Unclamping method and device adopting continuous jarring through spring periodically stretching out and drawing back

A technology of piston spring and spring assembly, which is applied in the field of downhole card release in horizontal wells in oilfields, can solve the problems of inability to salvage, and the inability to transmit the lifting force of a jar, achieve good dry running characteristics, improve vibration absorption performance, and improve fatigue the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

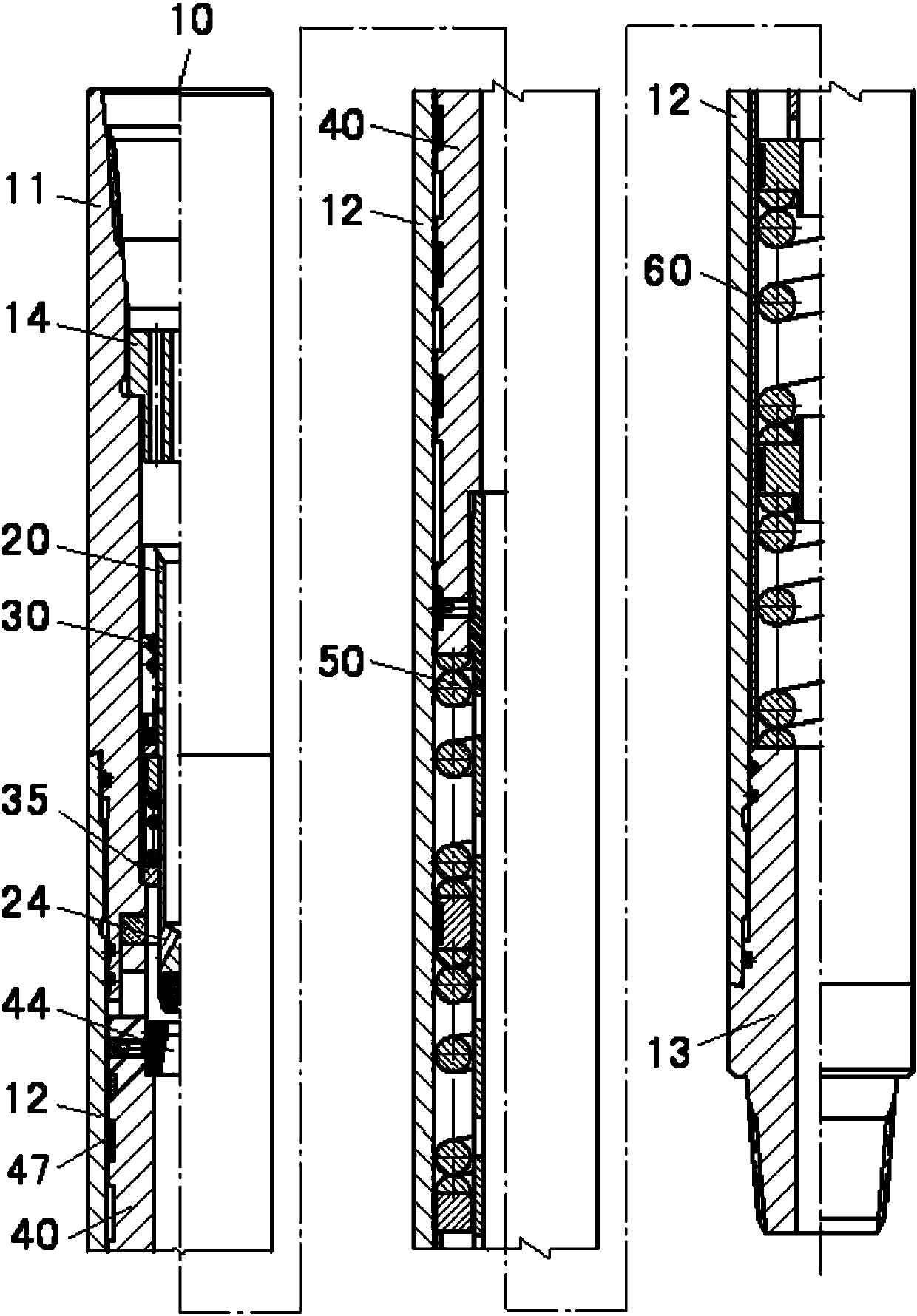

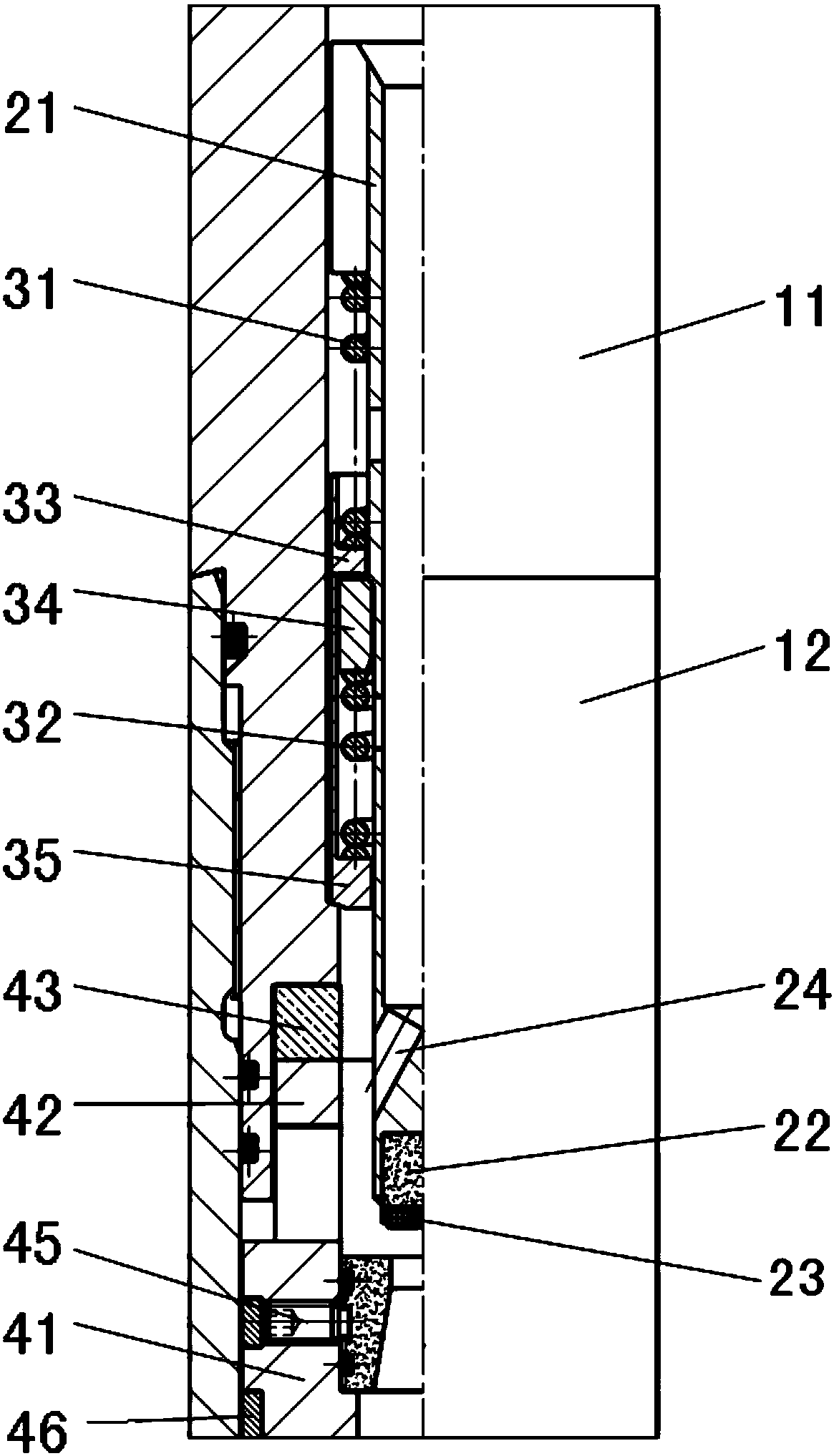

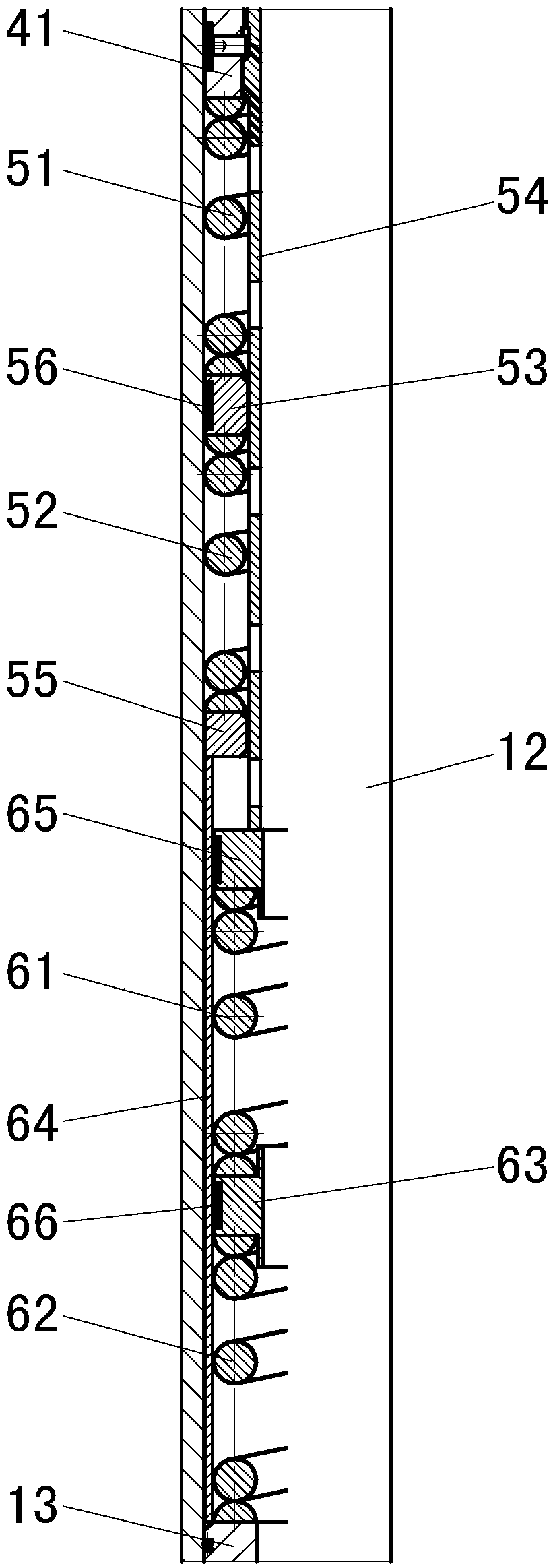

[0025] A method for unblocking the present invention using periodic stretching and continuous vibration of springs, such as Figure 1-3 As shown, the method in this example is to install a valve in the pipe string. When the circulating hydraulic pressure entering the pipe string is greater than the reaction force of the spring inside the pipe string, when the valve hole is closed, the circulating hydraulic pressure compresses the spring and converts it into the compression potential energy of the spring. When the compression potential energy of the spring gradually increases and equals the circulating fluid pressure, the valve opens, causing the pressure in the pipe string to become unbalanced instantly. The compression potential energy of the spring is released instantly and drives the shock hammer in the pipe string to suddenly impact upwards, and the impact kinetic energy passes through the pipe string. Transfer to the stuck point; after completing one impact, all components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com