Precision CNC milling fixture for servo mechanism oil pump swash plate parts

A technology of precision numerical control and servo mechanism, applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of low quality stability, long development cycle, low production efficiency, etc., achieve low manufacturing cost, assembly Easy to clamp and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

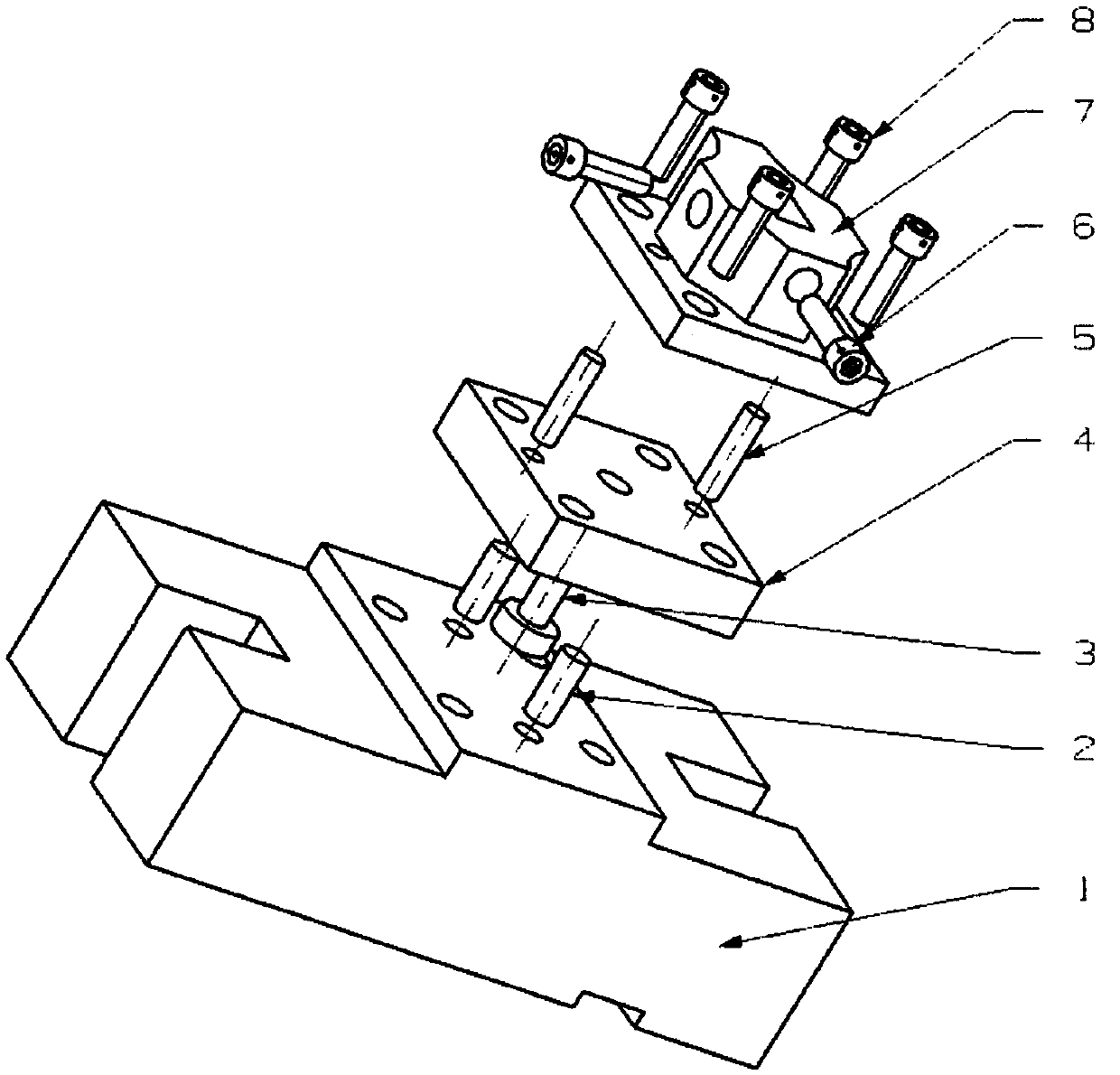

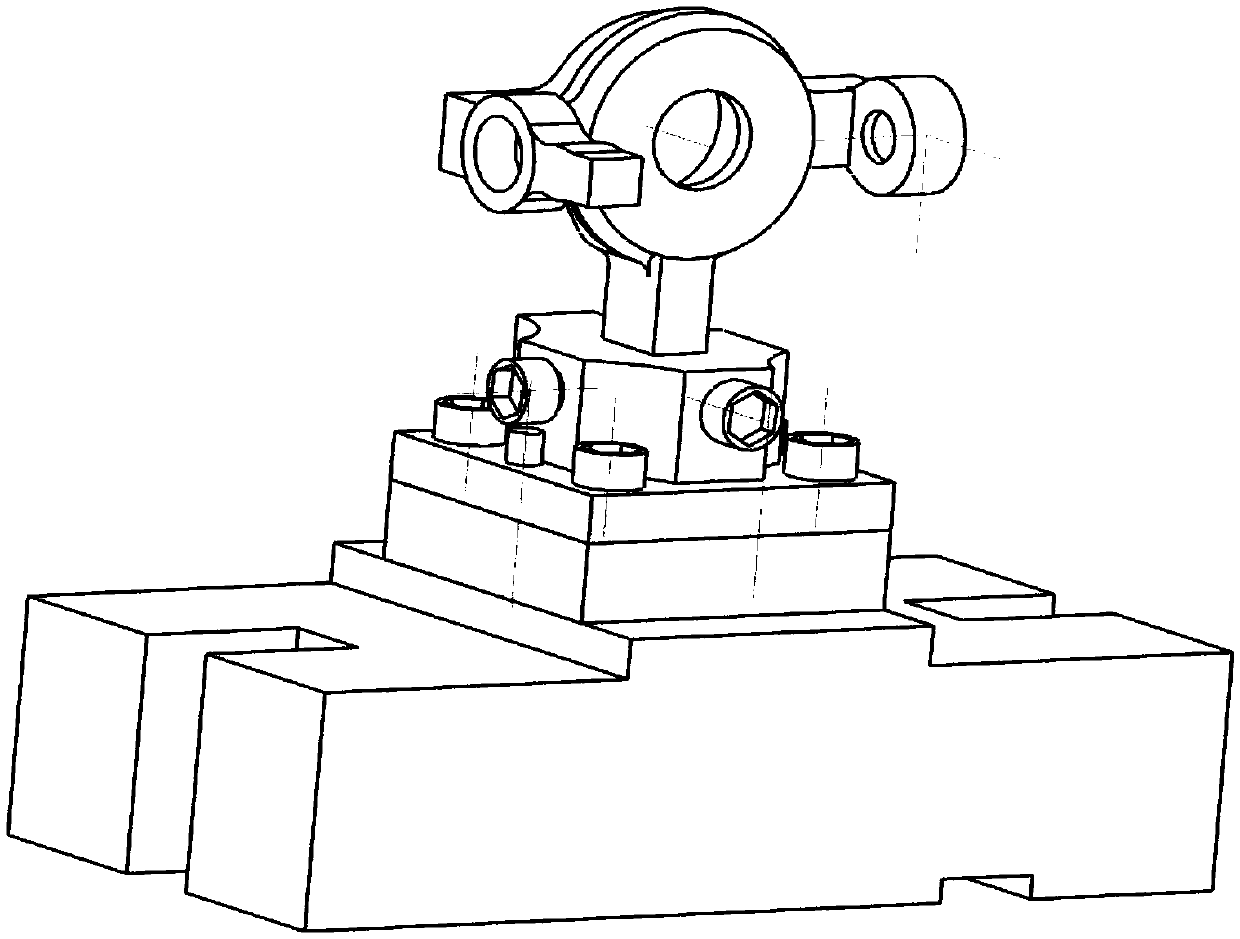

[0021] The features of the parts to be clamped are typical weakly rigid parts, which are hollow and sheet-shaped. Due to the poor rigidity of the parts themselves, in order to ensure the rigidity of the entire process system to ensure the geometric tolerance and surface roughness of CNC machining, it can also be To avoid interference among parts, fixtures and tools, the design process clamping device is a two-top and one-pull CNC fixture to meet the needs of CNC integrated processing. The clip specifically includes: mounting seat 1, positioning and orientation pin 2, pull-down bolt 3, pull block 4, interference pin 5, side tightening screw 6, chuck seat 7, and compression screw 8.

[0022] The mounting seat 1 is positioned on the basic block of the worktable of the numerical control equipment through the cross keyway of the bottom plane, and is fastened and connected with bolts. The upper end surface of the mounting seat 1 is provided with two pin holes and four mounting screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com