Flooring material including a PLA surface layer having wood patterns

A technology for floor materials and surface layers, applied in floor coverings, wood layered products, floors, etc., can solve problems such as insufficient strength, achieve the effect of solving height differences and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

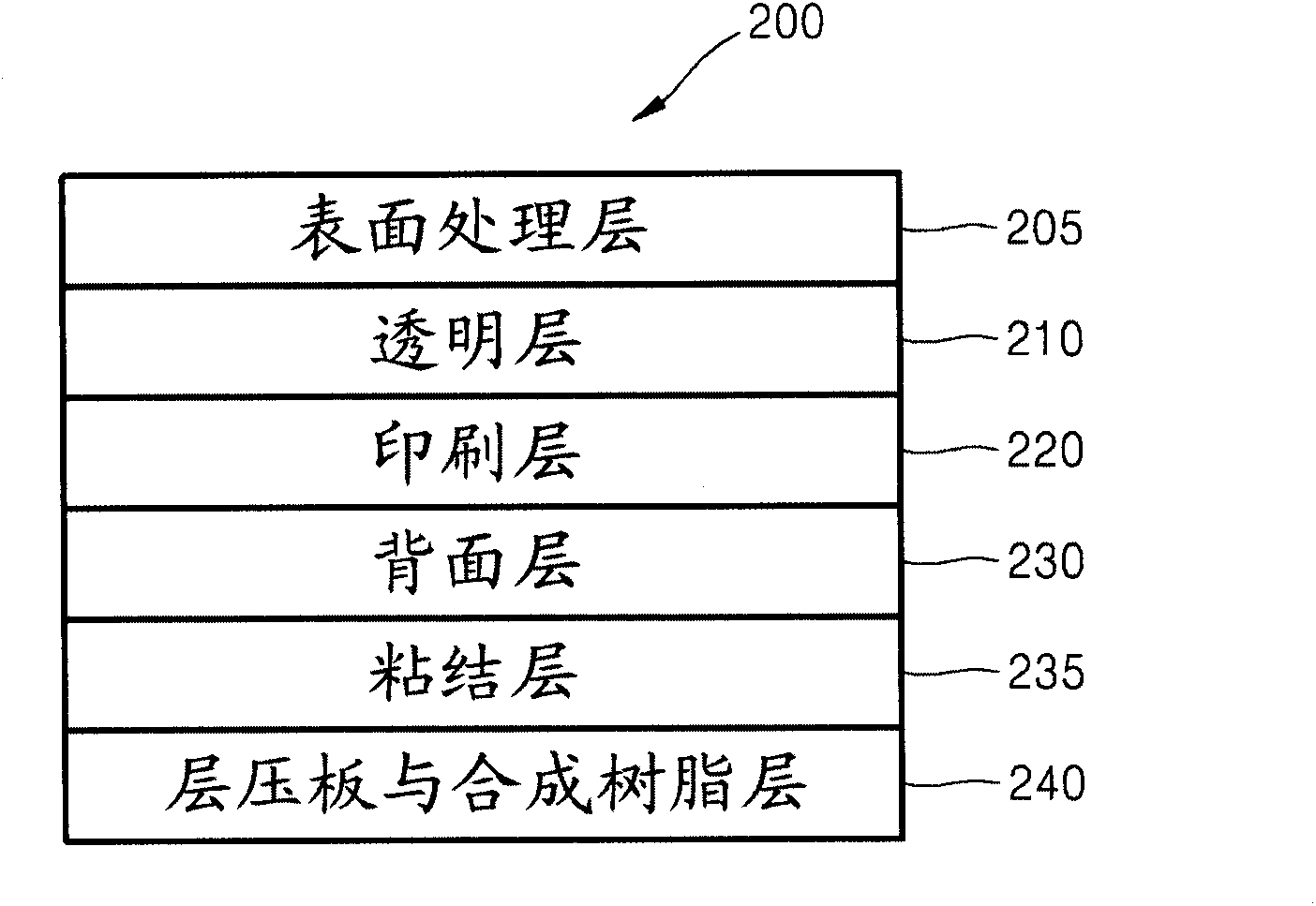

[0114] Preparation of transparent layer

[0115] For 100 parts by weight of PLA resin, 2002D (melt index: less than 3, NatureWorks LLC), 20 parts by weight of ATBC, 10 parts by weight of acrylic copolymer, 5 parts by weight of stearic acid, and 5 parts by weight of carbodiimide , first kneaded using an extruder, kneaded using a Banbury mixer at 140°C, and then underwent primary and secondary mixing at 140°C using 2 rolls. The prepared raw material was then subjected to calendering at 130° C., thereby producing a sheet having a thickness of about 0.6 mm.

[0116] Preparation of printing layers

[0117] Except using 100 parts by weight of PLA resin, 30 parts by weight of ATBC, 10 parts by weight of acrylic acid copolymer, 5 parts by weight of stearic acid, 5 parts by weight of diisocyanate, 5 parts by weight of carbodiimide, Except for 50 parts by weight of calcium carbonate, and 20 parts by weight of titanium dioxide, a 0.2 mm thick sheet was prepared in the same manner as fo...

example 1

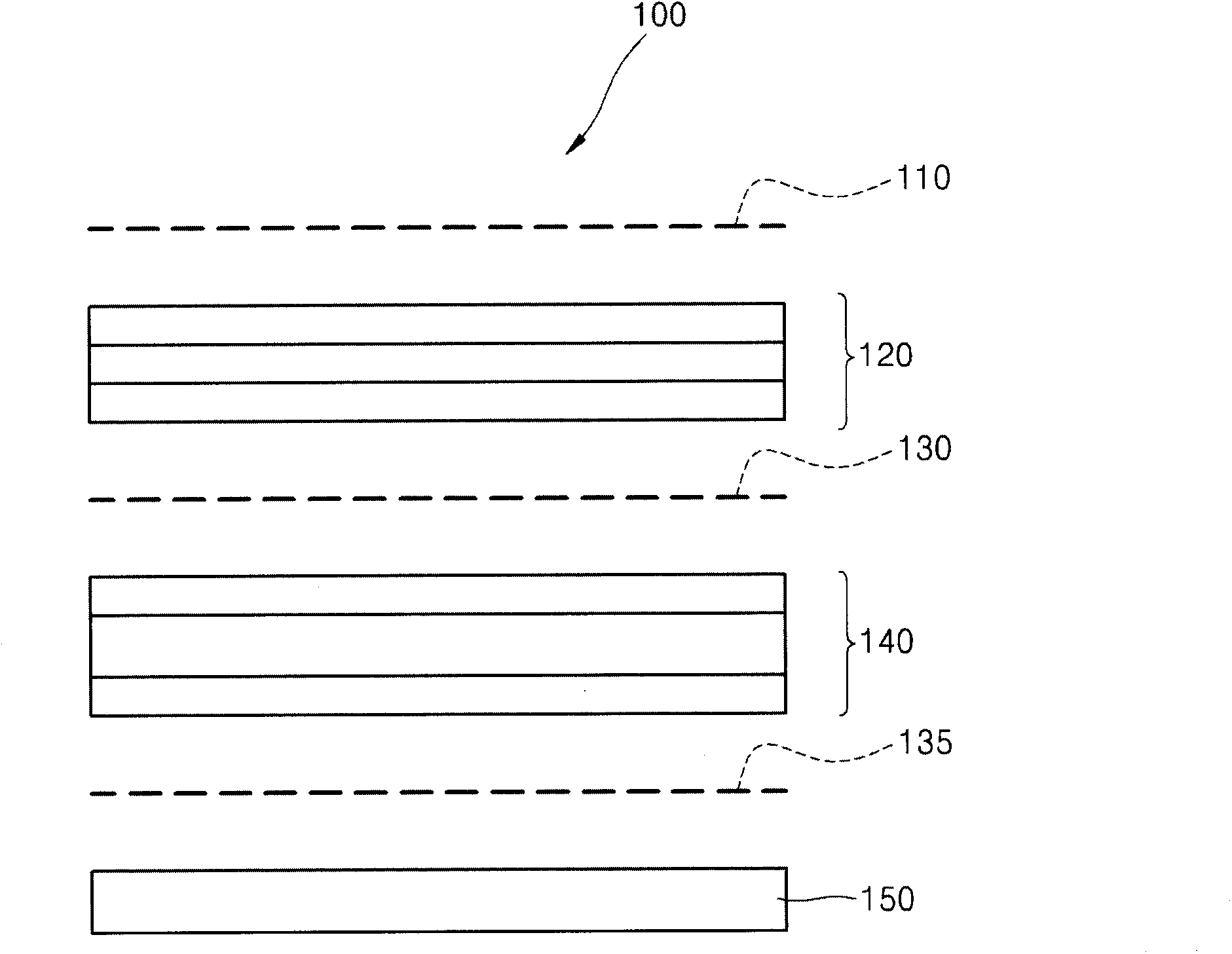

[0146] After depositing the adhesive, synthetic resin layers, plywood layers, and wood-grain PLA surface layers are stacked and integrated by cold pressing, followed by surface coating and cutting into tongue-and-groove shapes, thereby preparing wood-grain flooring Material f.

[0147] In this example, the PLA surface layer has a thickness of 0.3-3.0 mm, the plywood layer has a thickness of 4.2-12.0 mm, and the polyvinyl chloride layer is set as a synthetic resin layer having a thickness of 1.2-4.5 mm, so that the floor material has a thickness of 7.0 mm. -15mm total thickness.

example 2

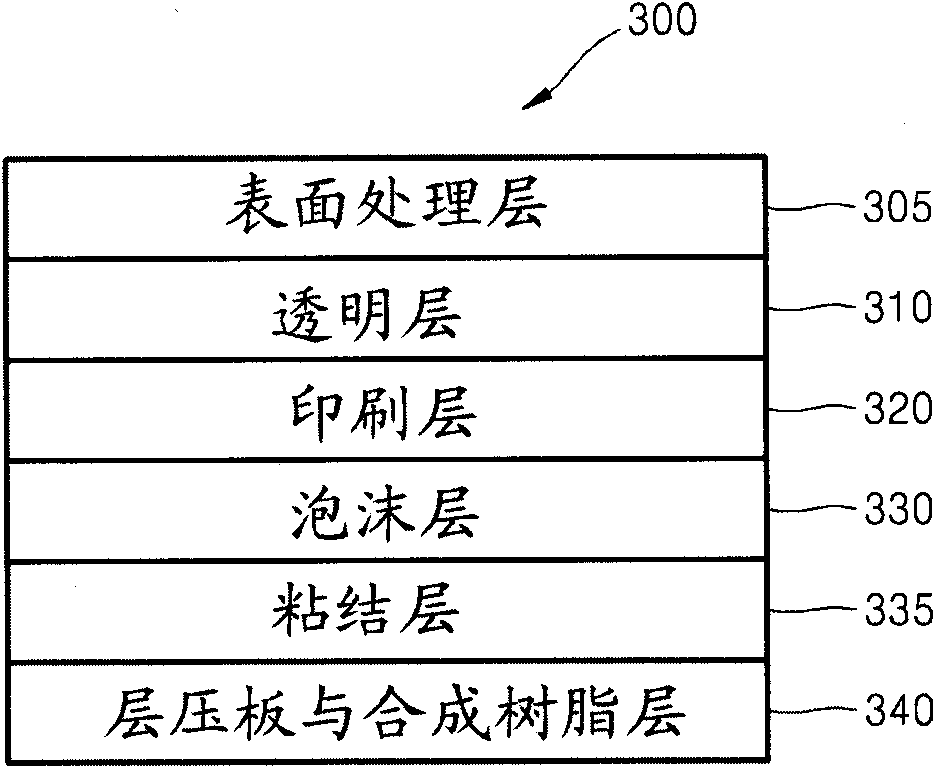

[0149] A flooring material was prepared in the same manner as in Example 1 except that the synthetic resin layer included 75 parts by weight of calcium carbonate based on 100 parts by weight of the polyvinyl chloride layer.

[0150] In addition, 10 parts by weight of emerald or loess are further added based on 100 parts by weight of calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com