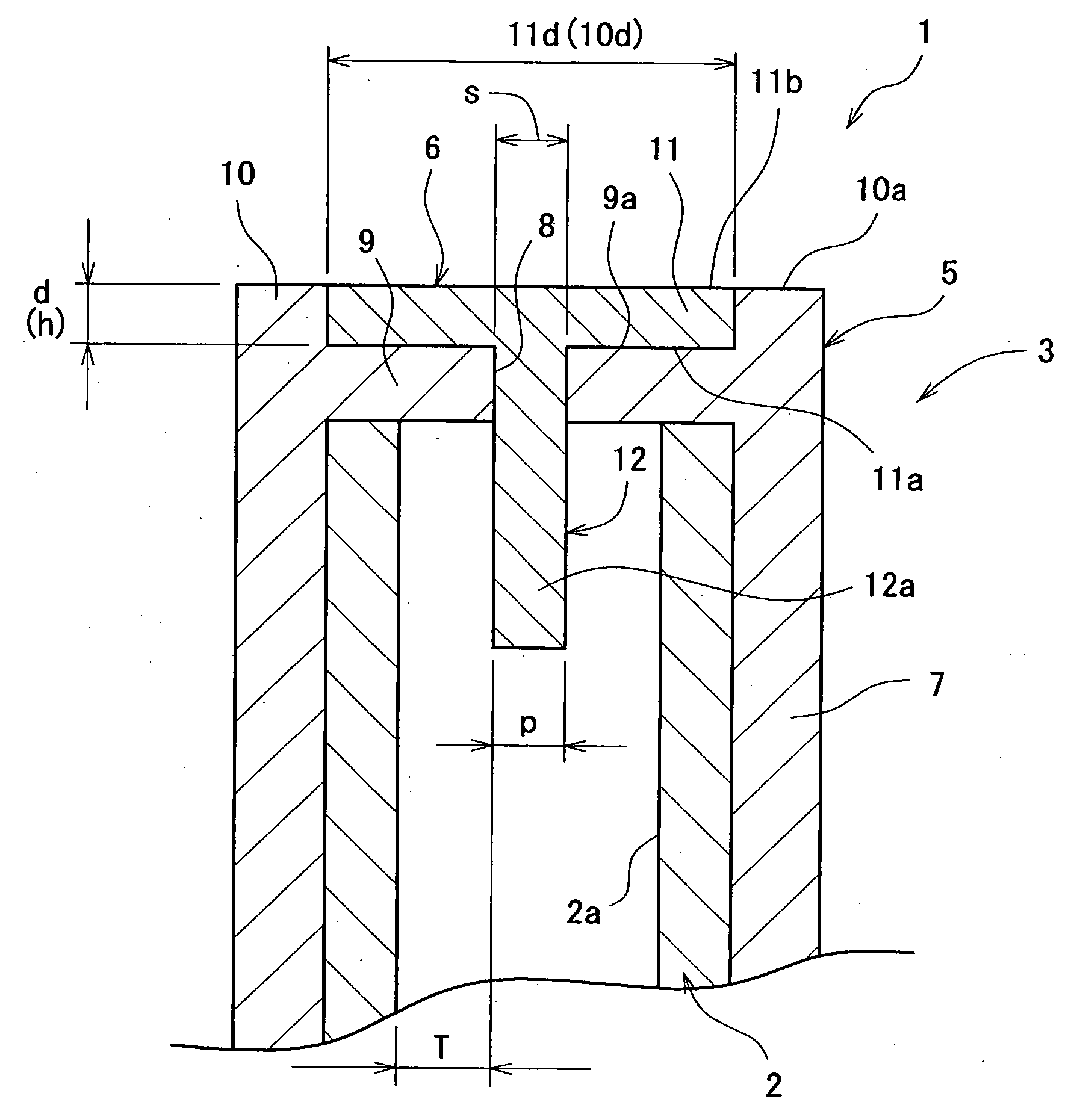

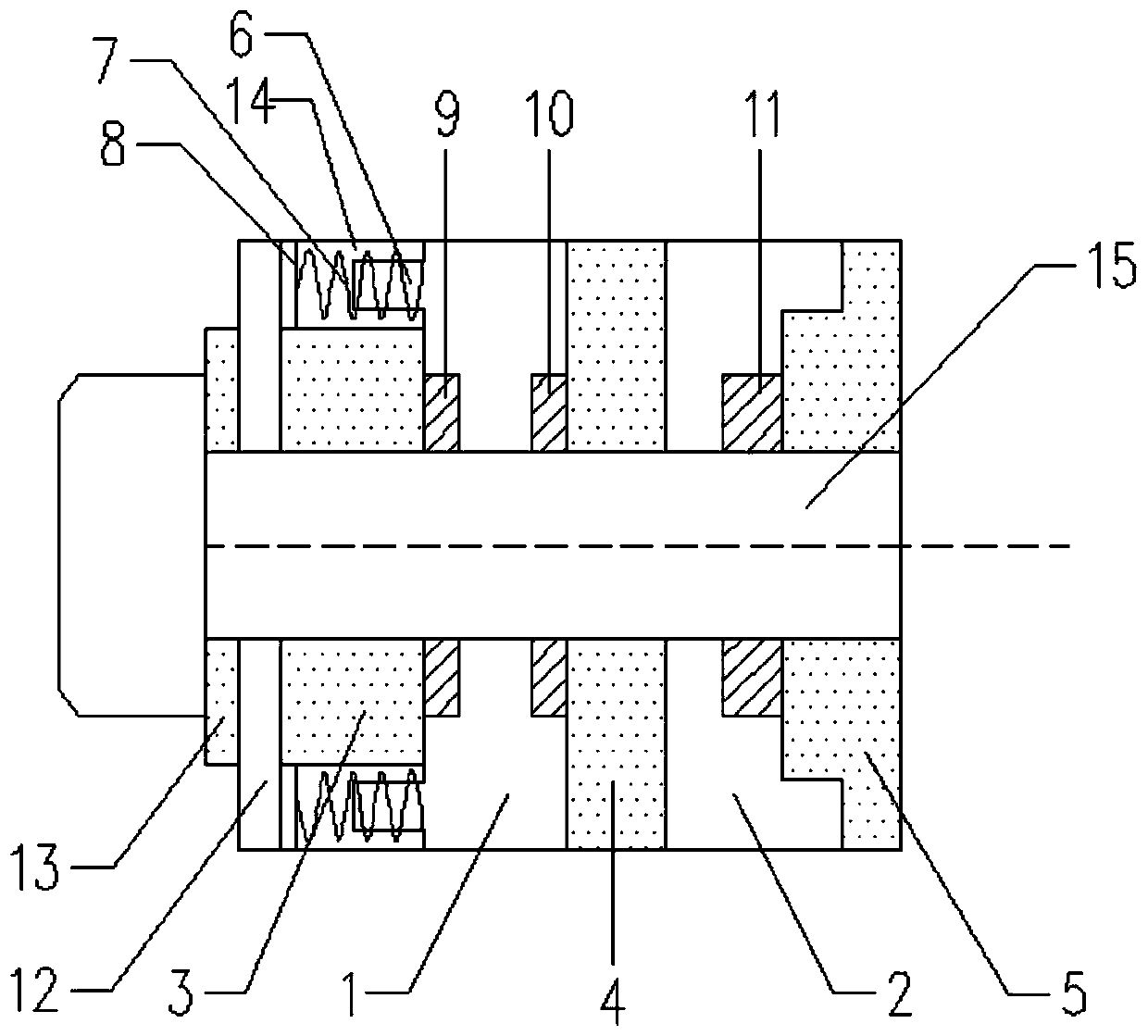

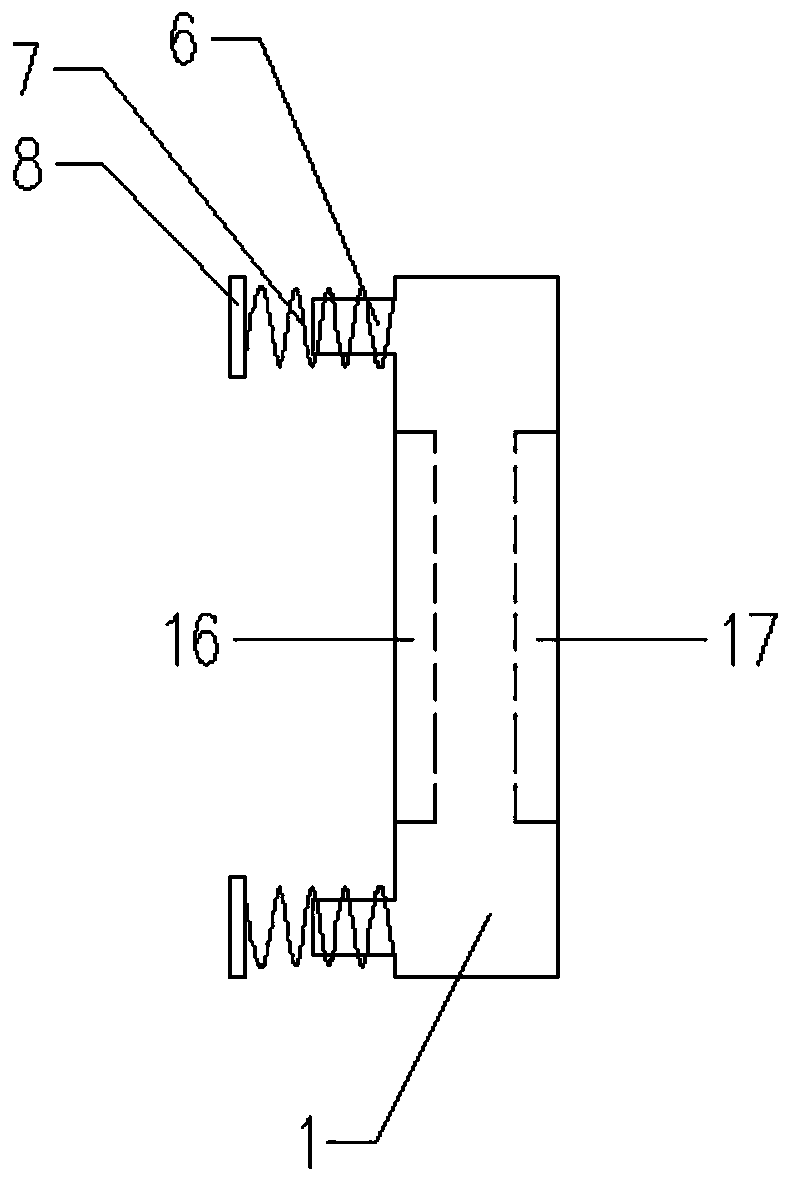

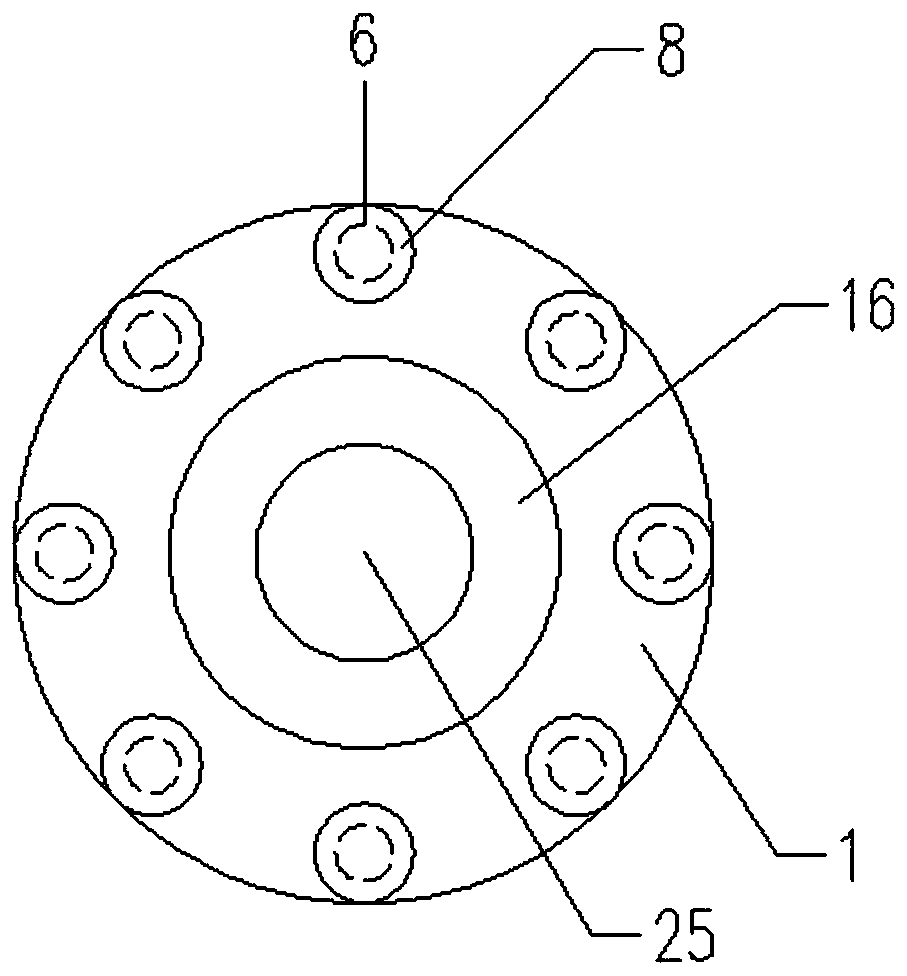

Damping energy dissipation device of shield tunnel bolt joint

ActiveCN110107577AEasy to installStrong shock absorption and energy dissipation effectNon-rotating vibration suppressionNutsUltrasound attenuationPetroleum engineering

The invention discloses a damping energy dissipation device of a shield tunnel bolt joint, and belongs to the technical field of shield tunnel shockproof engineering. The damping energy dissipation device comprises a joint gasket, a first rubber gasket, a first sleeve, a second rubber gasket, a second sleeve and a third rubber gasket which are coaxially arranged in sequence, the first sleeve is provided with a first elastic waterproof sealing ring and a second elastic waterproof sealing ring, a plurality of protrusions are uniformly arranged on the first sleeve in the circumferential direction, each protrusion is sleeved with a damping spring, each damping spring is provided with a round gasket, a plurality of through holes corresponding to the protrusions are formed in the first rubber gasket, the second sleeve is provided with a third step groove, the third rubber gasket is provided with a third step protrusion corresponding to the third step groove, and the third step groove is provided with a third elastic waterproof sealing ring. The damping energy dissipation device has the advantages of being convenient to install, high in damping energy dissipation effect, capable of effectively achieving attenuation vibration and good in waterproof effect.

Owner:NORTHEASTERN UNIV

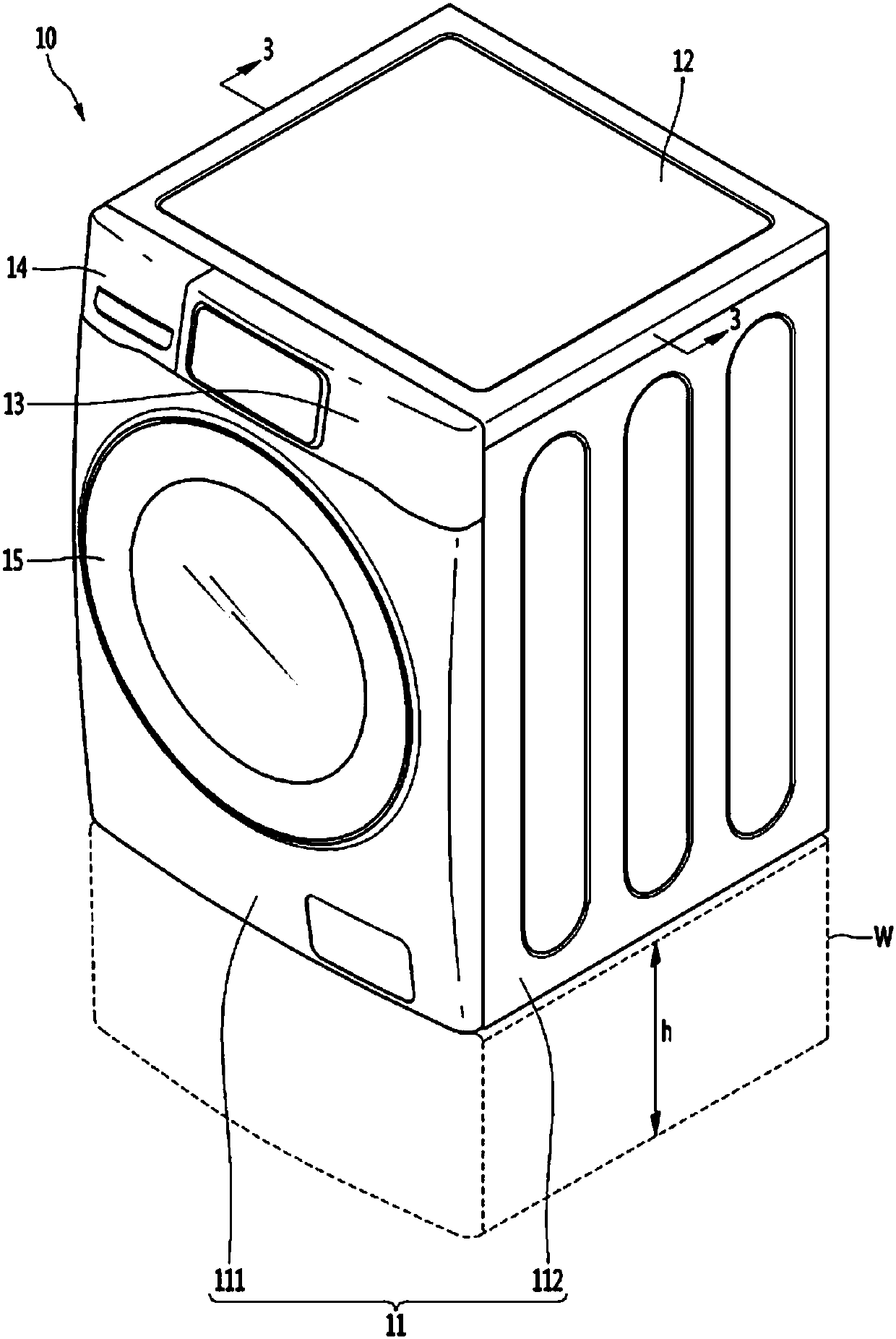

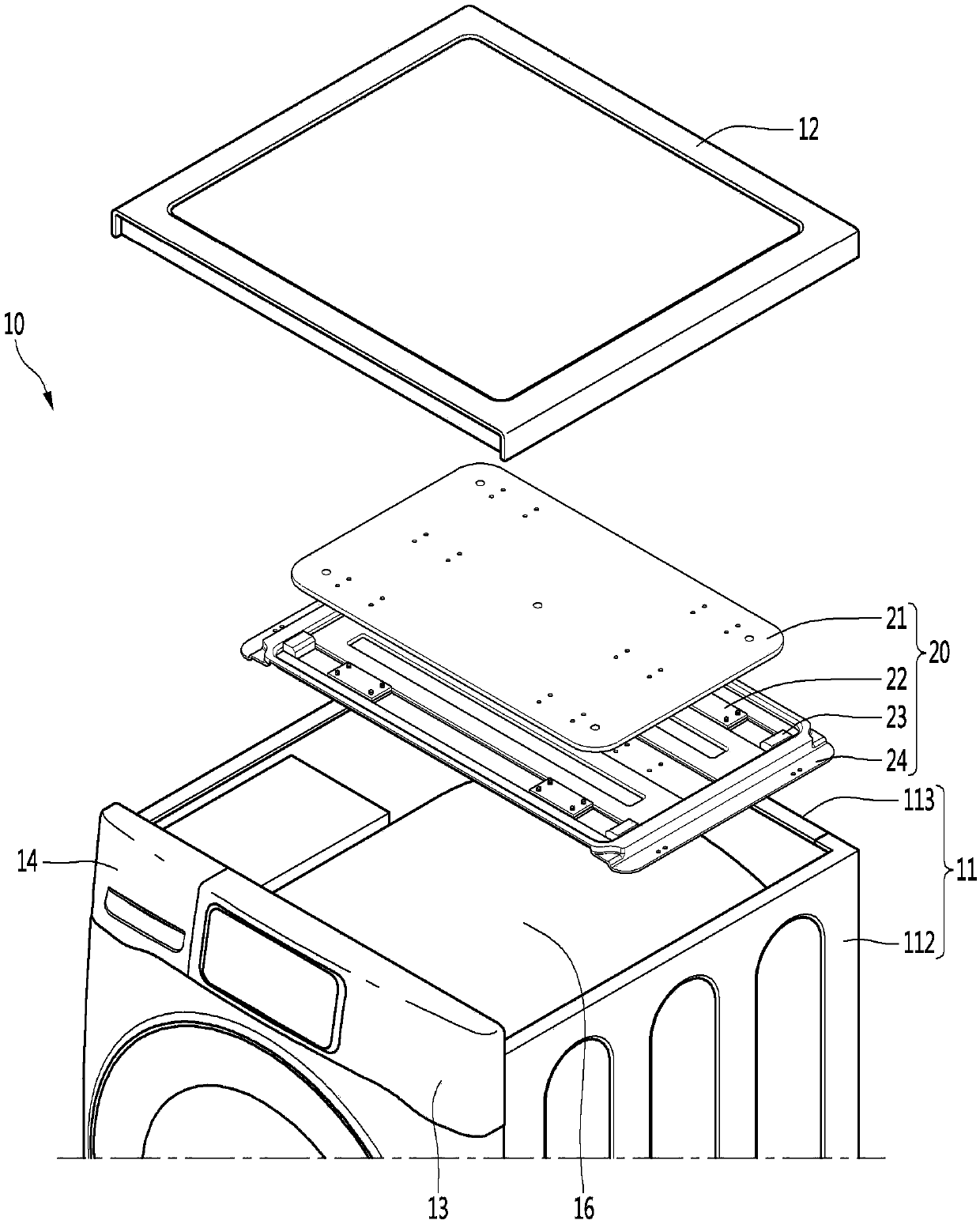

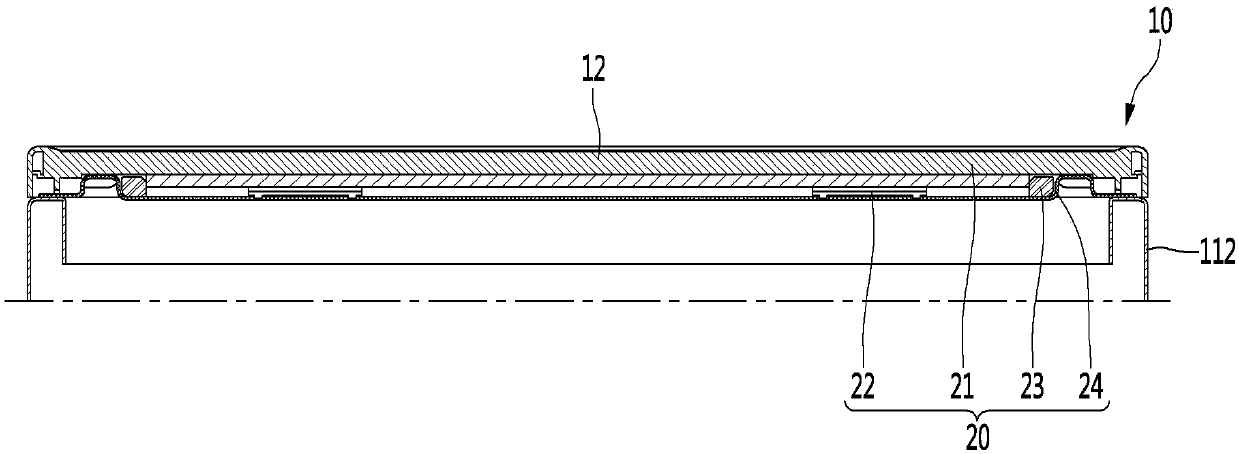

Laundry treating apparatus

ActiveCN107587313AImprove vibration damping abilityImproved vibration reduction effectNon-rotating vibration suppressionOther washing machinesLaundryEngineering

The invention relates to a laundry treating apparatus which includes a cabinet, a drum accommodated in the cabinet, a tub accommodating the drum, and a dynamic absorber provided to absorb oscillationof the cabinet. The dynamic absorber includes a support plate coupled to the cabinet, mass bodies movably provided on the support plate, and sliders arranged between the mass bodies and the support plate, and the sliders can enable the mass bodies to perform reciprocating motion on the support plate while attenuating due to frictional force.

Owner:LG ELECTRONICS INC

Spring guide and cushion device

ActiveCN102192264AReduce collision energyImprove noiseMotorised scootersAxle suspensionsCoil springResonance vibration

The invention provides a spring guide and a cushion device with good absorption characteristic capable of effectively suppressing the resonance vibration of a coil spring in the cushion device and effectively preventing the vibration generated by the noise of the coil spring. The approximately cylindrical spring guide is arranged between the coil spring and an outer shaft member. The coil spring houses a shaft portion of a damper set and arranged between the outer shaft member and an inner shaft member. In the damper set, the inner shaft member is fitted in the cylindrical outer shaft member slidably in an axial direction of the spring guide. Projecting portions projecting towards the shaft core direction are arranged on one end and another end of a main body . The invention also provided the cushion device with the spring guide. The vibration of the coil spring is effectively suppressed.

Owner:HONDA MOTOR CO LTD

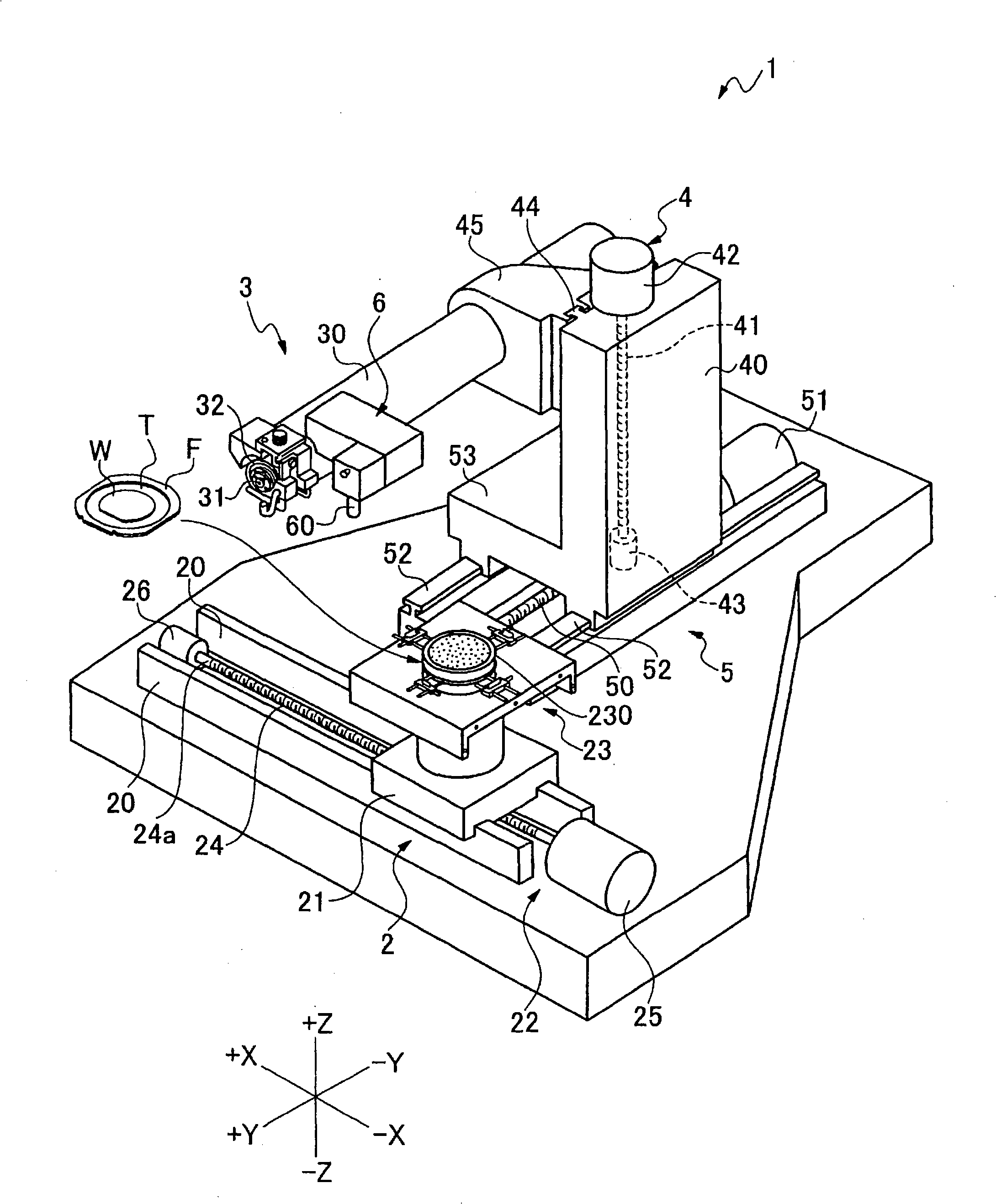

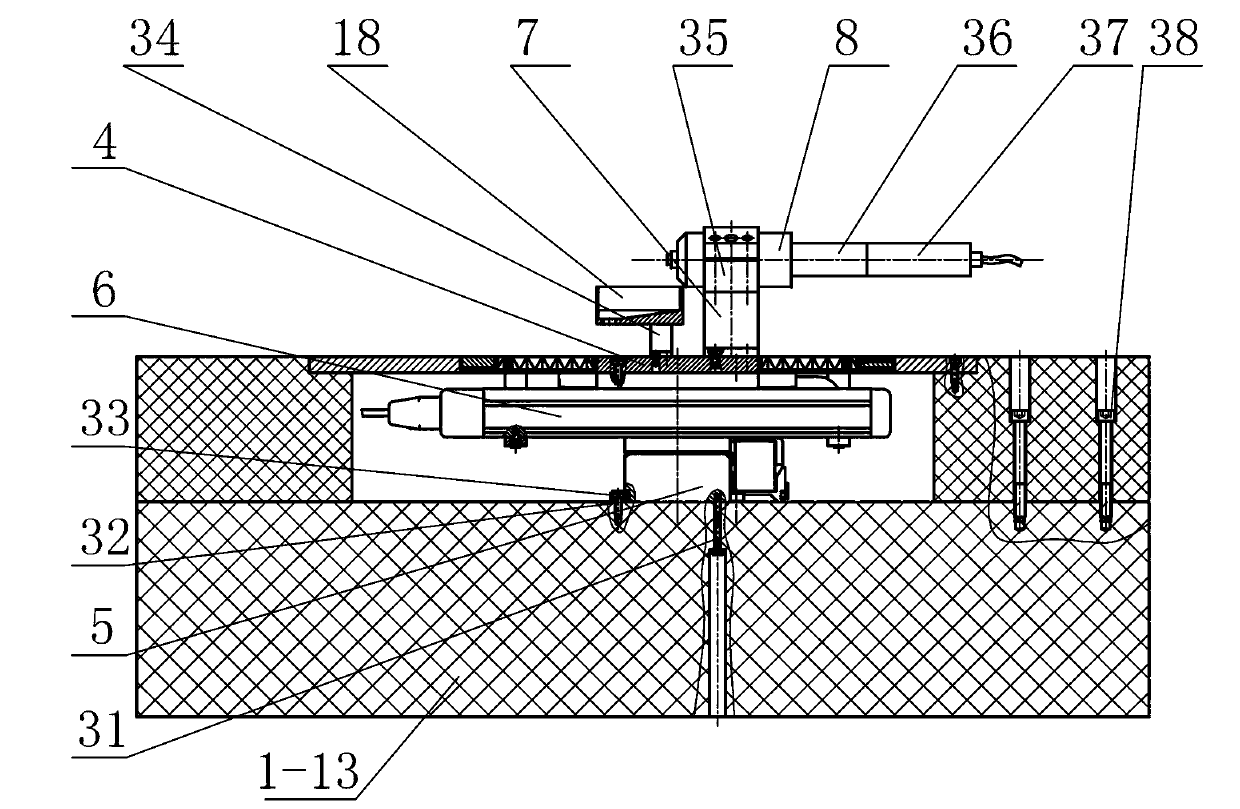

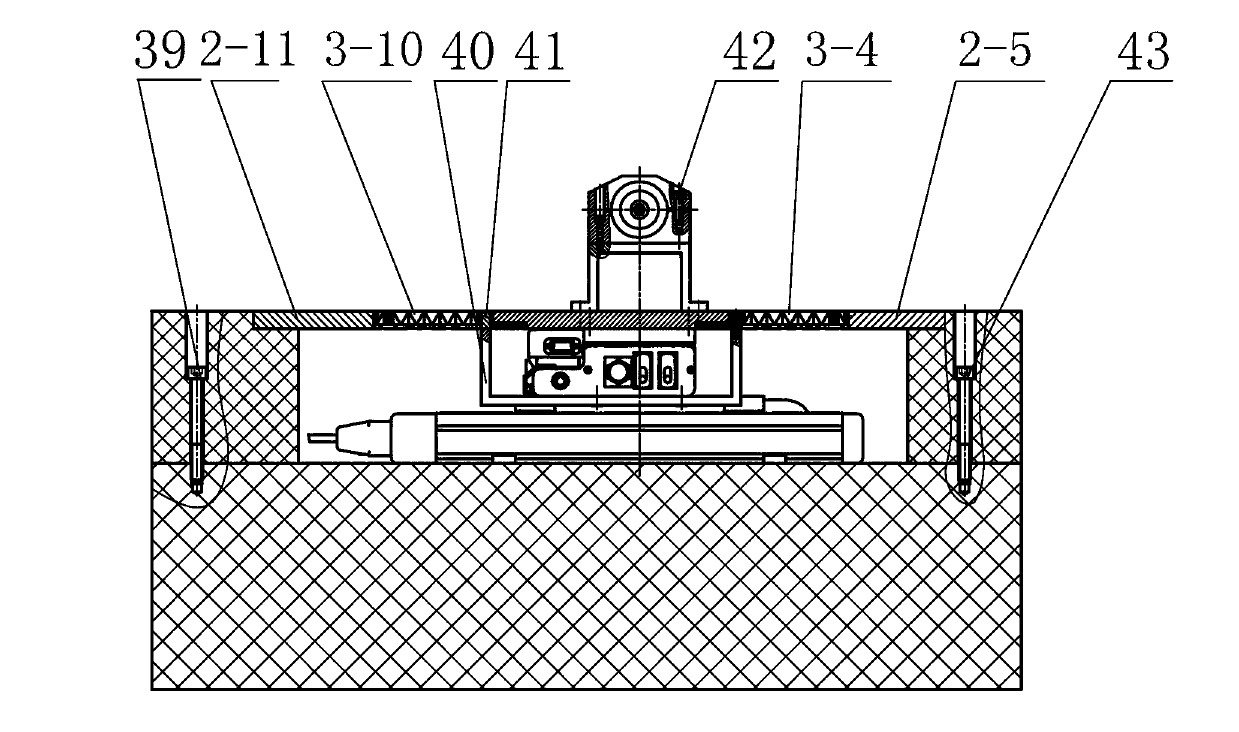

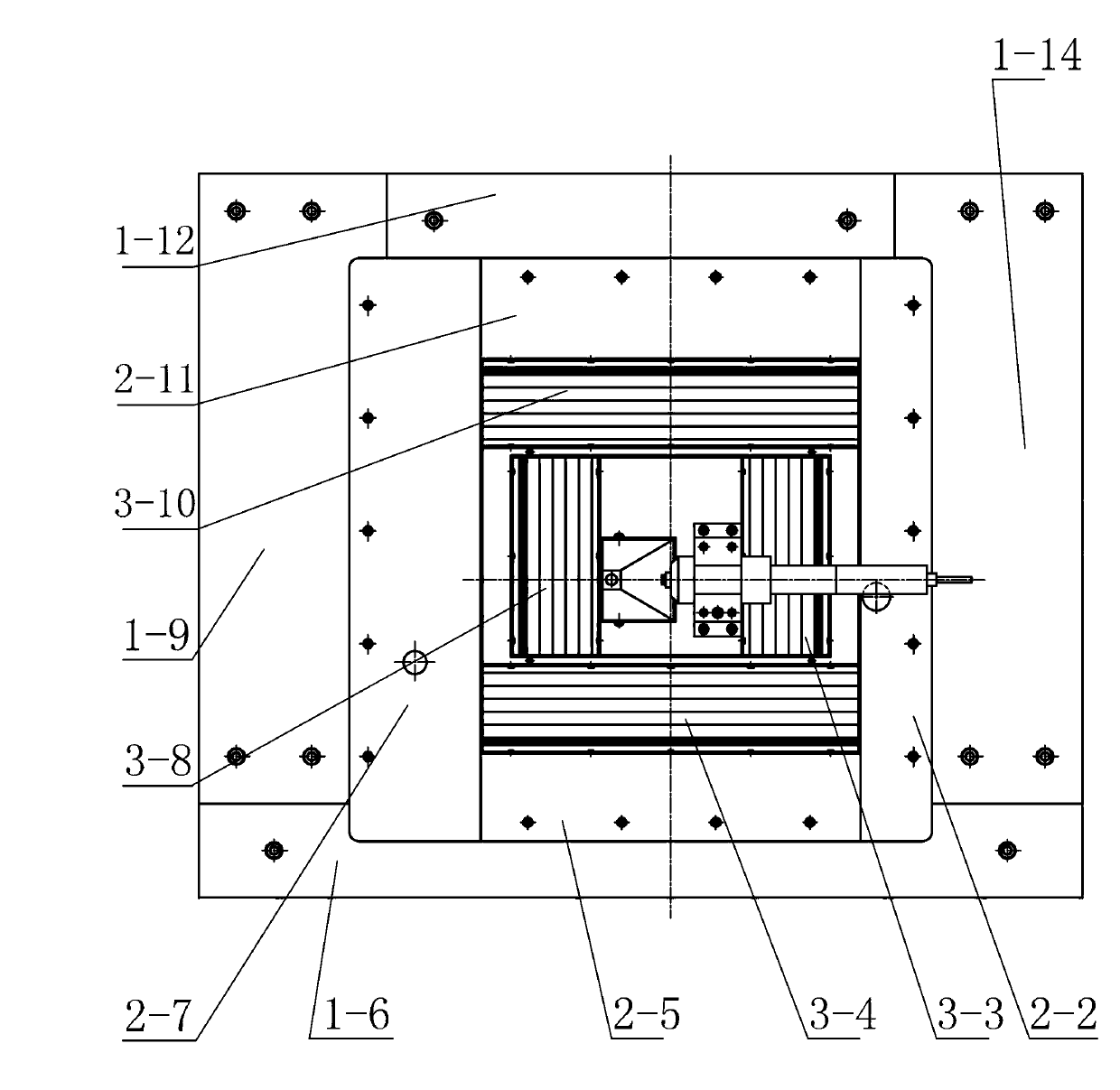

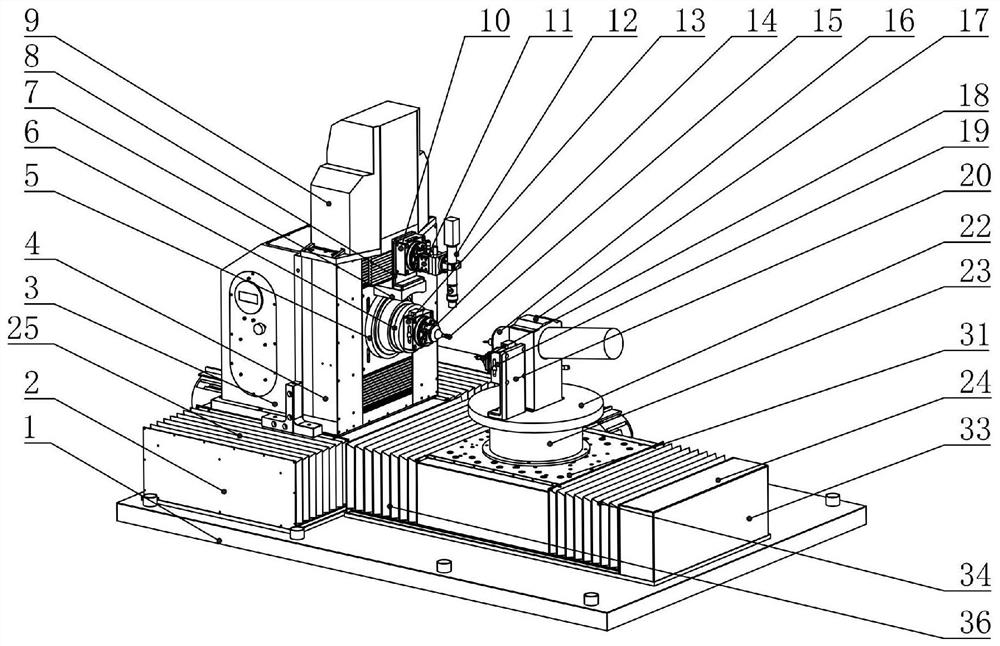

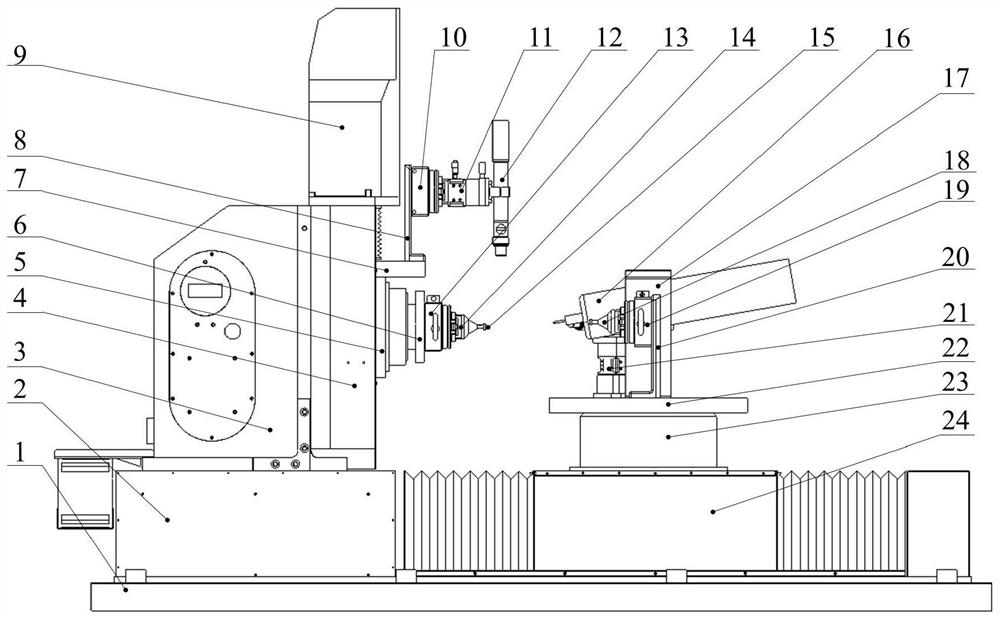

Workpiece shaft numerical control motion platform device for ultraprecision machining

ActiveCN103128602ARealize multi-axis linkageGood effectGrinding carriagesGrinding bedsNumerical controlWorking fluid

The invention discloses a workpiece shaft numerical control motion platform device for ultraprecision machining, and belongs to the technical field of polishing machining. The workpiece shaft numerical control motion platform device for the ultraprecision machining aims at solving the problems that an existing workpiece main shaft system is complex in structure and large in size, can not sufficiently meet the requirements of dust prevention, magnetism prevention and cutting fluid prevention for a high-precision linear motor, and is not suitable for being applied to a small-bore and non-ball curved surface machining lathe. An XY precision mobile platform is arranged in a containing cavity of a lathe base. A working platform is installed on an X axis straight line unit of the XY precision mobile platform. Cover plates are arranged on the periphery of the containing cavity. An organ-liked protective cover is arranged between the edge of the working platform and each cover plate. The workpiece main shaft is installed on the working platform through a workpiece main shaft support, and the axis of the workpiece main shaft is parallel to the motion axis of the X axis straight line unit. A liquid returning groove is formed in the working platform for recycling working fluid. A charge coupled device (CCD) tool setting device is installed on the cover plates. Safety protection of motion components is fully taken into consideration. A smear metal prevention device, a dust prevention device and a cutting fluid prevention device are arranged, and safe operation of the straight line motion unit is ensured.

Owner:HARBIN INST OF TECH

Golf club head

ActiveUS20100137072A1Suppress uncomfortable vibrationImproved vibration absorption performanceGolf clubsRacket sportsGolf clubHeel

A golf club head 2a of a first aspect is provided with a head body h1a, a double-stick tape w1, and an adherend s1a bonded to the head body h1a by the double-stick tape w1. When an average thickness of a lower part of the adherend s1a is defined as f1 and an average thickness of an upper part of the adherend s1a is defined as f2, the thickness f2 is smaller than the thickness f1. A golf club head 2 according to a second aspect is provided with a head body h1, a double-stick tape w1 and an adherend s1 bonded to the head body h1 by the double-stick tape w1. When an average thickness of a heel part of the adherend s1 is defined as t1 and an average thickness of a toe part of the adherend s1 is defined as t2, the thickness t2 is smaller than the thickness t1.

Owner:SUMITOMO RUBBER IND LTD

Stereoscopic knitwork

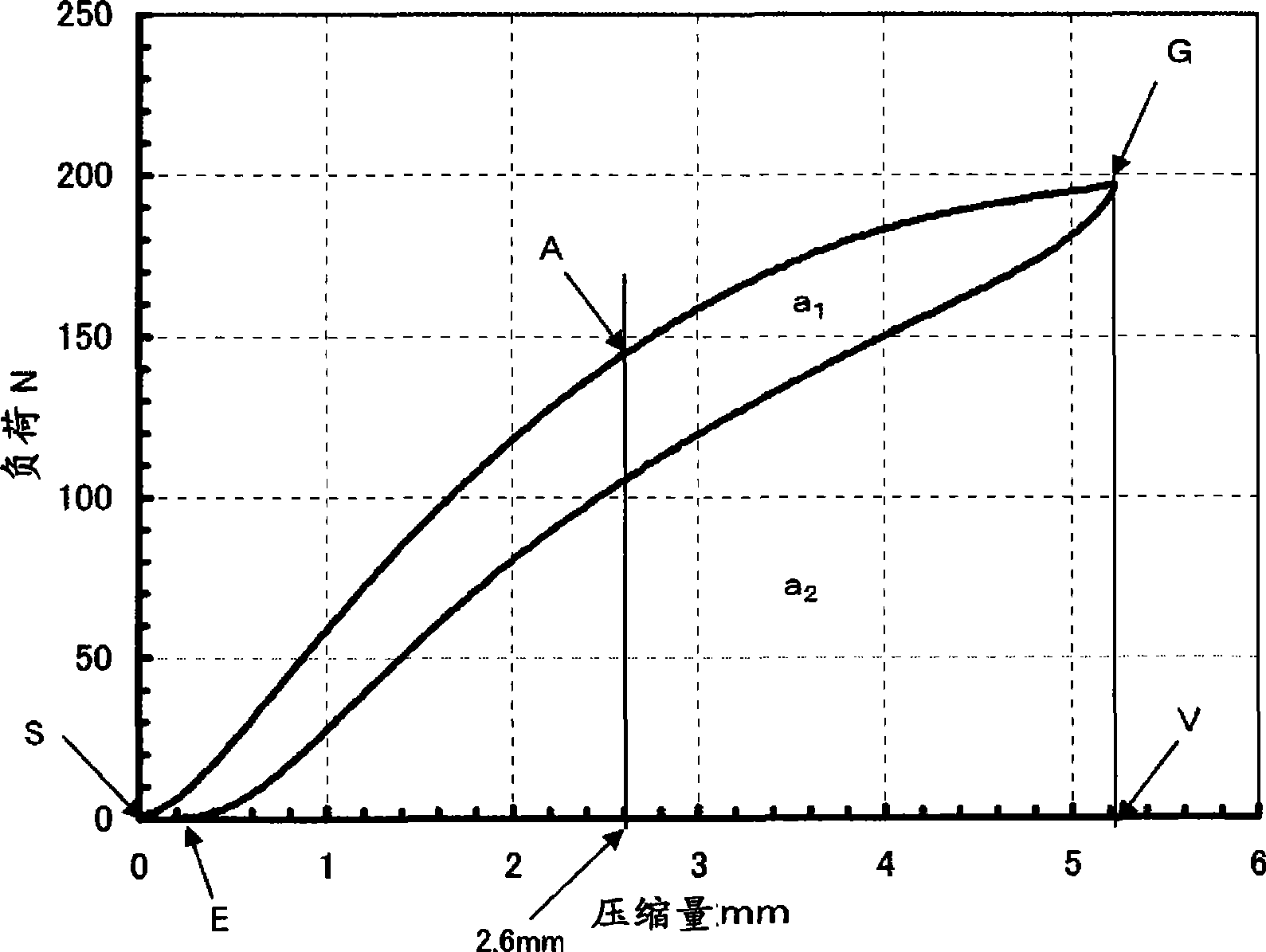

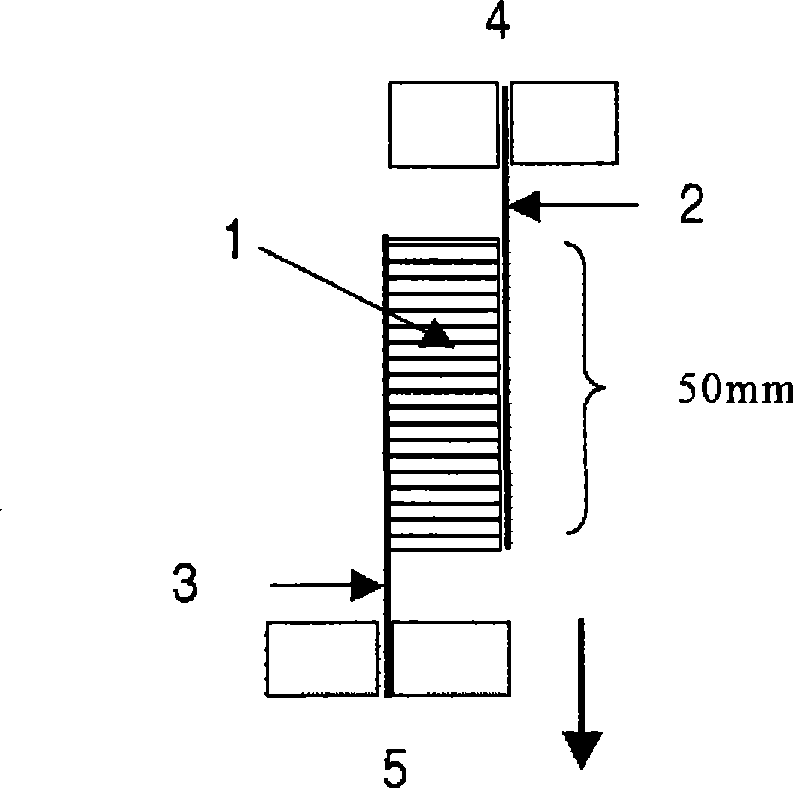

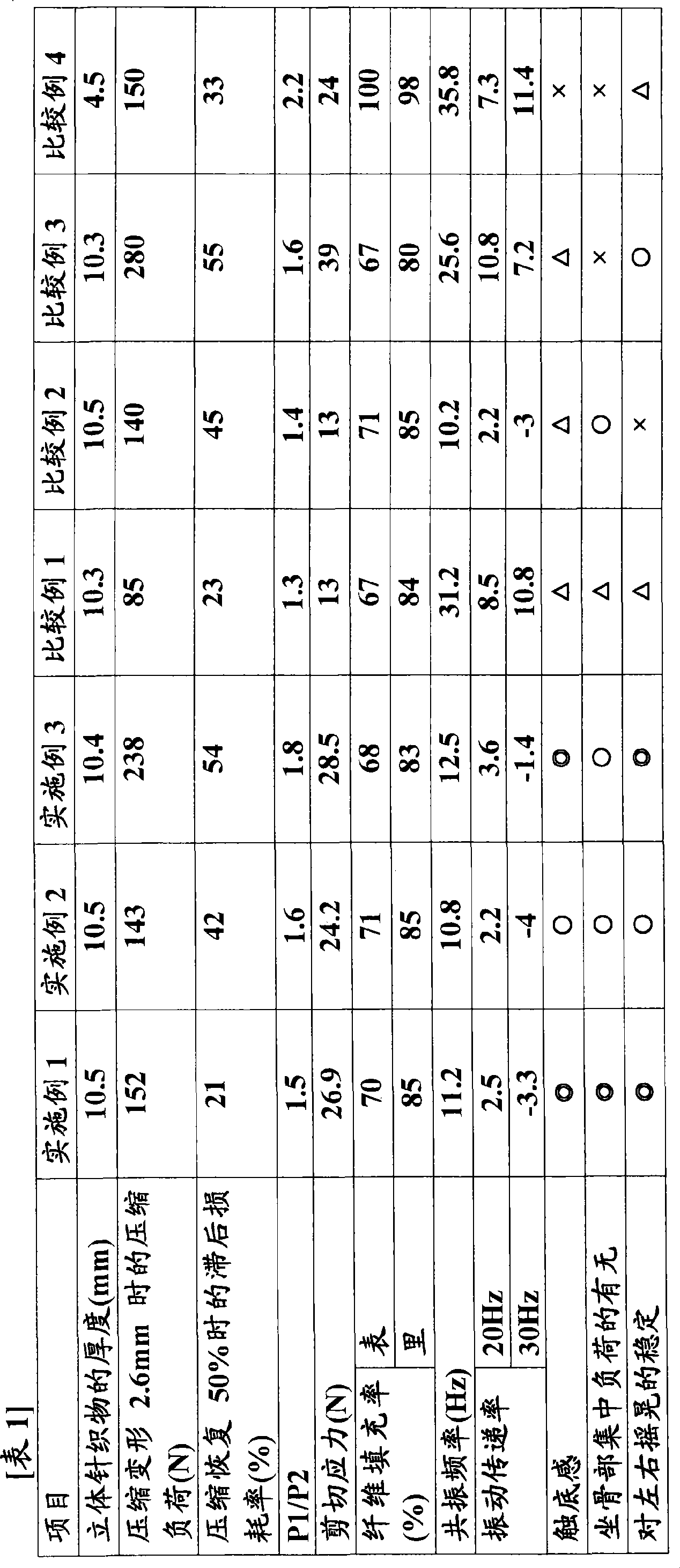

InactiveCN101384762APrevent concentrated loadImproved vibration absorption performanceSeat coveringsStuffed mattressesYarnShear stress

A stereoscopic knitwork including two layers of knitting fabric respectively disposed on the front and back sides and a monofilament connecting yarn for connecting of the two layers of knitting fabric, characterized in that the compressive load at 2.6 mm compressive deformation of a compressed sheet of 5 to 25 mm thickness and 100 mm diameter from the stereoscopic knitwork is in the range of 100 to 250 N, and that the shearing stress at 5 mm lateral transition (transition along the course line) of the knitting fabric disposed on the front and back sides in parallel relationship is in the range of 15 to 35 N.

Owner:ASAHI KASEI FIBERS CORPORATION

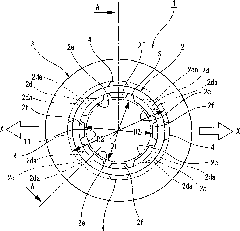

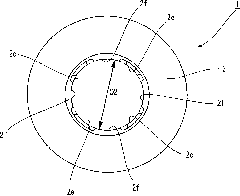

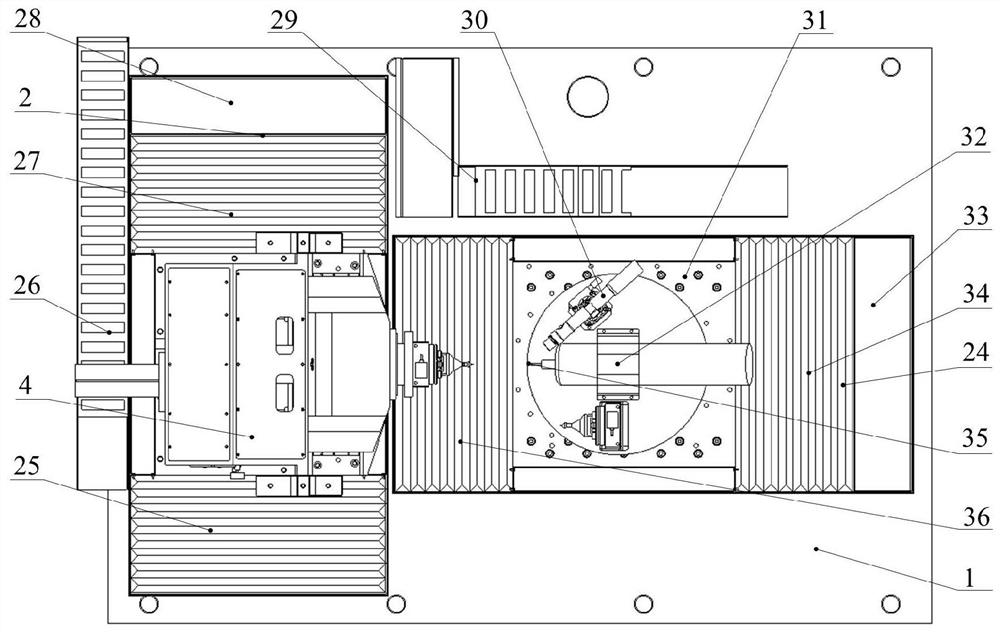

Machining device for full-surface micro-pit structure of thin-wall spherical shell type micro-component

ActiveCN113695646AAchieve high precision machiningExcellent contour errorWork clamping meansMeasurement/indication equipmentsImage resolutionMonitoring system

The invention discloses a machining device for a full-surface micro-pit structure of a thin-wall spherical shell type micro-component, and relates to the technical field of micro-component surface machining devices. The problems that under the constraint of the micro-space scale, the thin-wall spherical shell type micro-component has special structural characteristics, is non-uniform in material, asymmetric in surface and has tiny surface defects, and fluid mechanics is not stable in the machining process are solved. According to the machining device, a base is made of granite materials, and therefore vibration can be well absorbed; a high-precision linear unit and a high-precision rotating unit are adopted as main moving parts of the device, and a workpiece clamping system, a high-resolution CCD monitoring system, a zero point positioning system and a turning secondary clamping quick-change system are installed on the base in a centralized mode; the structural design is compact, and the technical problems of clamping, turning, tool setting, capturing and recognizing of the micro-pit structure and the like of the thin-wall spherical shell type micro-component can be effectively solved; and an air static pressure workpiece shaft is adopted for rotational motion of a workpiece, a milling shaft is obliquely arranged, and therefore the high machining speed and the high machining precision can be achieved.

Owner:HARBIN INST OF TECH

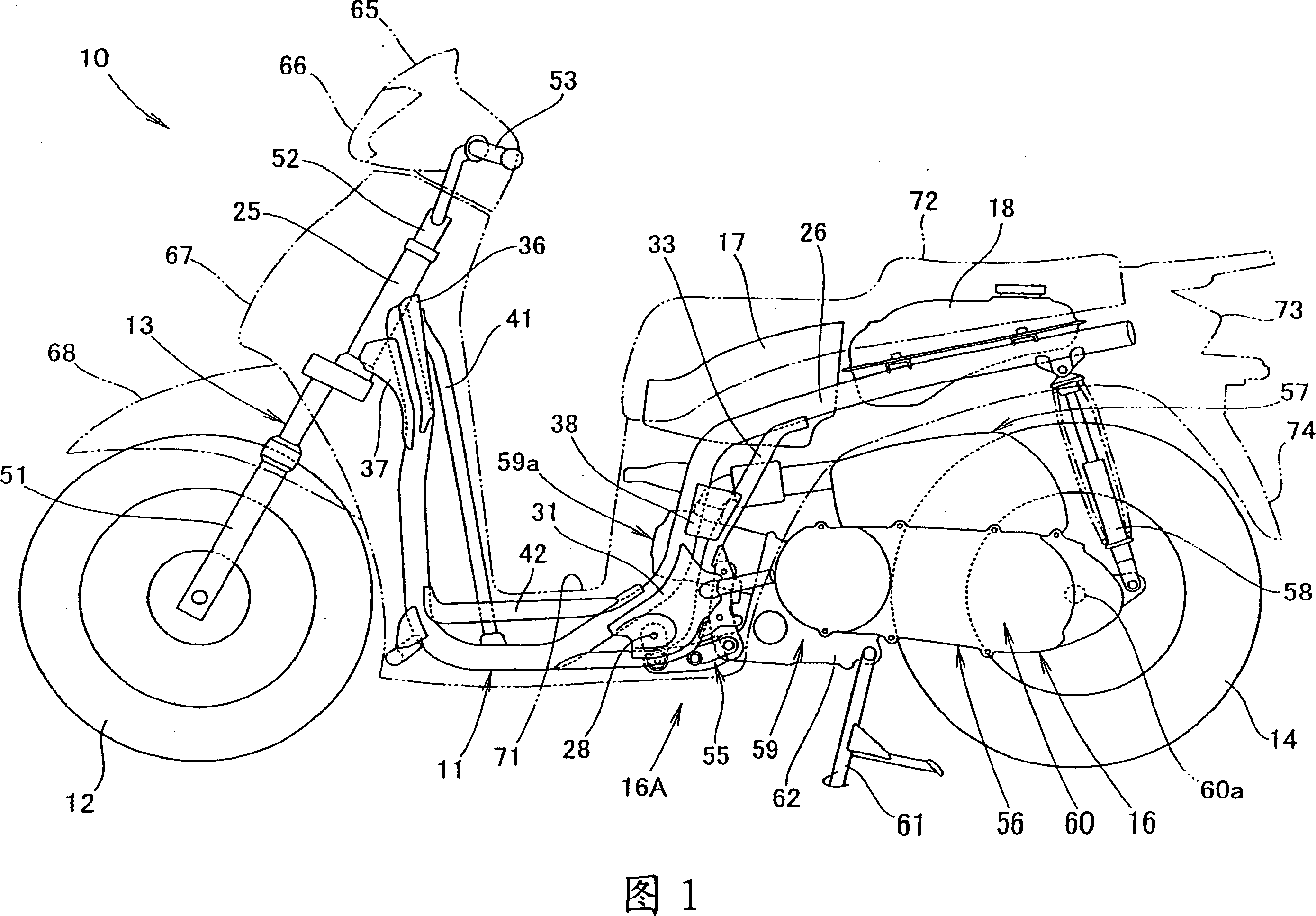

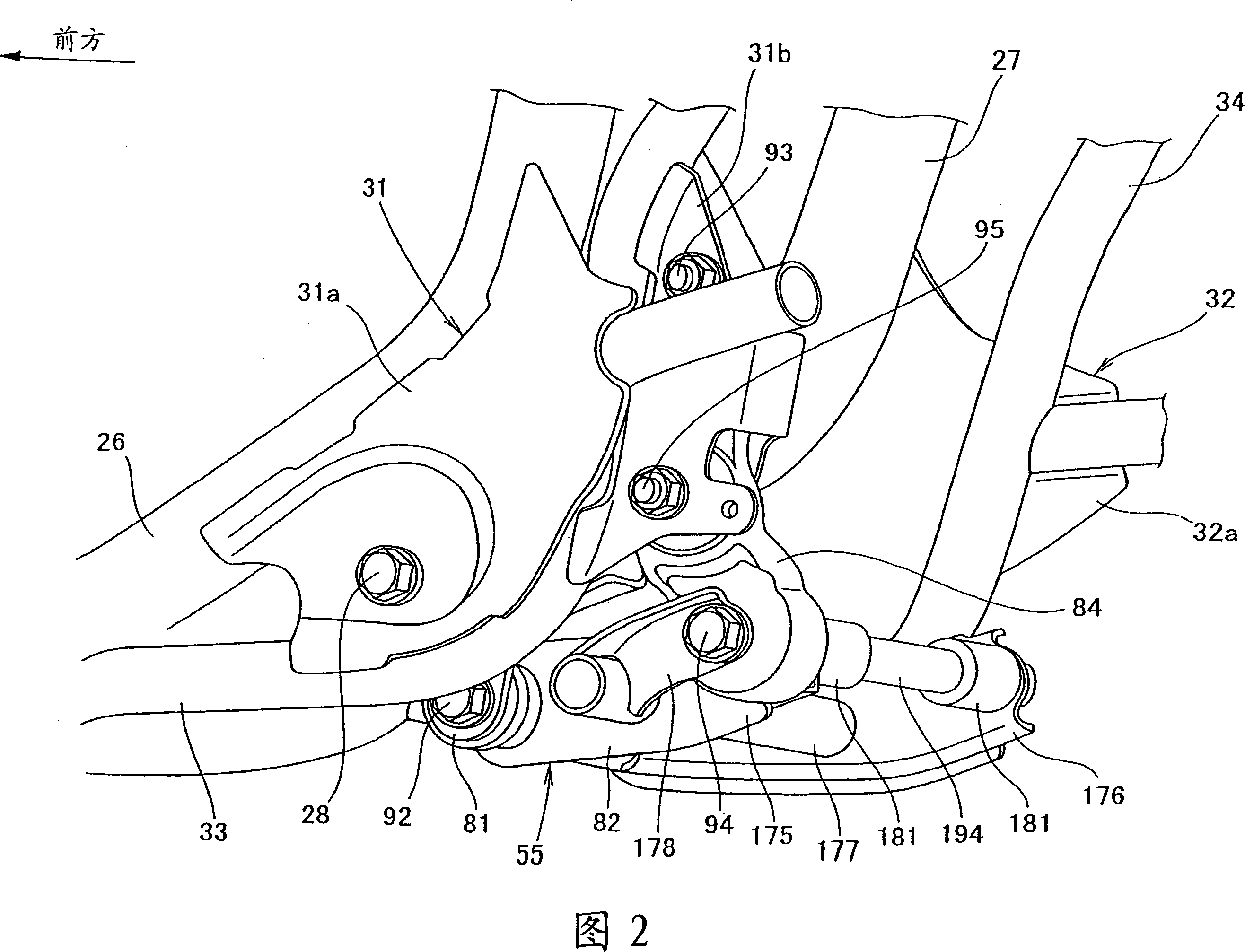

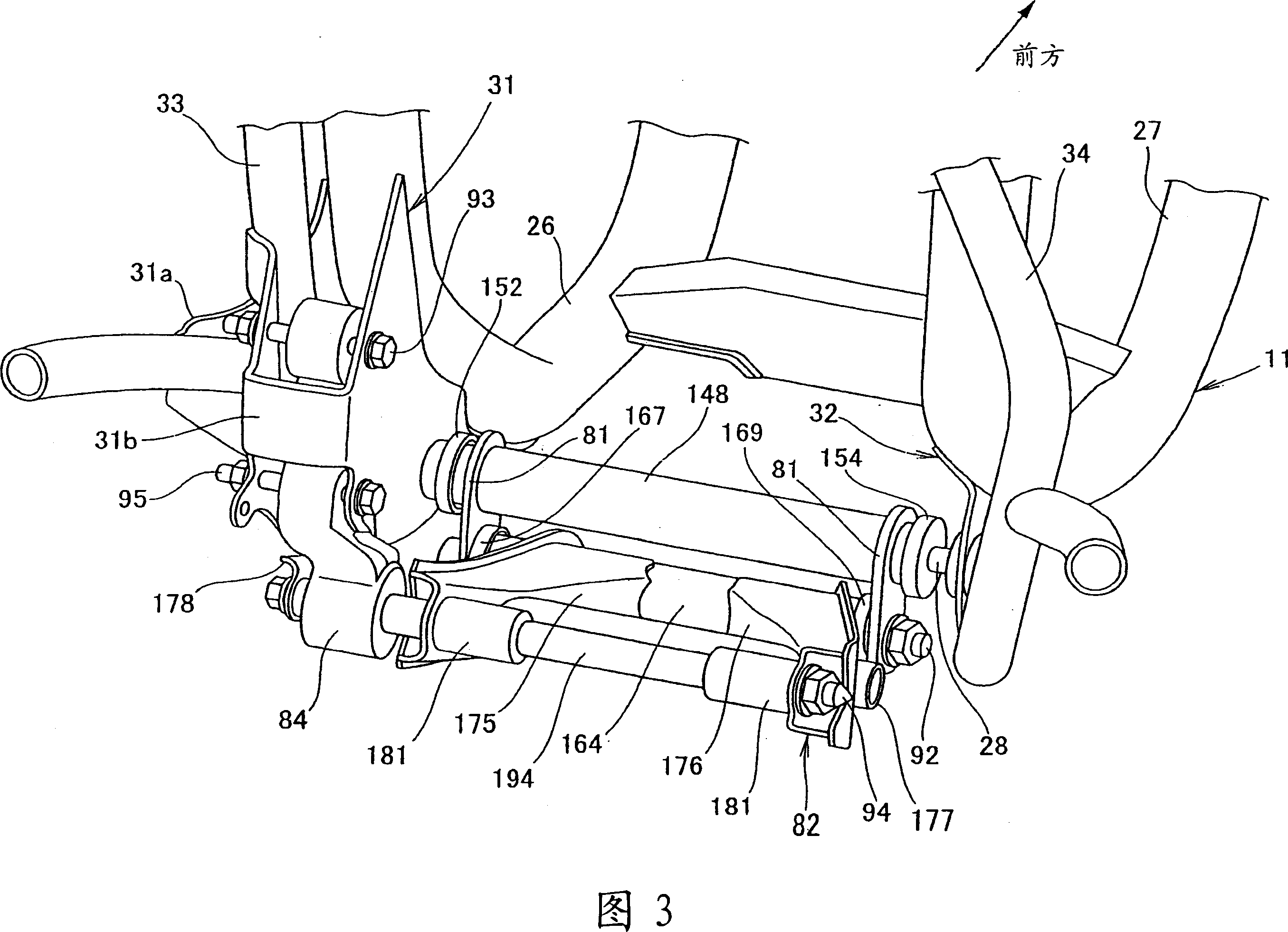

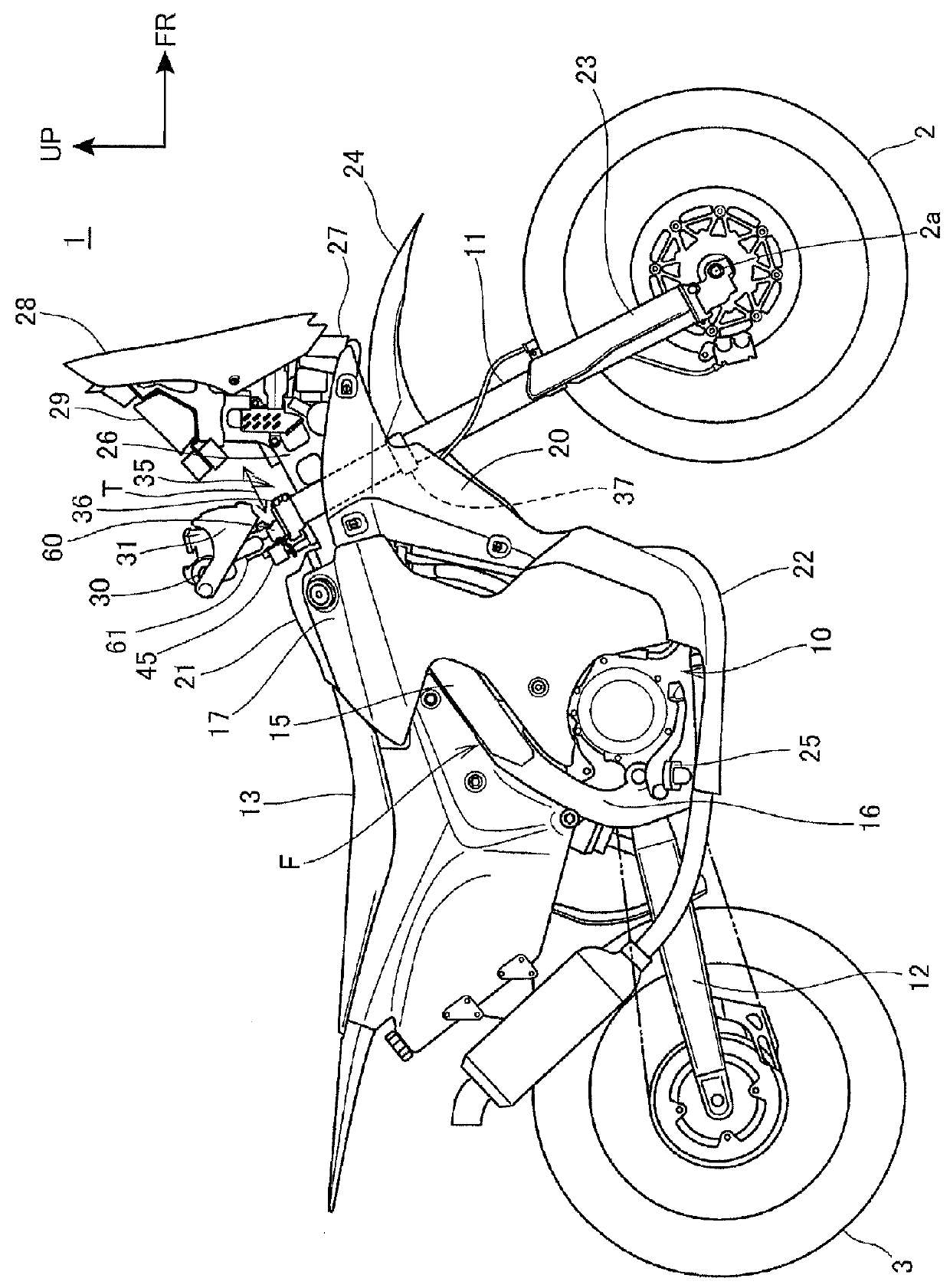

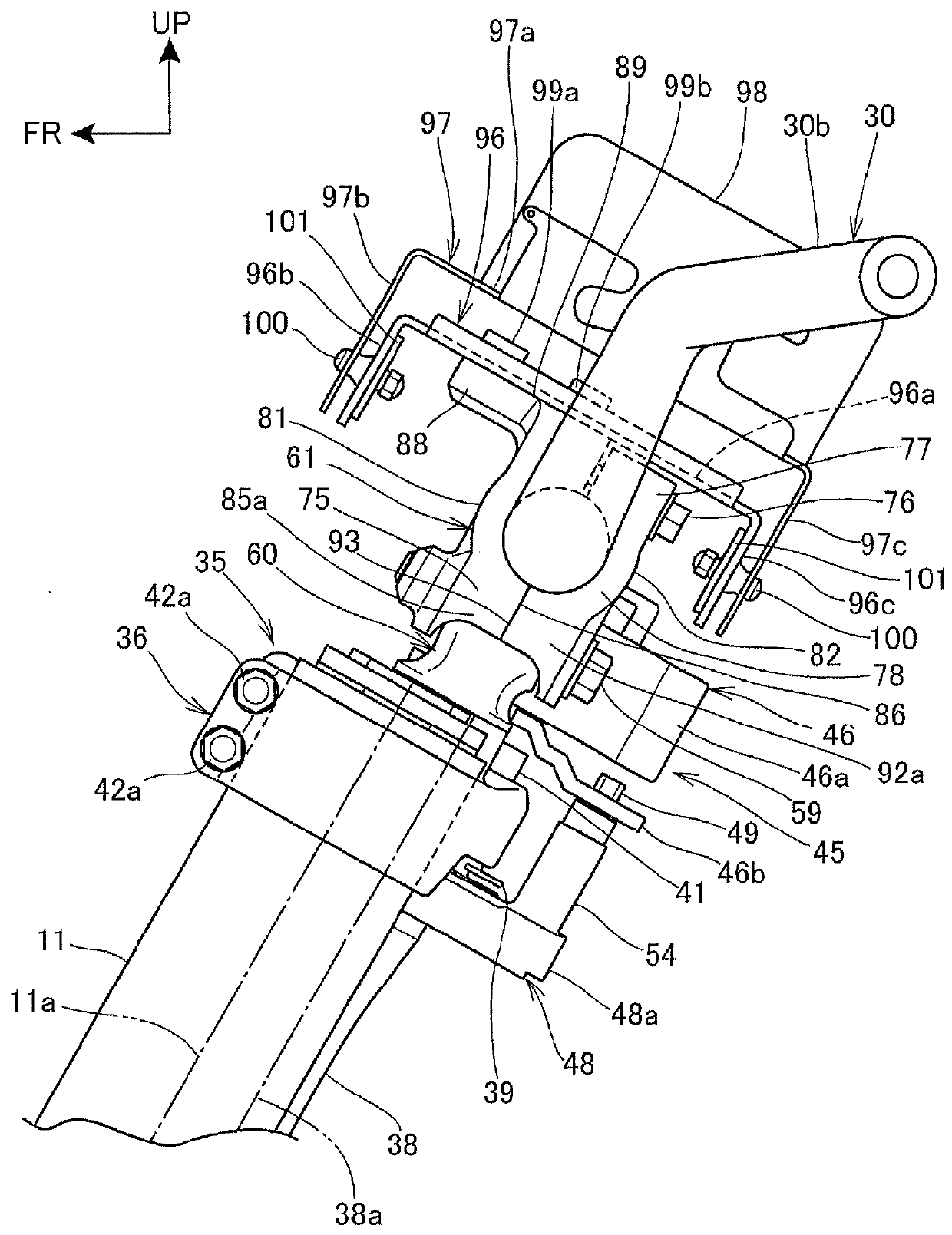

Power unit suspension gear for minitype motorcycle type vehicle

InactiveCN1923610ASimple structureReduce the numberJet propulsion mountingInternal combustion mountingEngineeringPower unit

The invention provides a power unit suspension device of a small motorcycle type vehicle, which can simplify the structure of a limiter for limiting the vertical movement of the power unit and rear wheels. One end of the connecting rod (84) is swingably installed on the inner pivot plate (31b), the power unit (56) is swingably installed on the other end of the connecting rod (84), and the inner pivot plate (31b ) and the connecting rod (84) are provided with a limit mechanism (105), which is used to limit the movement of the power unit (56) in the front and rear direction, and make the third pivot arranged on the connecting rod (84) (93) The line segment connected with the fourth pivot (94) extends in the vertical direction, and meanwhile, the fourth pivot (94) is supported by the connecting rod (84) through the rubber bushing (112).

Owner:HONDA MOTOR CO LTD

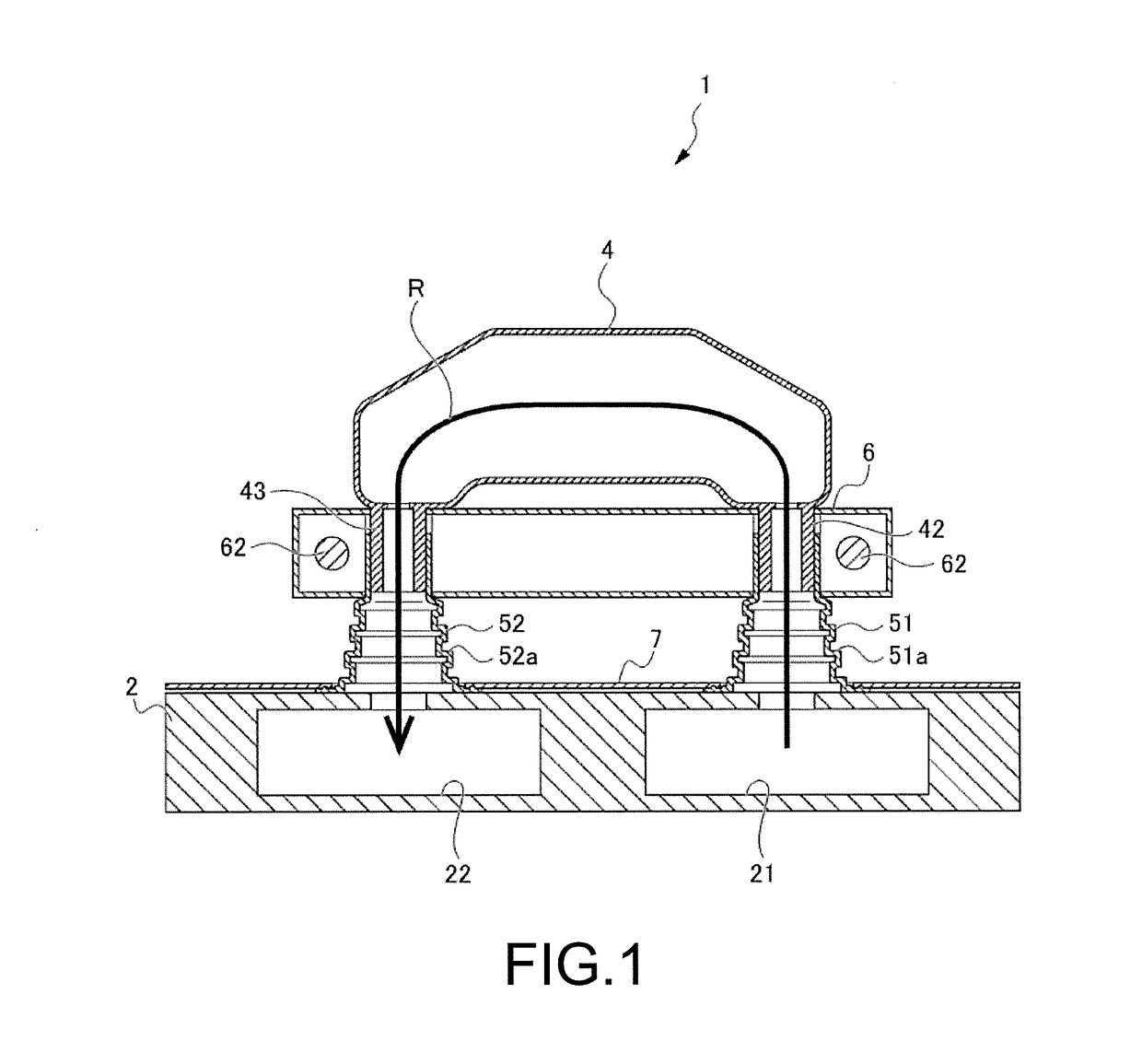

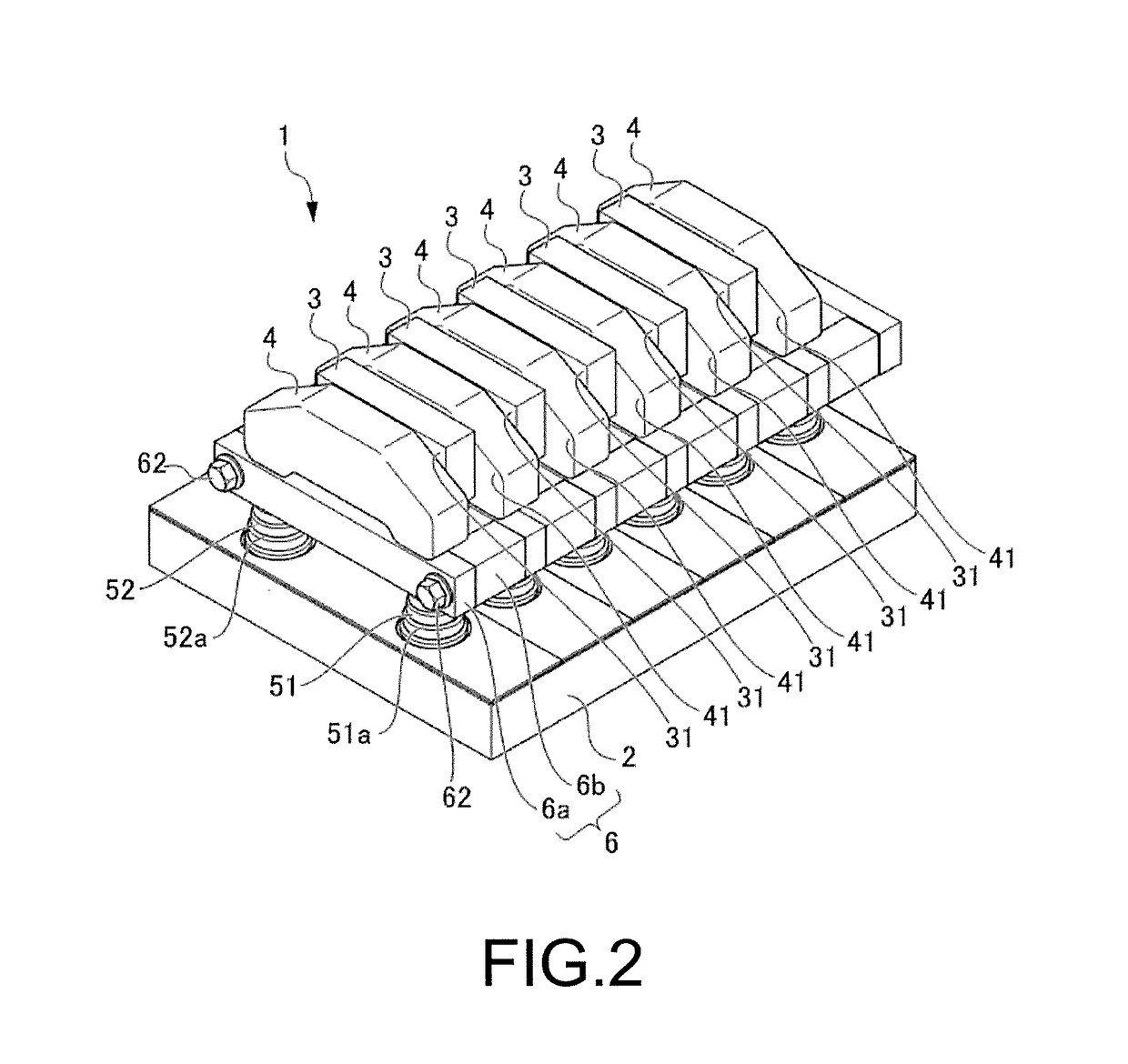

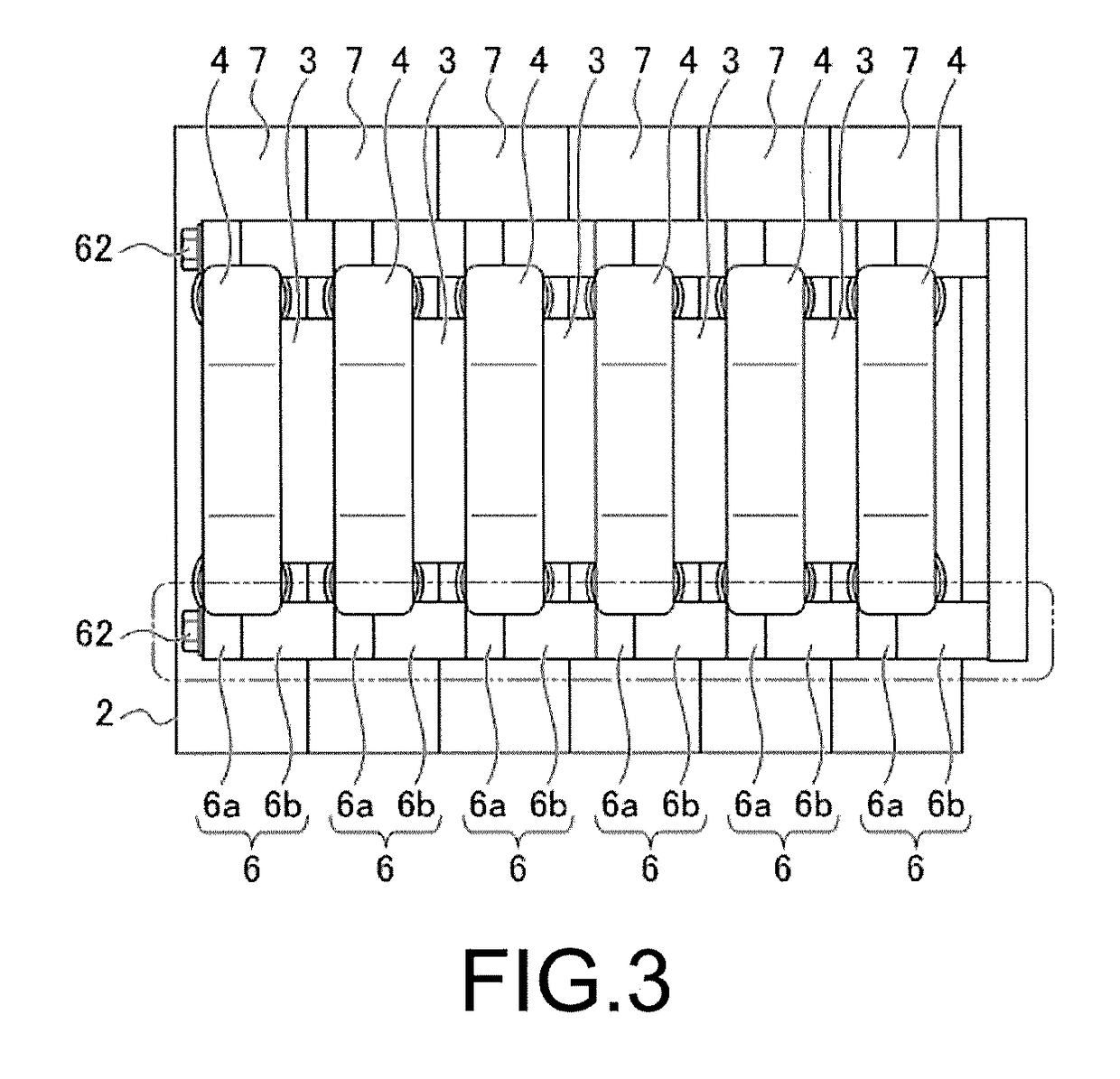

Power converter

ActiveUS10225962B2Sufficient degree of absorption of unevennessImproved vibration absorption performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringRefrigerant

A power converter includes: a refrigerant flow channel member in which a refrigerant cooling an electronic device flows; a flat refrigerant pipe portion stacked with a power module, provided for a refrigerant cooling the power module to flow therein, and including a contact surface portion contacting the power module to exchange heat; an inlet pipe portion that is disposed at one end of the refrigerant pipe portion and through which the refrigerant flows to the refrigerant pipe portion; an outlet pipe portion that is disposed at the other end of the refrigerant pipe portion and through which the refrigerant flows from the refrigerant pipe portion; an inlet connection portion connecting the inlet pipe portion to the refrigerant flow channel member and formed of a tubular elastic member; and an outlet connection portion connecting the outlet pipe portion to the refrigerant flow channel member and formed of a tubular elastic member.

Owner:HONDA MOTOR CO LTD

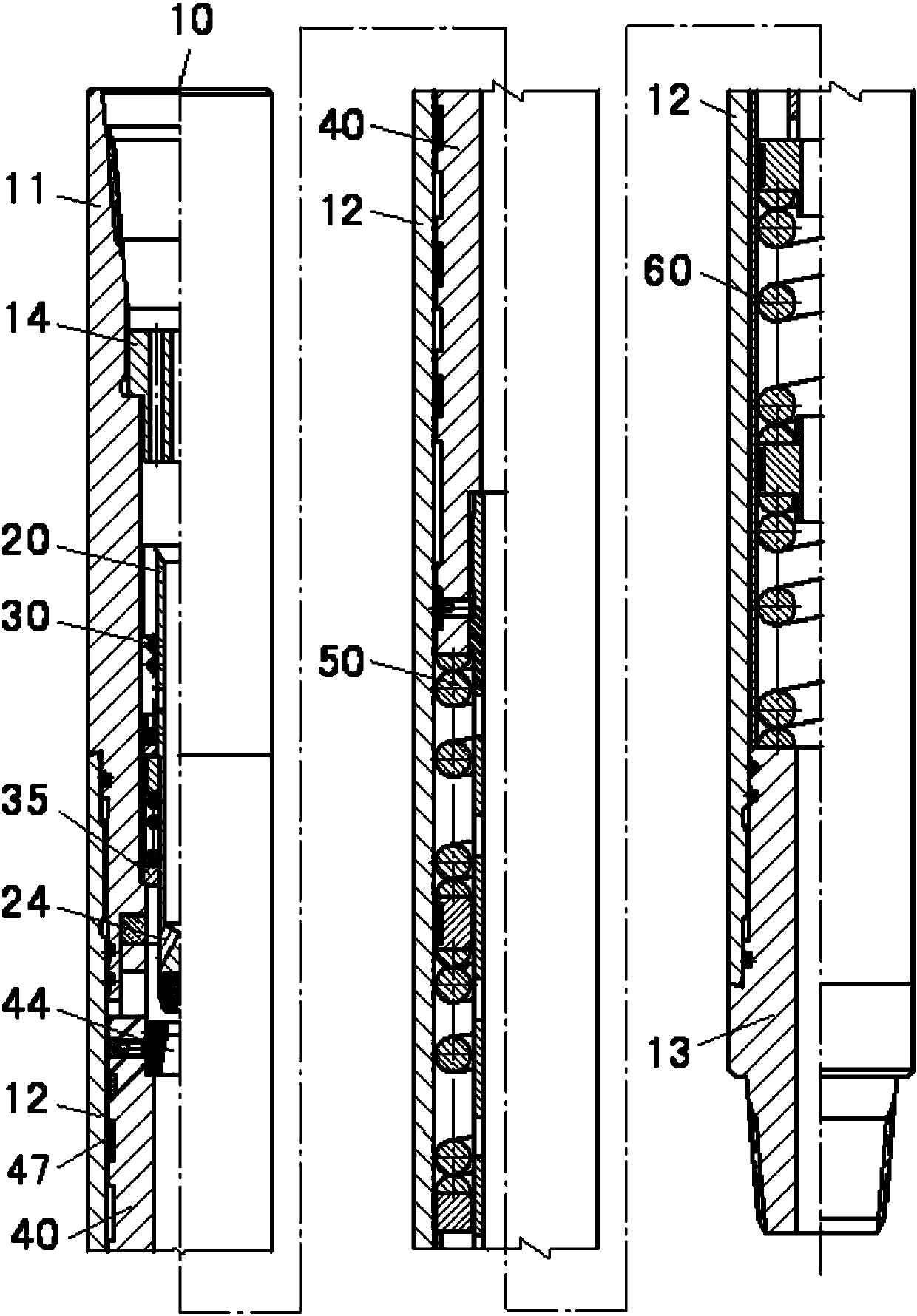

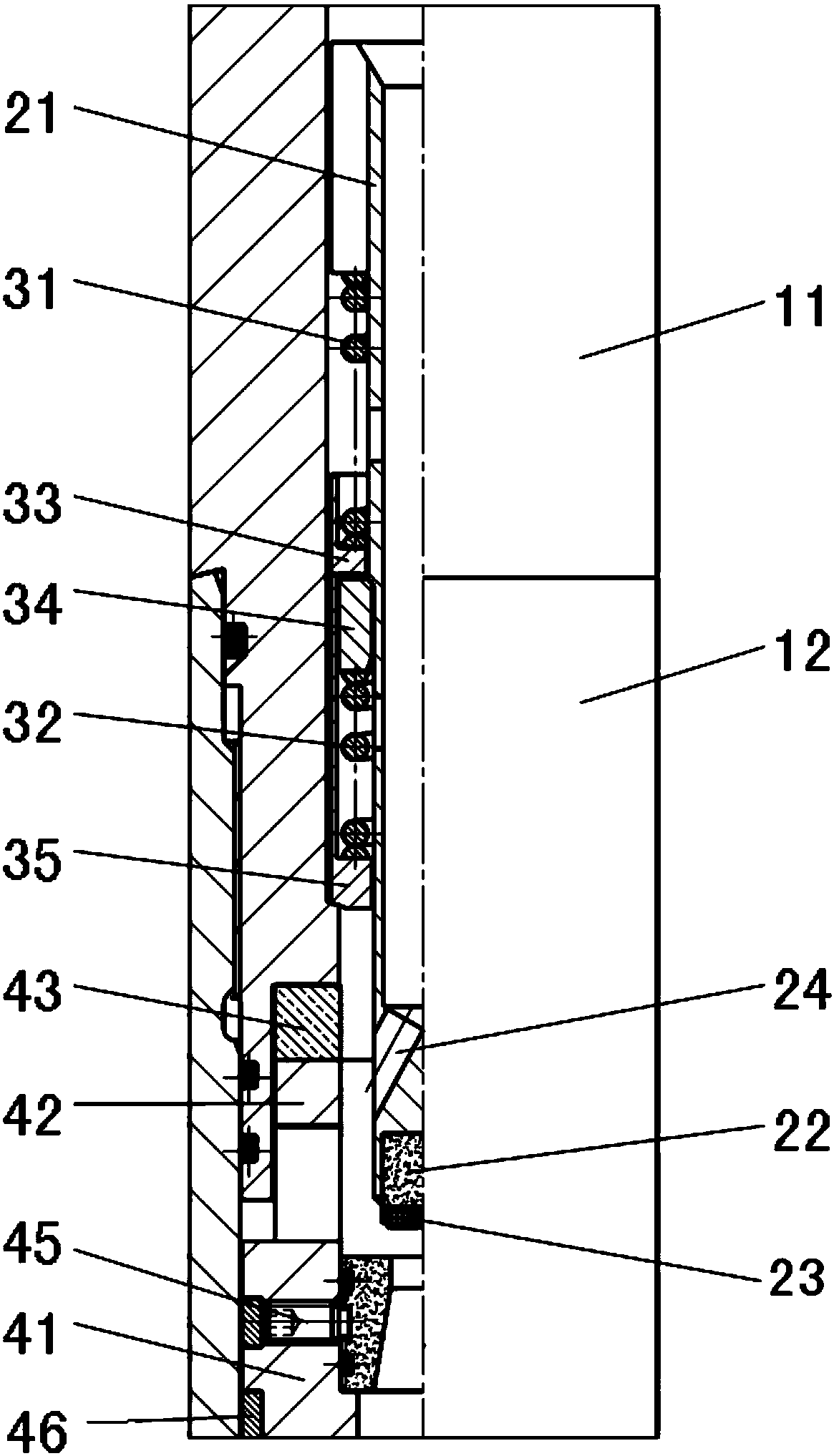

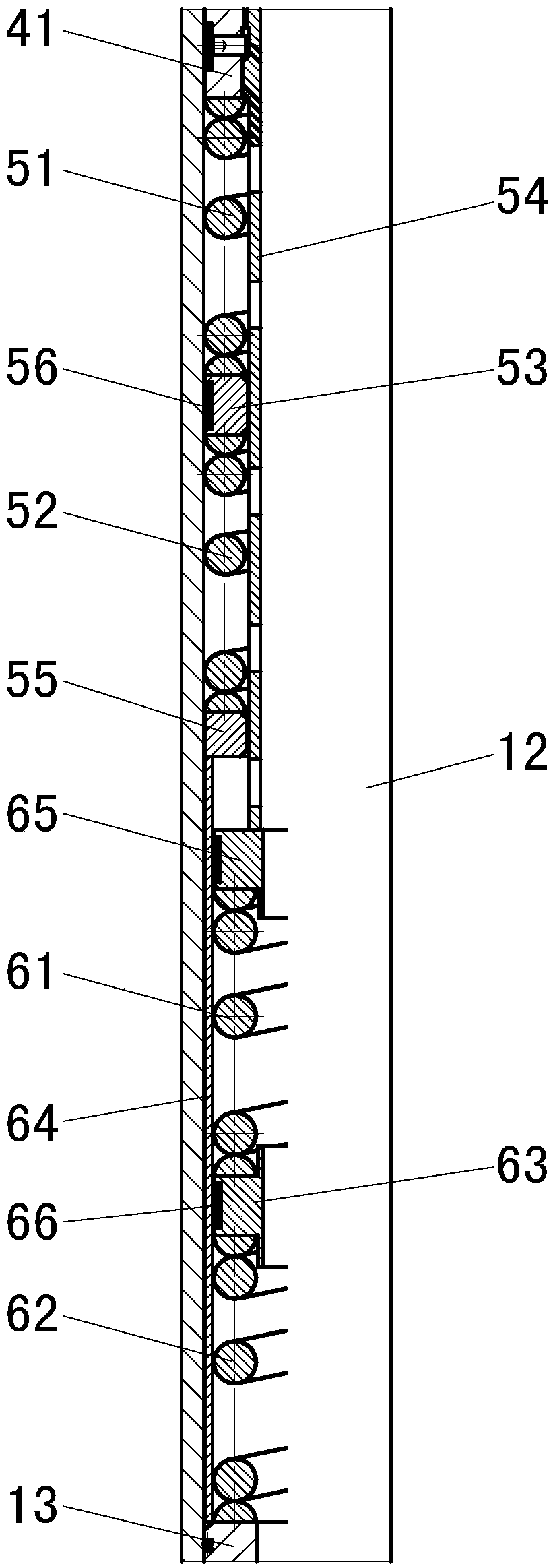

Unclamping method and device adopting continuous jarring through spring periodically stretching out and drawing back

PendingCN107687328AMeet rigid requirementsMeet travel requirementsBorehole/well accessoriesInternal pressureHorizontal wells

The invention discloses an unclamping method and device adopting continuous jarring through spring periodically stretching out and drawing back. According to the unclamping method and device, a valveis arranged in a tubular column, when the pressure of circulating fluid entering the tubular column is larger than the counter-acting force of a spring inside the tubular column and a valve hole is closed, the pressure of the circulating fluid compresses the spring and is converted into compressed elastic potential energy of the spring, when the compressed elastic potential energy of the spring isincreased gradually and equal to the pressure of the circulating fluid, the valve hole is opened, the pressure inside the tubular column is unbalanced instantly, the compressed elastic potential energy of the spring is released instantly and drives a jar weight inside the tubular column to upwards impact suddenly, and impacting kinetic energy is transmitted to the clamping point through the tubular column; after one-time impacting is completed, all components inside the tubular column are reset simultaneously to well prepare for energy storage impact of the next time, the process is repeated,and periodical repeat jarring is formed till unclamping is achieved. The unclamping method and device can be used for salvage operation of vertical wells and can also be used for unclamping and salvage operation of deviated wells, greatly-displaced wells and horizontal wells; and during operation, manual resetting operation is not needed, continuous jarring can be achieved till unclamping is achieved, and the unclamping method and device are more efficient and quicker than a conventional technology.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

Complex hosel structure for a golf club head having a high degree of vibrational absorbability and elastic deformability

InactiveUS20070191133A1High-degree of vibrational absorbabilityImproved vibration absorption performanceGolf clubsRacket sportsEngineeringGolf Ball

A golf club head includes a golf club head body and a complex hosel. The golf club head body includes a neck portion located at a heel-side portion, and a connecting portion formed on the neck portion. The complex hosel is constructed from a one-piece tubular member made from a two-layer or multi-layer complex substrate combined along a longitudinal direction such that the complex hosel has at least one first tubular, segmental wall and at least one second tubular, segmental wall that possess two different characteristics of vibrational absorbability and elastic deformability. The complex hosel can provide different vibrational absorbability and elastic deformability characteristics in different radial directions of the neck portion of the golf club head body when assembled.

Owner:FUSHENG IND CO LTD

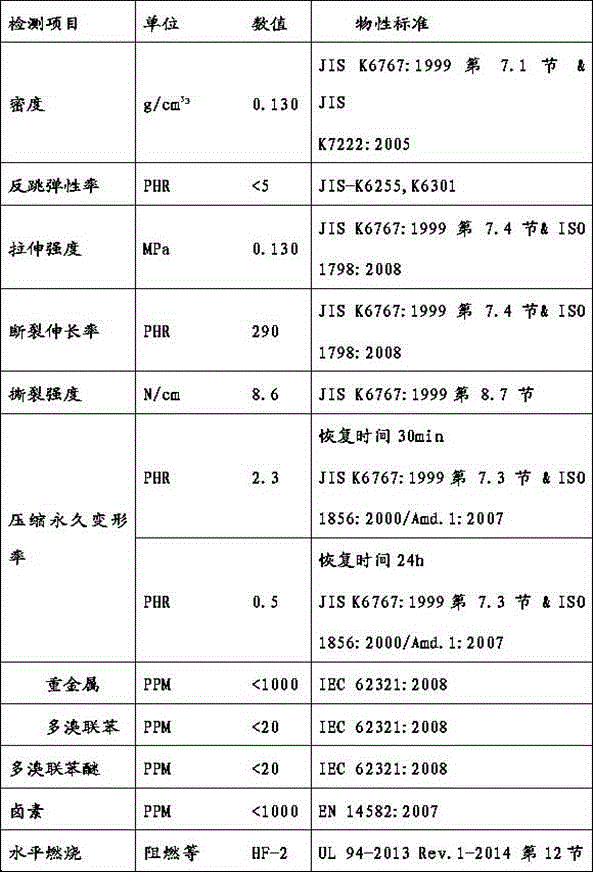

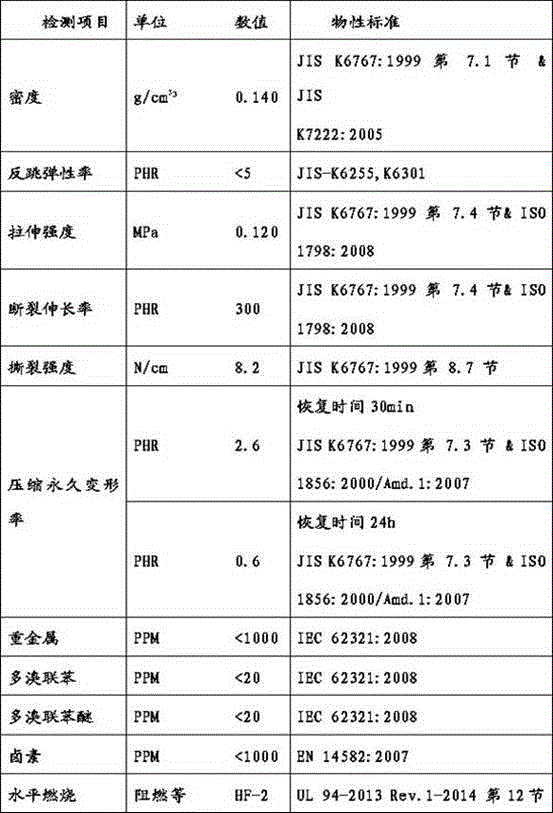

Environment-friendly inflaming retarding butyl rubber and ethylene propylene diene monomer rubber multielement blended blind-hole secondary foaming material and preparation method thereof

ActiveCN105585784AExcellent damping (i.e. vibration absorptionExcellent vibration absorptionPolymer scienceHeat resistance

The invention relates to the technical field of foaming materials, and provides an environment-friendly inflaming retarding butyl rubber and ethylene propylene diene monomer rubber multielement blended blind-hole secondary foaming material and a preparation method thereof. Butyl rubber with low elasticity and excellent damping performance and air tightness and ethylene propylene diene monomer rubber with excellent weather fastness, ozone resistance, heat resistance, electrical insulating performance and chemical mediator corrosion resistance are subjected to compatible blending to form the multielement blended blind-hole foaming material with good comprehensive performance and low cost. Good vibration absorption performance and excellent air tightness brought by the low-elasticity characteristic and excellent damping performance of the butyl rubber are kept, and meanwhile the product passes the ROHS international environmental requirement and has the novel inflaming retarding property.

Owner:YIBAO FUJIAN POLYMER MATERIALS

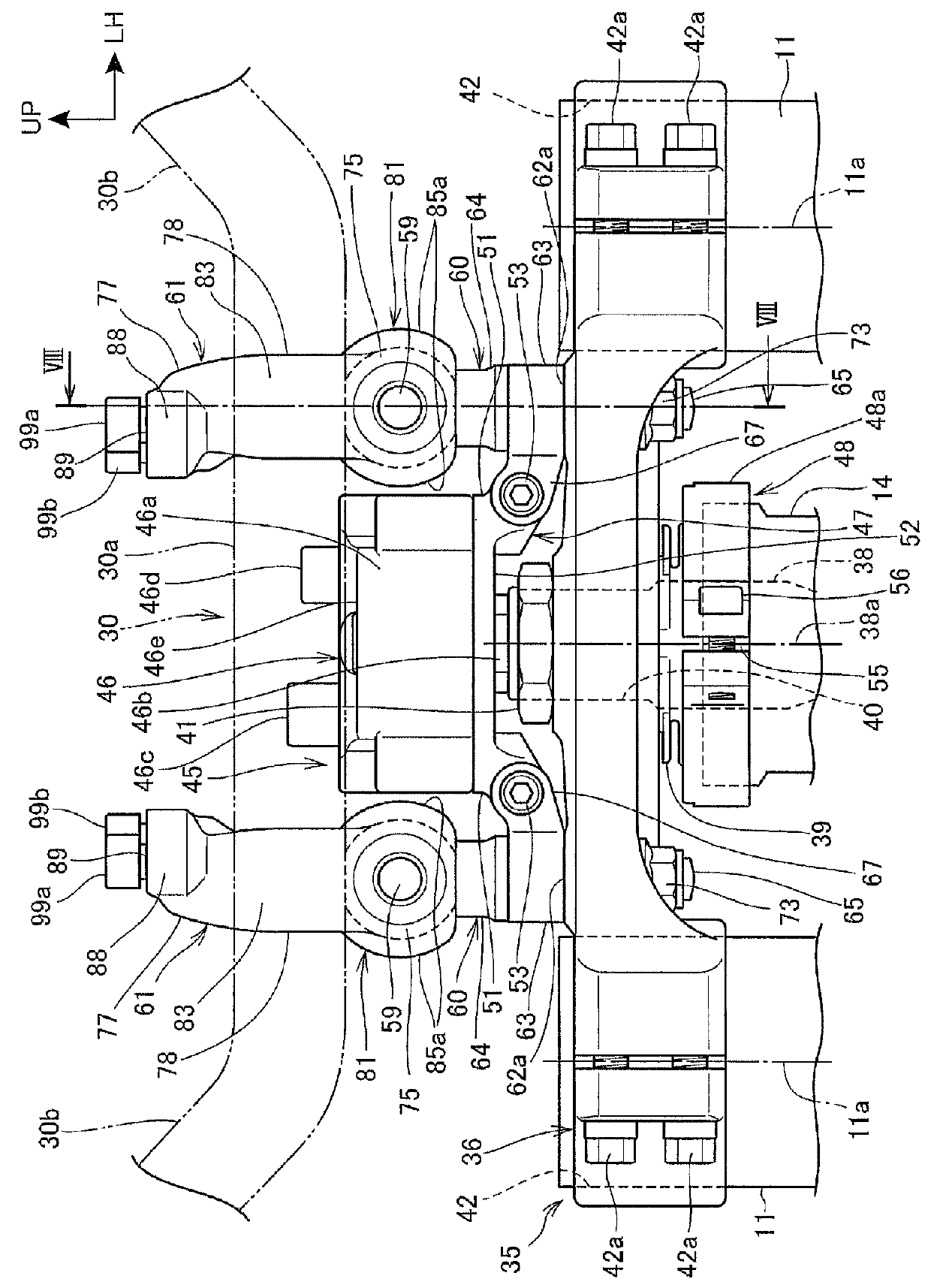

Handlebar fixing structure

InactiveUS20160031520A1High positionImproved vibration absorption performanceFoot-driven leversWheel based transmissionAxial forceEngineering

A handlebar fixing structure enabling a handlebar to be attached to a high position to provide high vibration absorbency. The handlebar fixing structure includes a handlebar, a handlebar post supported above a steering system, and a handlebar clamper for fixing the handlebar to the handlebar post. The handlebar clamper includes a first damper member and a second damper member disposed so as to sandwich a cylindrical portion of the handlebar post and the handlebar from a direction orthogonal to the vehicle widthwise direction. An elastic member is interposed between the first clamper member and the handlebar post and between the second damper member and the handlebar post. The first damper member and the second clamper member are coupled with each other by a bolt and include abutting faces for abutting with each other so as to receive an axial force of the bolt.

Owner:HONDA MOTOR CO LTD

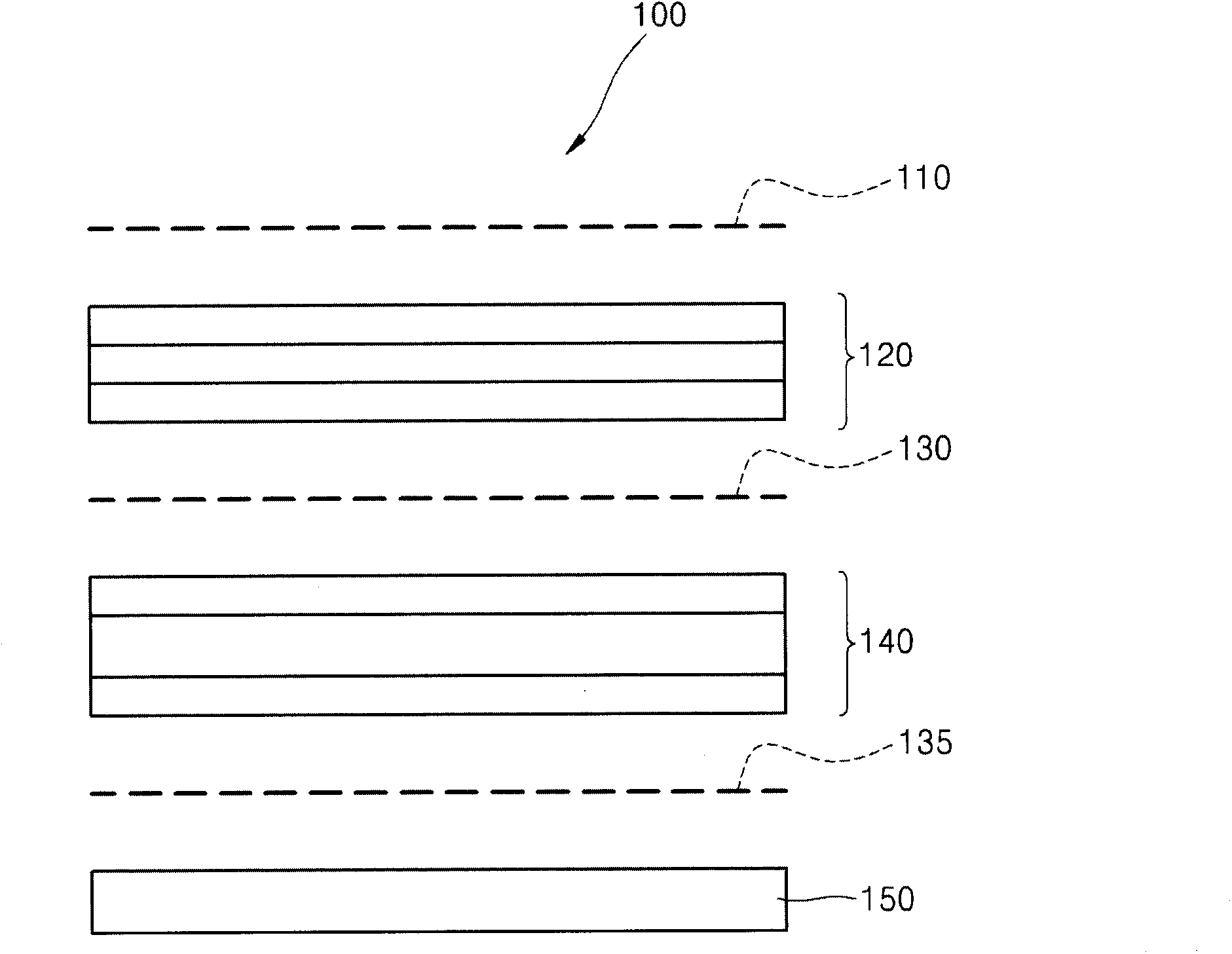

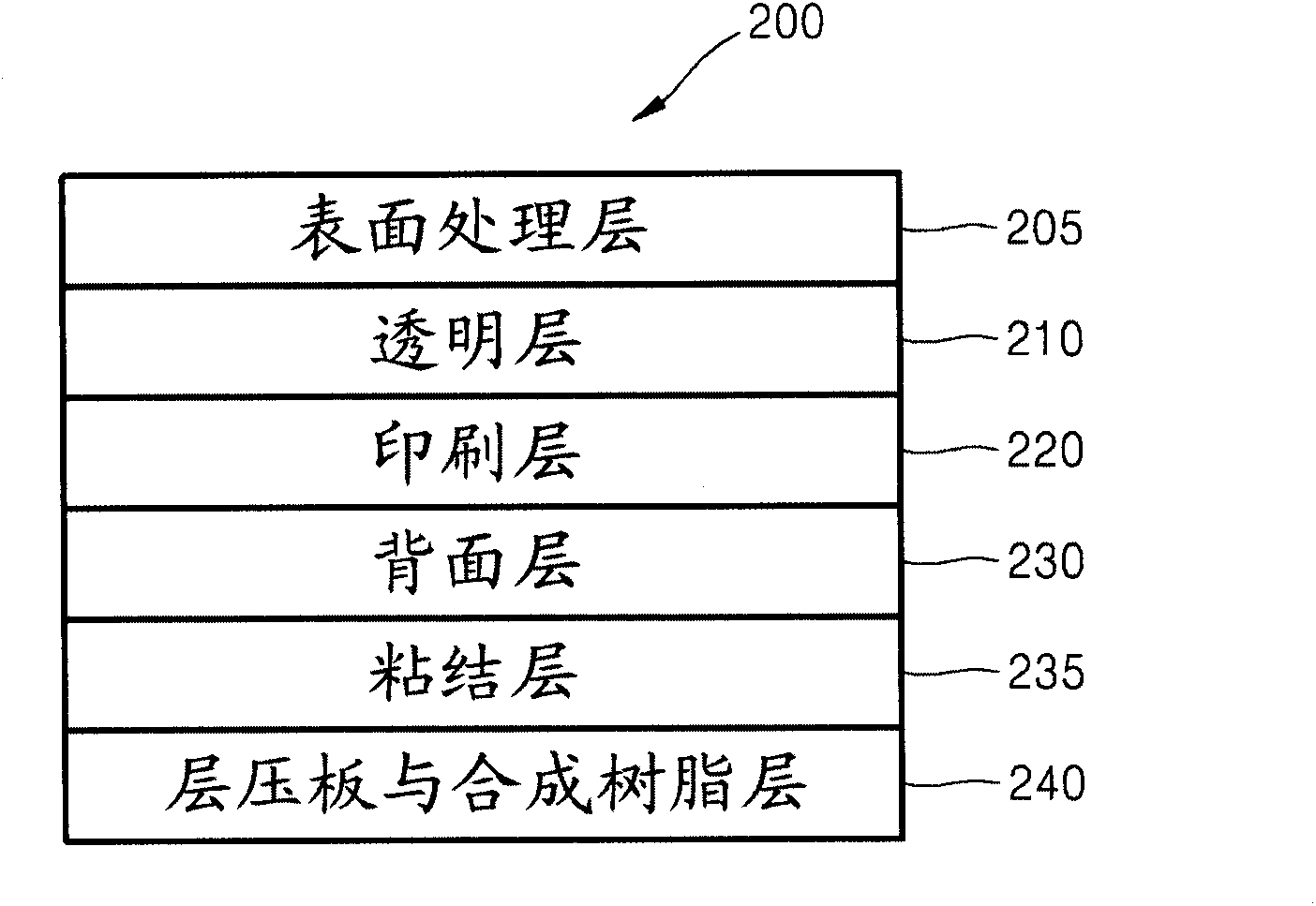

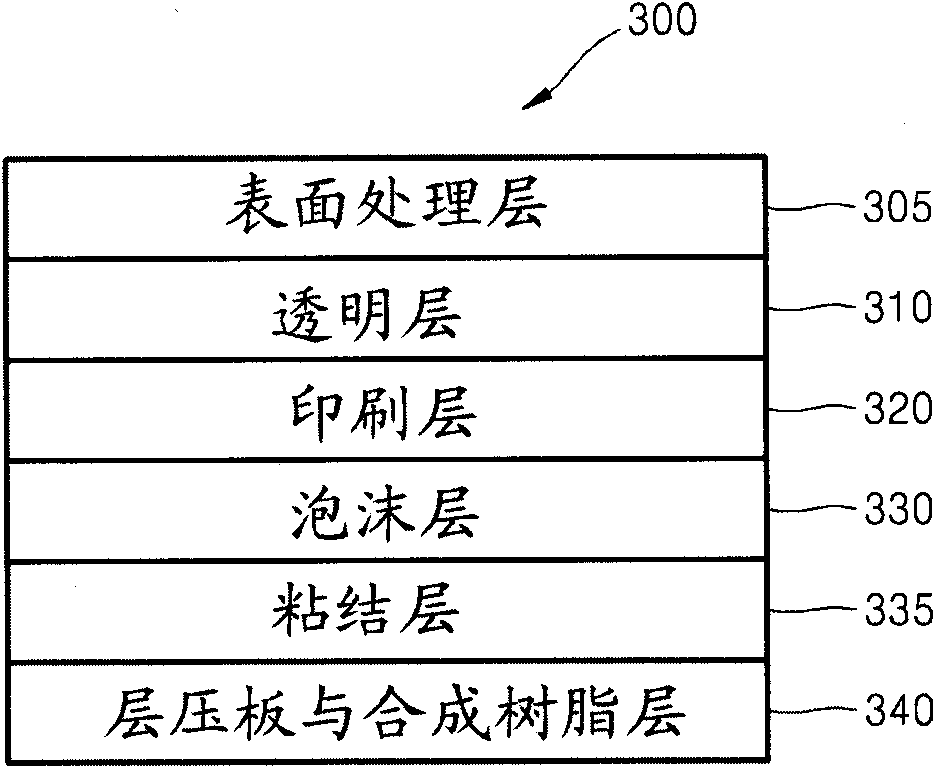

Flooring material including a PLA surface layer having wood patterns

InactiveCN103299009AGood formabilityImprove waterproof performanceSynthetic resin layered productsFloor coveringsSurface layerSynthetic resin

The present invention relates to a flooring material including a PLA surface layer having a wood pattern. The flooring material includes a surface layer including at least one layer containing a PLA resin, a plywood layer including a veneer disposed on the undersurface of the surface layer, and a synthetic resin layer disposed on the undersurface of the plywood layer. The flooring material is cut in a tongue & groove shape.

Owner:LG HAUSYS LTD

Design method of metal rubber shock absorber for pipe support

ActiveCN104866663AReduce vibrationSolution to short lifeSpecial data processing applicationsMetal rubberEngineering

The present invention discloses a design method of a metal rubber shock absorber for pipe support. According to the method, different molding densities are employed for the shock absorber blocks at different positions along a circumferential direction of a pipeline; according to a basic law that the smaller the molding density of the metal rubber, the smaller the support rigidness, and the better the shock absorption performance, a metal rubber shock absorber block having a greater molding density is used at a position under a greater pressure to improve the support rigidness, and a metal rubber shock absorber block having a small molding density is used at a position under a small pressure to improve the shock absorption performance. In this way, under the circumstances of ensuring safe serving of the entire shock absorber, a more reasonable shock absorption effect is achieved. According to the present invention, a plurality of rectangular-approximate shock absorber blocks having different densities are employed and are embedded between a plurality of limiting plates in the pipe. The internally-interconnected spatial mesh structure of the shock absorber block ensures good elasticity and damping performance. The shock absorber blocks at different positions employ different densities under the pressure distribution caused by self-weights, so as to obtain a better shock absorption effect.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com