Multi-station triaxial force application testing machine

A multi-station, testing machine technology, applied in the field of machinery, can solve problems such as inflexibility, low test efficiency, and inconsistency with the actual vehicle force application state, and achieve the effect of improving efficiency and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described now in conjunction with accompanying drawing.

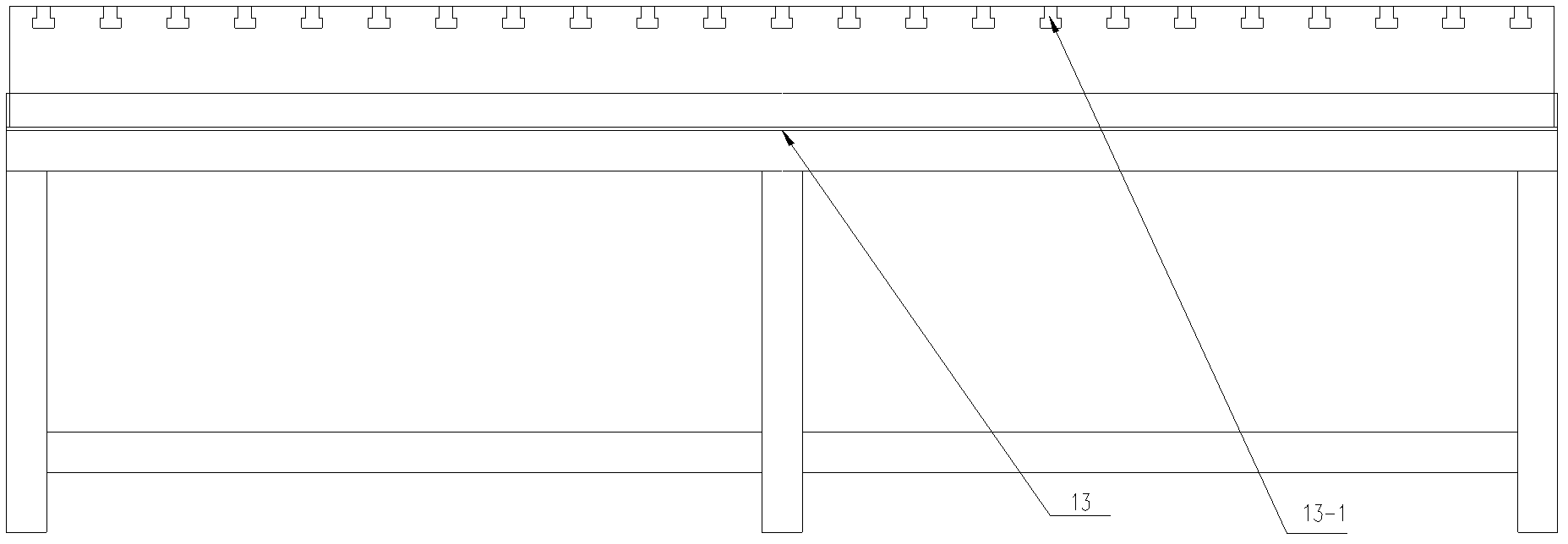

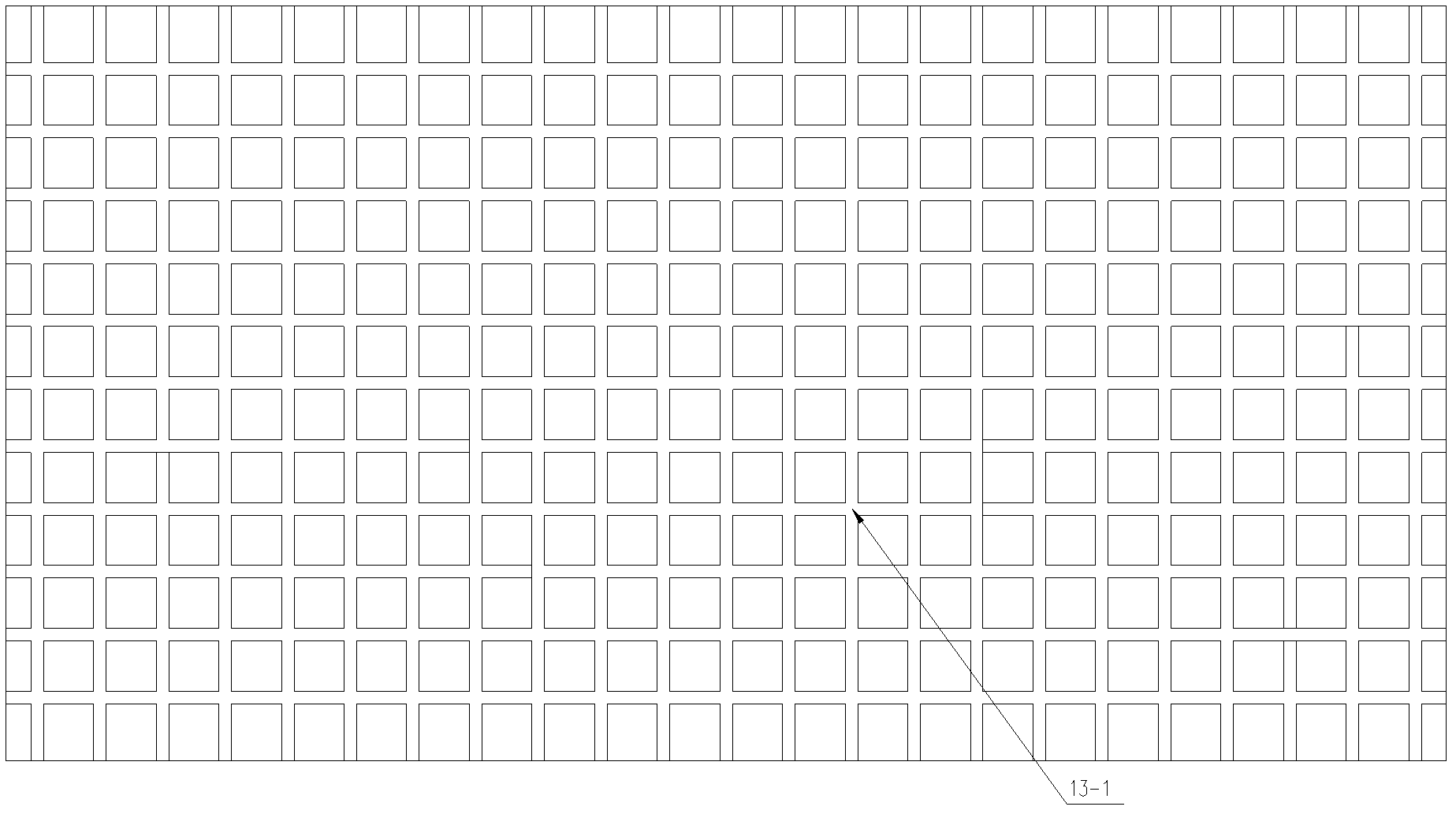

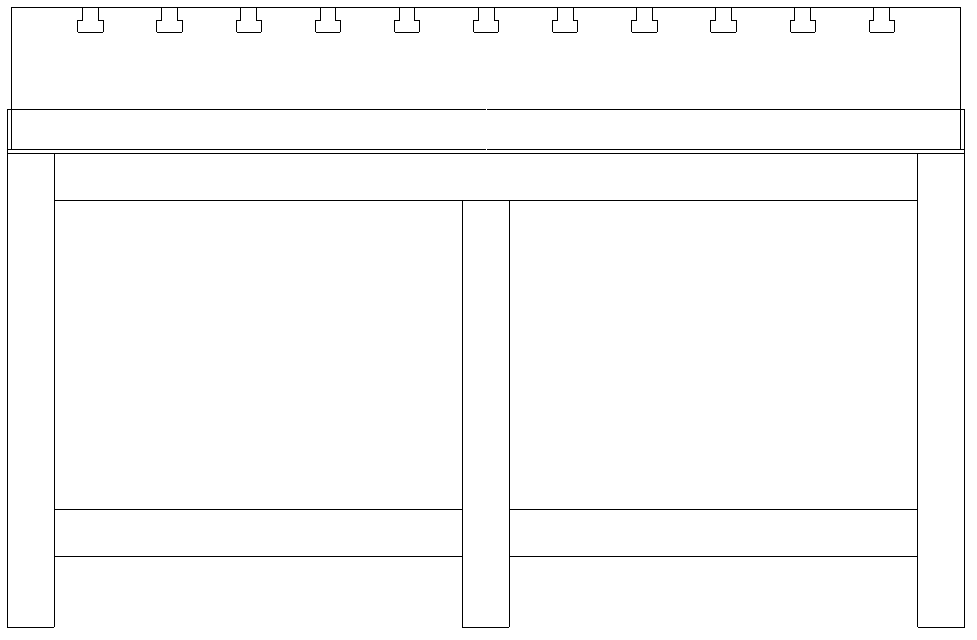

[0034] see Figure 17 In the present invention, the multi-station three-axis force-applying testing machine includes a platform, a driving mechanism, a control system, a force-applying mechanism in X, Y, and Z directions and an adjustable sample fixing mechanism for fixing the sample to be tested. The X, Y, Z direction force applying mechanism and the adjustable sample fixing mechanism are all arranged on the platform. In order to facilitate the placement and combination of the X, Y, Z direction force applying mechanism and the adjustable sample fixing mechanism, the platform 13 The slots can be arranged in a well-shaped shape, and the slot 13-1 is a T-shaped slot, see Figure 1(a) ~ Figure 1(c) .

[0035] see Figure 17 and figure 2 , the structures of the X-direction force application mechanism 17-1 and the Y-direction force application mechanism 17-2 are consistent, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com