Stereoscopic knitwork

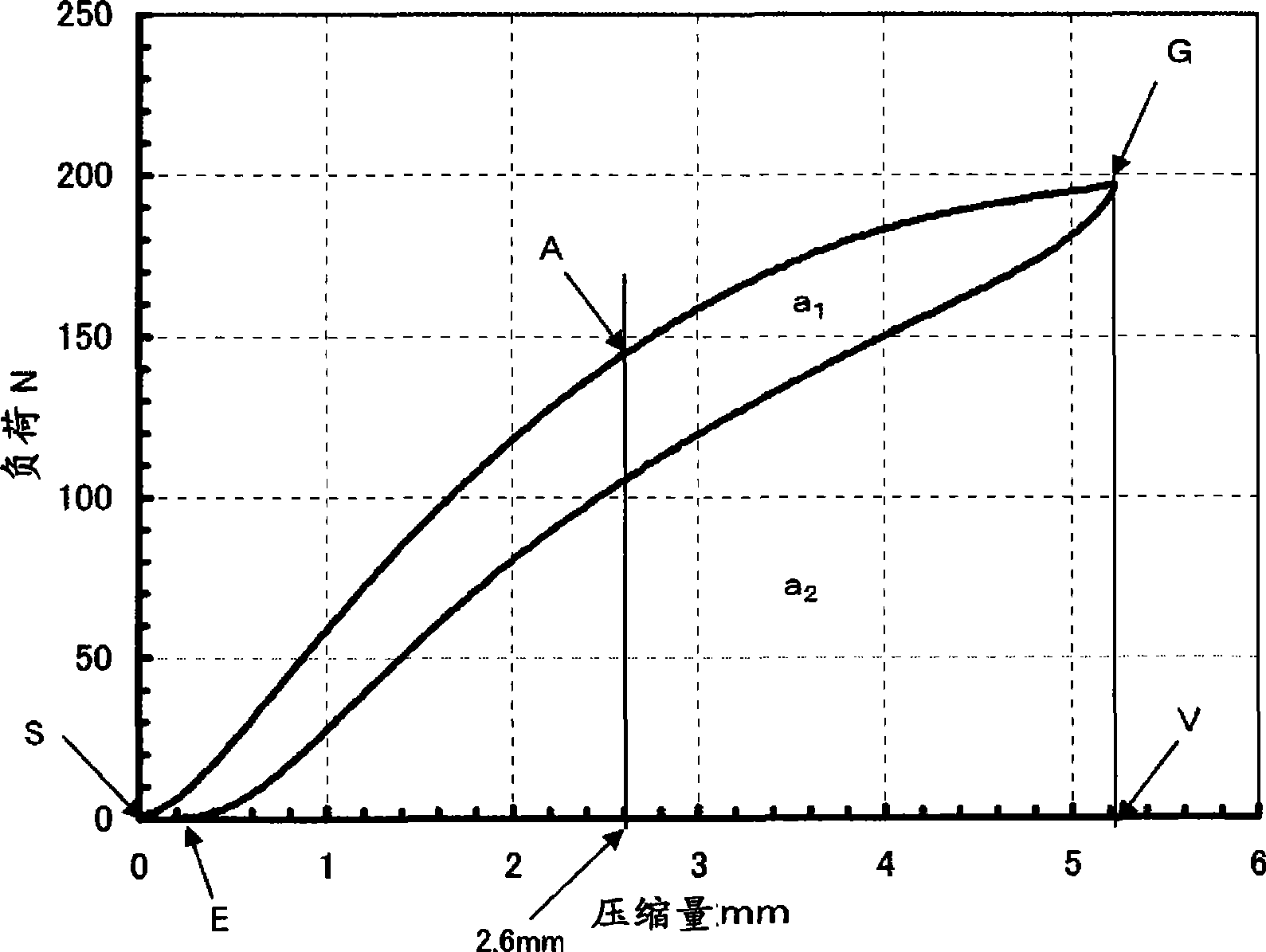

A knitted fabric and three-dimensional technology, applied in the field of three-dimensional knitted fabrics, can solve the problems of insufficient vibration absorption and insufficient shaking stability in the left and right directions, and achieve excellent vibration absorption, good stability, and the effect of preventing concentrated loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

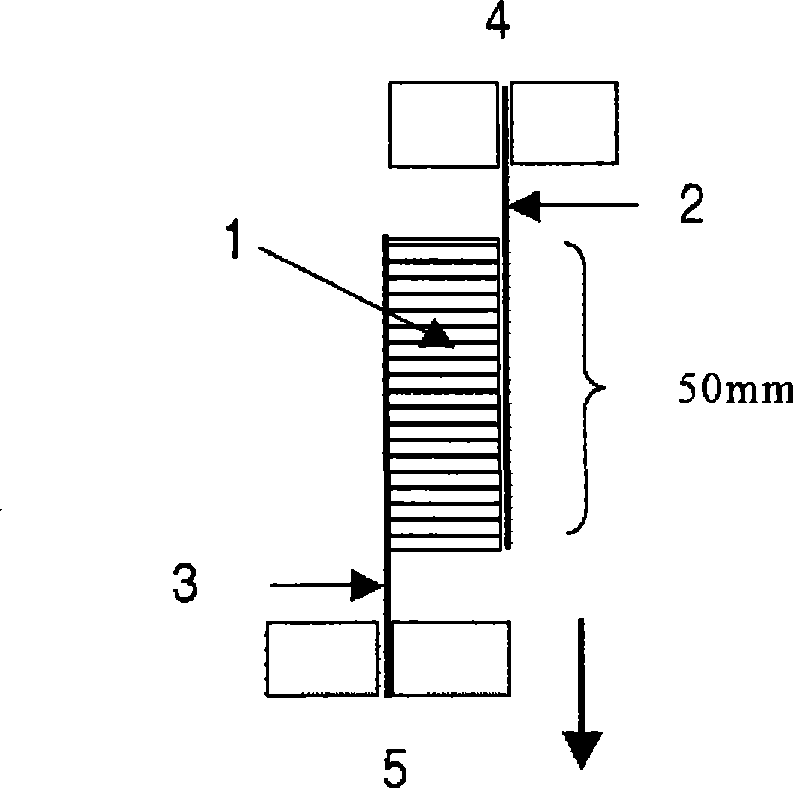

[0073] Using a double-needle bed Raschel knitting machine equipped with 6 guide bars (guide bar) with a gauge of 14 and a needle bed interval of 14.2mm, the 500 False-twisted processed yarn of polyethylene terephthalate fiber with dtex 144 monofilaments, 2 pulls, 1 wear (in) 1 empty (out) (L1) and 1 empty 1 wear (L2) Arrangement and supply of 440 decitex poly(1,3-trimethylene terephthalate fiber monofilaments (manufactured by Sorotex Co., Ltd.)) from the two combs (L3, L4) forming the connection part. Air (L3) and 1 empty 1 wear (L4) are supplied in an arrangement, and then 500 decitex 144 monofilaments are supplied in an all in arrangement from 1 bar (L5) forming the inner knitted layer Polyethylene terephthalate fiber false-twisted processed yarn is supplied with 440 decitex polyethylene terephthalate monofilament (Solotex( Co., Ltd.).

[0074] A gray fabric of a three-dimensional knitted fabric was knitted at a weft density of 12.8 courses / 2.54 cm using the (knitting stru...

Embodiment 2

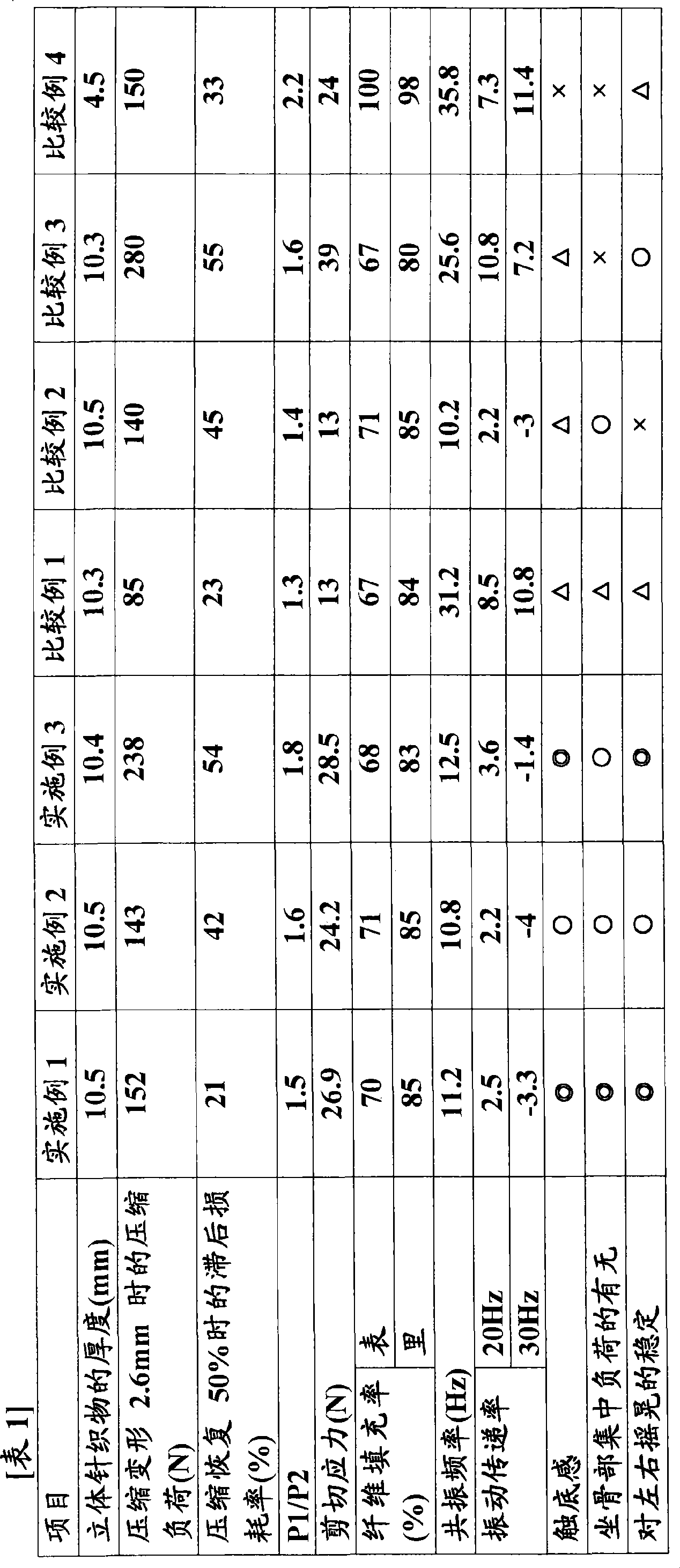

[0083] A gray fabric of a three-dimensional knitted fabric was knitted in the same manner as in Example 1, except that 440 dtex polybutylene terephthalate fiber monofilaments were supplied from the two bars (L3, L4) forming the connecting portion. For the obtained gray cloth 4%, carry out dry heat setting under the condition of 170°C×2 minutes and 30 seconds with an overfeed rate of 1%, with 15.5 courses / 2.54cm, 14.2 wales / 2.54cm, and a thickness of 10.5mm , forming a part of one continuous connecting yarn into a triangular shape with the surface side knitted layer as the base, and obtaining a number ratio of 1:1 of connecting yarns forming a triangular shape and an oblique shape, the surface side knitted layer A three-dimensional knitted fabric in which reinforcing yarns are inserted into the mesh openings. The physical properties of the obtained three-dimensional knitted fabric are shown in Table 1.

Embodiment 3

[0085] Except that 440 dtex polyethylene terephthalate fiber monofilaments are supplied from the two bars (L3, L4) forming the connecting portion, and the weft density is 12.0 courses / 2.54cm, the same as in Example 1 The gray cloth of three-dimensional knitted fabric. 6% of the obtained gray cloth was dry heat-set with an overfeed rate of 1% at 155°C for 2 minutes and 30 seconds, with 14.5 courses / 2.54cm, 14.0 wales / 2.54cm, and a thickness of 10.4mm. , forming a part of one continuous connecting yarn into a triangular shape with the surface side knitted layer as the base, and obtaining a number ratio of 1:1 of connecting yarns forming a triangular shape and an oblique shape, the surface side knitted layer A three-dimensional knitted fabric in which reinforcing yarns are inserted into the mesh openings. The physical properties of the obtained three-dimensional knitted fabric are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com