Workpiece shaft numerical control motion platform device for ultraprecision machining

A technology of ultra-precision machining and motion platform, used in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problem that high-precision linear motors cannot fully meet the requirements of dustproof, magnetic isolation, cutting fluid resistance, and discomfort. Small-caliber aspheric surface processing machine tools, bulky and other problems, to achieve the effects of high rotation accuracy, improved performance, and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

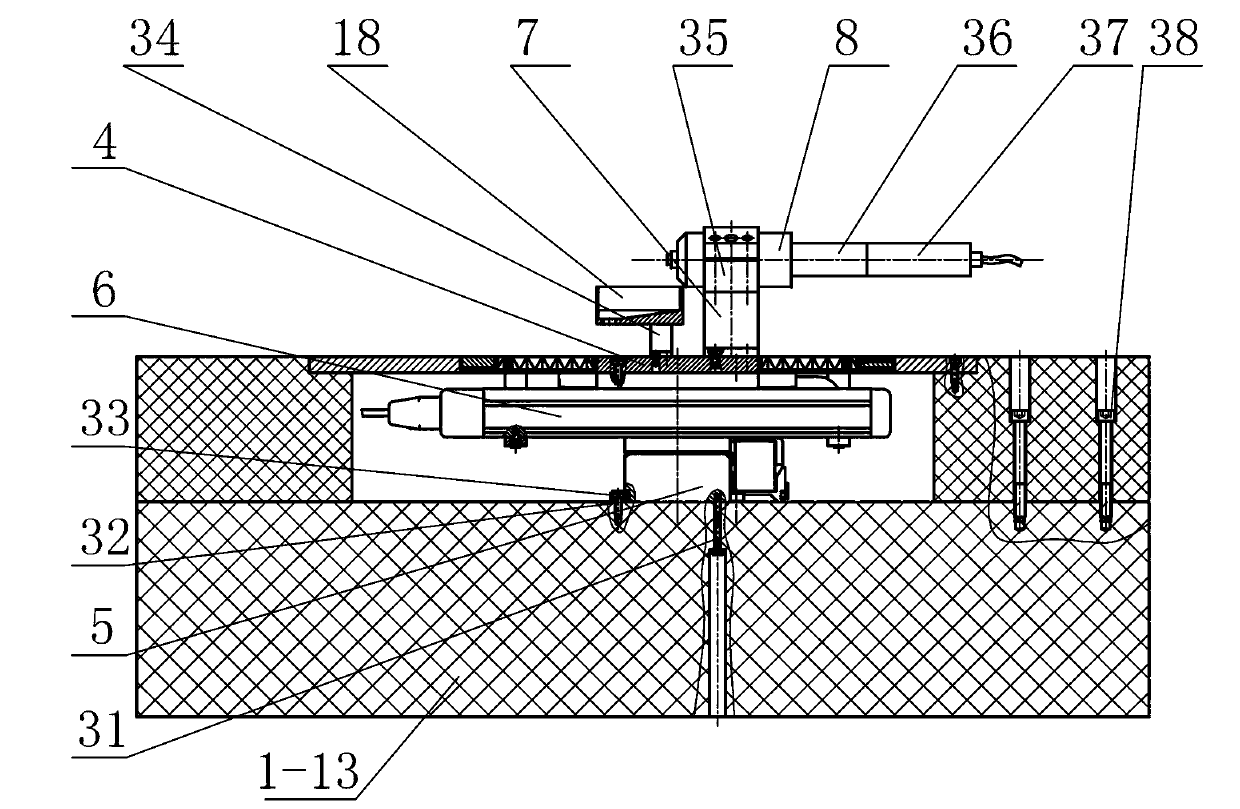

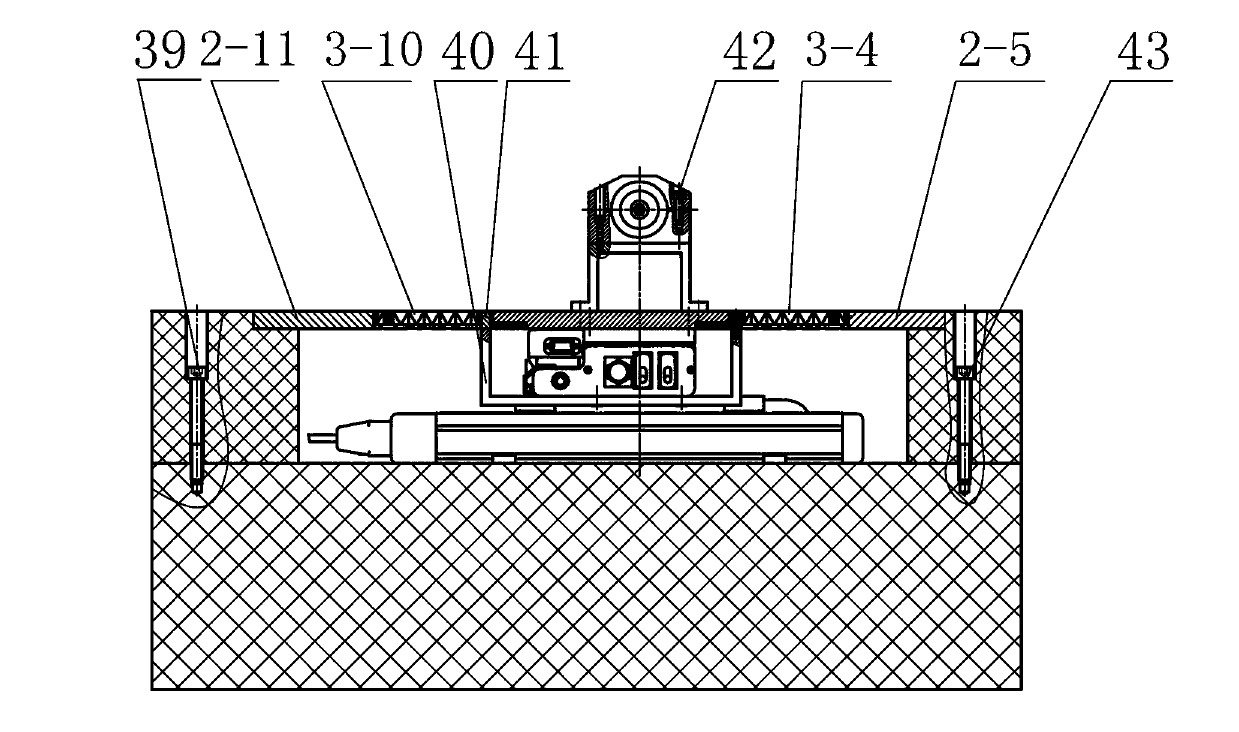

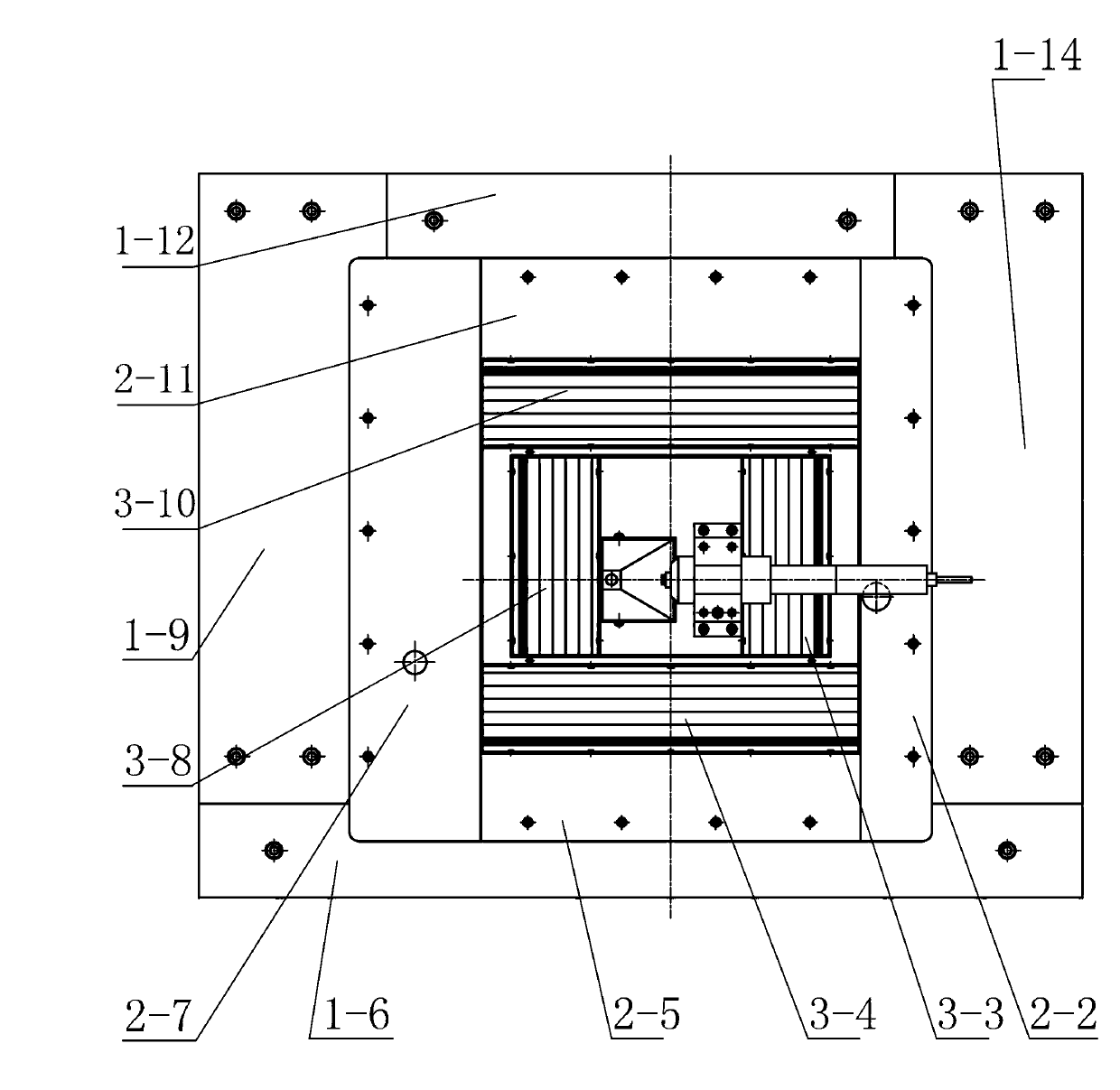

[0017] Specific implementation mode one: as Figure 1-7 As shown, a workpiece axis CNC motion platform device for ultra-precision machining described in this embodiment includes an XY precision mobile platform, a machine base 1, a cover plate 2, an organ protective cover 3, a workbench 4, a workpiece spindle support 7, and a workpiece Main shaft 8, CCD tool setting device 17 and liquid return tank 18; the XY precision mobile platform includes an X-axis linear unit 6 and a Y-axis linear unit 5, and the X-axis linear unit 6 is placed on the Y-axis linear unit 5; There is a cavity 1-1 for accommodating the XY precision mobile platform, the XY precision mobile platform is placed in the cavity 1-1 of the machine base 1, and the workbench 4 is installed on the upper end surface of the X-axis linear unit 6 of the XY precision mobile platform , a cover plate 2 is arranged around the chamber 1-1, an organ protective cover 3 is arranged between the edge of the workbench 4 and the cover ...

specific Embodiment approach 2

[0018] Specific implementation mode two: as Figure 1-7 As shown, the XY precision mobile platform described in this embodiment adopts the linear motor platform 404T01LXR of Parker Company of the United States. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: as Figure 1-7 As shown, the workpiece spindle 8 in this embodiment adopts the precision electric spindle NR50-5100ATC of NSK Corporation of Japan. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com