Wood golf club head

a golf club head and wood technology, applied in the field of golf clubs, to achieve the effect of reducing weight, reducing weight, and increasing siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

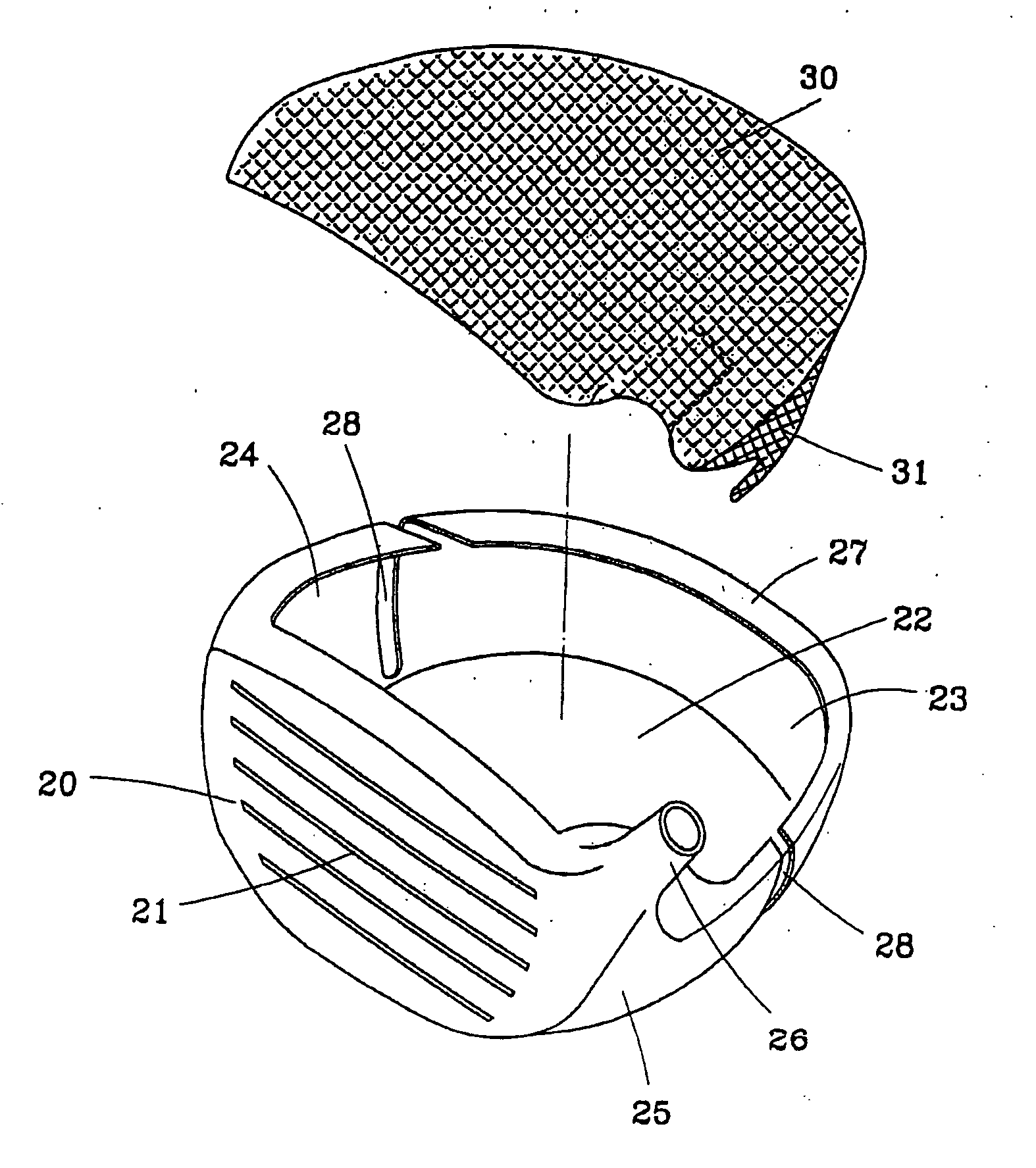

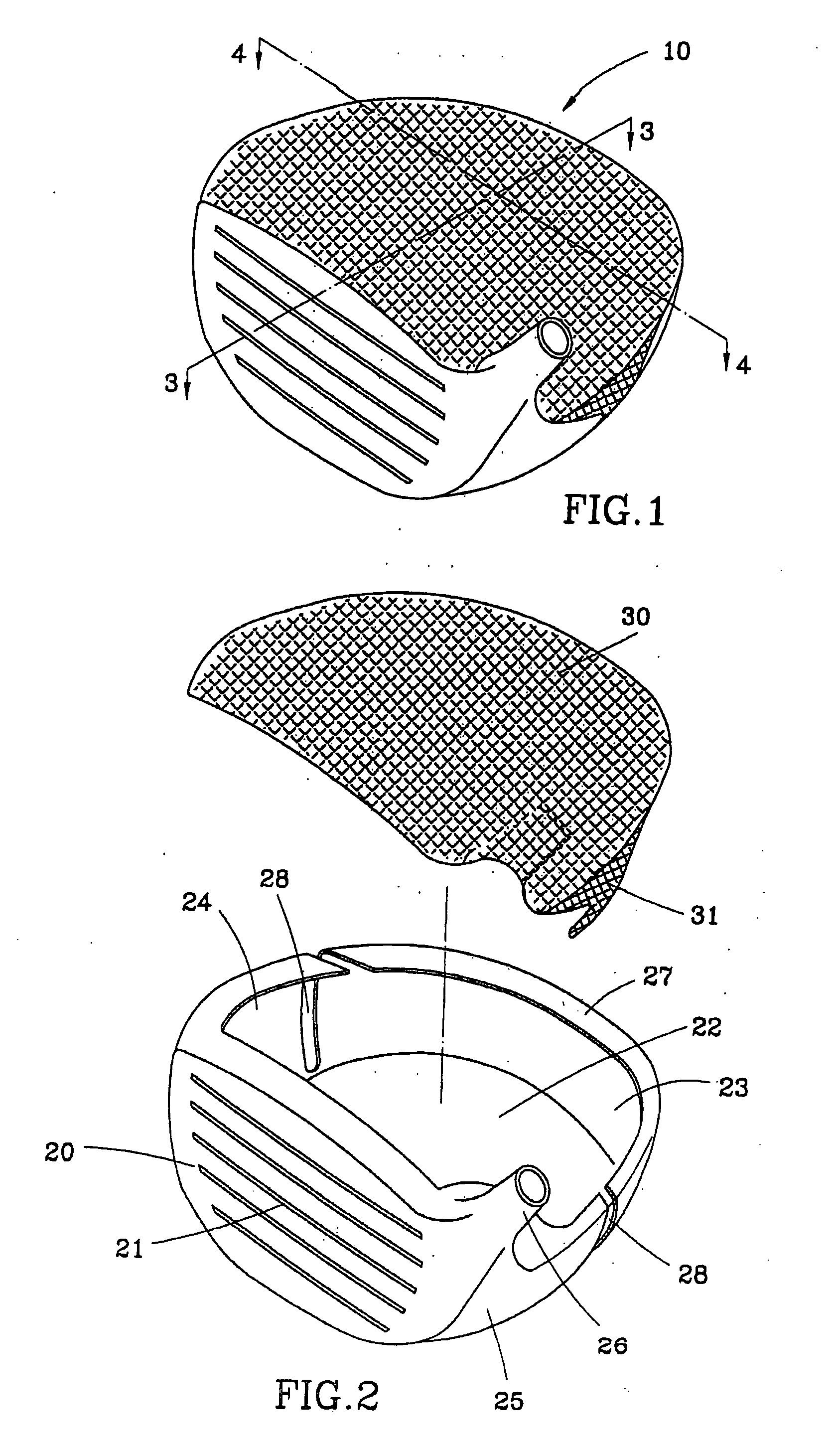

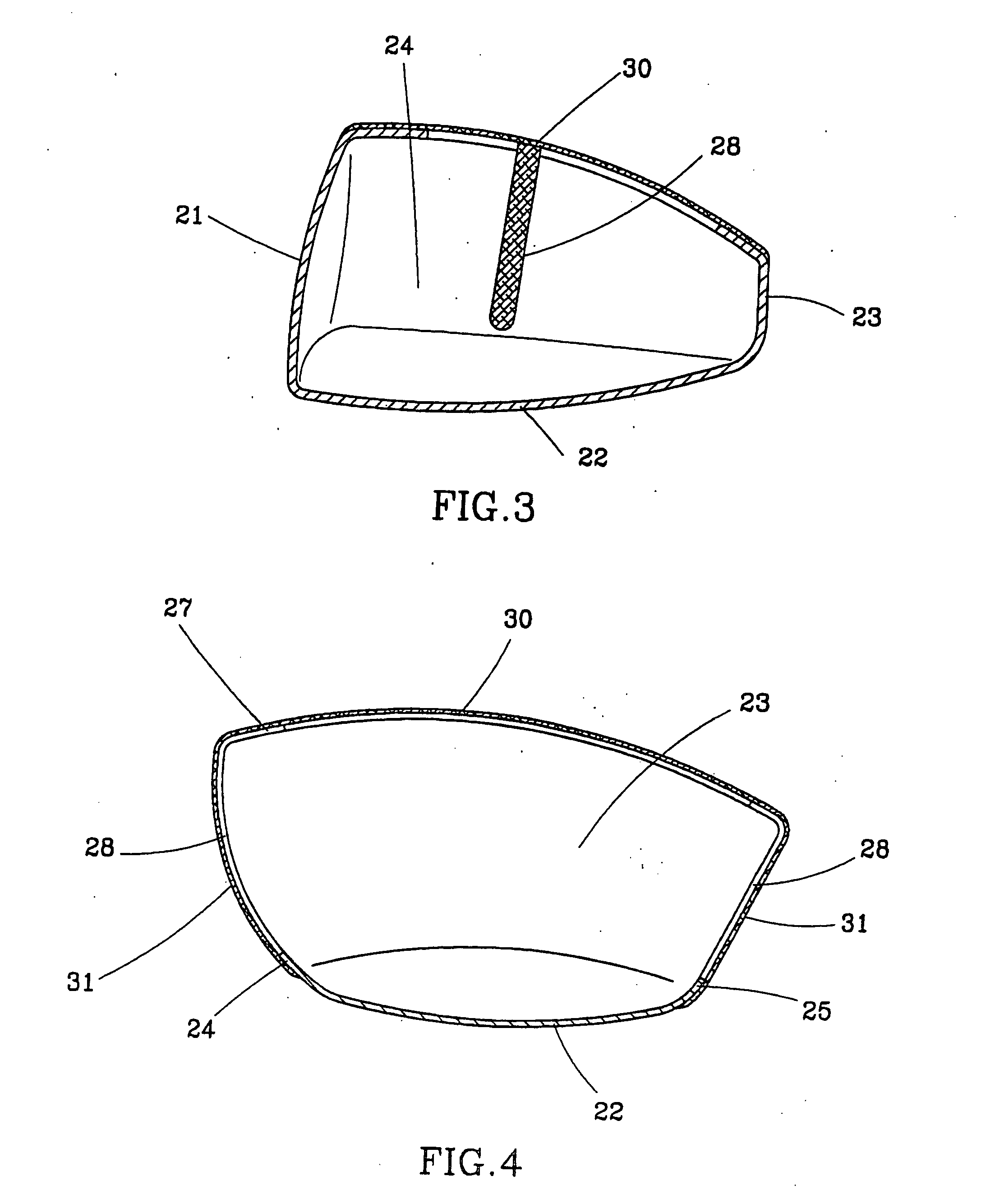

[0014] As shown in FIGS. from FIG. 3 to FIG. 5, a golf club head 10 of the first preferred embodiment of the present invention comprises:

[0015] A metallic head housing 20 has a face 21, a sole 22, a rear 23, a toe 24, a heel 25, and a neck 26. The head housing 20 is hollow and has an opening at a top thereof. Around the top of the head housing 20 is an annular shoulder portion 27 and at the toe 24 and the heel 24 is a gap 28 respectively. The gaps 28 are extended downwardly from the shoulder portion 27 to the toe 24 and the heel 24 at where adjacent to the sloe 22 respectively.

[0016] A nonmetallic crown 30, which is made of carbon fiber prepreg epoxy resin, or other fiber reinforced resin or plastics in the present preferred embodiment, has two arms 31 at opposite sides thereof. The crown is a thin plate to be coupled to the top of the head housing 20, in which the shoulder portion 27 is attached to a bottom of the crown 30 and the arms 31 of the crown 30 are attached on the toe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com