Environment-friendly inflaming retarding butyl rubber and ethylene propylene diene monomer rubber multielement blended blind-hole secondary foaming material and preparation method thereof

A technology of EPDM and butyl rubber, applied in the field of foaming materials, can solve the problems of increasing costs of downstream production enterprises, affecting the health of the industry, orderly development, and declining profits, so as to improve ozone resistance and make up for resistance. Flammability requirements, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

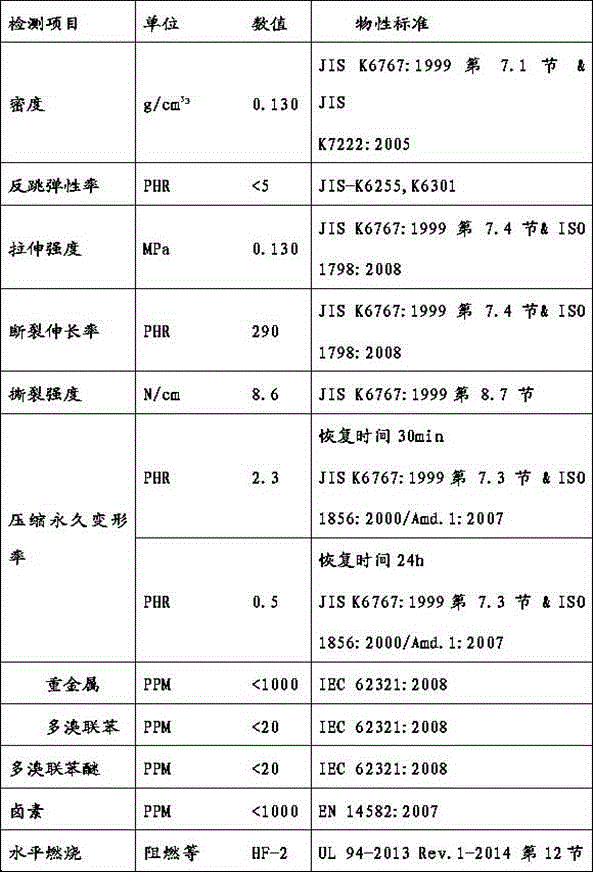

Embodiment 1

[0047] The preparation method of the environment-friendly flame-retardant butyl rubber and EPDM multi-component blended closed-cell secondary foaming material comprises the following steps:

[0048] (1) Butyl rubber mastication: put 100PHR of butyl rubber and 0.2PHR of stearic acid into a 75L diamond-shaped leaf shaft W-type heavy hammer internal mixer, pressurize to 7 kg, and knead for 10 minutes. Continuously fill with cold water to cool down, and when the temperature reaches 110°C, the butyl rubber is discharged to obtain butyl rubber; put the butyl rubber into the 18-inch automatic turning mill, the temperature is controlled at 85°C, and the 5mm turning is 180 seconds , thin through 2mm thickness fluttering cut into the corresponding weight respectively static processing;

[0049](2) EPDM rubber refining: Put 100PHR of EPDM rubber and 0.1PHR of stearic acid into a 75L diamond-shaft W-type hammer internal mixer, pressurize to 7 kg, and knead for 10 minutes , during the kne...

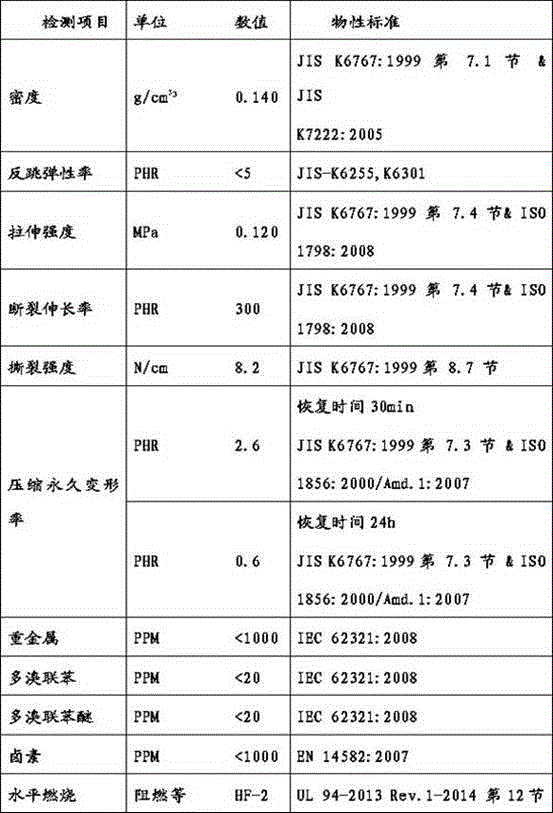

Embodiment 2

[0059] The preparation method of the environment-friendly flame-retardant butyl rubber and EPDM multi-component blended closed-cell secondary foaming material comprises the following steps:

[0060] (1) Butyl rubber mastication: put 100PHR of butyl rubber and 0.2PHR of stearic acid into a 75L diamond-shaped leaf shaft W-type heavy hammer internal mixer, pressurize to 7 kg, and knead for 10 minutes. Continuously fill with cold water to cool down, and when the temperature reaches 115°C, discharge to obtain butyl rubber mastic; put the butyl rubber mastic into the 18-inch automatic turning mill, control the temperature at 90°C, and turn 5mm for 180 seconds , thin through 2mm thickness fluttering cut into the corresponding weight respectively static processing;

[0061] (2) EPDM rubber refining: Put 100PHR of EPDM rubber and 0.1PHR of stearic acid into a 75L diamond-shaft W-type hammer internal mixer, pressurize to 7 kg, and knead for 10 minutes , during the kneading process, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com